Dispensing technology for processing and applying viscous media

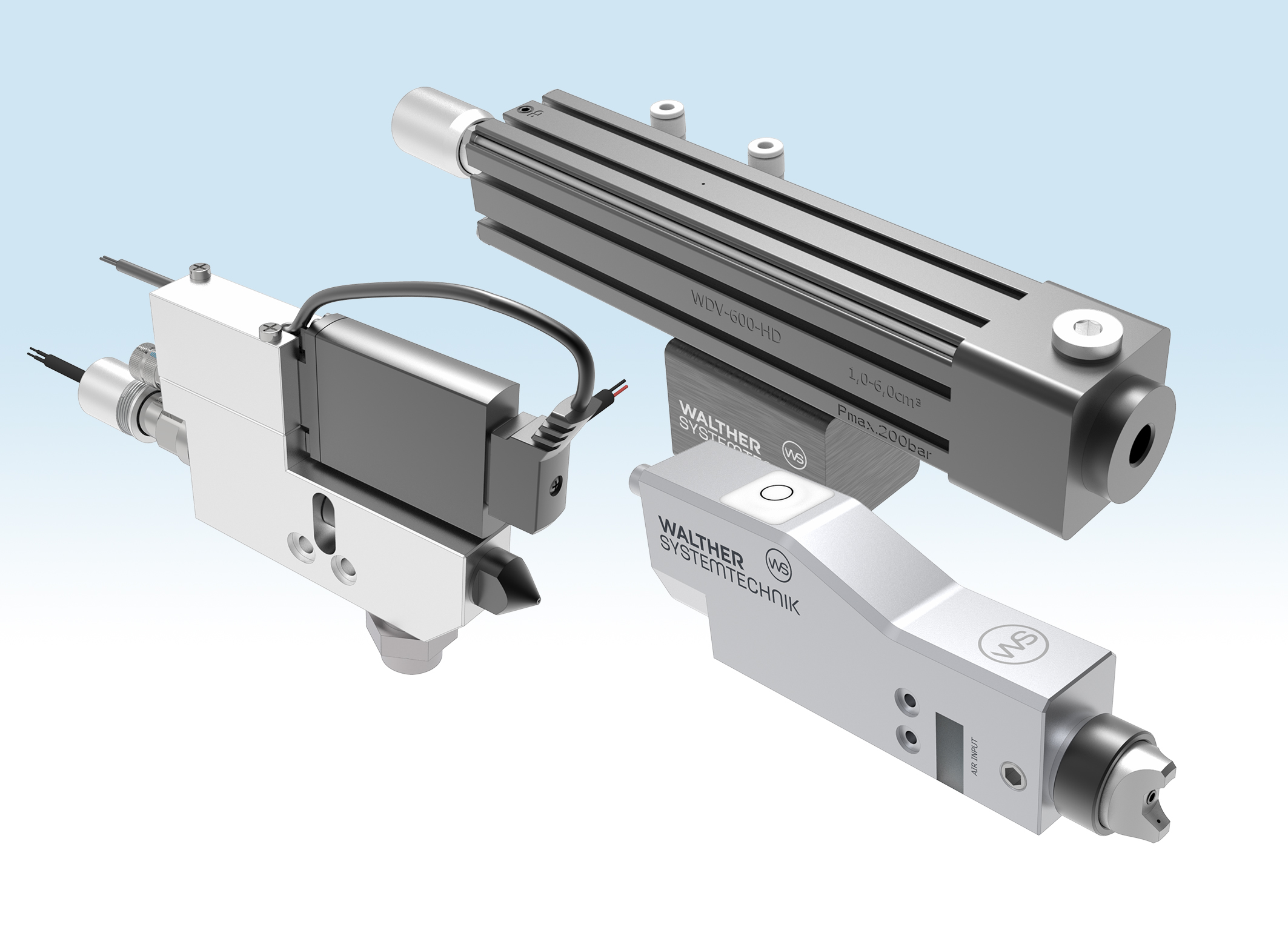

