Devise customised dosing systems cost-effectively without design expertise.

Dosing systems are crucial for the precise handling and processing of a wide range of liquid, viscous and pasty media such as waxes, silicones, adhesives, bonded coatings, oils and greases. They offer a technically sophisticated solution for the exact control of dispensing quantities and the precise placement of materials on components. In sectors such as the electrical, sanitary and automotive industries, dispensing systems make a significant contribution to optimising production processes and ensuring consistently high product quality.

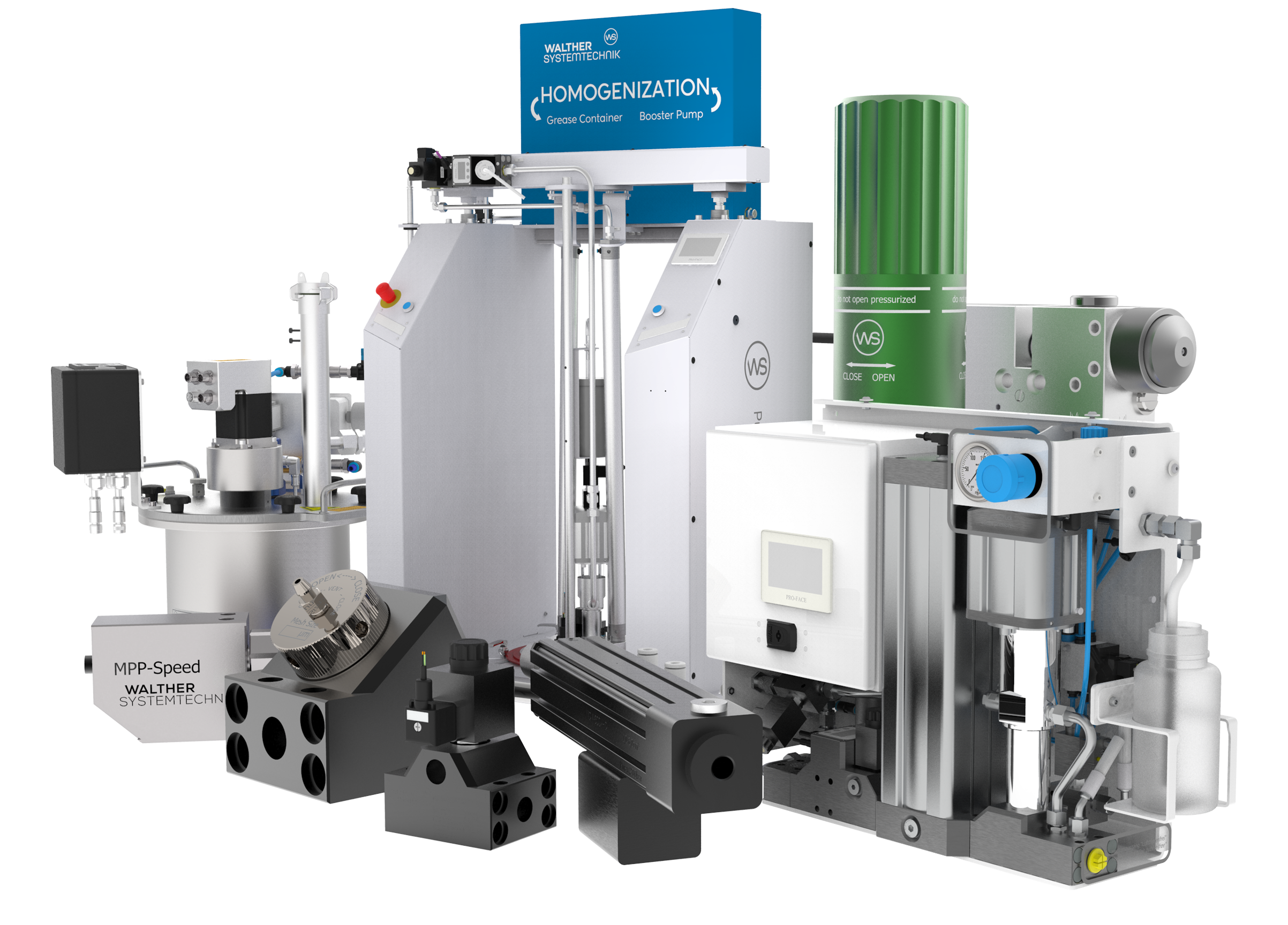

In order to realise a perfectly functioning dosing system, the individual components must be carefully selected and optimally coordinated. The conveyor technology ensures the continuous supply of the medium, while filter and degassing units optimise the preparation of the material. Pipes and hoses ensure that the medium is transported smoothly, while dosing valves ensure exact delivery and precise placement. Modern sensor and control technology also monitors and controls the processes reliably and precisely. Only by optimising the integration of all components can consistently accurate dosing be guaranteed.

This is where the strength of our modular product portfolio becomes apparent in its trend-setting flexibility. Similar to a modular system, the functions of a customised dosing system can be realised through the targeted combination of different system components. The modular design enables precise customisation to specific requirements without the need for costly new developments.

More efficiency, more profitability

The modular design of dosing systems offers considerable advantages in terms of process optimisation and cost reduction. The use of standardised and proven components significantly simplifies planning and project management, which shortens the time required and minimises the engineering risk. At the same time, the modular design of the dosing systems simplifies maintenance and repair, which reduces operating costs and maximises system availability.

Designed for perfect interaction

With WALTHER MODULAR, we are giving our systemic solution approach even more scope.

- Individual, combinable components

- Space-saving compact design

- Standardised geometry and interfaces

- Maximum flow optimisation

- Less prone to leaks

- and much more

All components in the MODULAR series can be blocked in next to no time and without additional pipework, offering a wide range of benefits.