Dosing devices

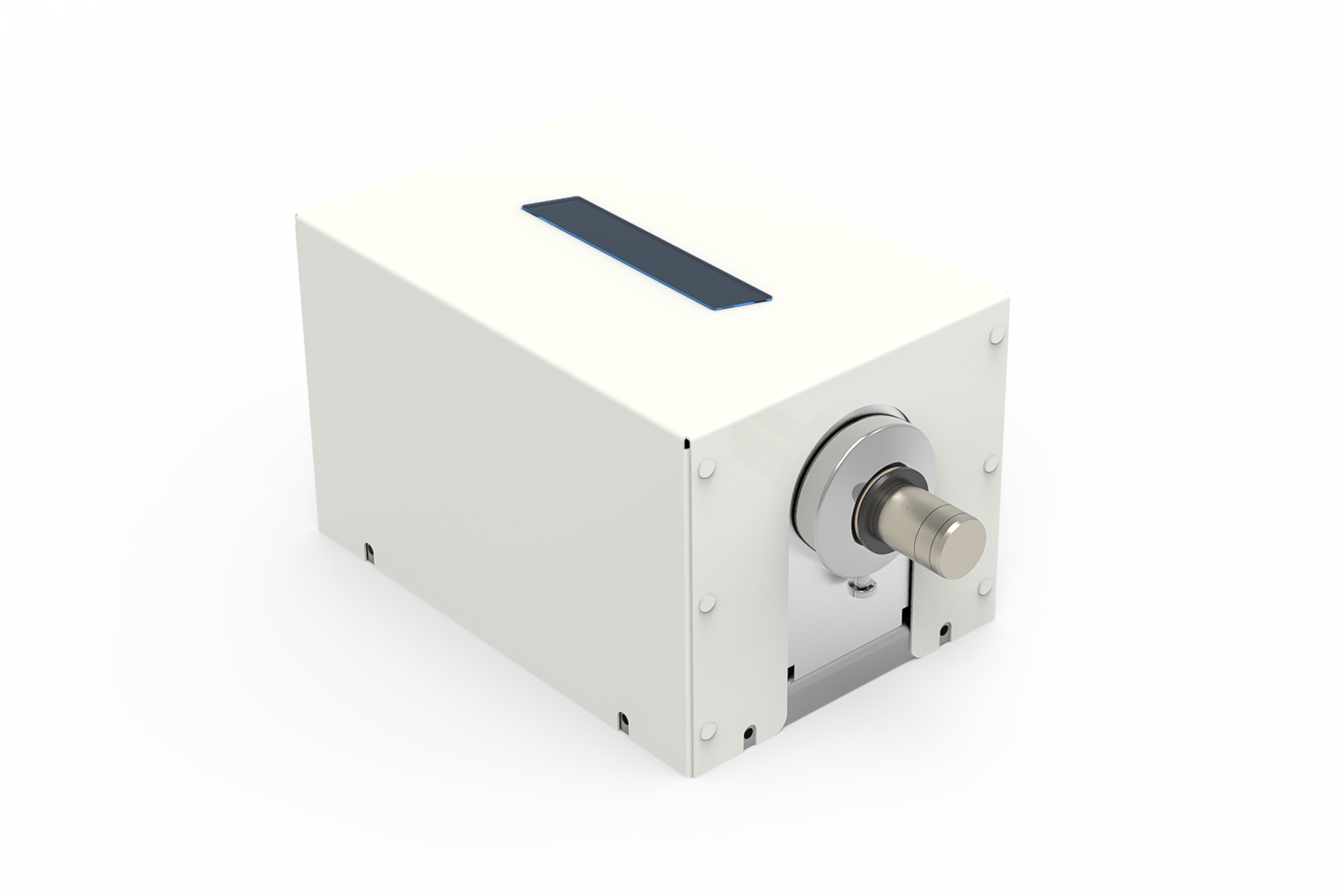

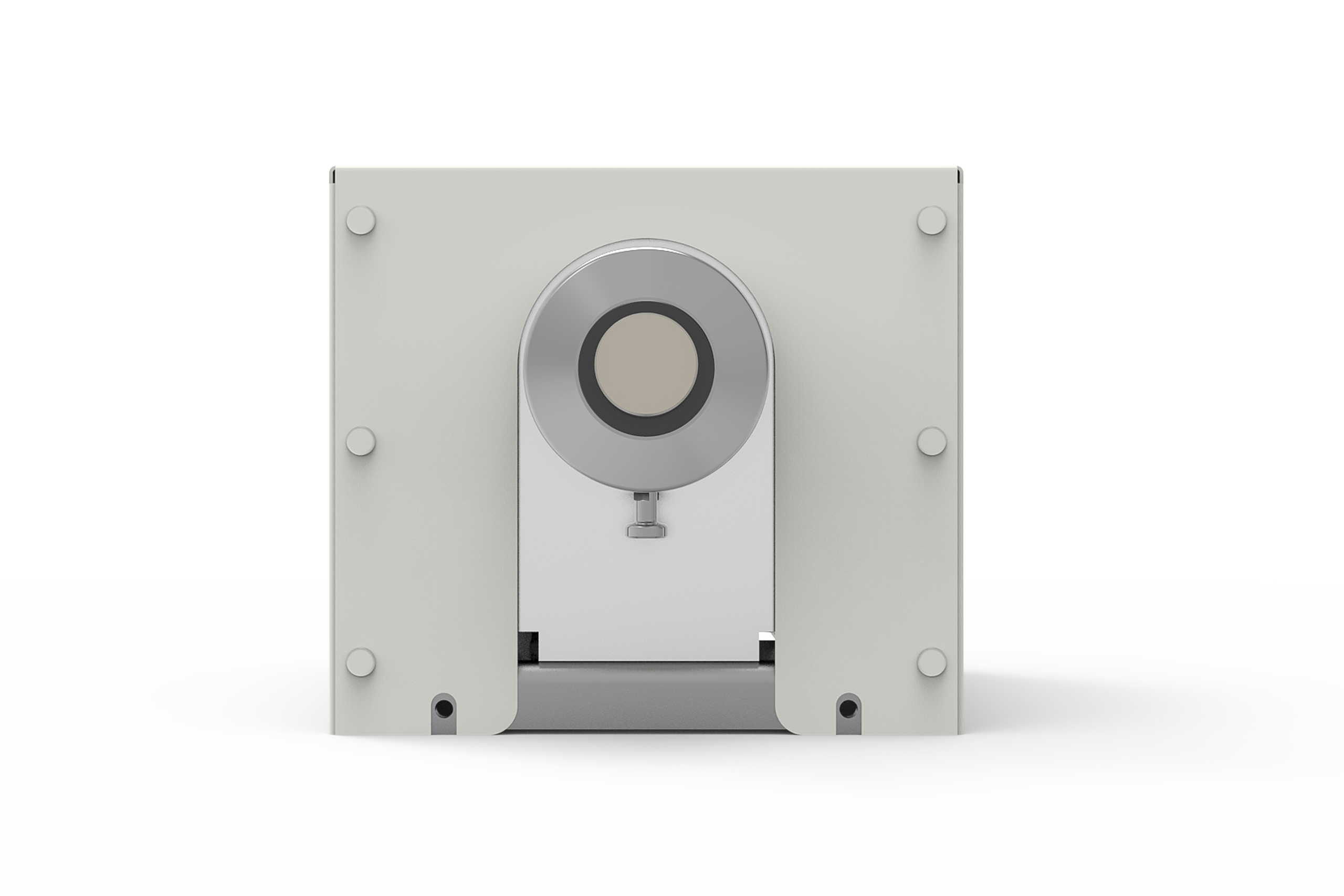

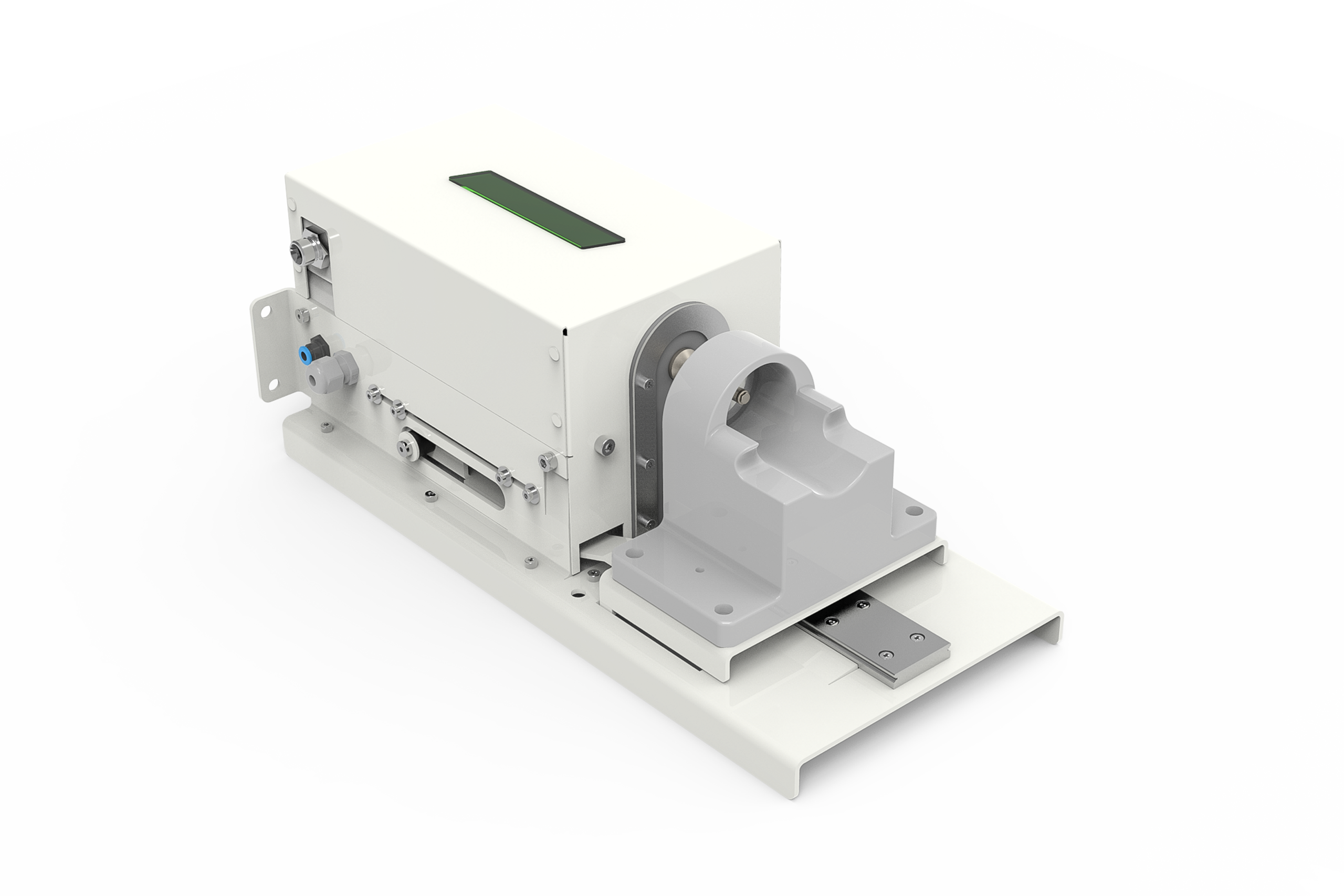

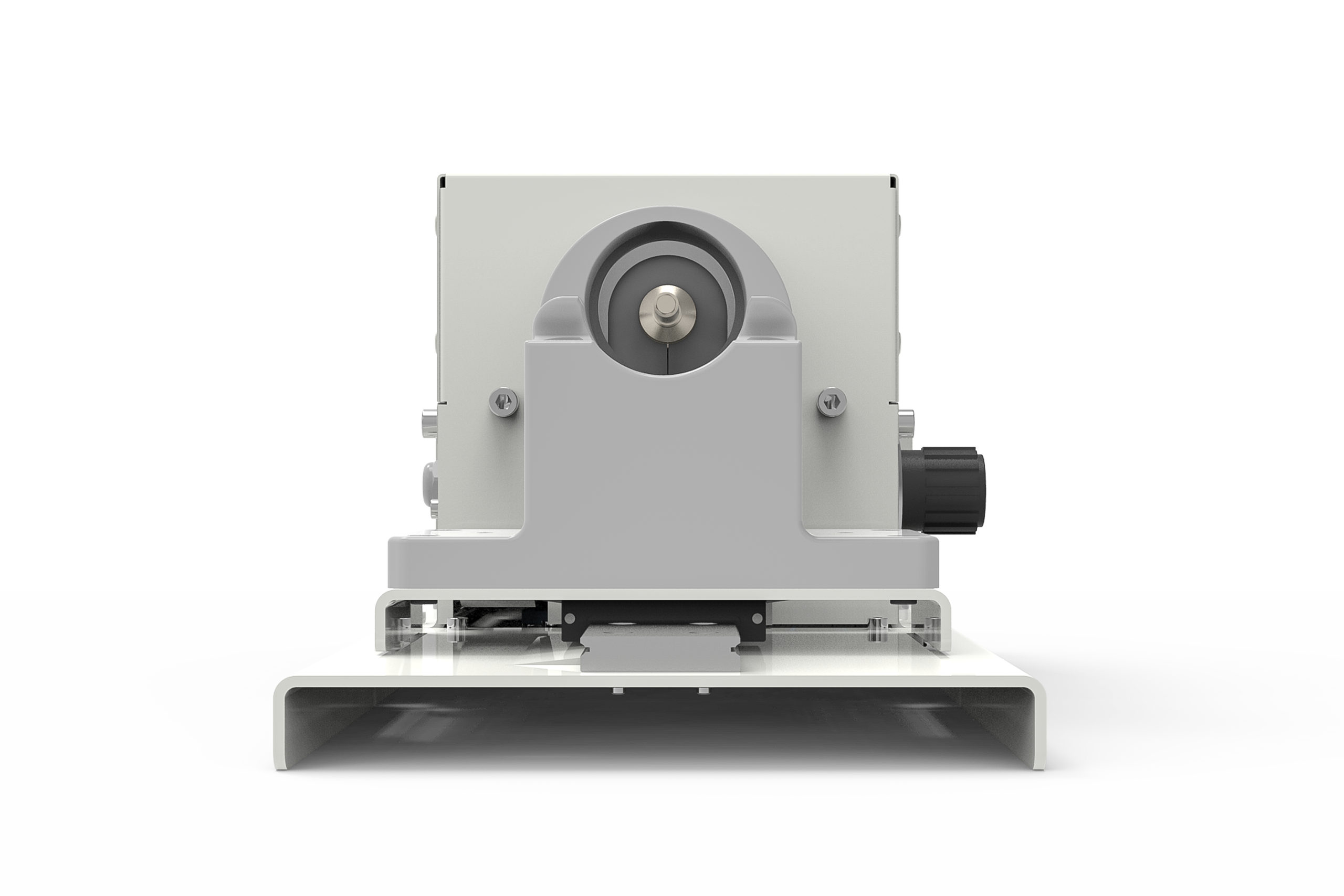

A dispensing device is a compact, function-specific system designed for the precise application of low- to high-viscosity media onto specific areas of technical components. It ensures reproducible, quantity-controlled dosing and is used wherever components must be wetted, coated, or selectively treated with media at defined positions and with high precision – for example, in assembly processes, integrated inspection applications, or