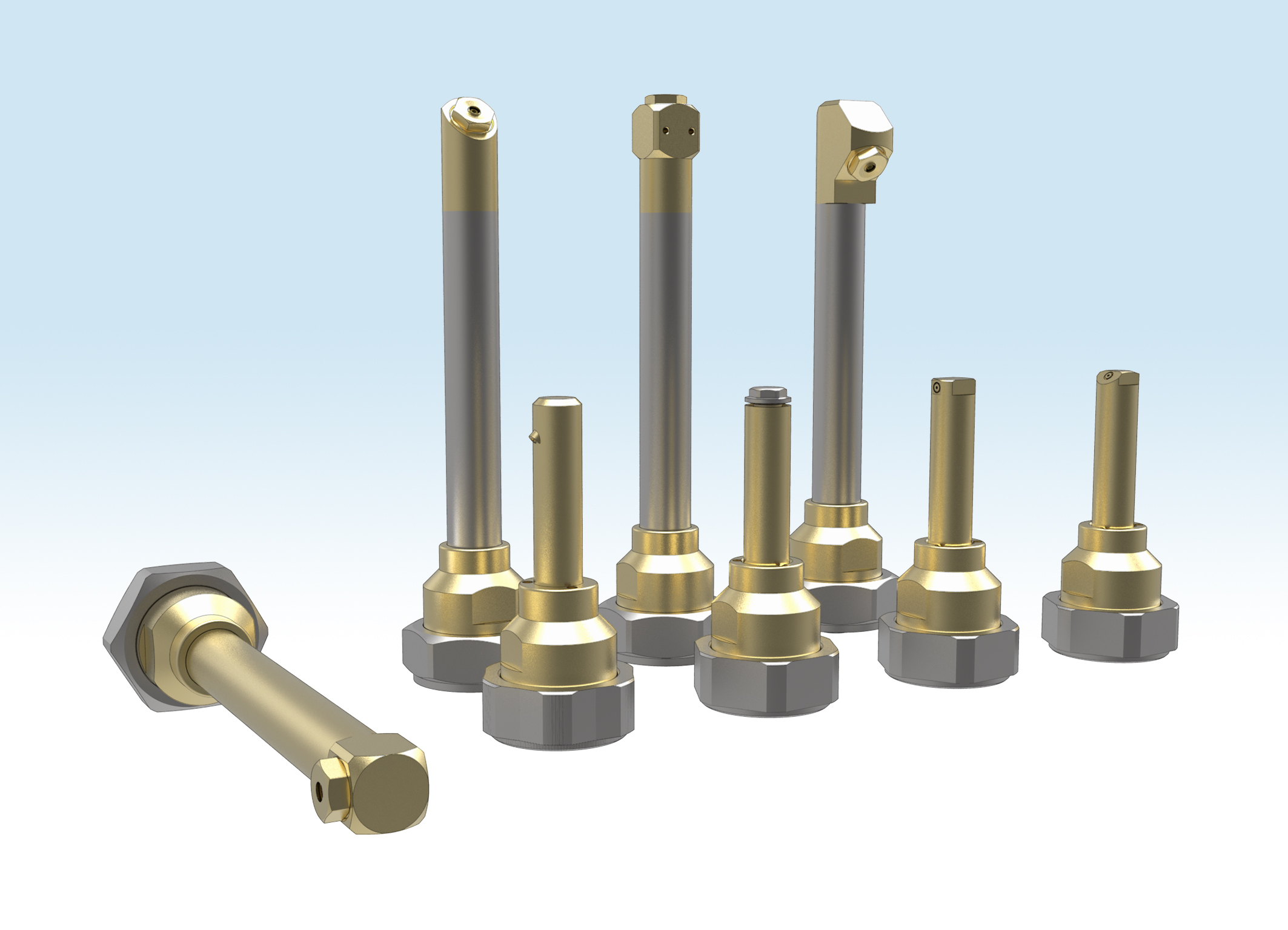

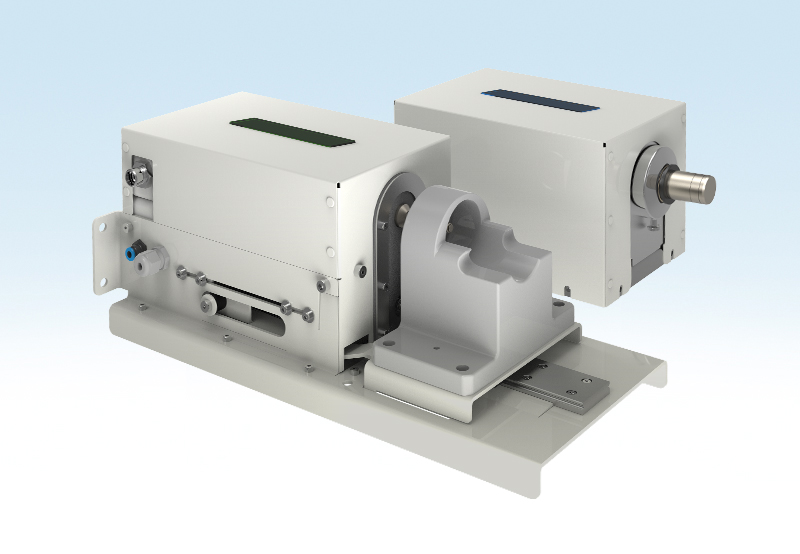

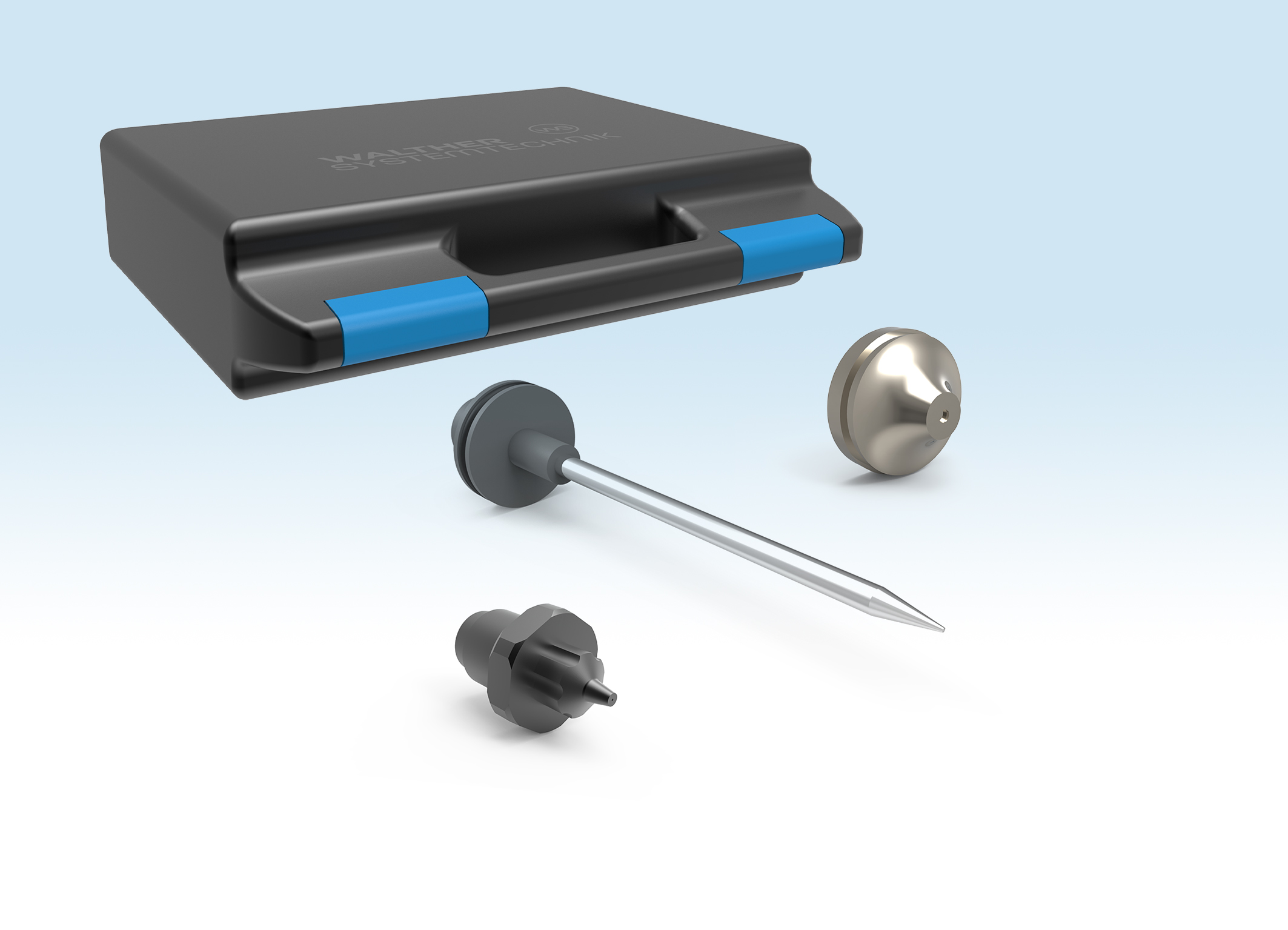

