World Savings Day – and what it has to do with dispensing technology

30 Oct 2023, 13:25:00

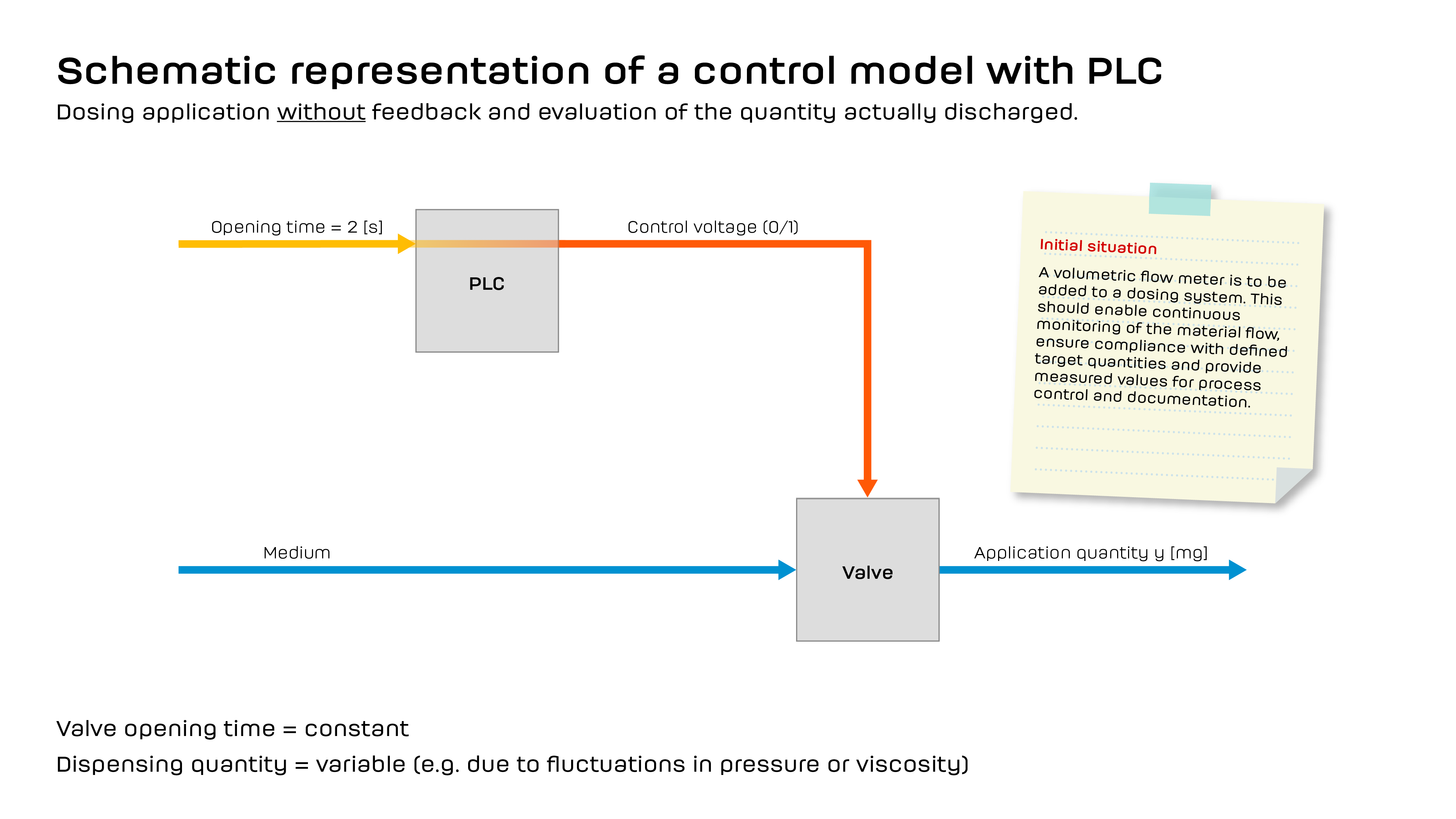

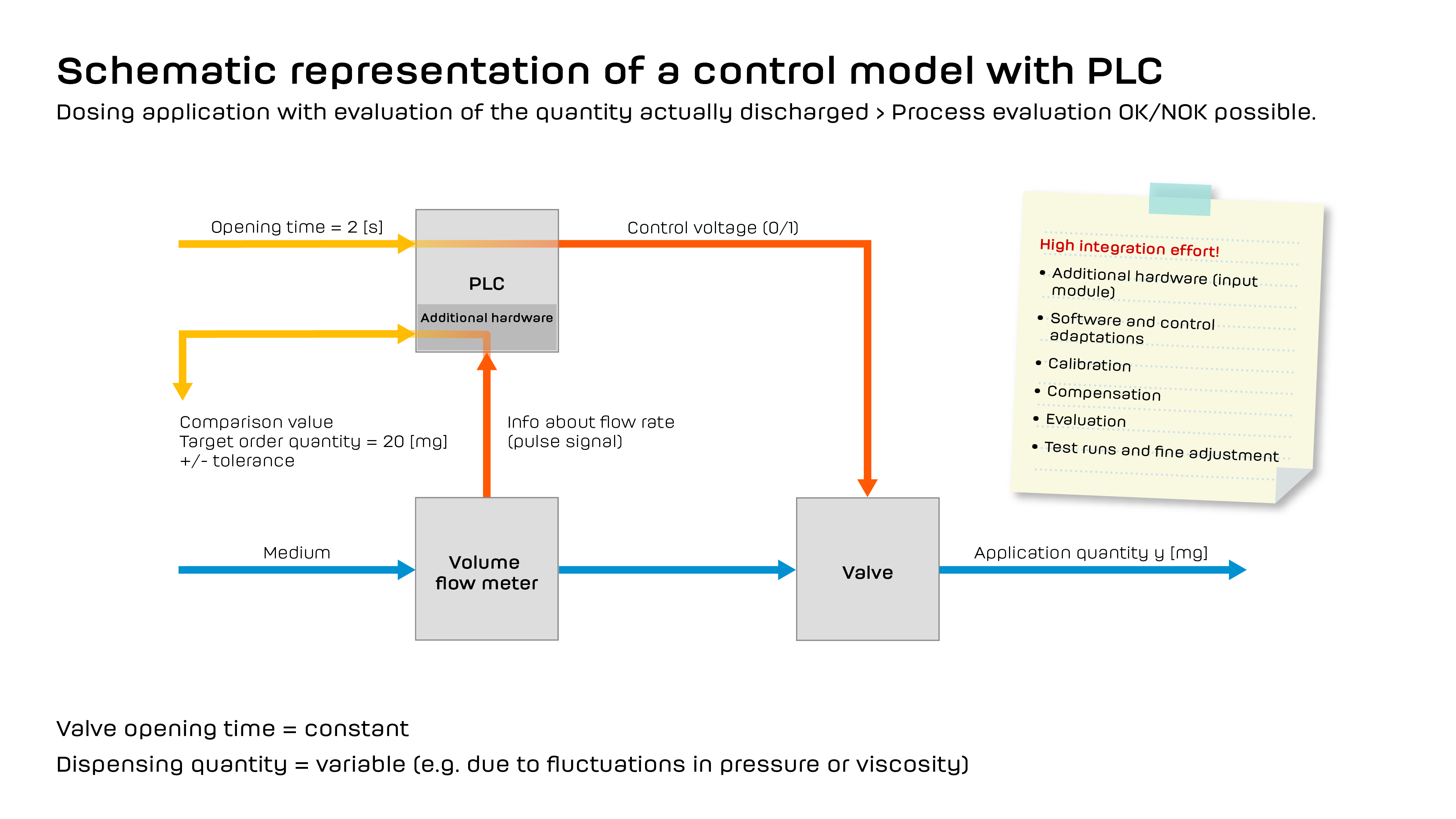

Saving is not only a matter of cost, but above all of efficiency. Those who deploy resources in a targeted and controlled manner increase productivity while simultaneously reducing material and process costs. For this reason, integrated process monitoring plays a central role in the development of new products at Walther Systemtechnik.