final processing. The focus is on intuitive operation and minimal integration effort – ideal for industrial use.

Typically, a dispensing device consists of three core components: a media supply, a dosing or application module, and a control unit. Media is applied either via contact-based methods – for example via an application valve with a dedicated application head – or through non-contact technologies such as spray or jet systems. The central objective is always operator-independent, repeatable application to ensure maximum process reliability.

Our dispensing devices are primarily used in industrial lubrication applications. They enable uniform and precisely targeted distribution of lubricants such as oils and greases, significantly contributing to the functional reliability and service life of tribologically stressed components. Even on complex geometries, they deliver reliable results – for instance, in the lubrication of O-rings, radial shaft seals, plain and needle bearings, splined shafts, or wheel hubs. The outcome: stable processes and consistent product quality.

The lubrication and dispensing devices of the ReadyLube series exemplify user-friendly, self-contained units designed with a high degree of practical relevance. They are developed specifically for clean, efficient, and process-safe implementation of common lubrication tasks – whether at manual workstations or in semi- or fully automated production lines. Their high integrability, combined with minimal installation effort, makes them a strong choice for a wide range of manufacturing environments.

In addition to standardized system solutions, we also offer custom-engineered dispensing solutions as part of our special-purpose machinery portfolio – precisely tailored to specific process parameters and manufacturing requirements.

Price on request

Price on request