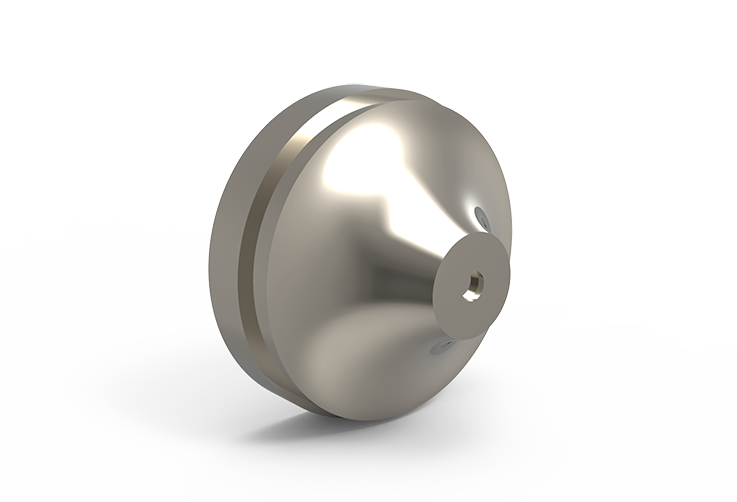

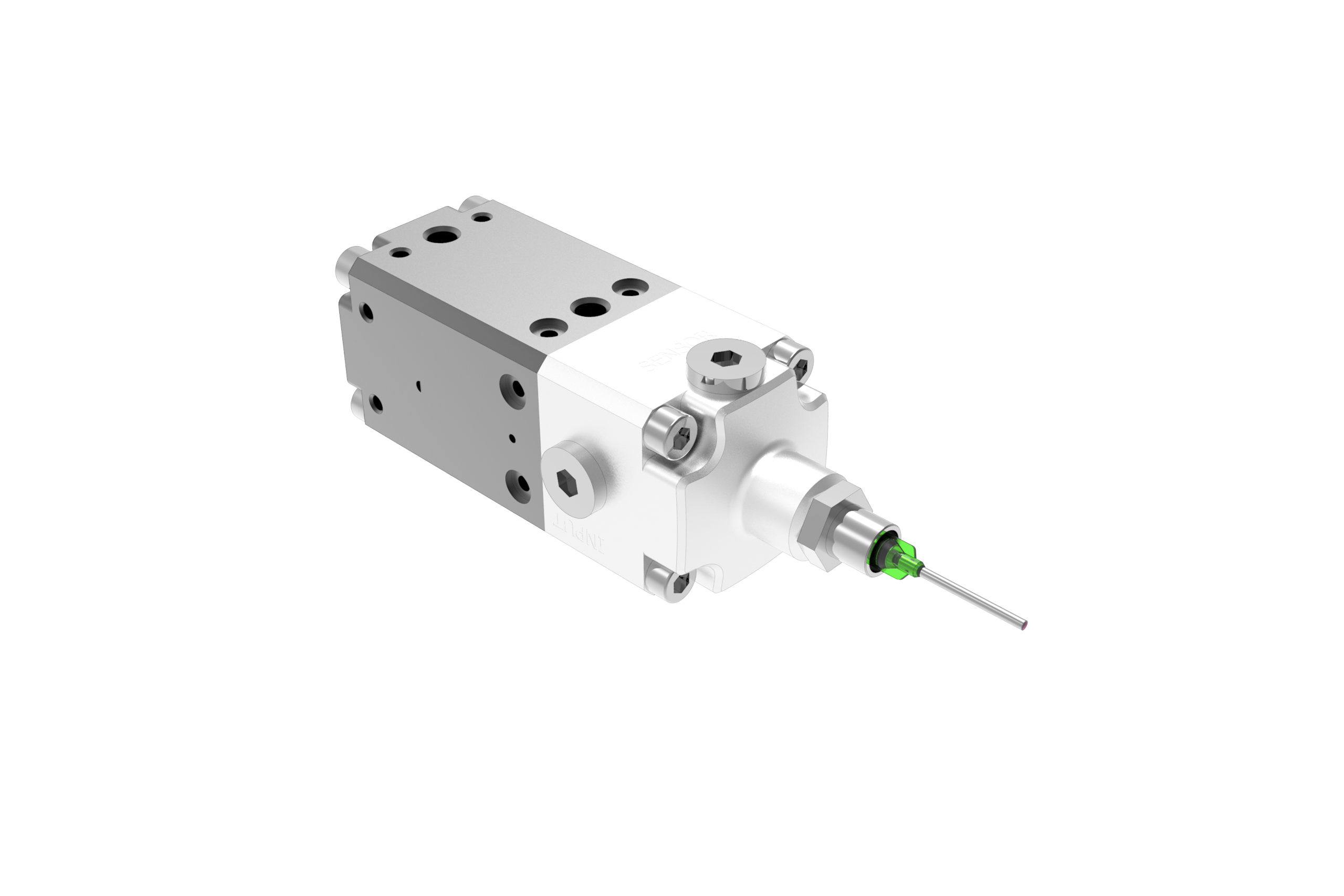

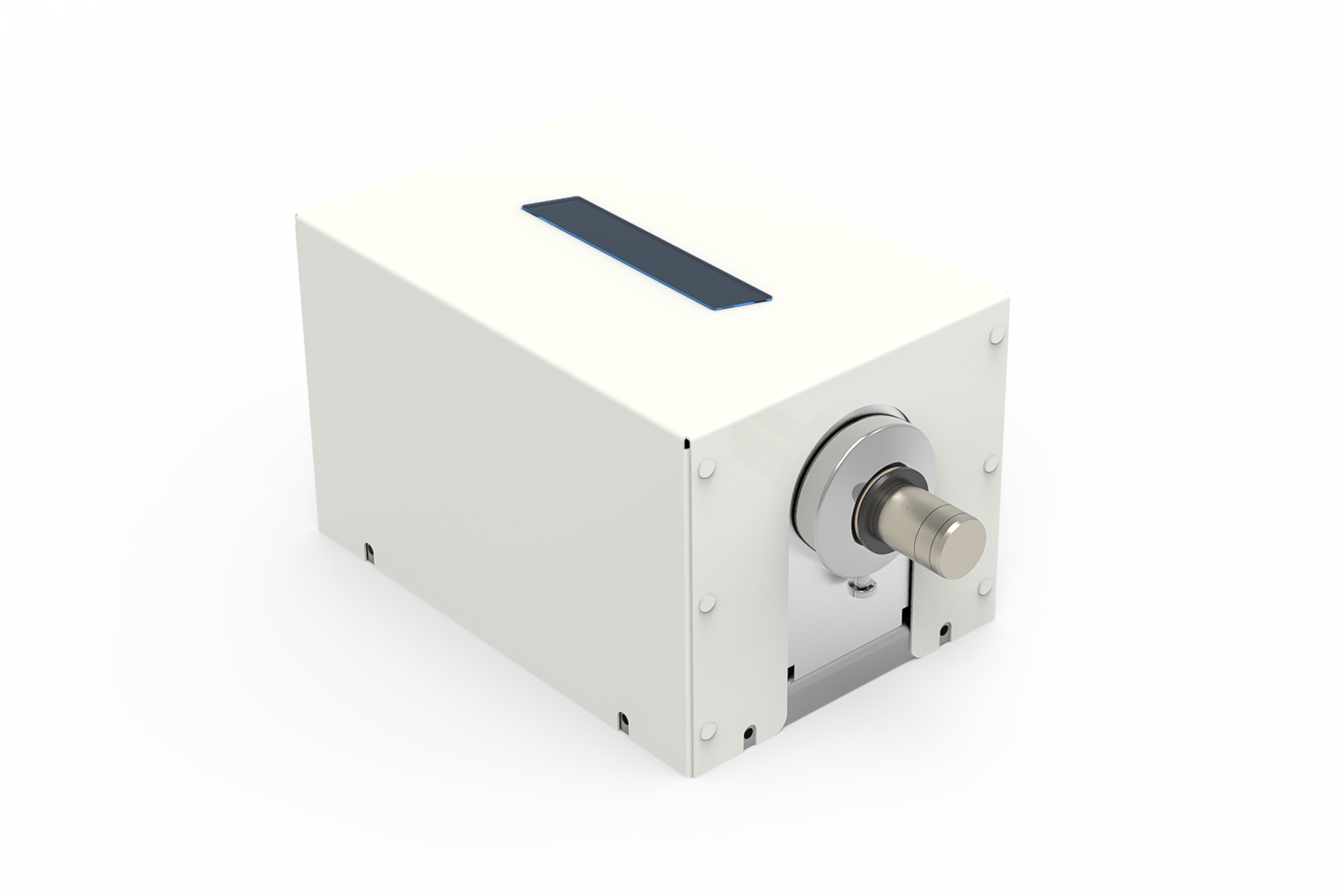

