Lubrication of rolling bearings – project successfully completed

16 Jan 2024, 09:00:00

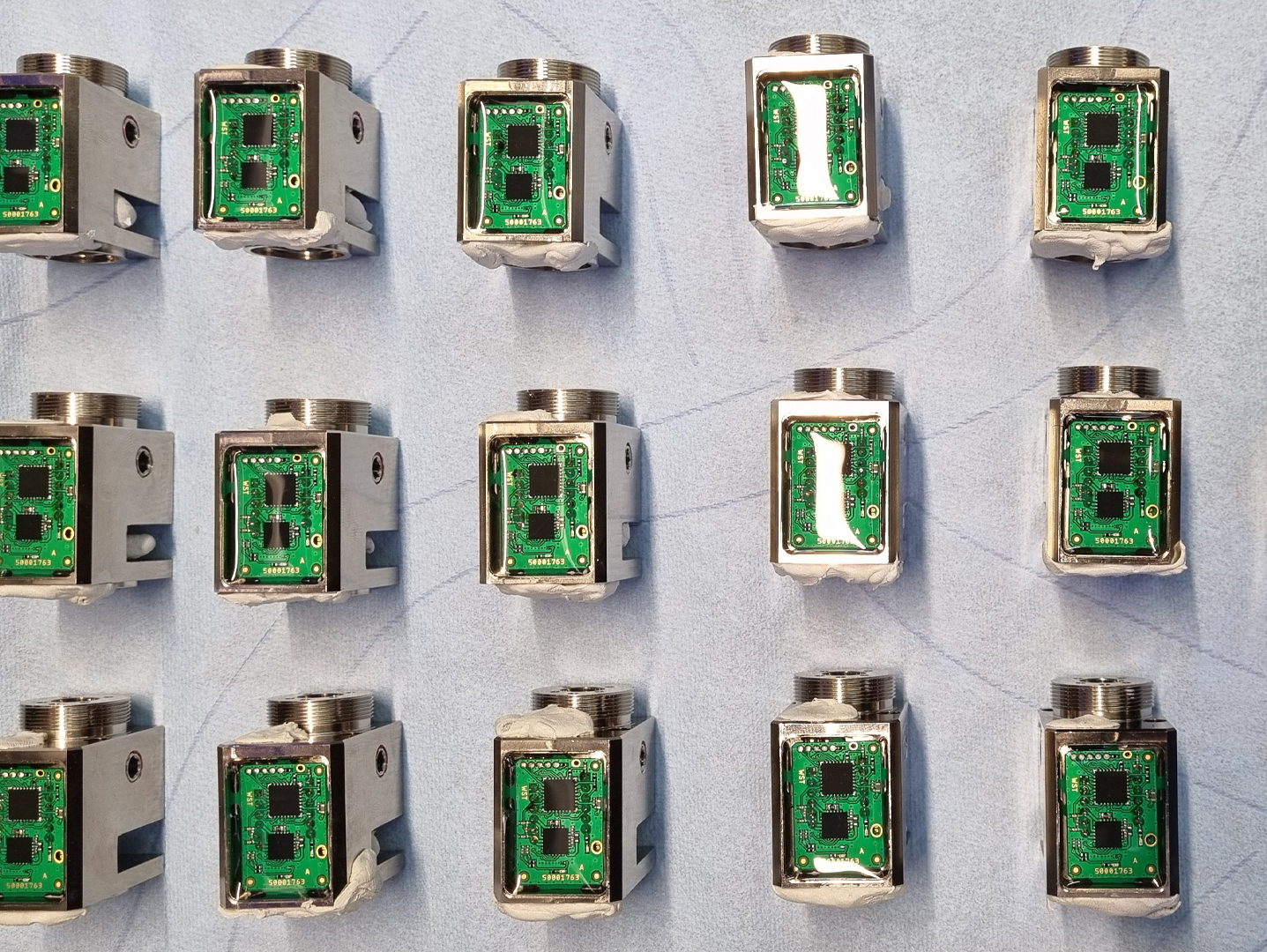