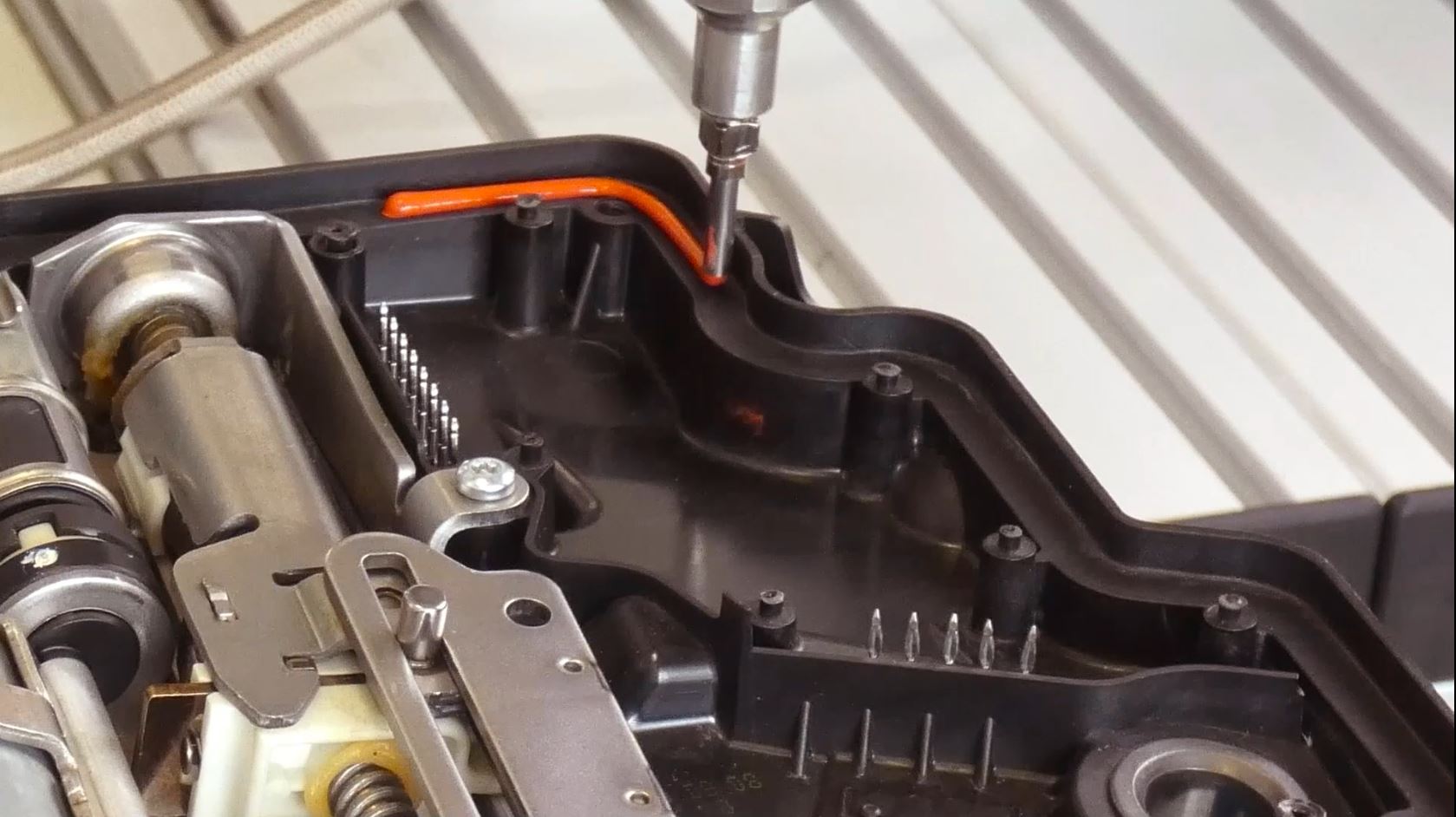

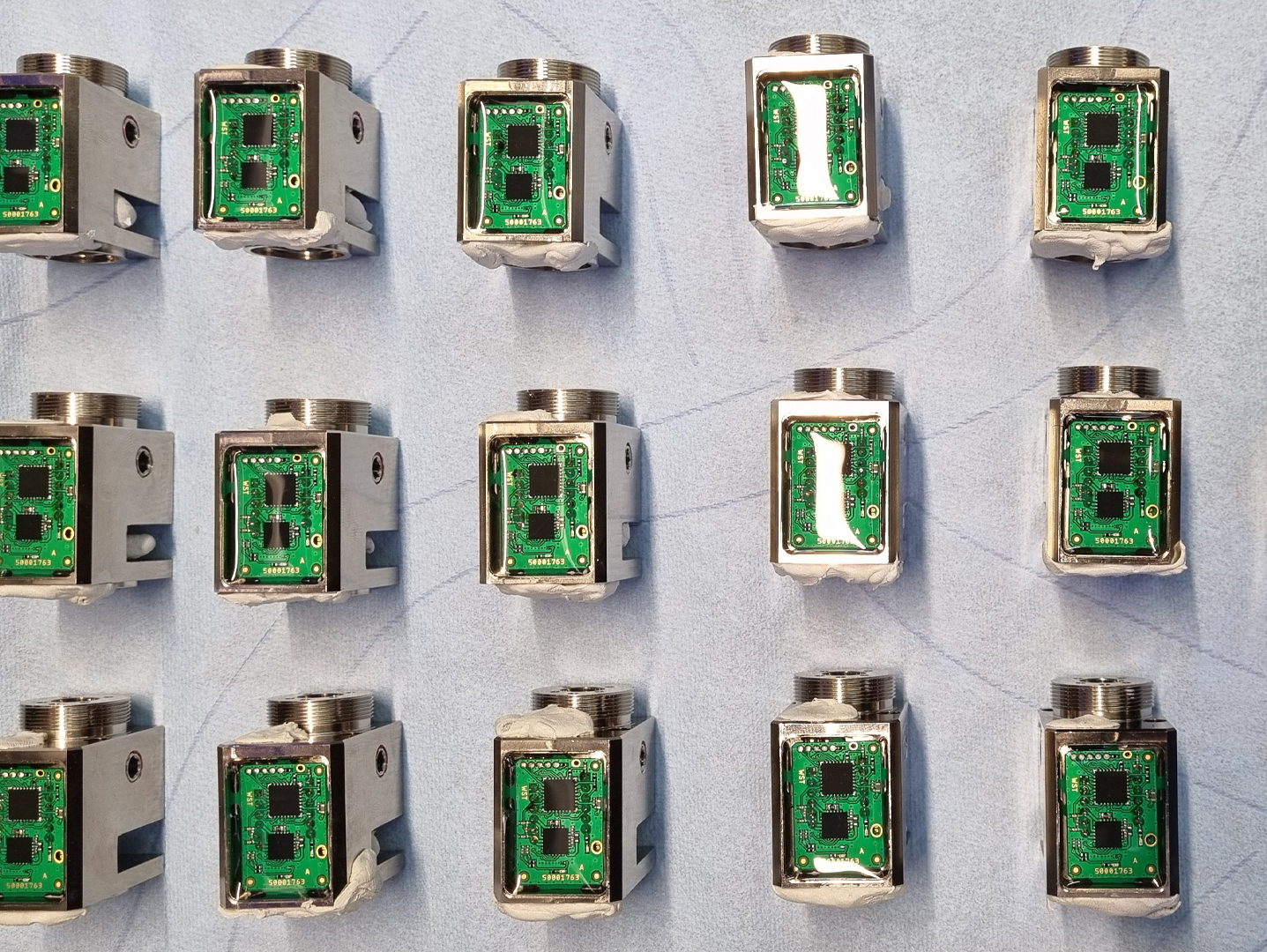

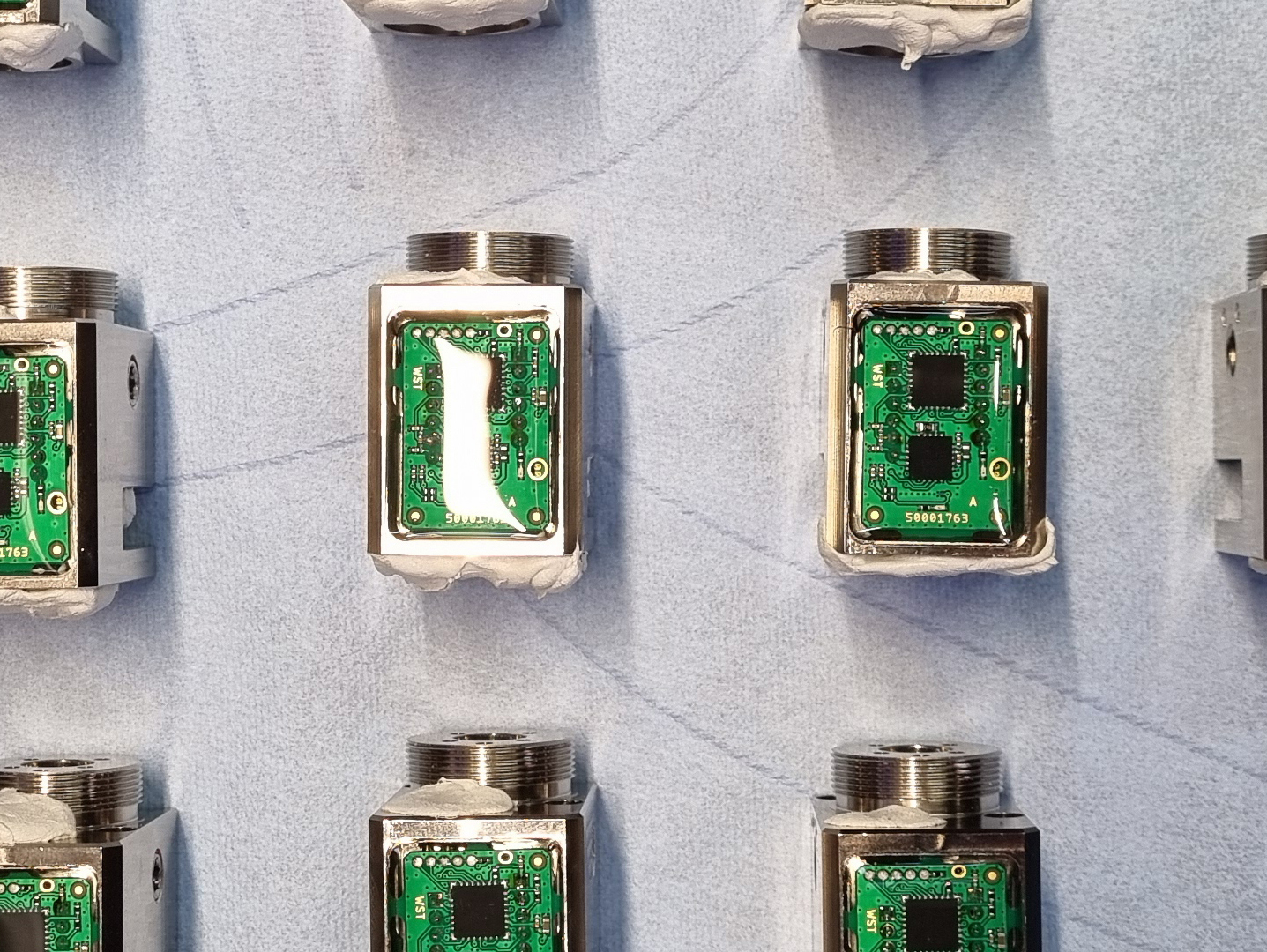

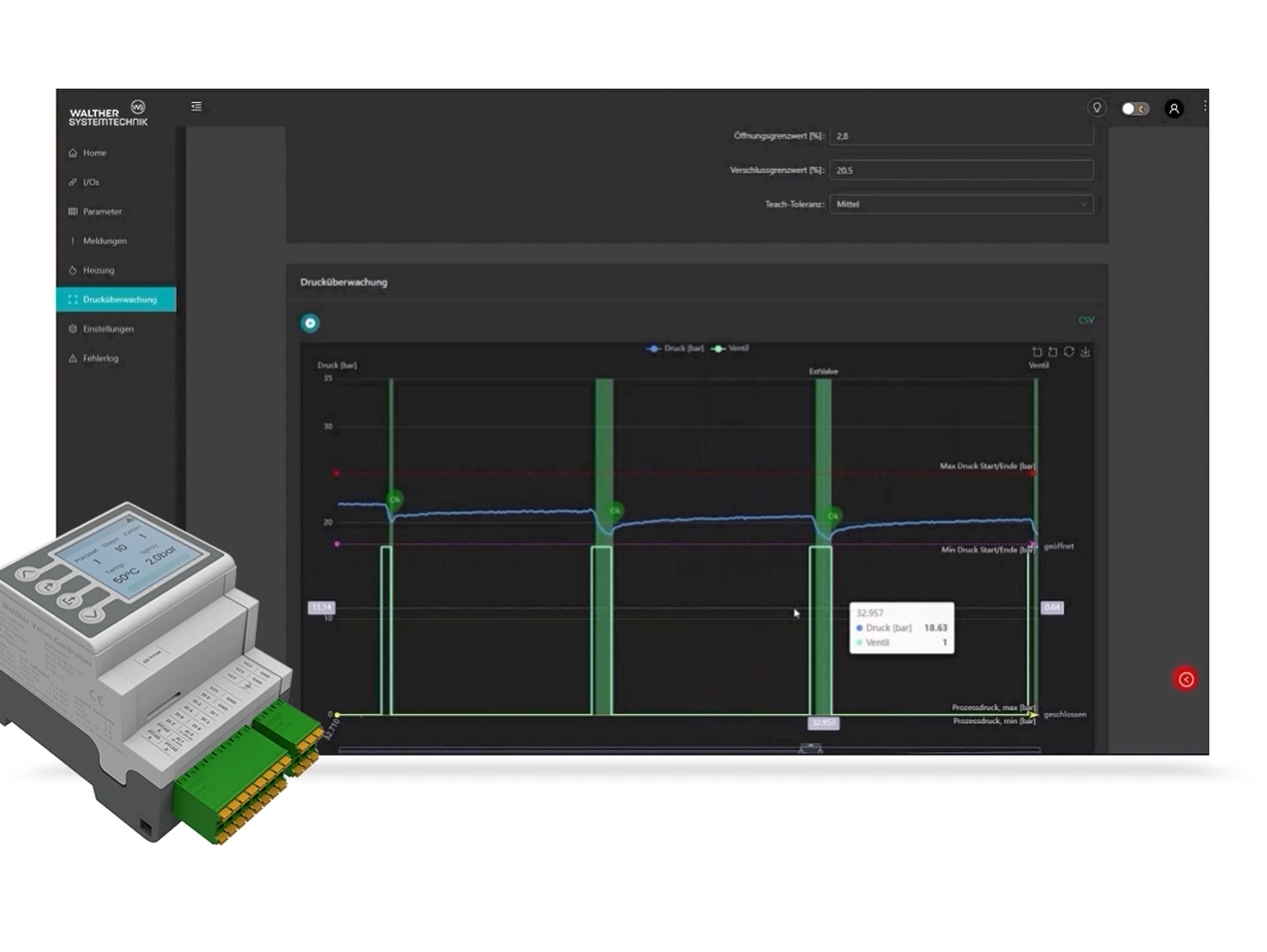

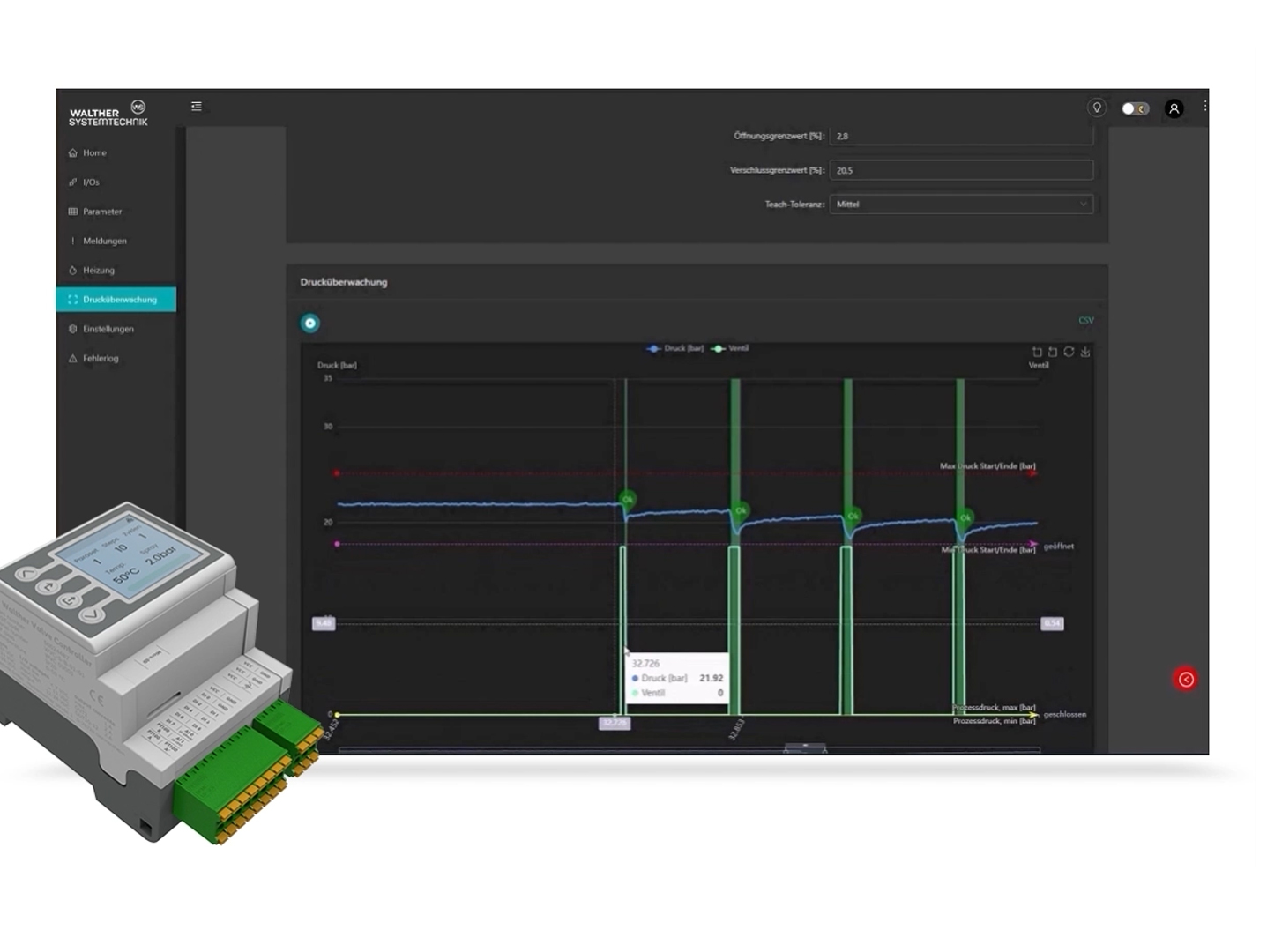

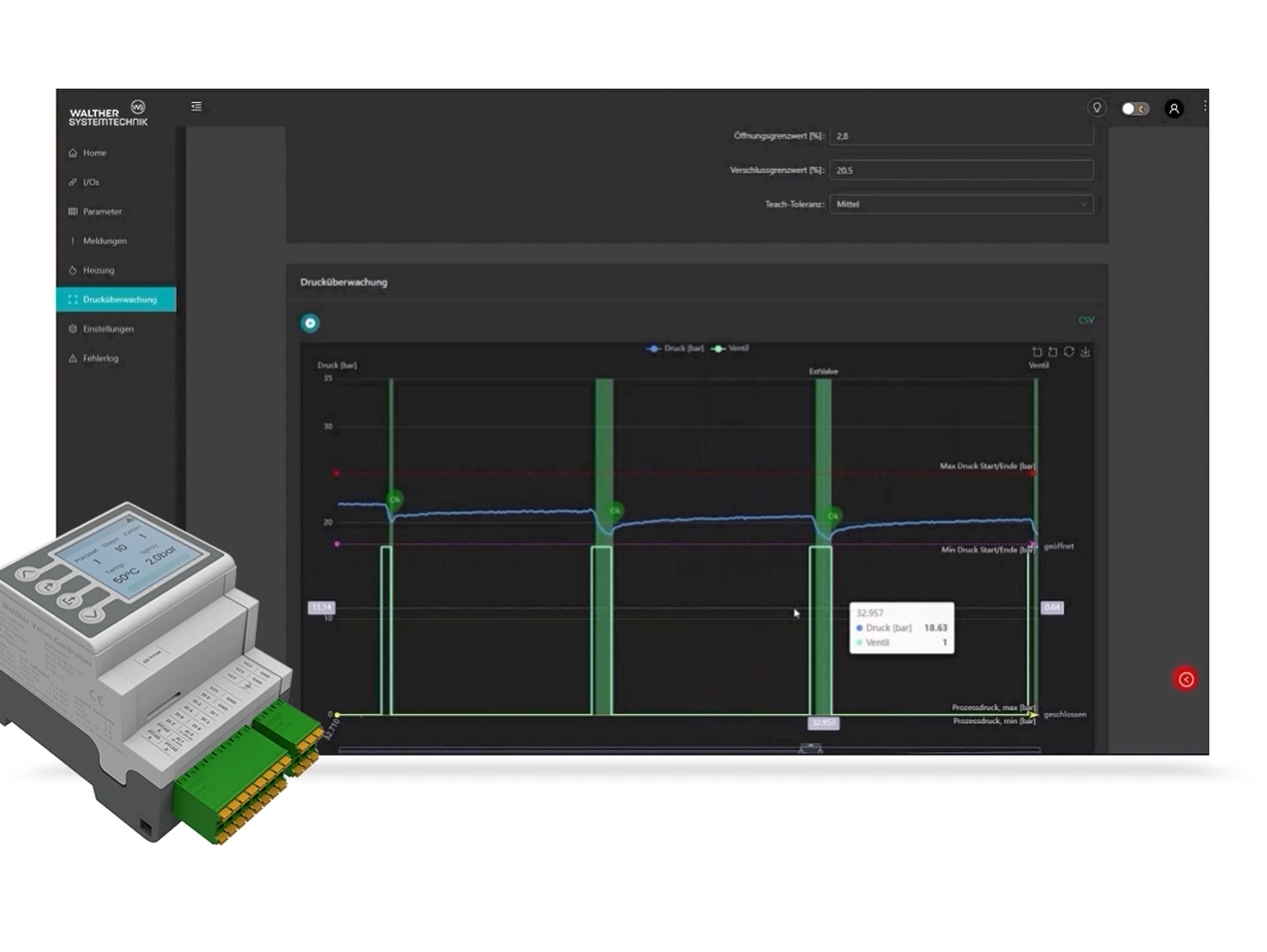

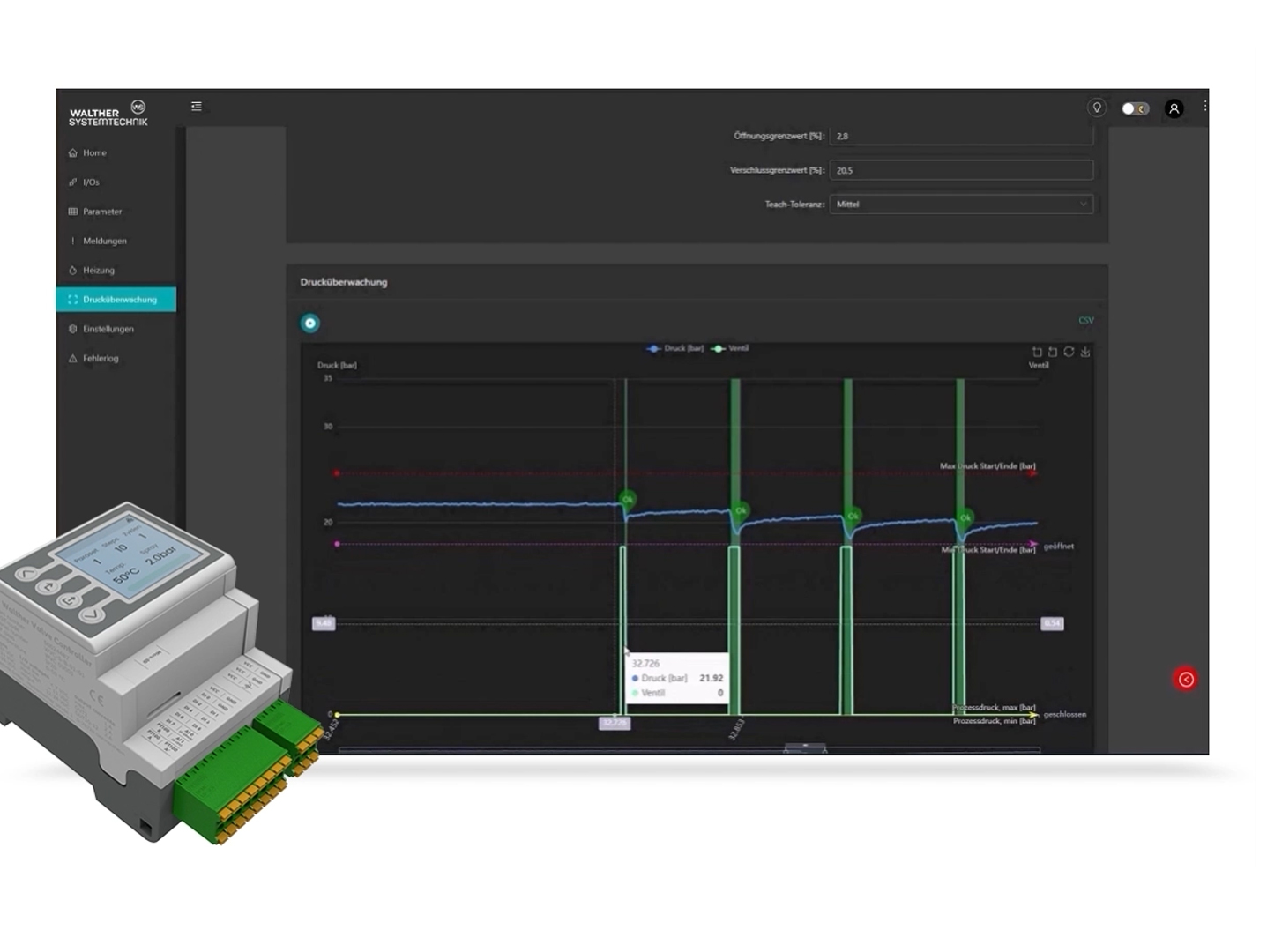

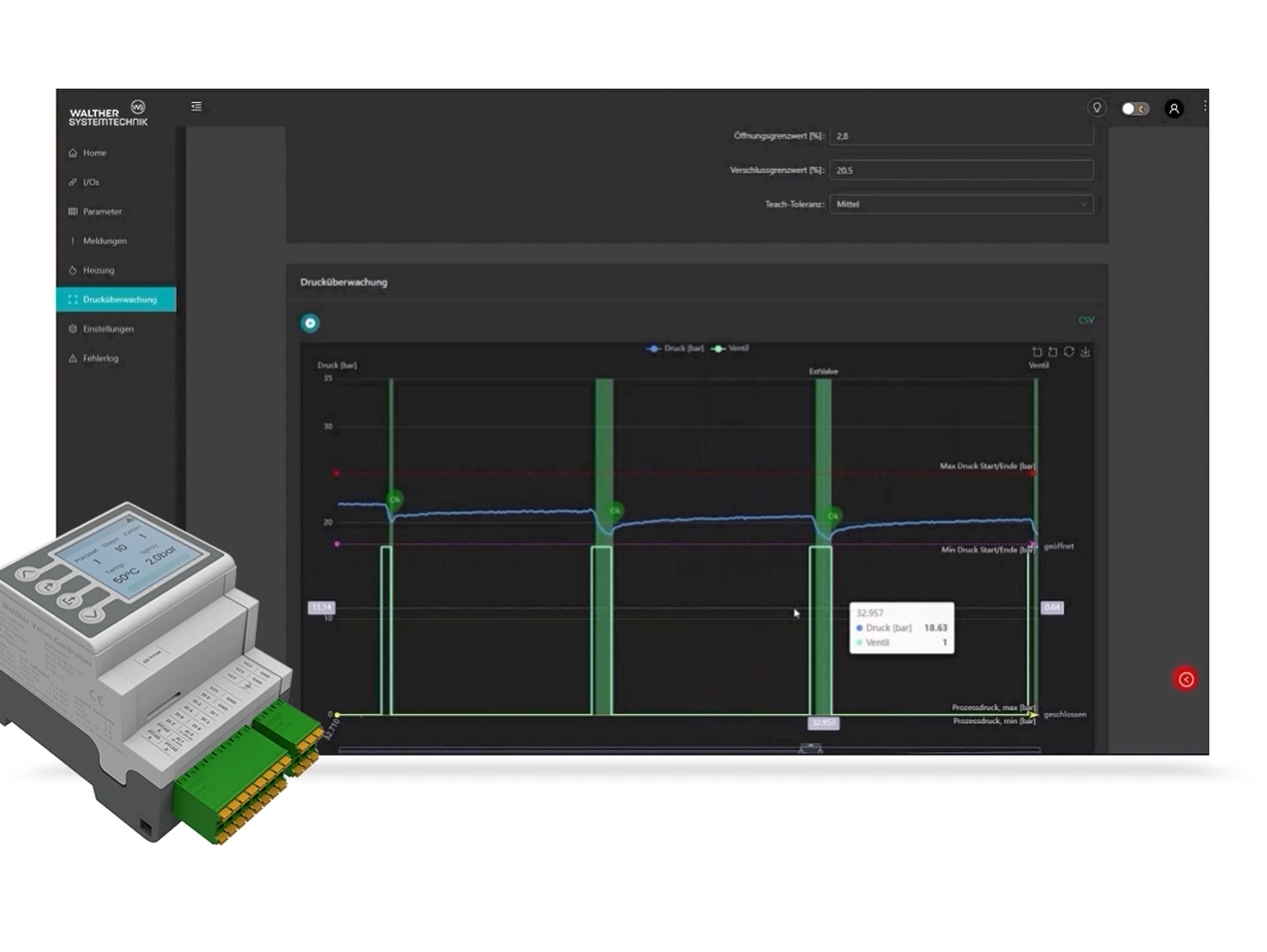

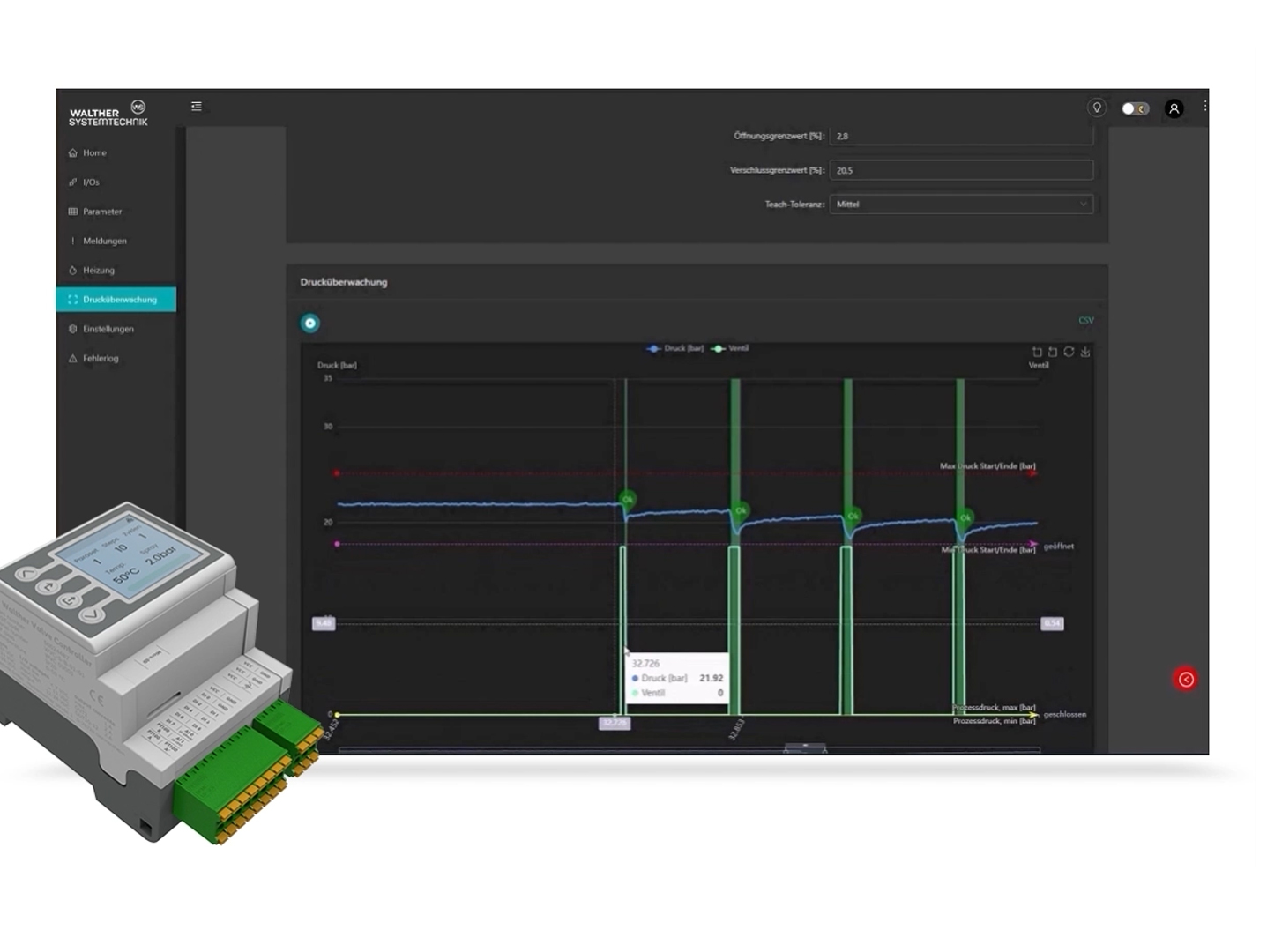

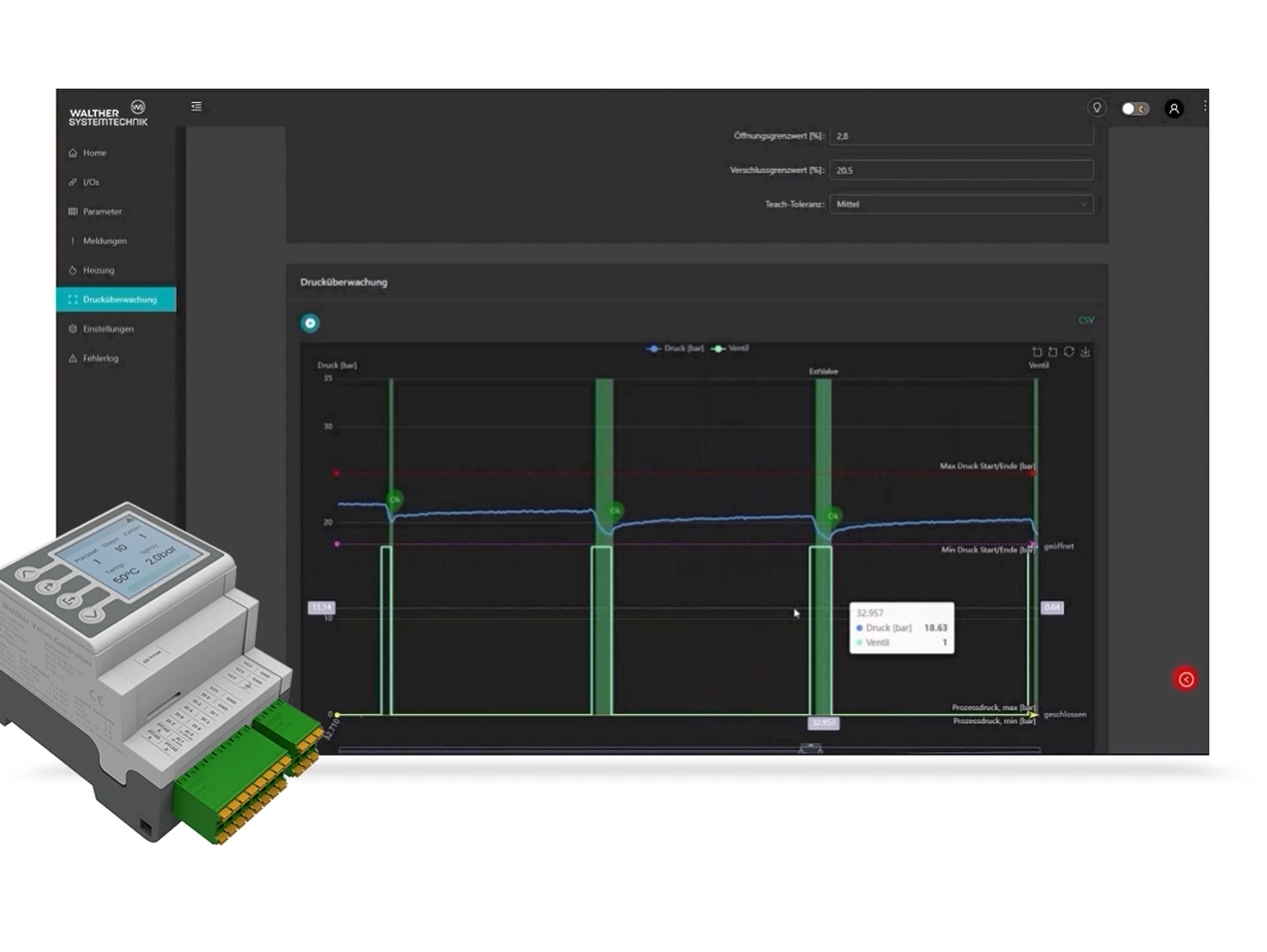

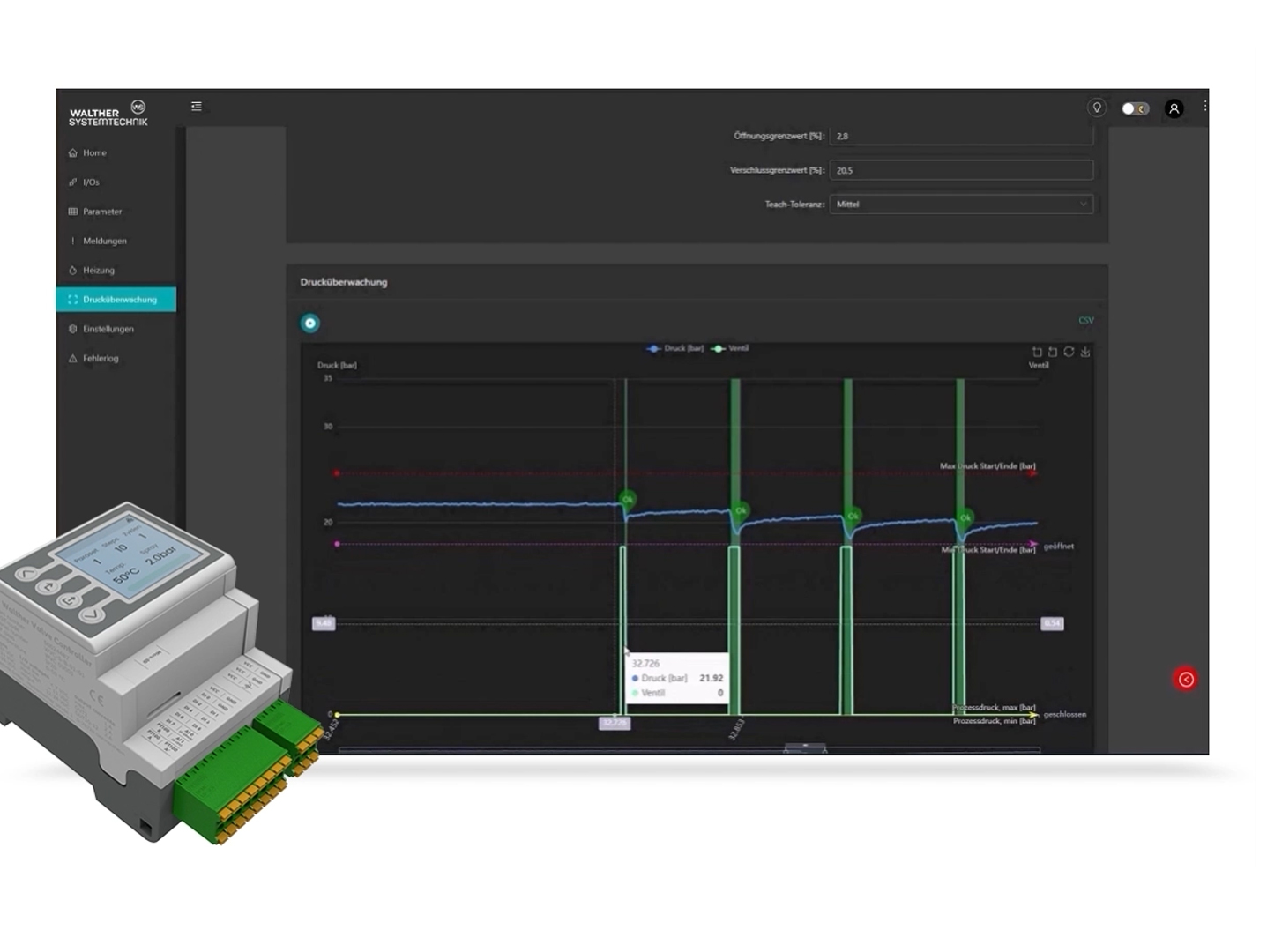

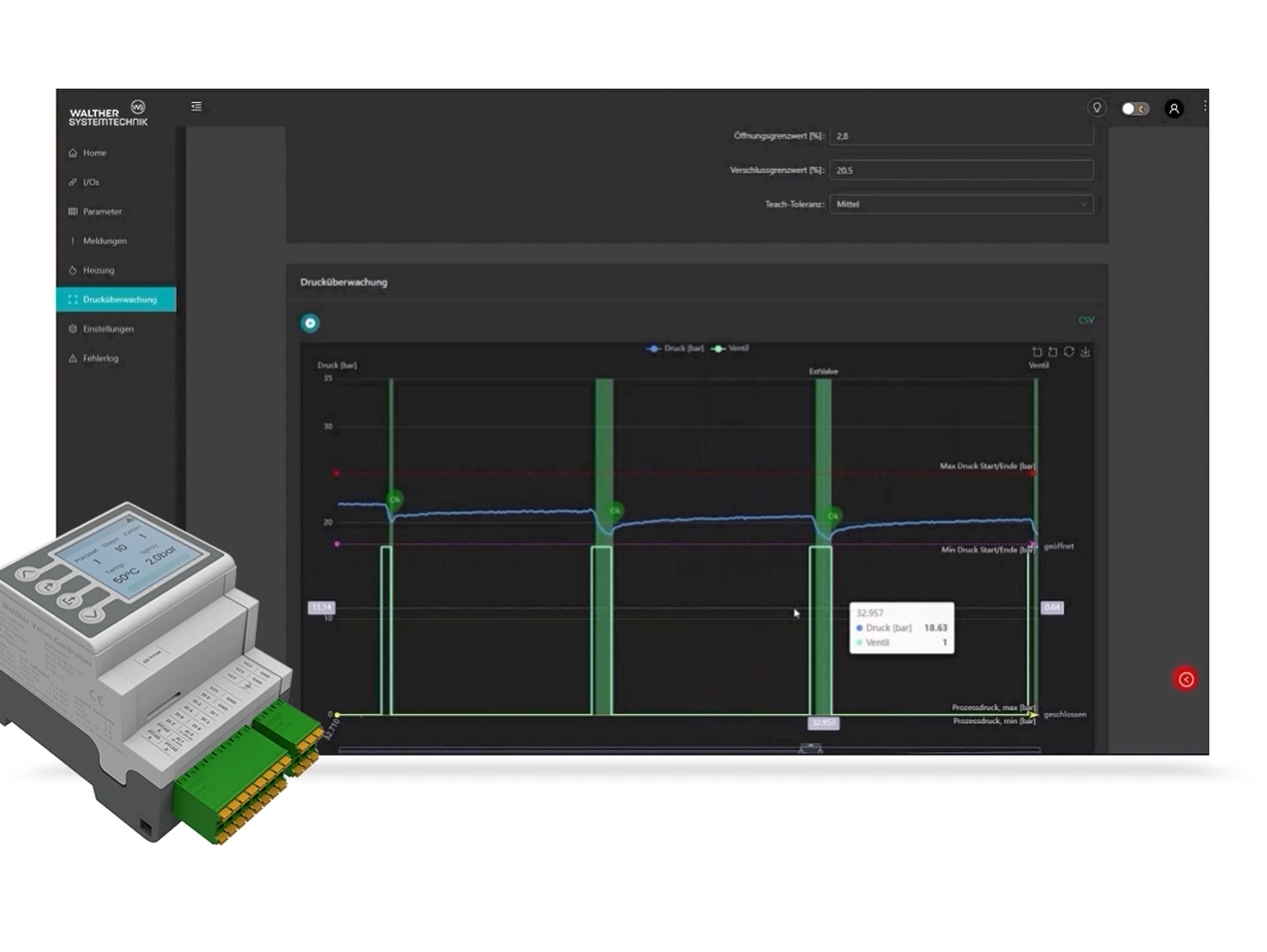