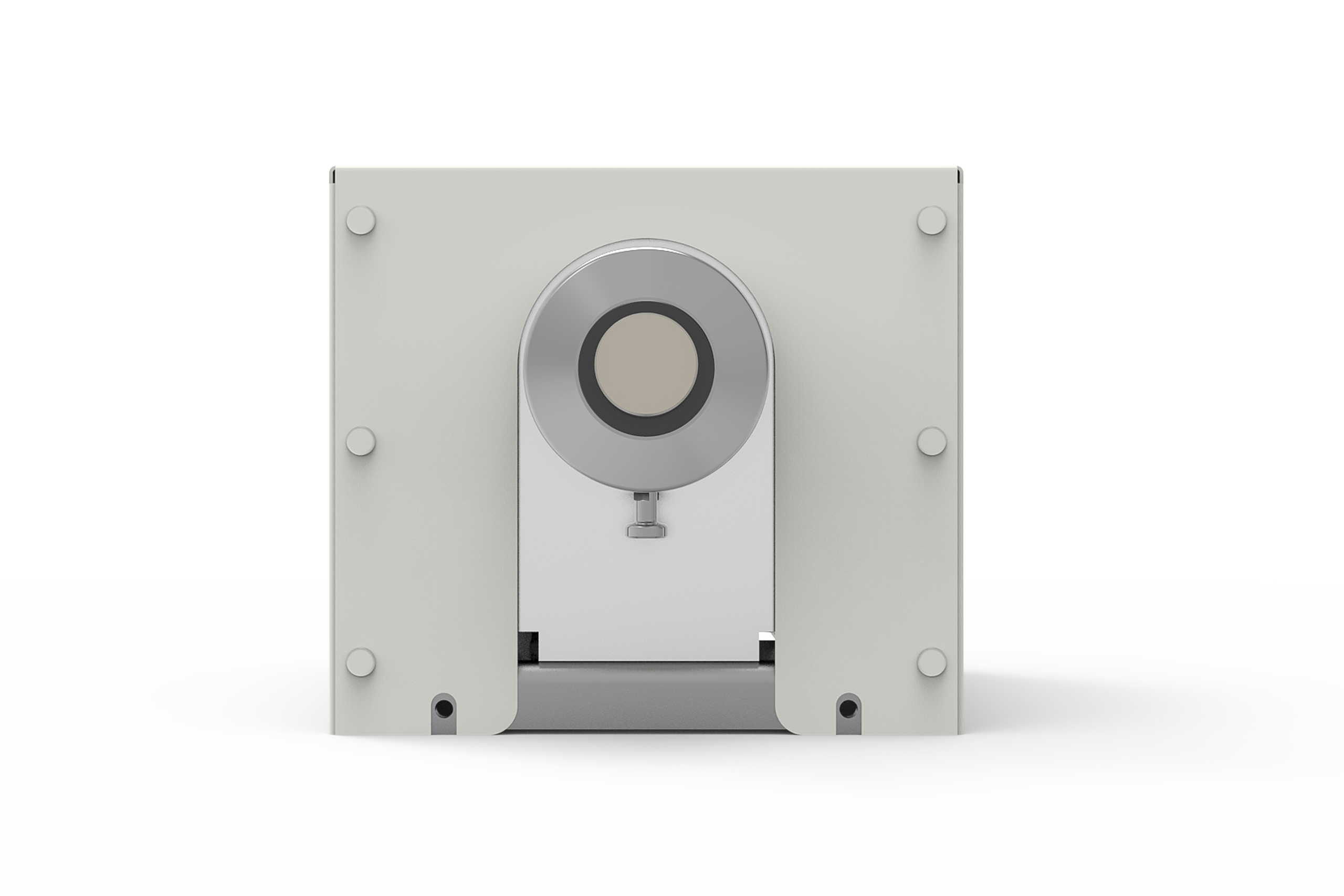

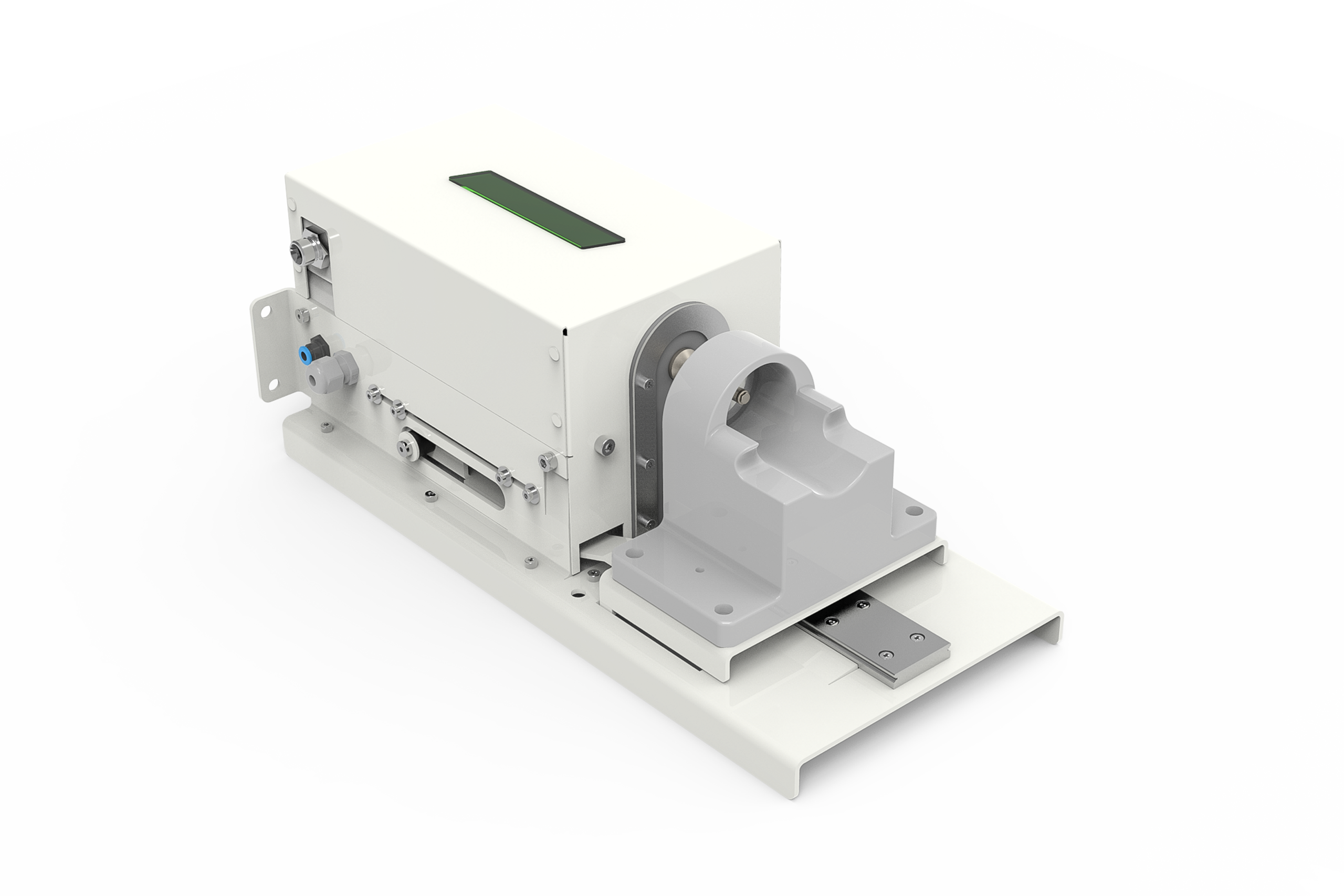

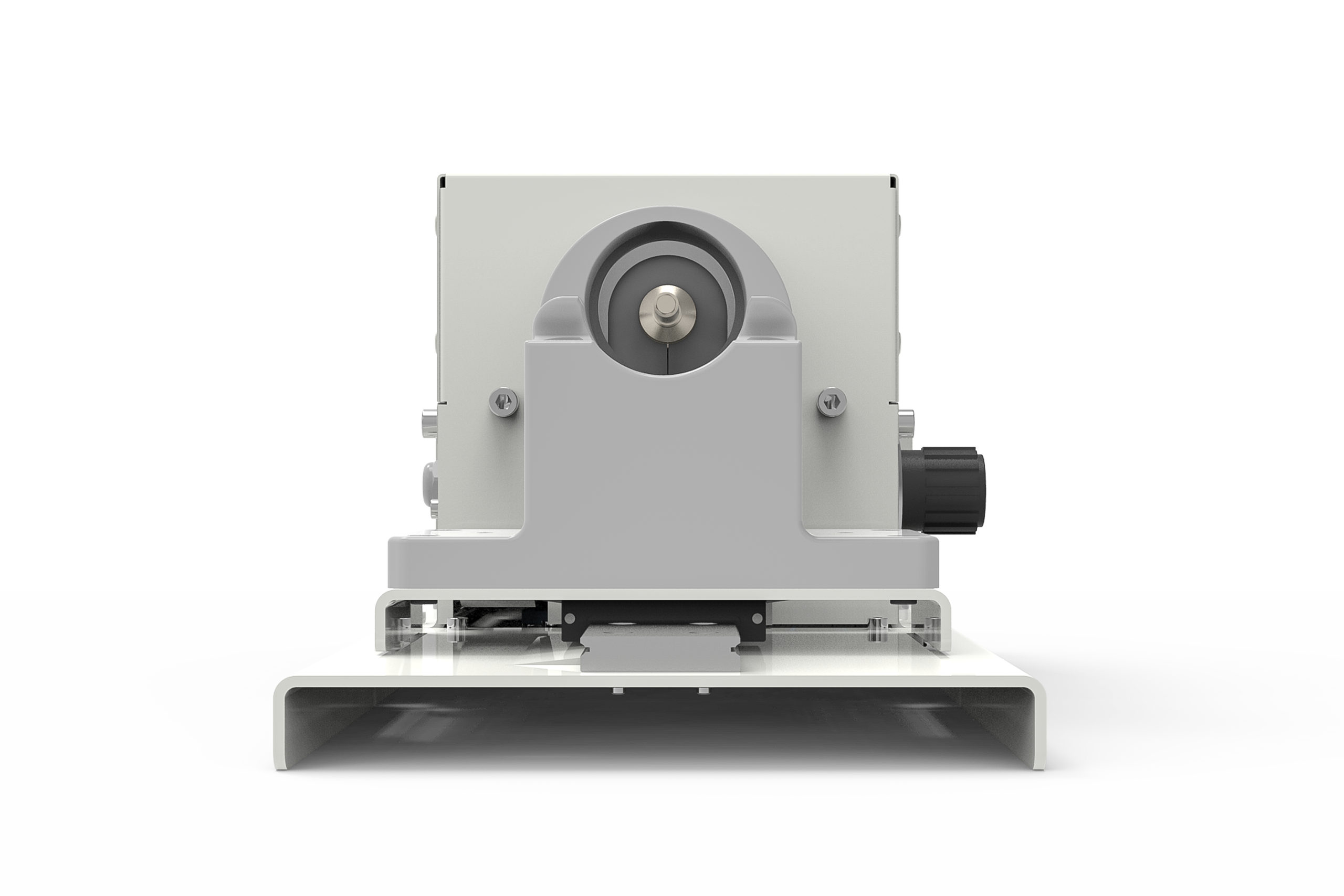