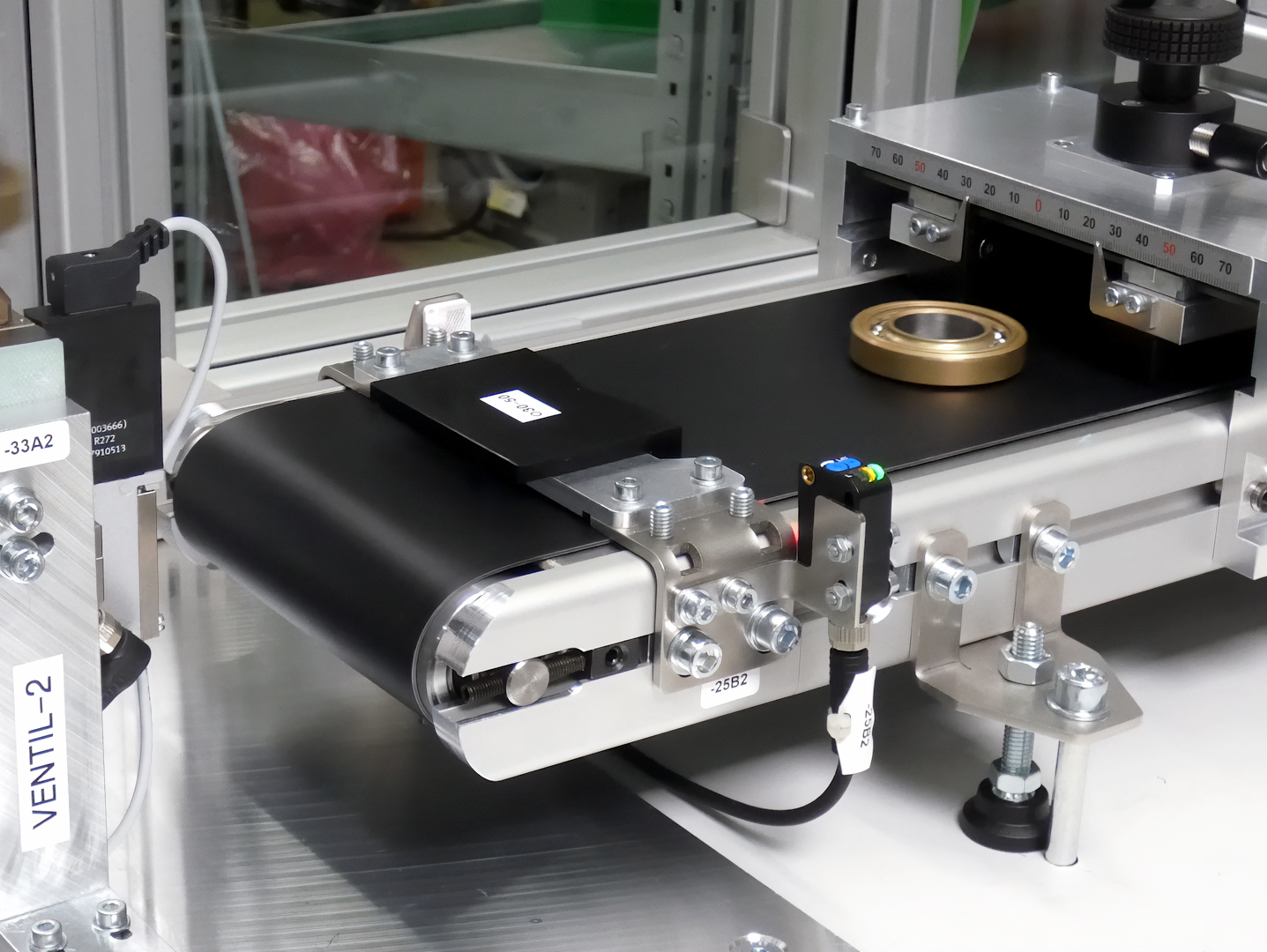

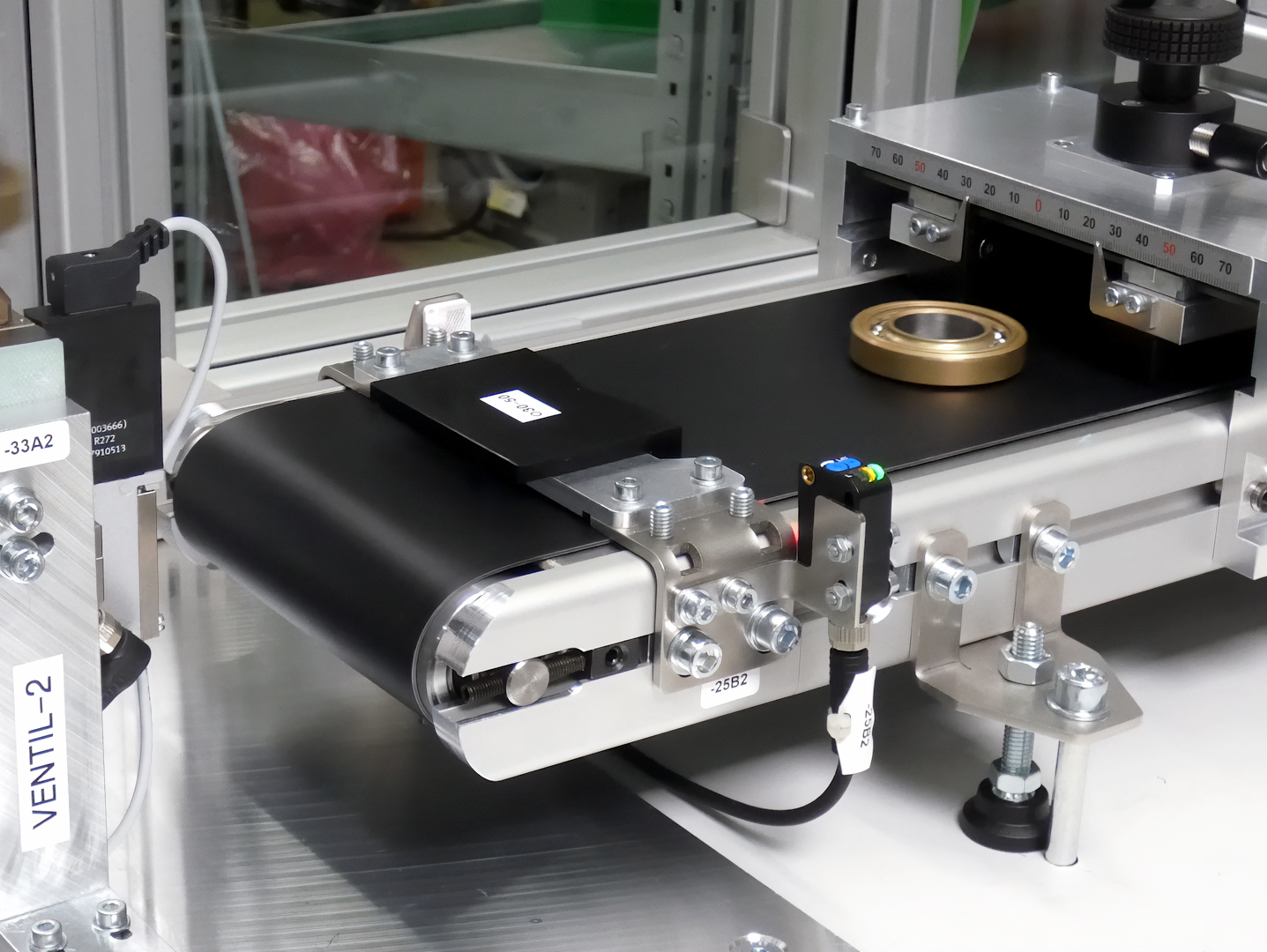

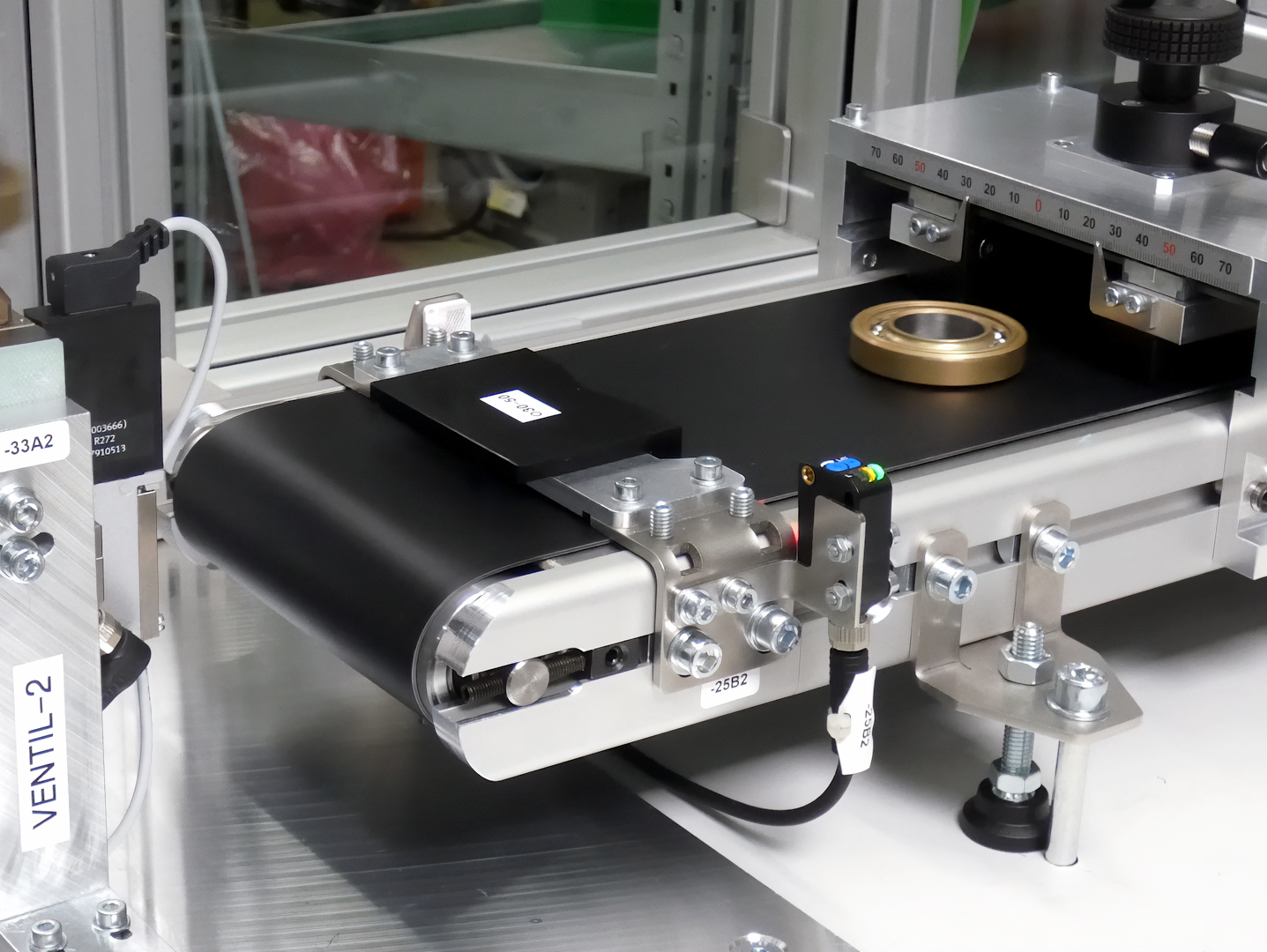