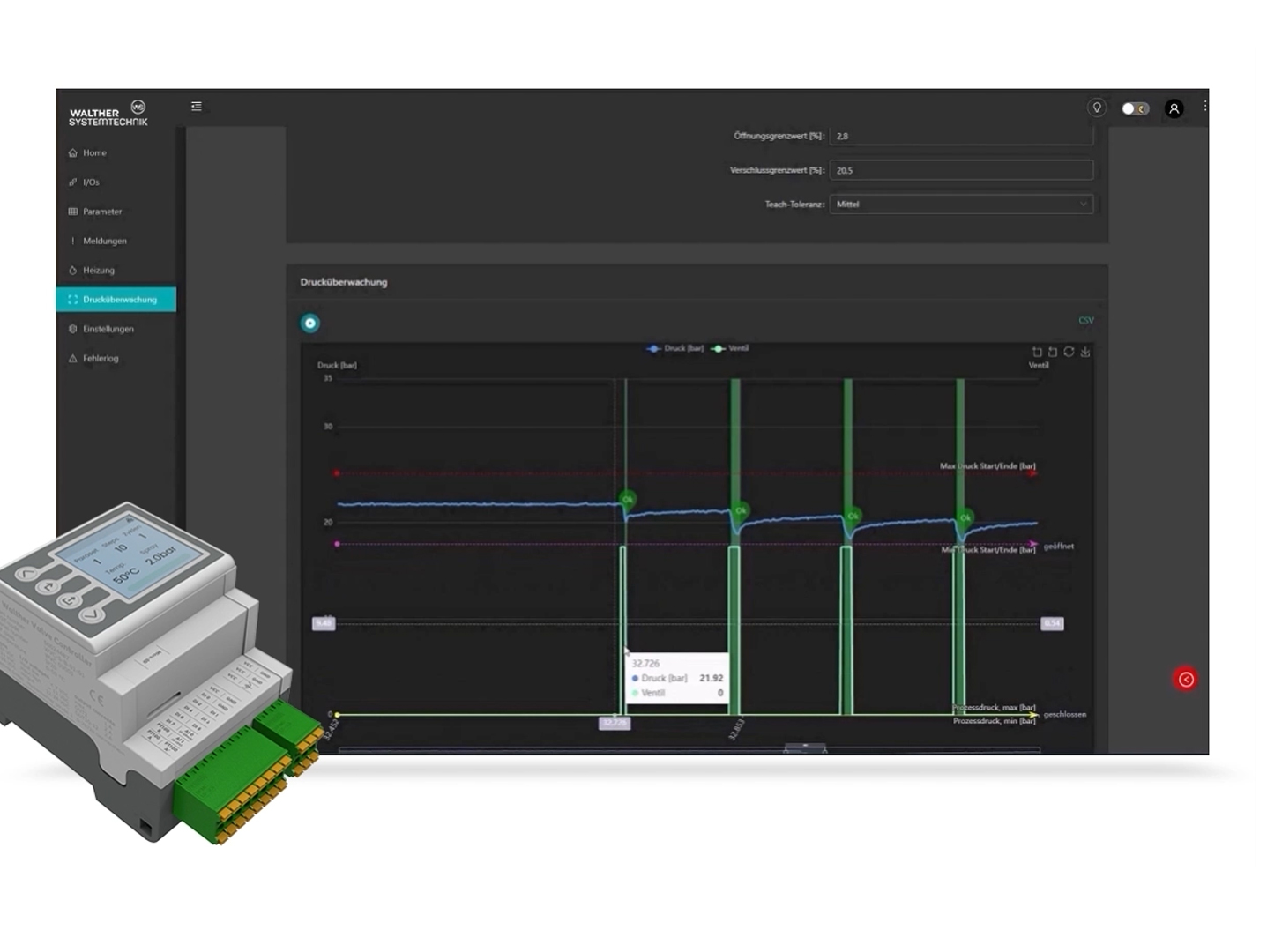

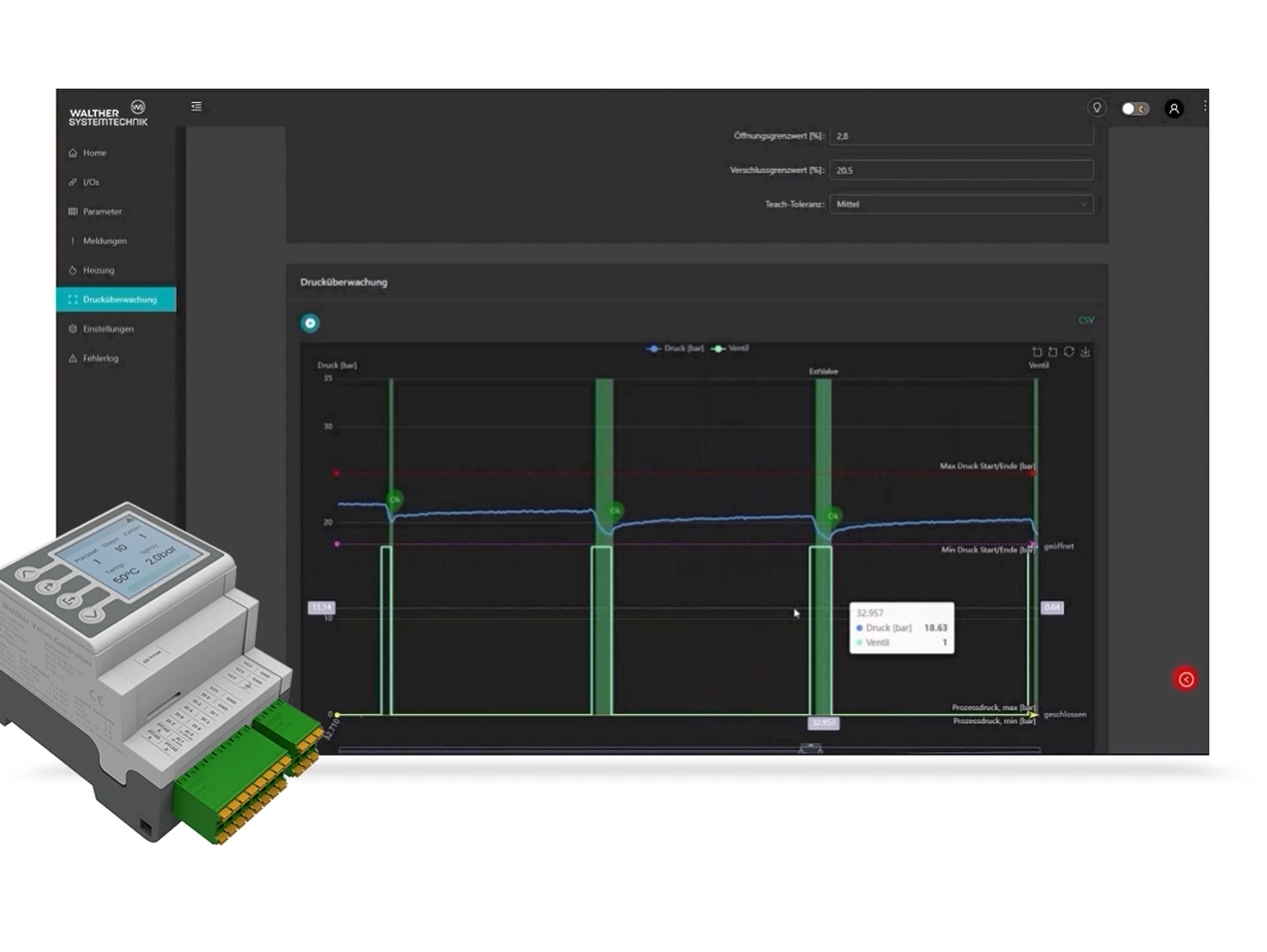

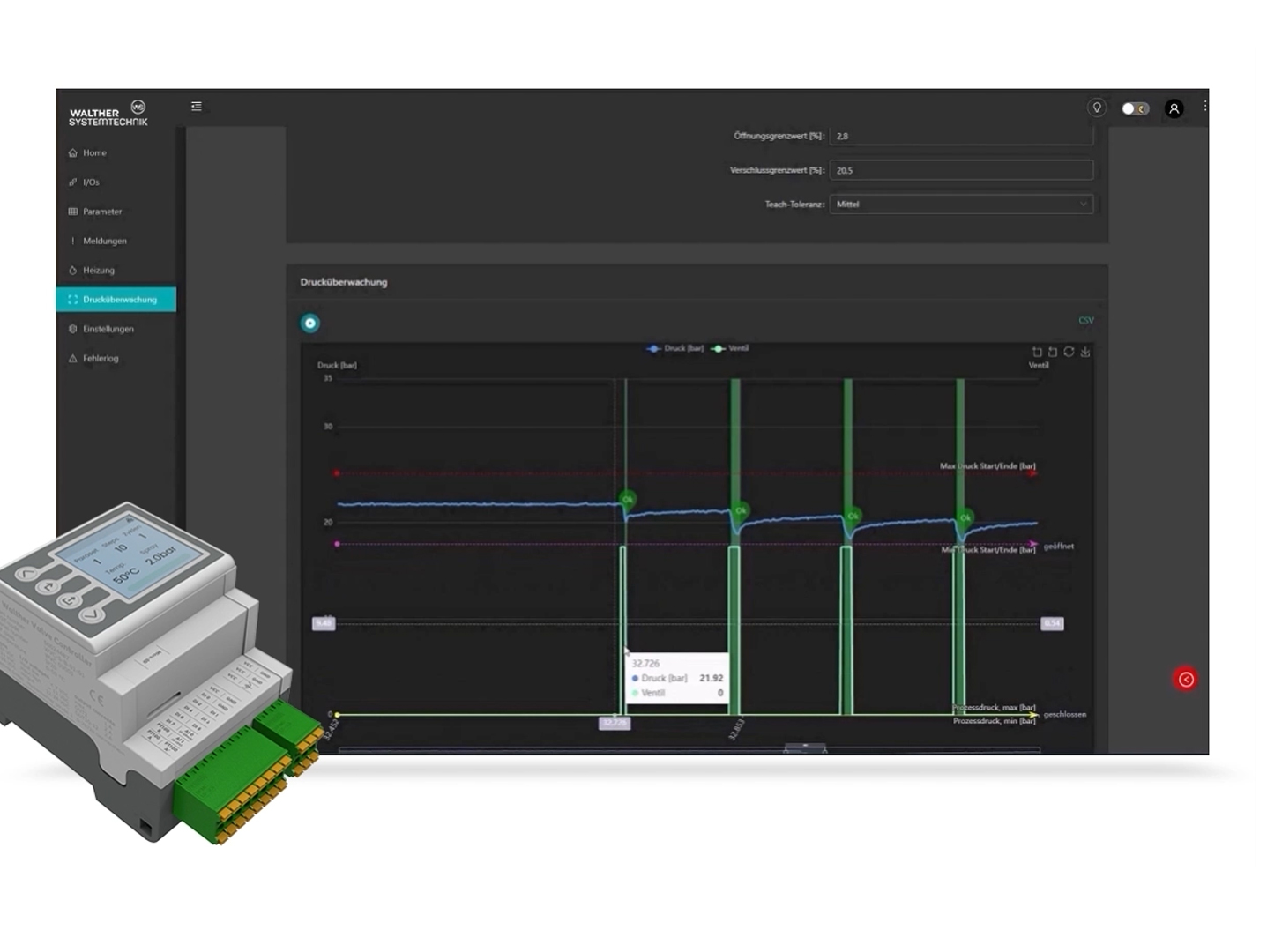

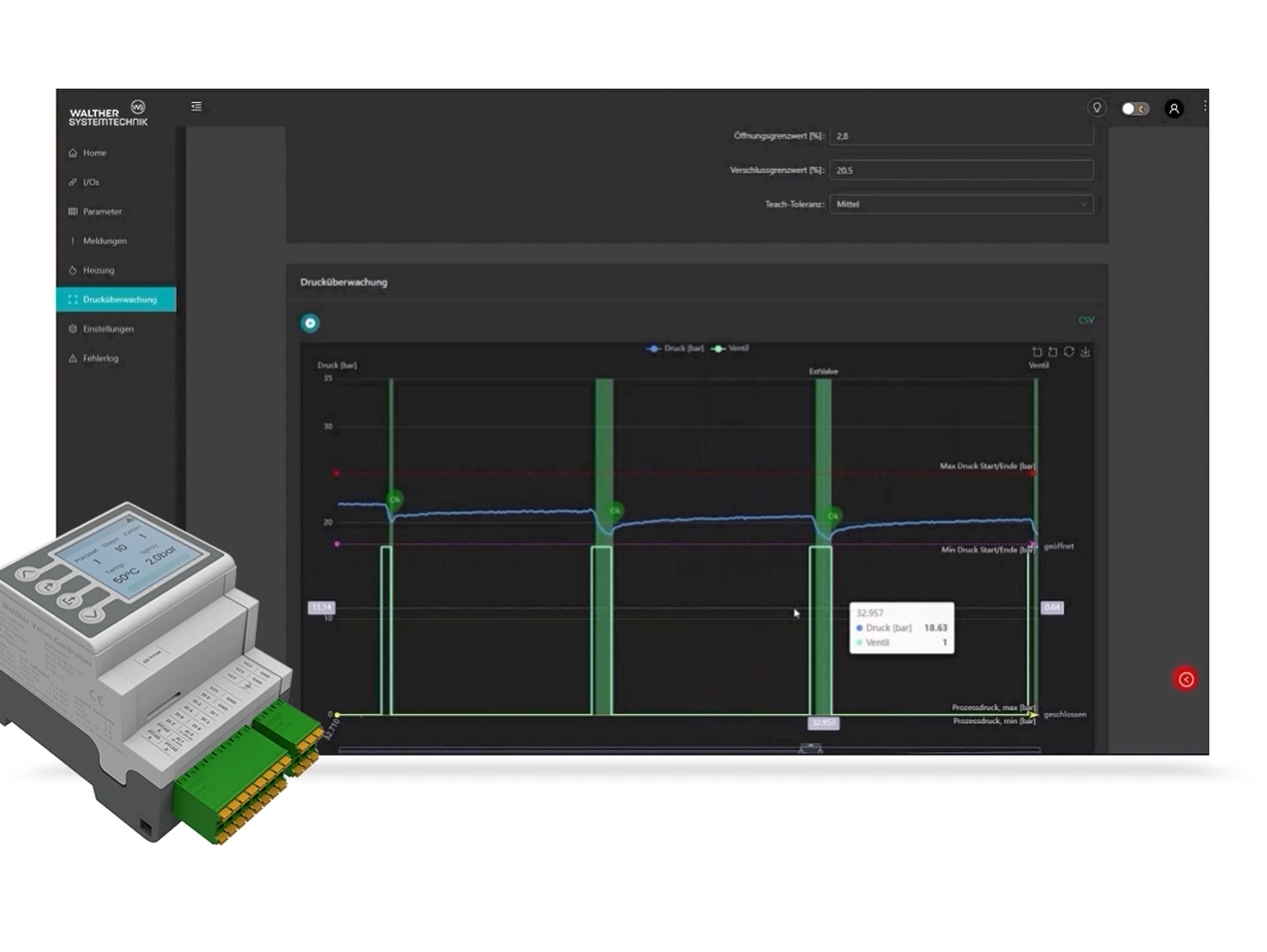

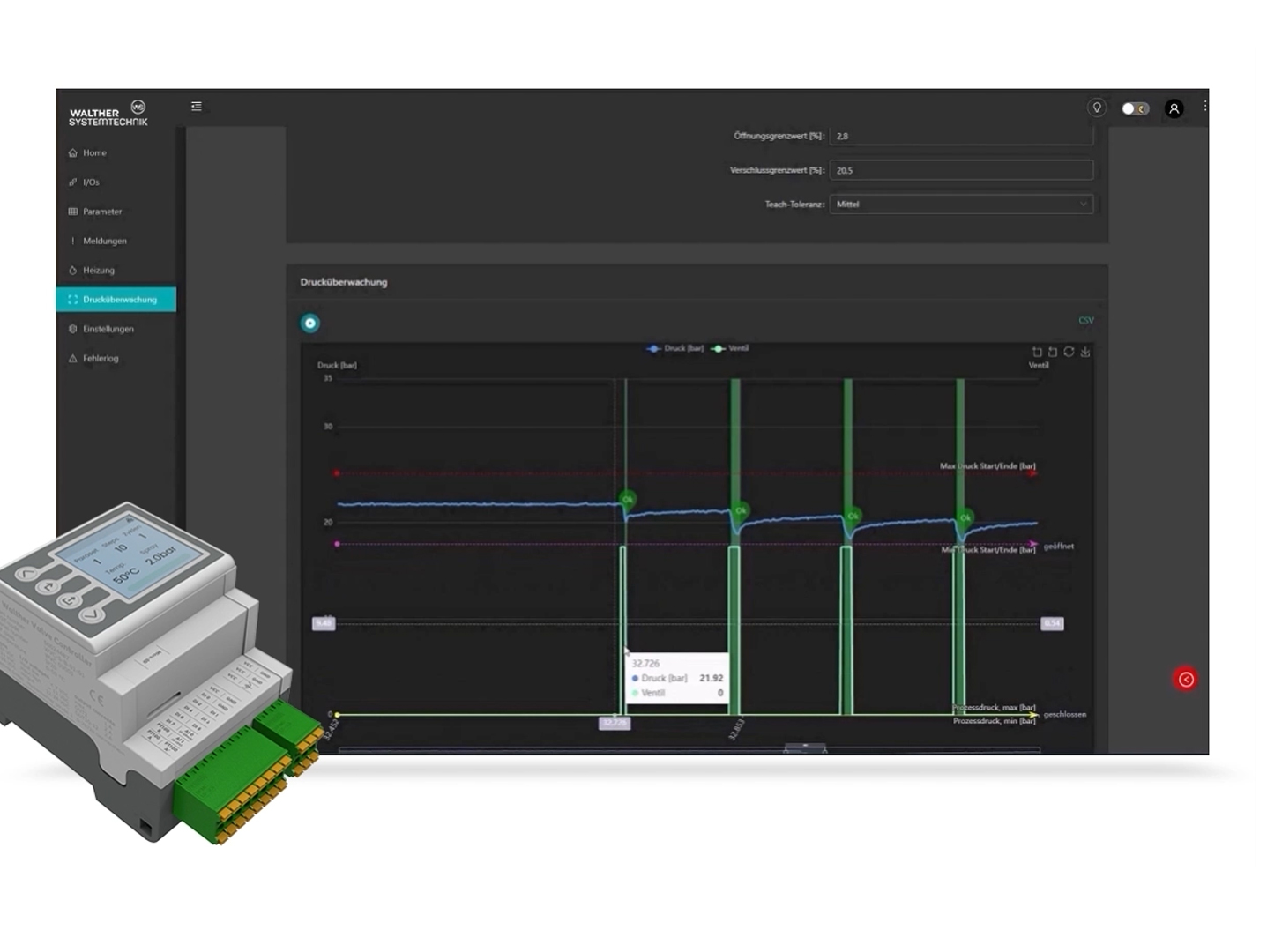

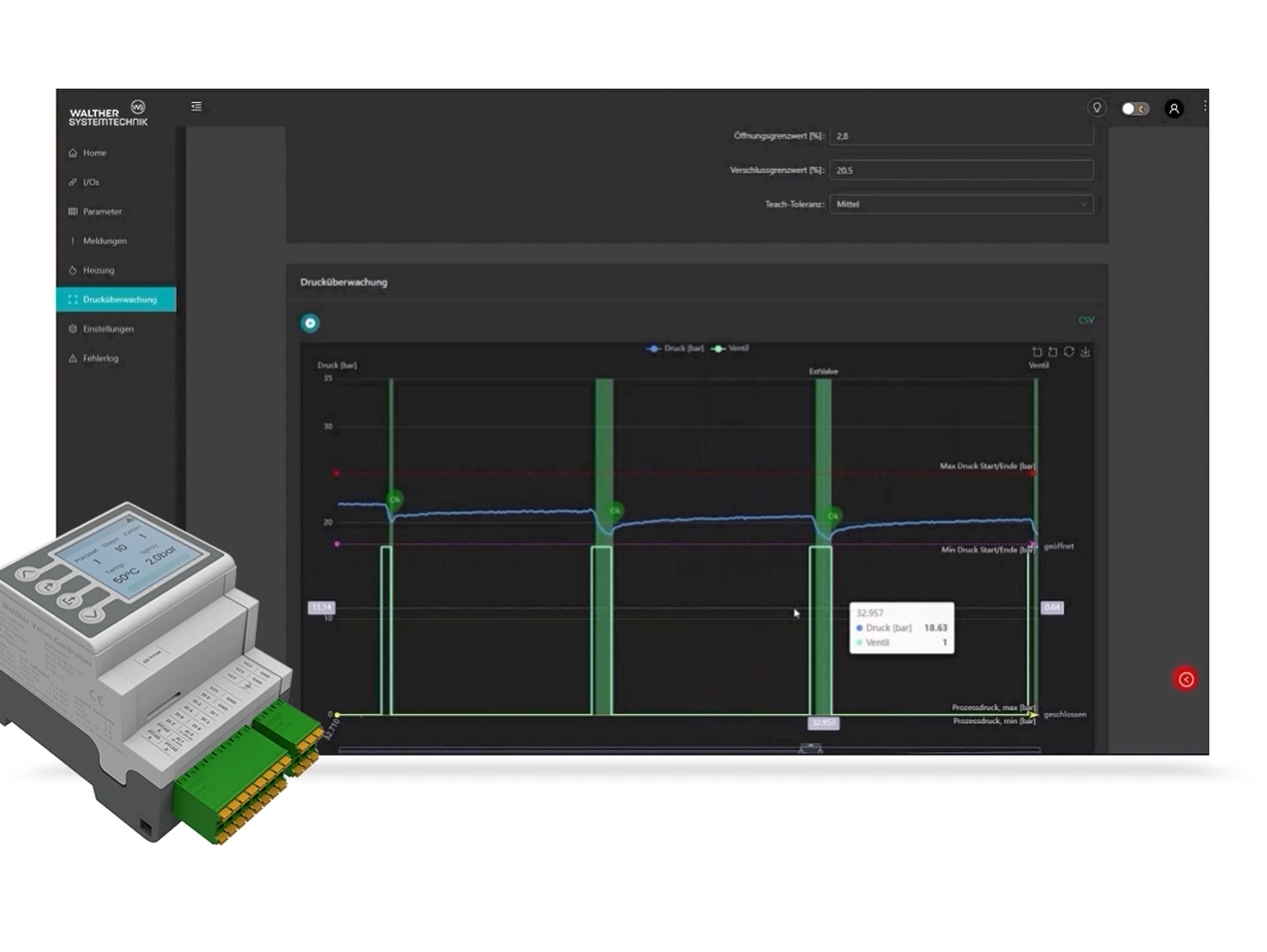

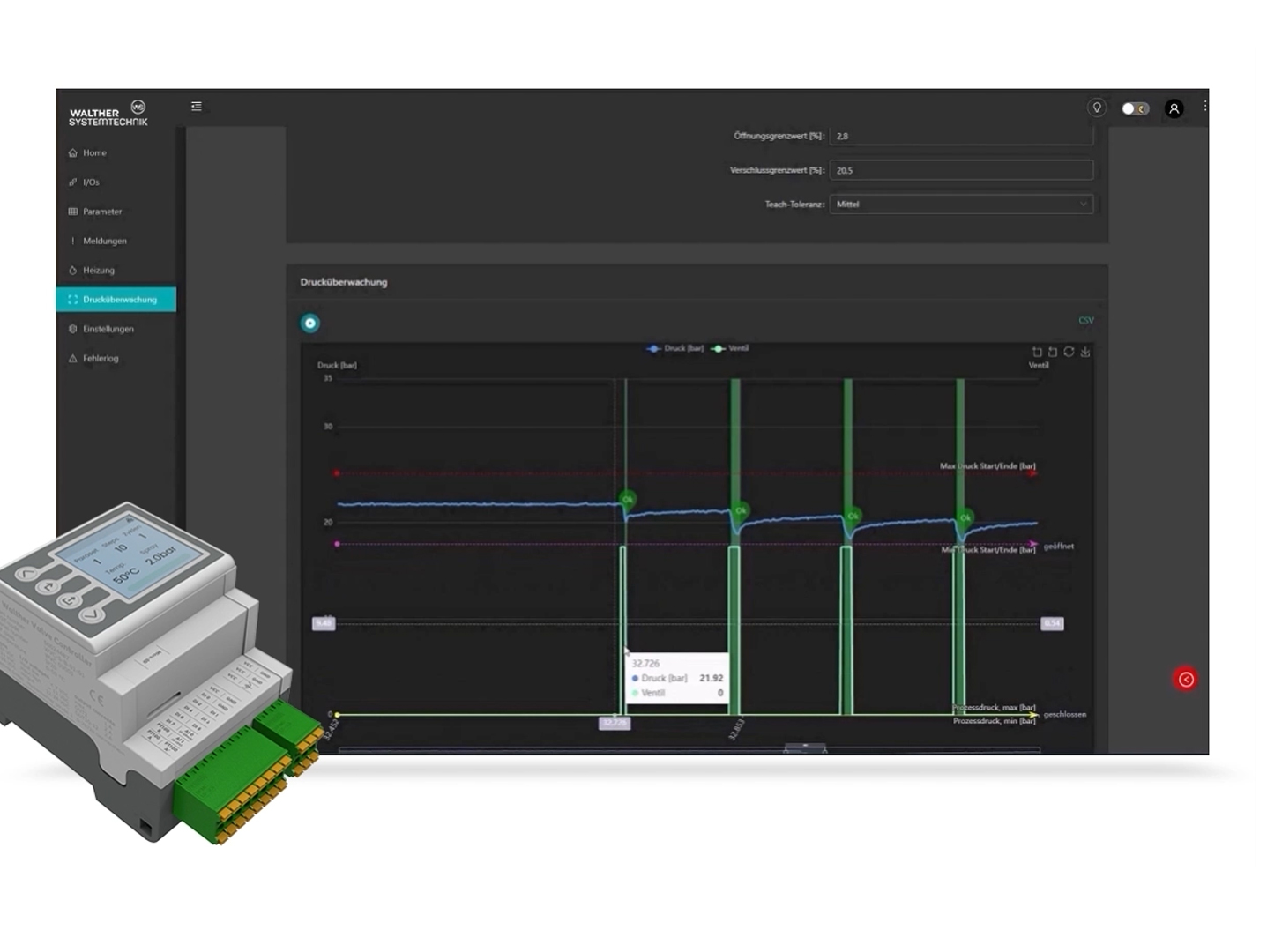

Whether pump systems, valve control units or smart application valves, integrated monitoring functions create transparency regarding the current process status. Using pressure monitoring with the Walther ValveController WVC as an example, it