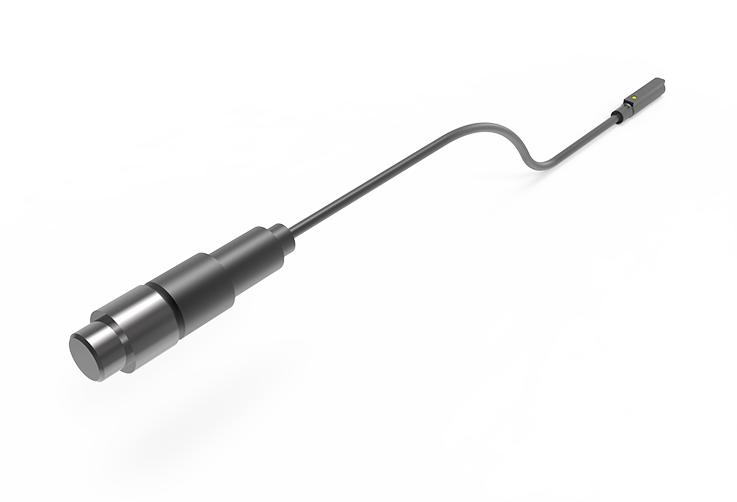

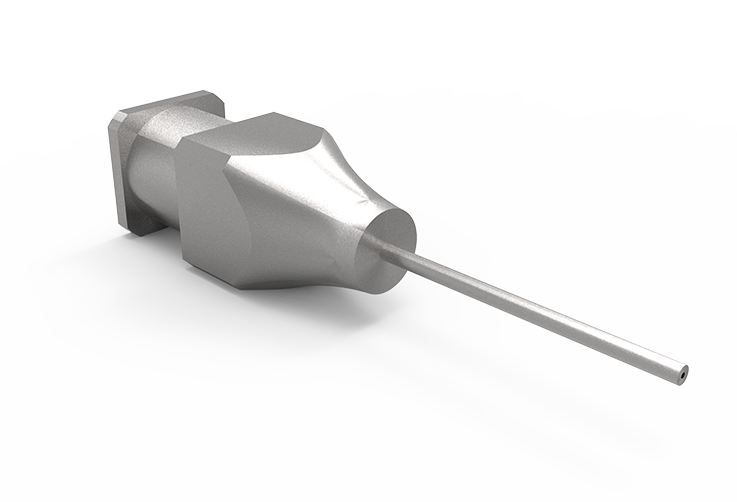

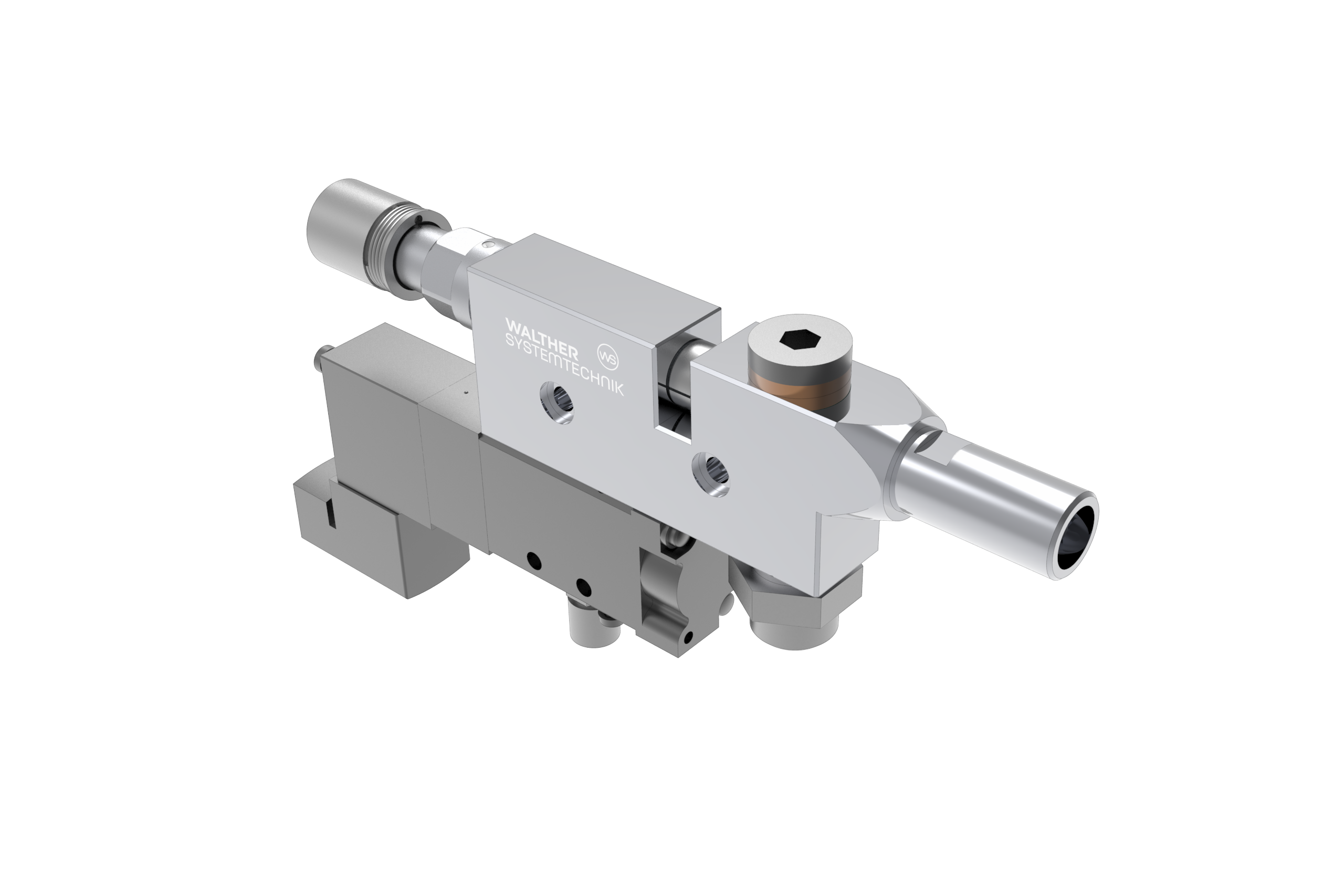