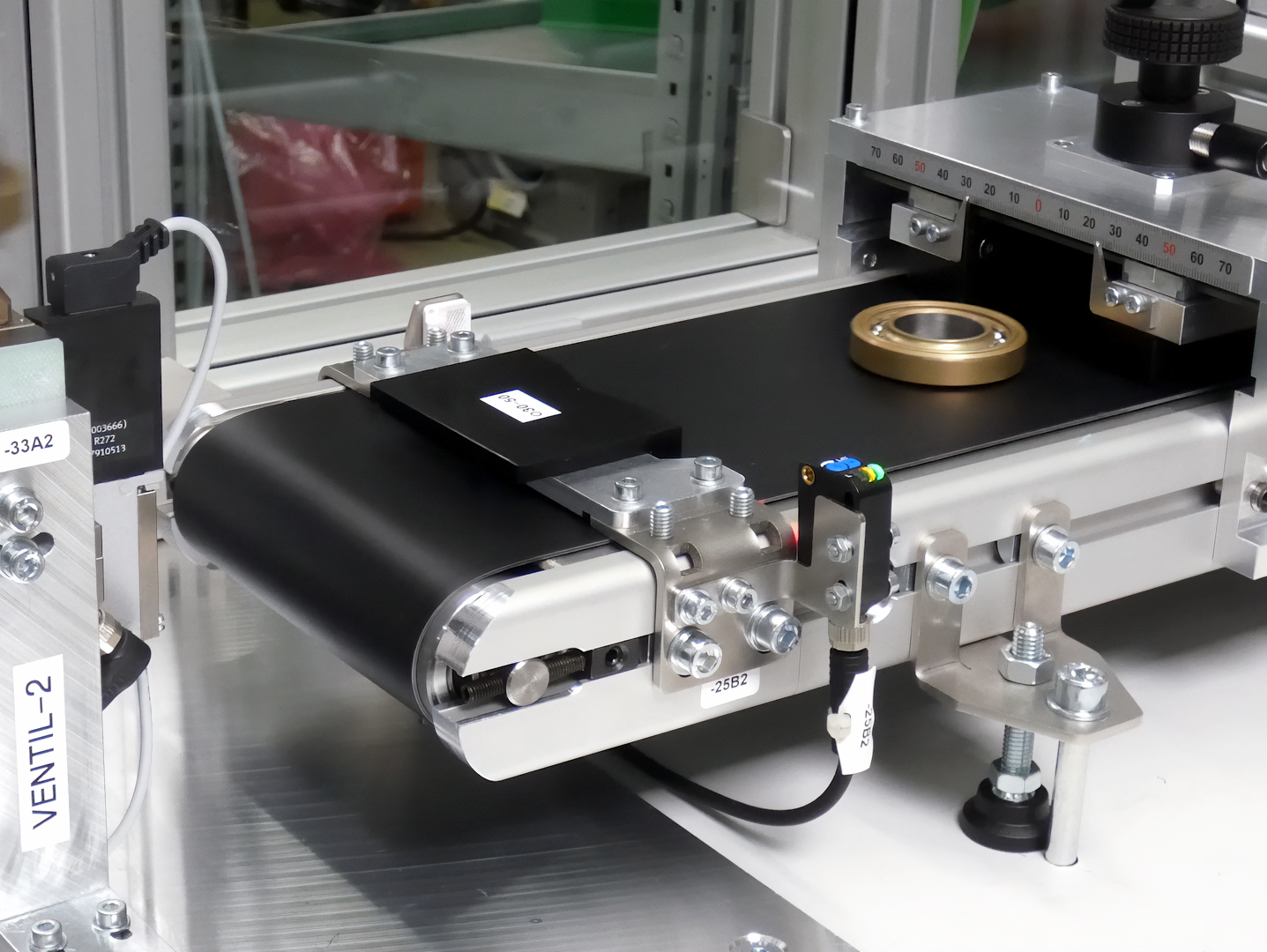

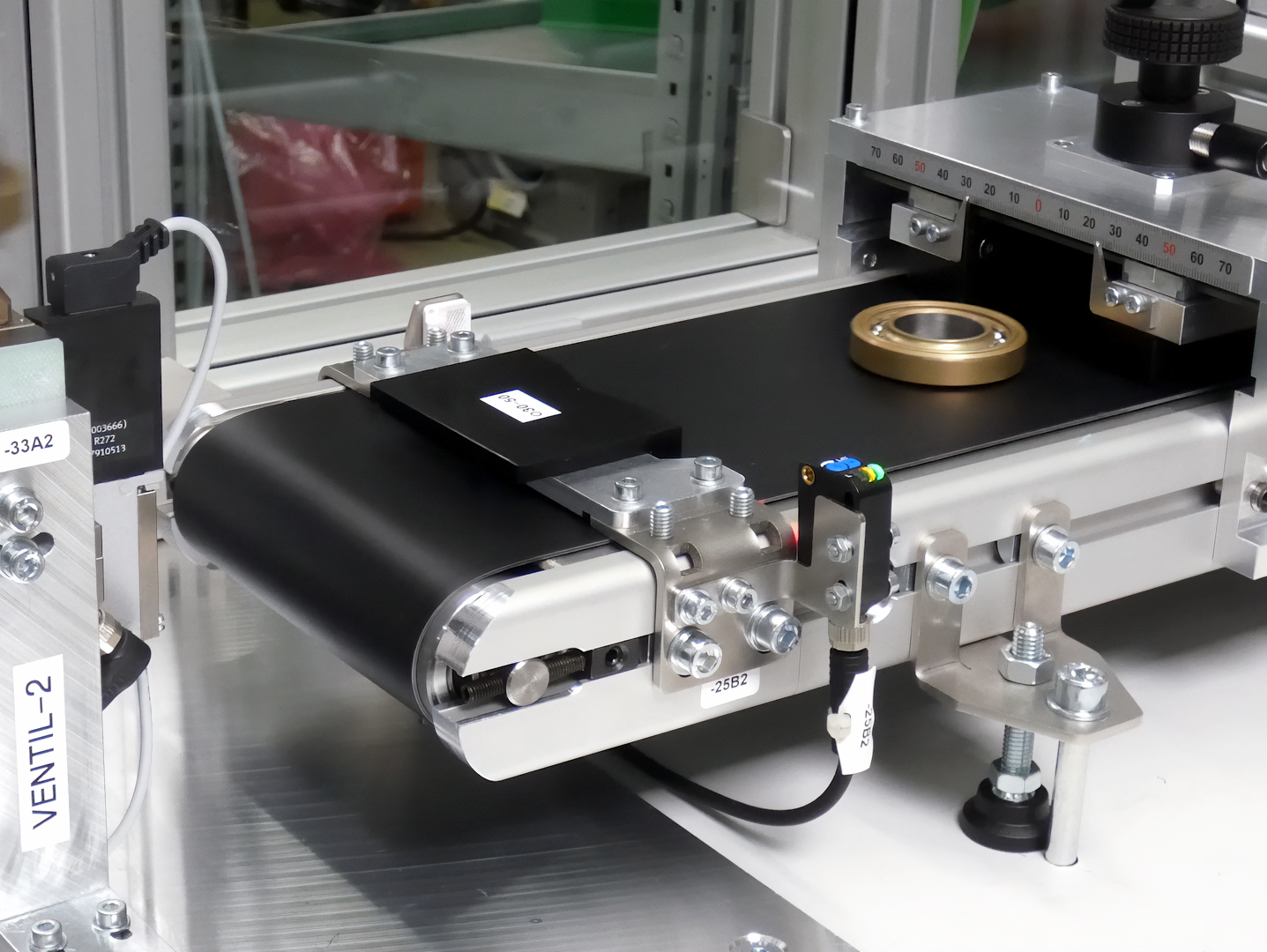

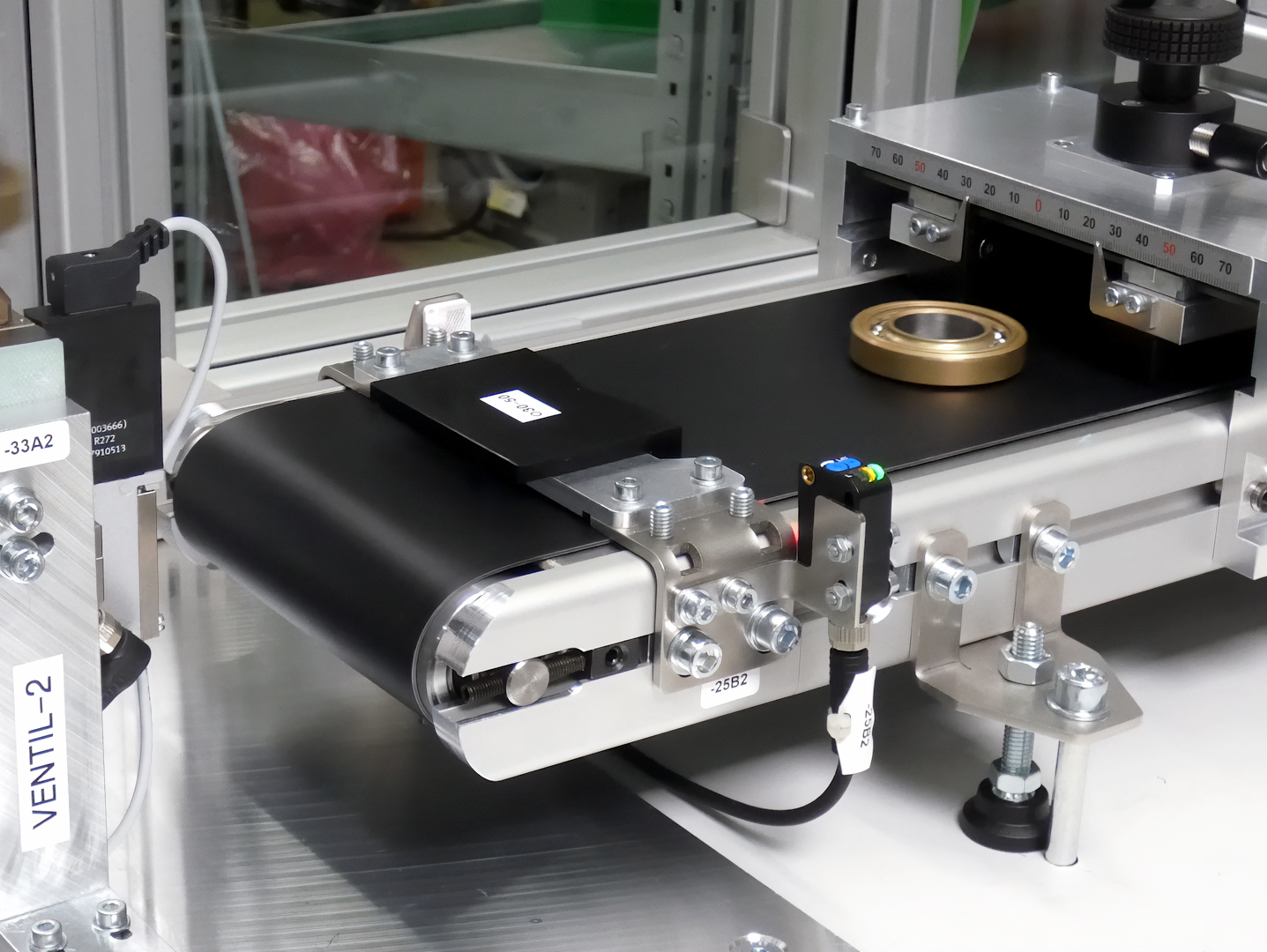

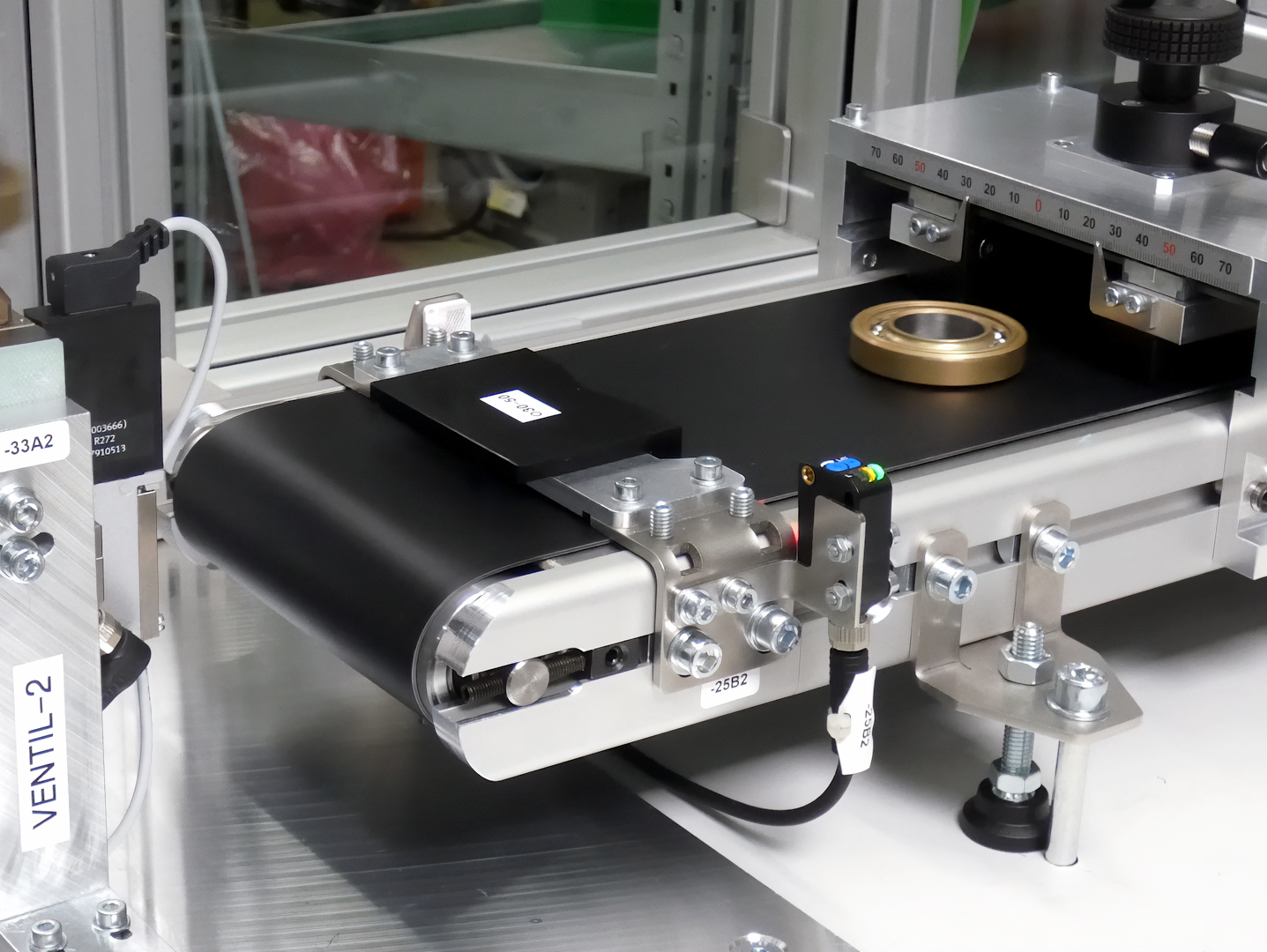