becomes clear how relevant process parameters can be continuously recorded and evaluated. Users thus gain a reliable real-time overview of their fluid application process.

Systematic process monitoring makes it possible to detect quality deviations at an early stage and correct them in a targeted manner. This reduces scrap and rework, directly contributing to cost savings. In addition, further benefits arise:

- Early detection of process faults to avoid unplanned downtime and increase system availability

- Process optimisation through more efficient use of media, energy and resources

- Data-driven decision-making that supports continuous improvement of process stability and quality

Process monitoring is therefore a key element in increasing quality, efficiency and productivity in industrial manufacturing. At the same time, it helps to sustainably reduce costs and strengthen the long-term competitiveness of companies.

World Savings Day – and what it has to do with dispensing technology

Saving is not only a matter of cost, but above all of efficiency. Those who deploy resources in a targeted and controlled manner increase productivity while simultaneously reducing material and process costs. For this reason, integrated process monitoring plays a central role in the development of new products at Walther Systemtechnik.

Whether pump systems, valve control units or smart application valves, integrated monitoring functions create transparency regarding the current process status. Using pressure monitoring with the Walther ValveController WVC as an example, it becomes clear how relevant process parameters can be continuously recorded and evaluated. Users thus gain a reliable real-time overview of their fluid application process.

Systematic process monitoring makes it possible to detect quality deviations at an early stage and correct them in a targeted manner. This reduces scrap and rework, directly contributing to cost savings. In addition, further benefits arise:

- Early detection of process faults to avoid unplanned downtime and increase system availability

- Process optimisation through more efficient use of media, energy and resources

- Data-driven decision-making that supports continuous improvement of process stability and quality

Process monitoring is therefore a key element in increasing quality, efficiency and productivity in industrial manufacturing. At the same time, it helps to sustainably reduce costs and strengthen the long-term competitiveness of companies.

Weitere Beiträge

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request