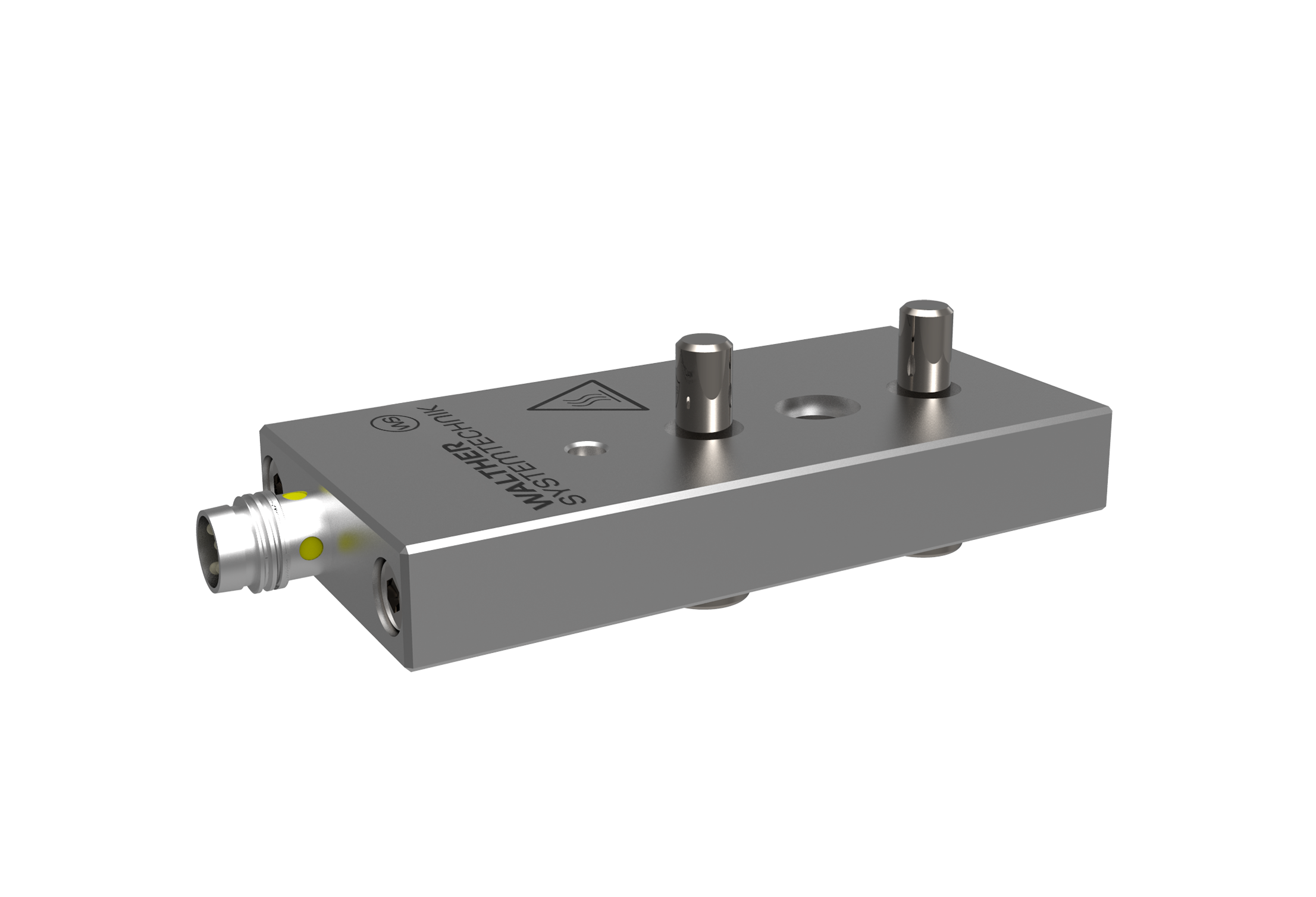

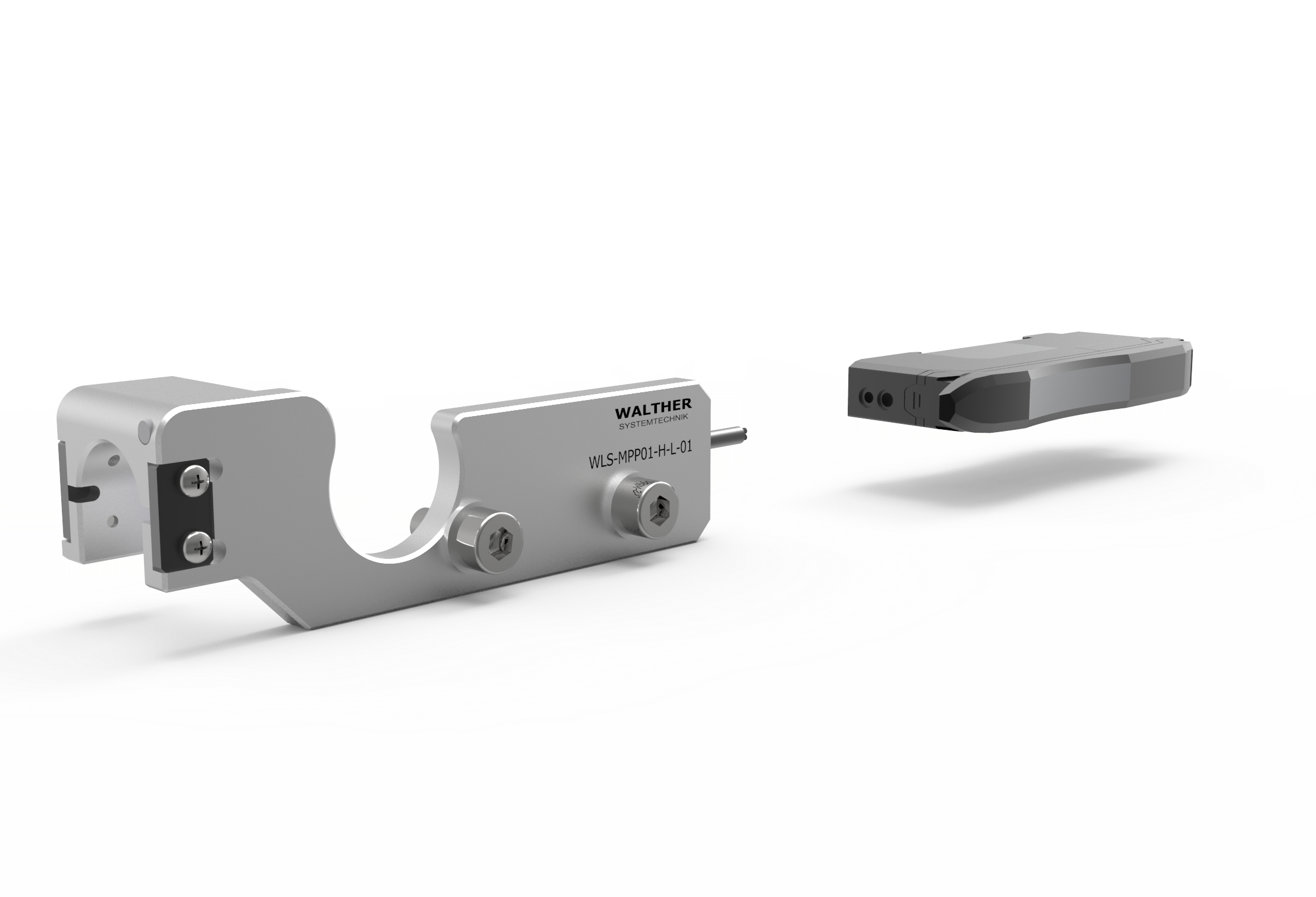