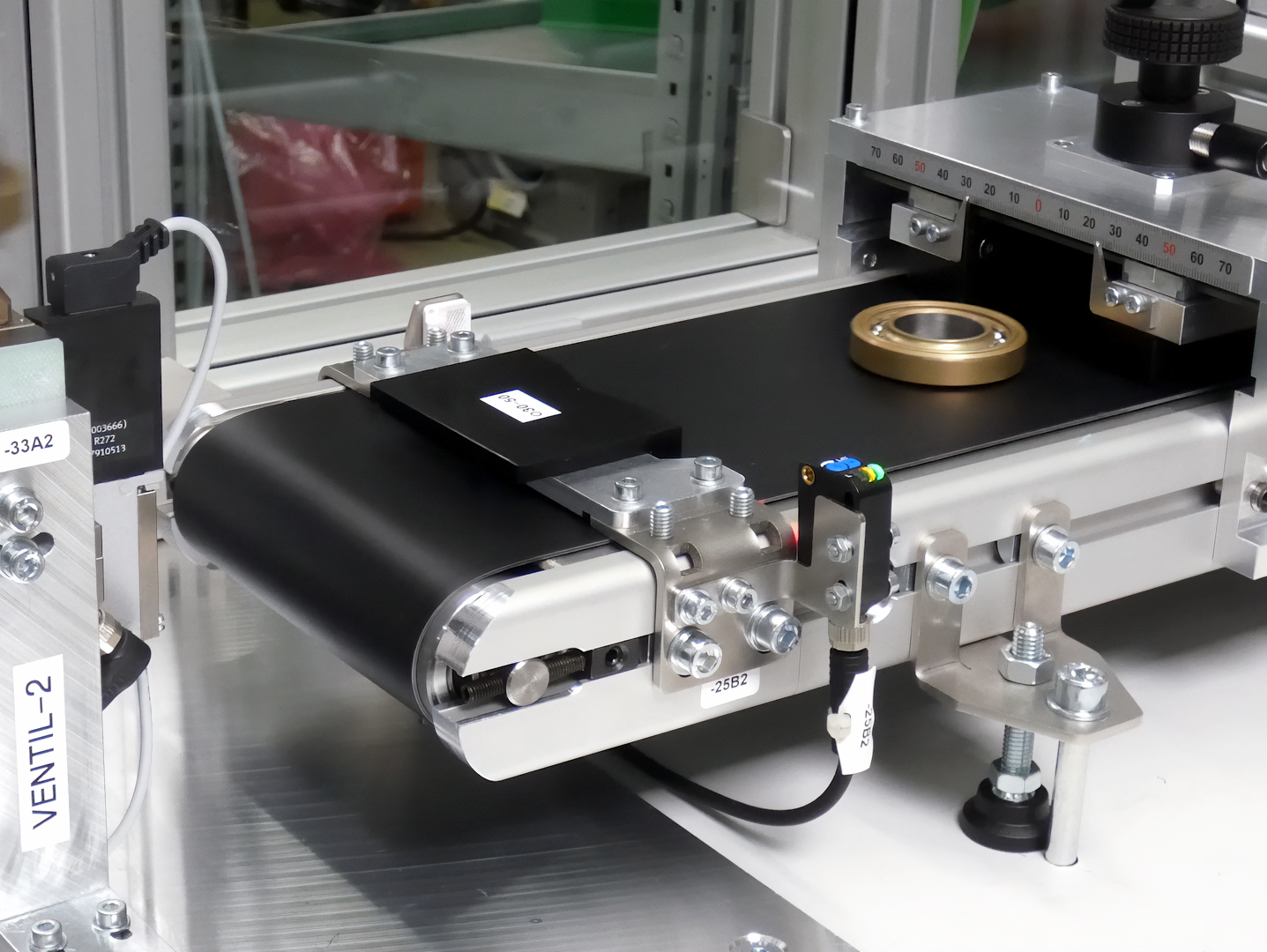

For the precise lubrication of rolling bearings, Walther Systemtechnik has developed and successfully implemented an advanced lubricant application system. The system specifically addresses the high requirements for component lubrication in rolling bearing production, particularly for small batch sizes and a high degree of product variation.

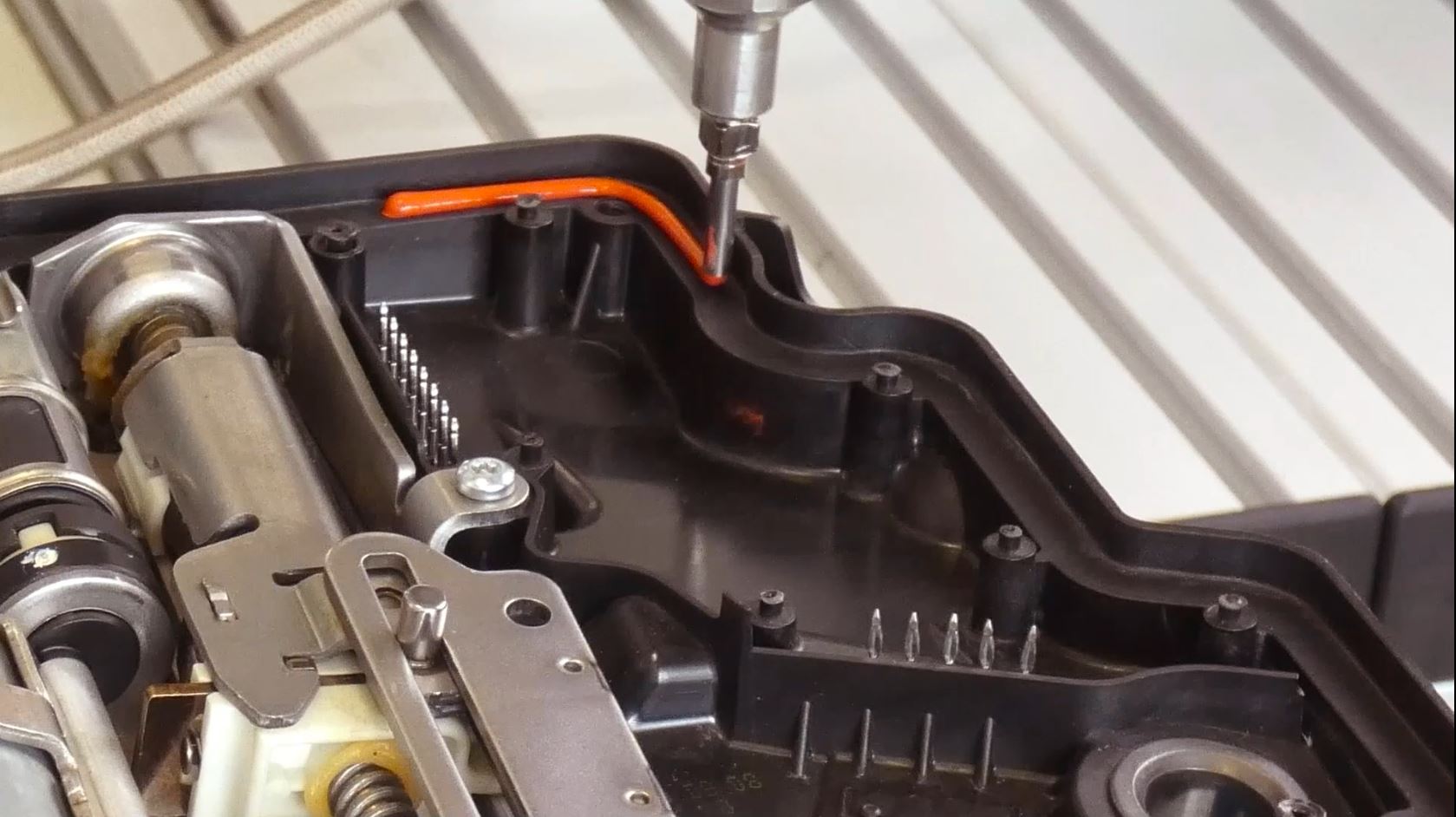

The core of the solution is the use of pulse valves, which enable pinpoint and reproducible lubricant application. The system is designed to be adapted quickly and efficiently to changing production requirements. Automation, low set-up effort, integrated recipe management and continuous process monitoring are consistently combined within a single solution.

- High flexibility and fast changeover: By simply replacing the gripper jaws, the system can be quickly adapted to different bearing dimensions and bearing types. This enables short set-up times and economical production even with frequent product changeovers.

- Automated lubrication process: Manual loading of the rolling bearings is complemented by a fully automated sequence. This includes component pick-up, positioning and alignment, single- or double-sided lubricant application, and subsequent component removal. The result is consistently high quality and excellent repeatability of the lubrication process.

- Integrated recipe management: Lubricant recipes and application parameters can be stored and retrieved on a bearing-type-specific basis. This increases process reliability, reduces operating errors and ensures that each bearing variant is lubricated exactly in accordance with its technical requirements.