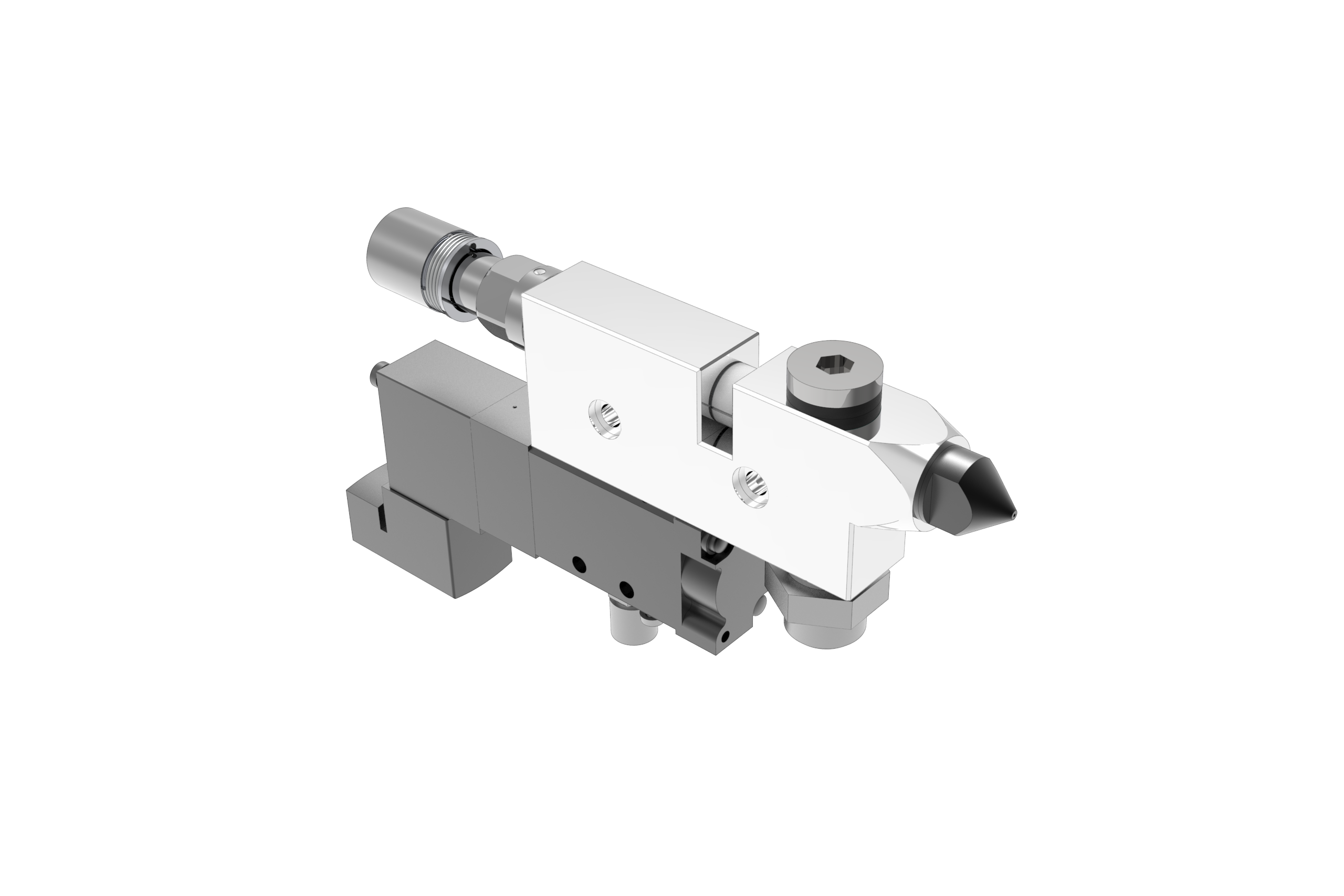

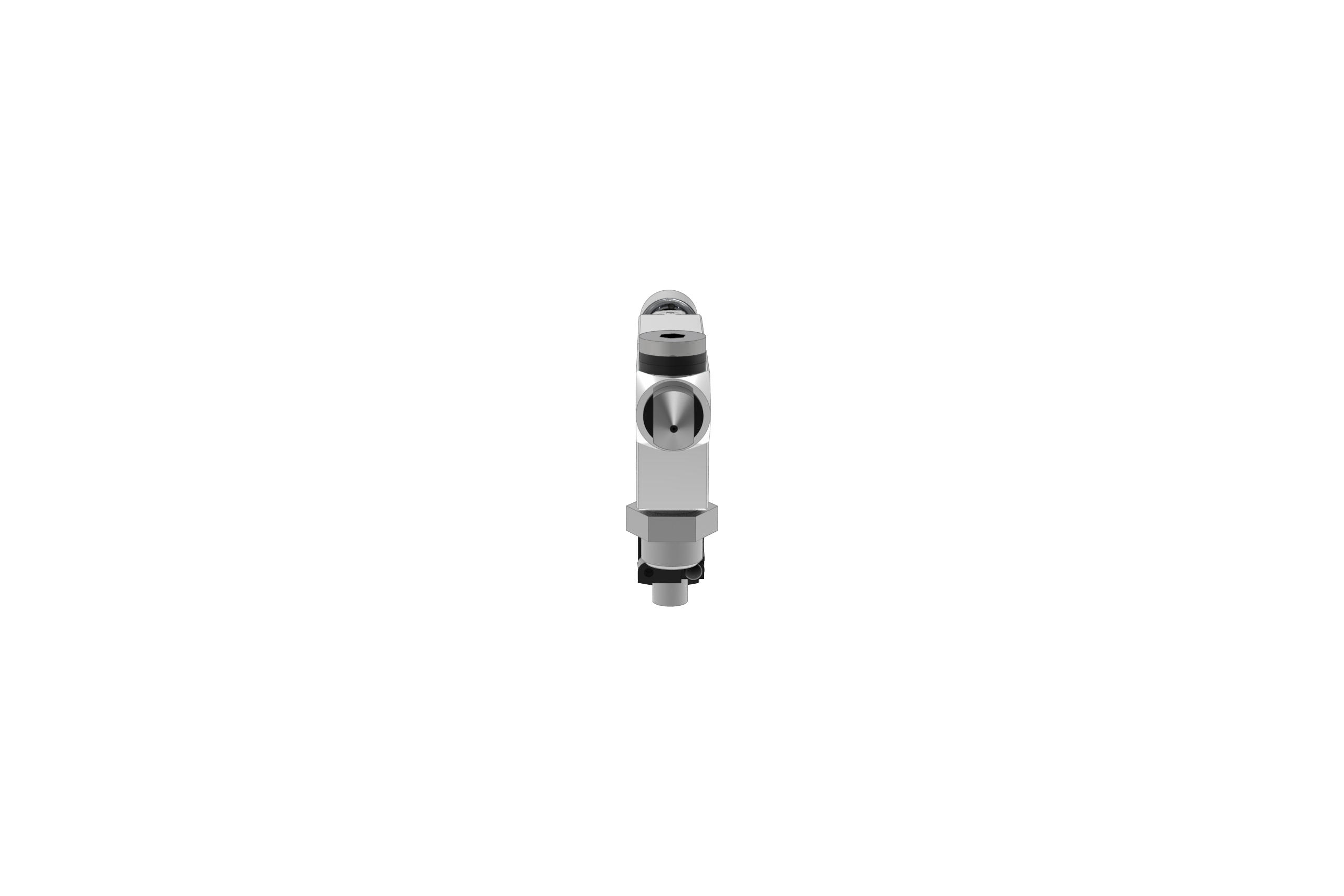

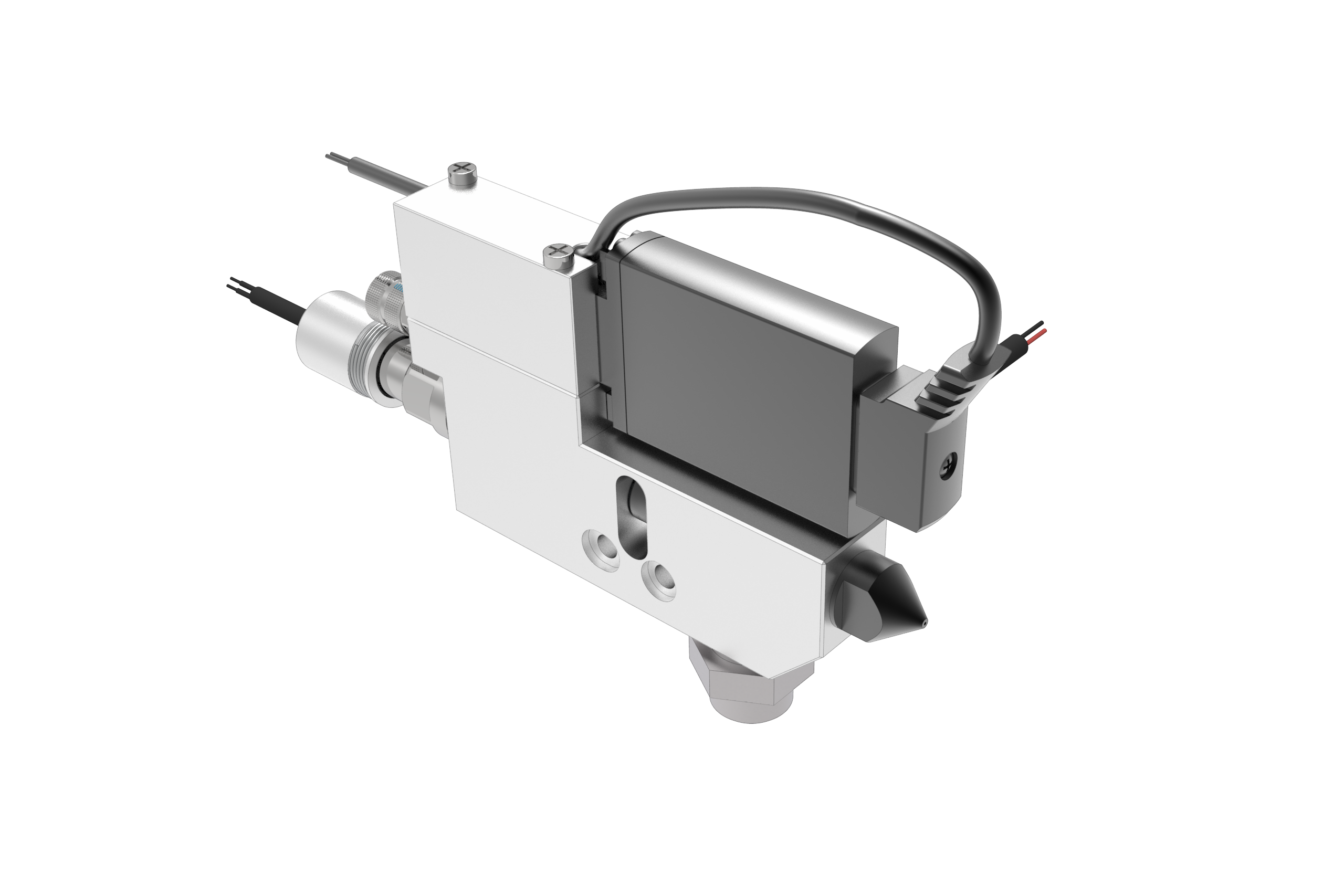