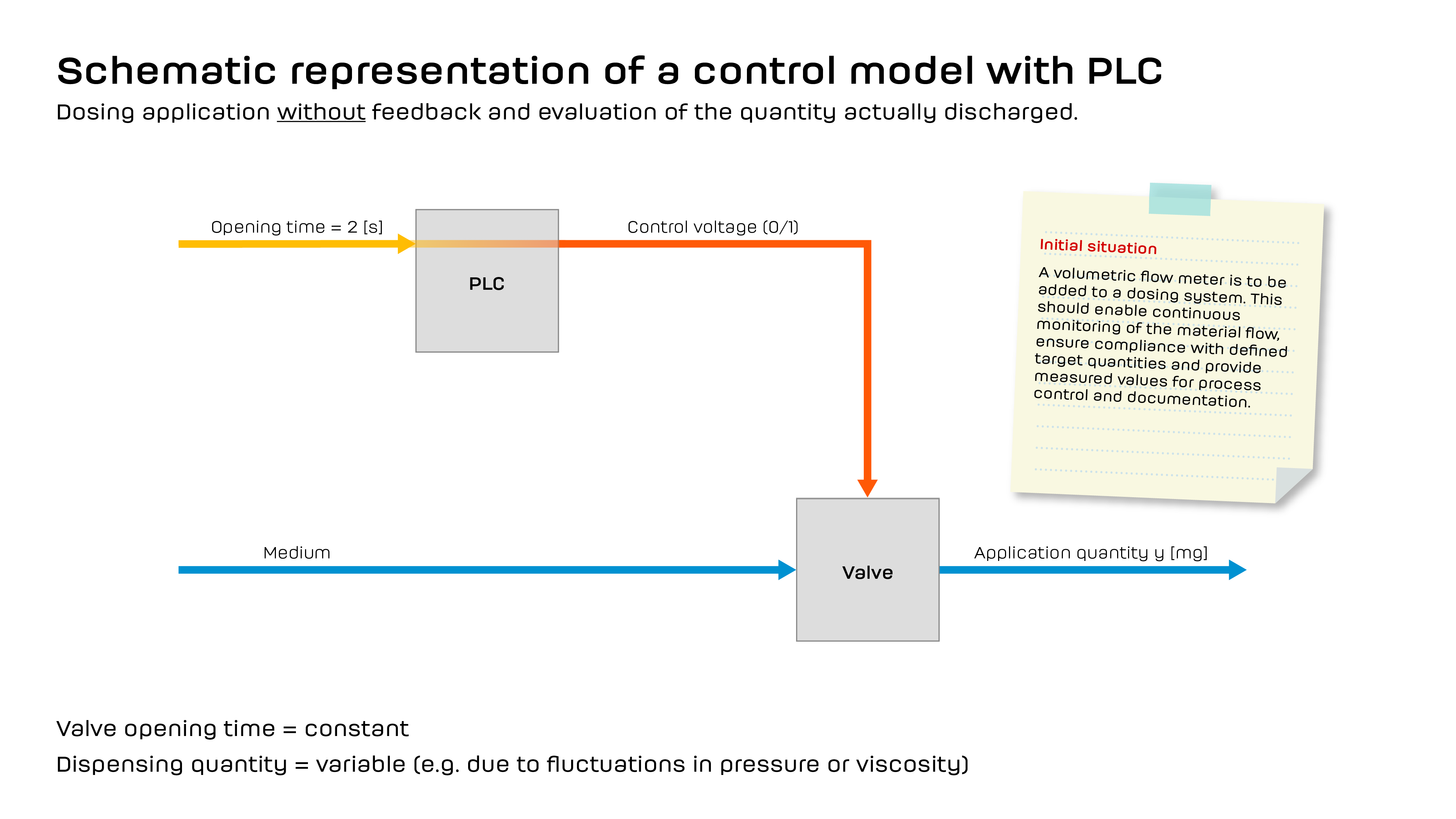

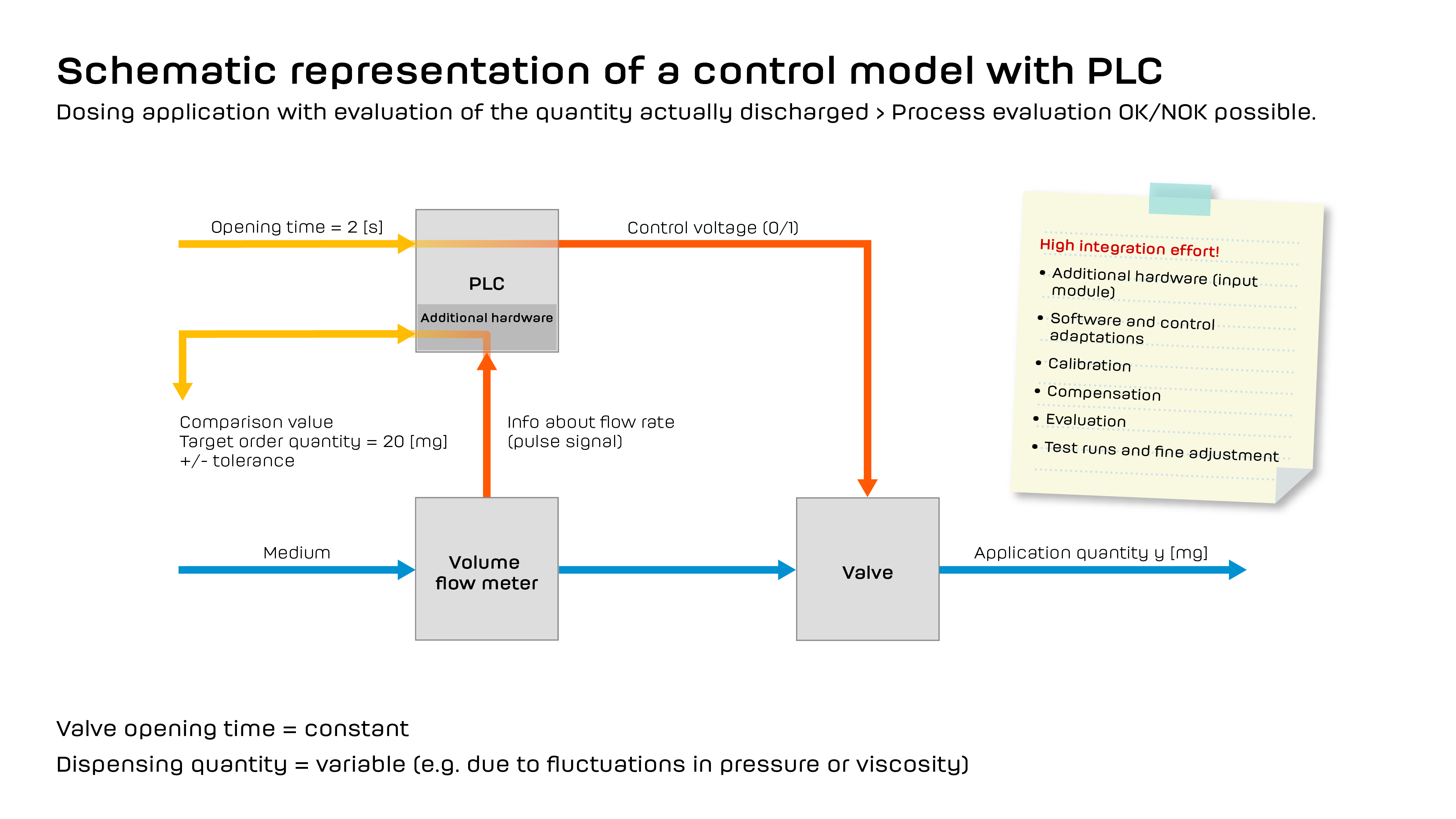

- Reliable process control: Integrated monitoring functions continuously safeguard the lubricant application process. Dispensed volume and application position are monitored, ensuring precise dosing and a high level of process stability.

Lubrication of rolling bearings – project successfully completed

For the precise lubrication of rolling bearings, Walther Systemtechnik has developed and successfully implemented an advanced lubricant application system. The system specifically addresses the high requirements for component lubrication in rolling bearing production, particularly for small batch sizes and a high degree of product variation.

The core of the solution is the use of pulse valves, which enable pinpoint and reproducible lubricant application. The system is designed to be adapted quickly and efficiently to changing production requirements. Automation, low set-up effort, integrated recipe management and continuous process monitoring are consistently combined within a single solution.

- High flexibility and fast changeover: By simply replacing the gripper jaws, the system can be quickly adapted to different bearing dimensions and bearing types. This enables short set-up times and economical production even with frequent product changeovers.

- Automated lubrication process: Manual loading of the rolling bearings is complemented by a fully automated sequence. This includes component pick-up, positioning and alignment, single- or double-sided lubricant application, and subsequent component removal. The result is consistently high quality and excellent repeatability of the lubrication process.

- Integrated recipe management: Lubricant recipes and application parameters can be stored and retrieved on a bearing-type-specific basis. This increases process reliability, reduces operating errors and ensures that each bearing variant is lubricated exactly in accordance with its technical requirements.

- Reliable process control: Integrated monitoring functions continuously safeguard the lubricant application process. Dispensed volume and application position are monitored, ensuring precise dosing and a high level of process stability.

Weitere Beiträge

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request