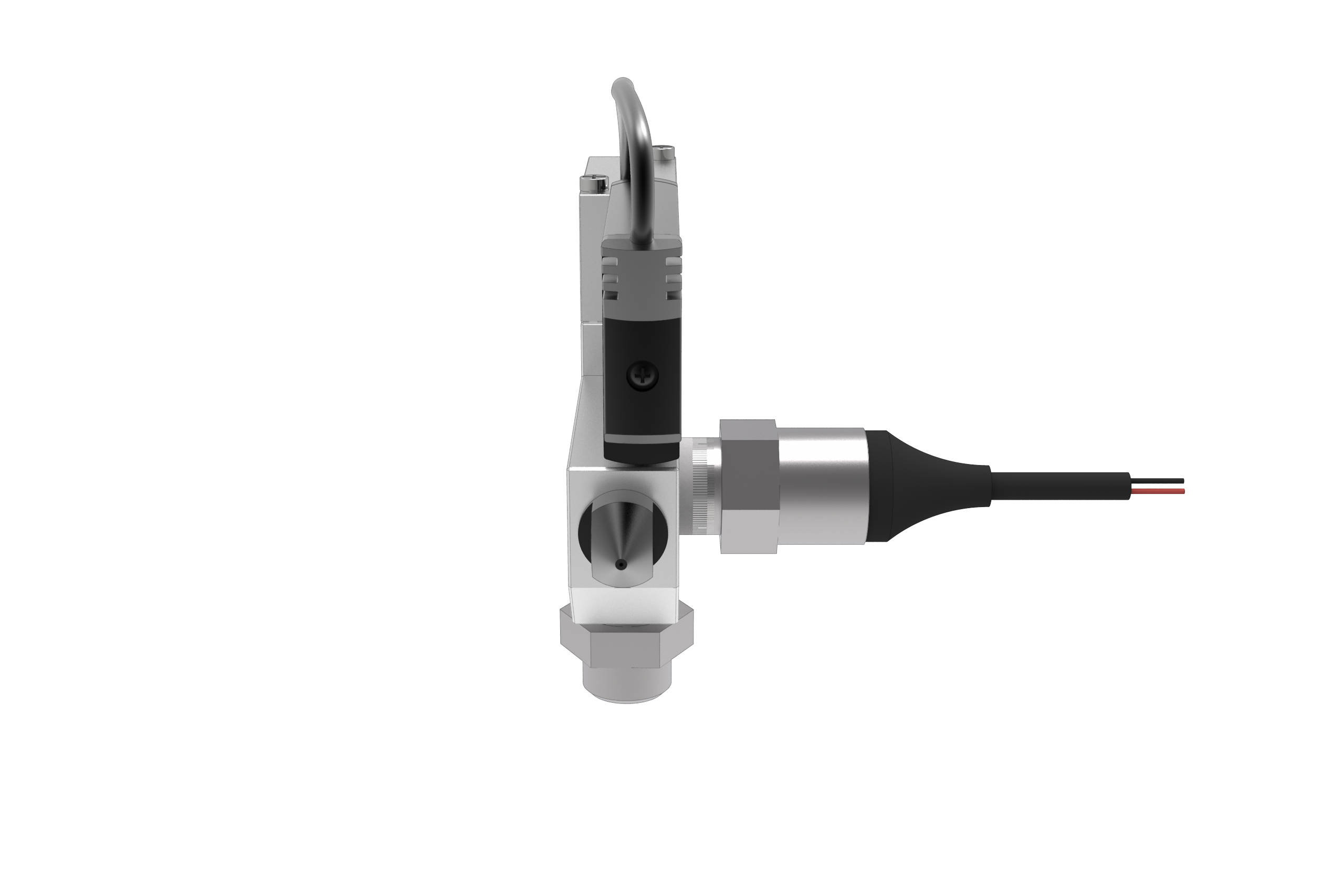

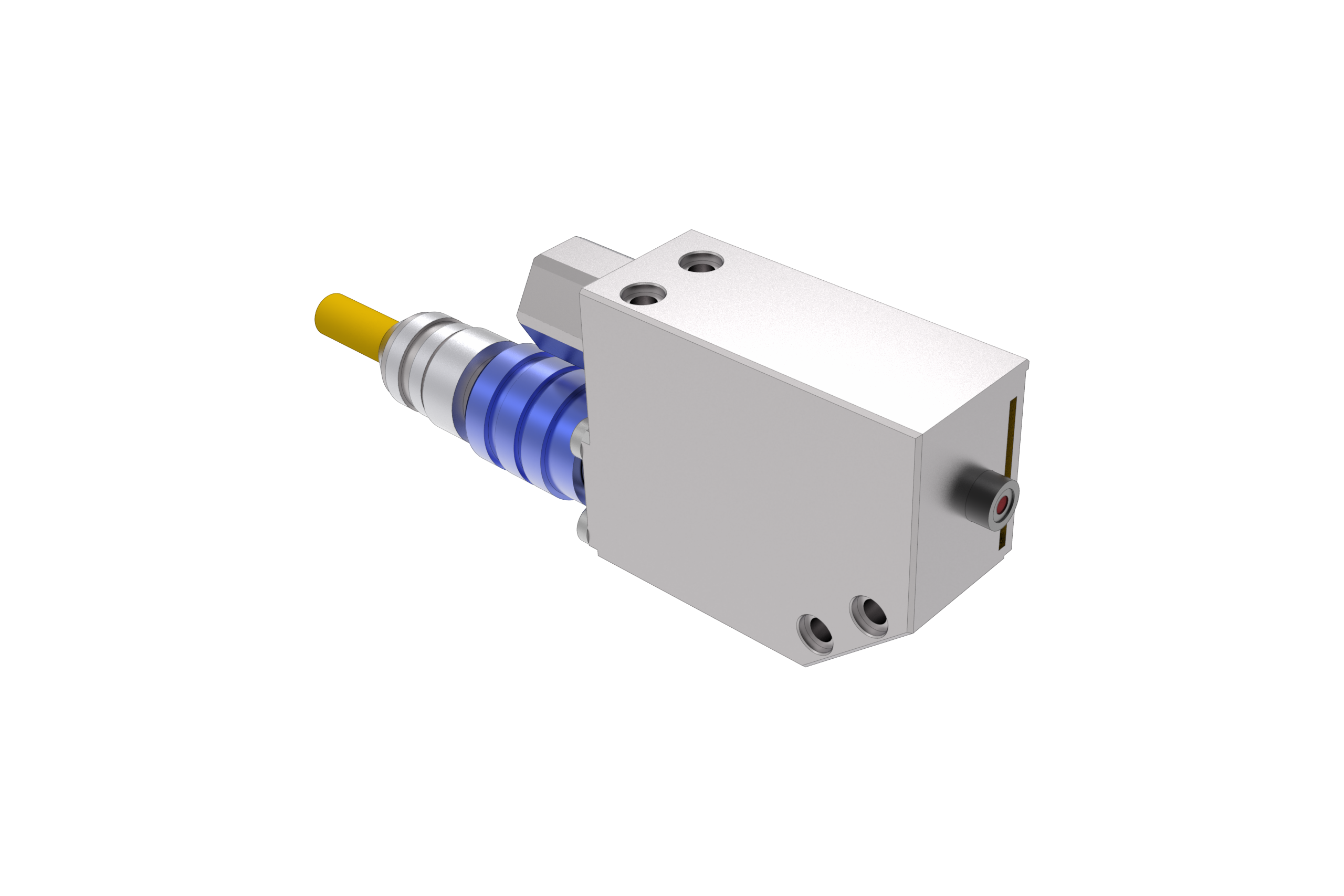

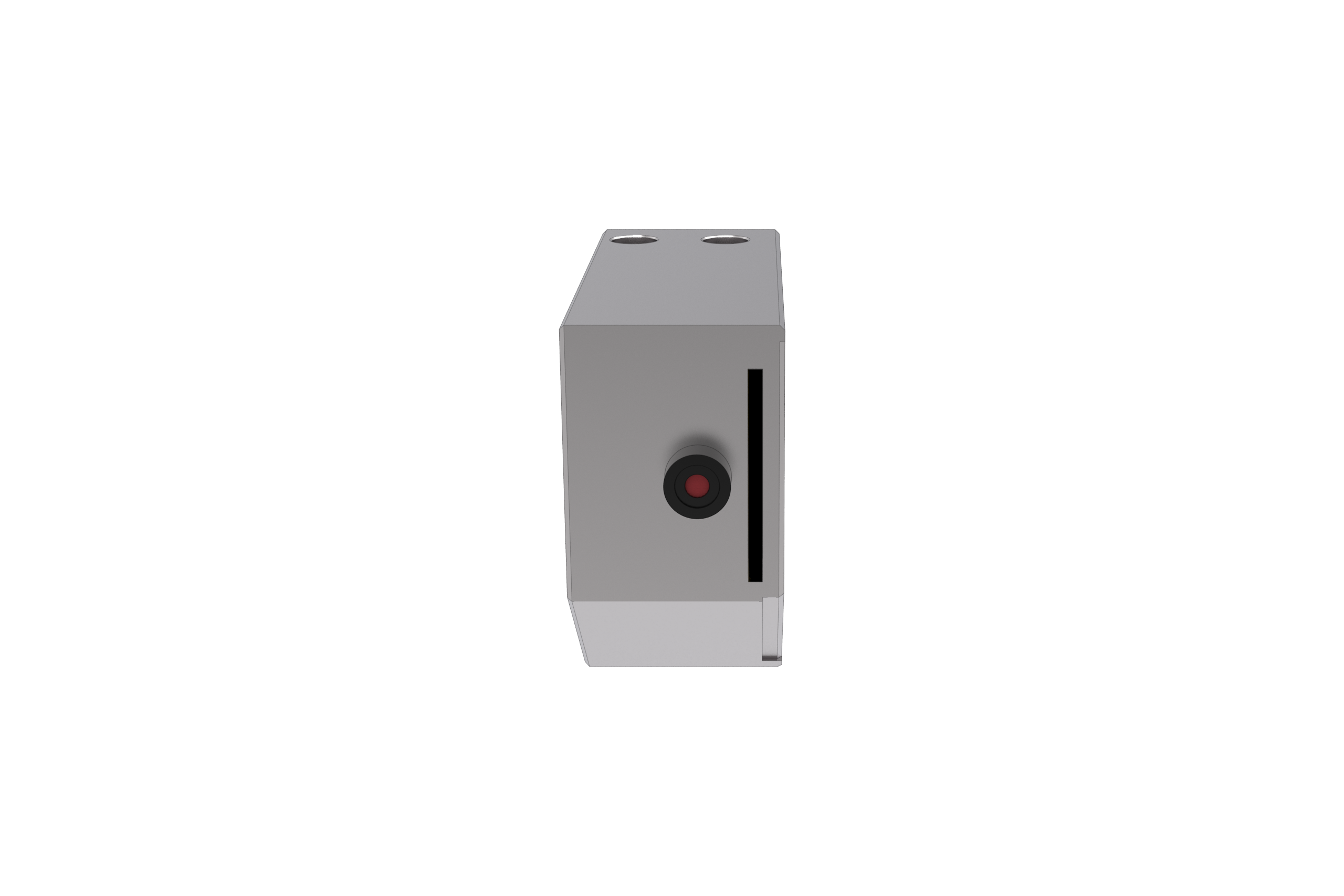

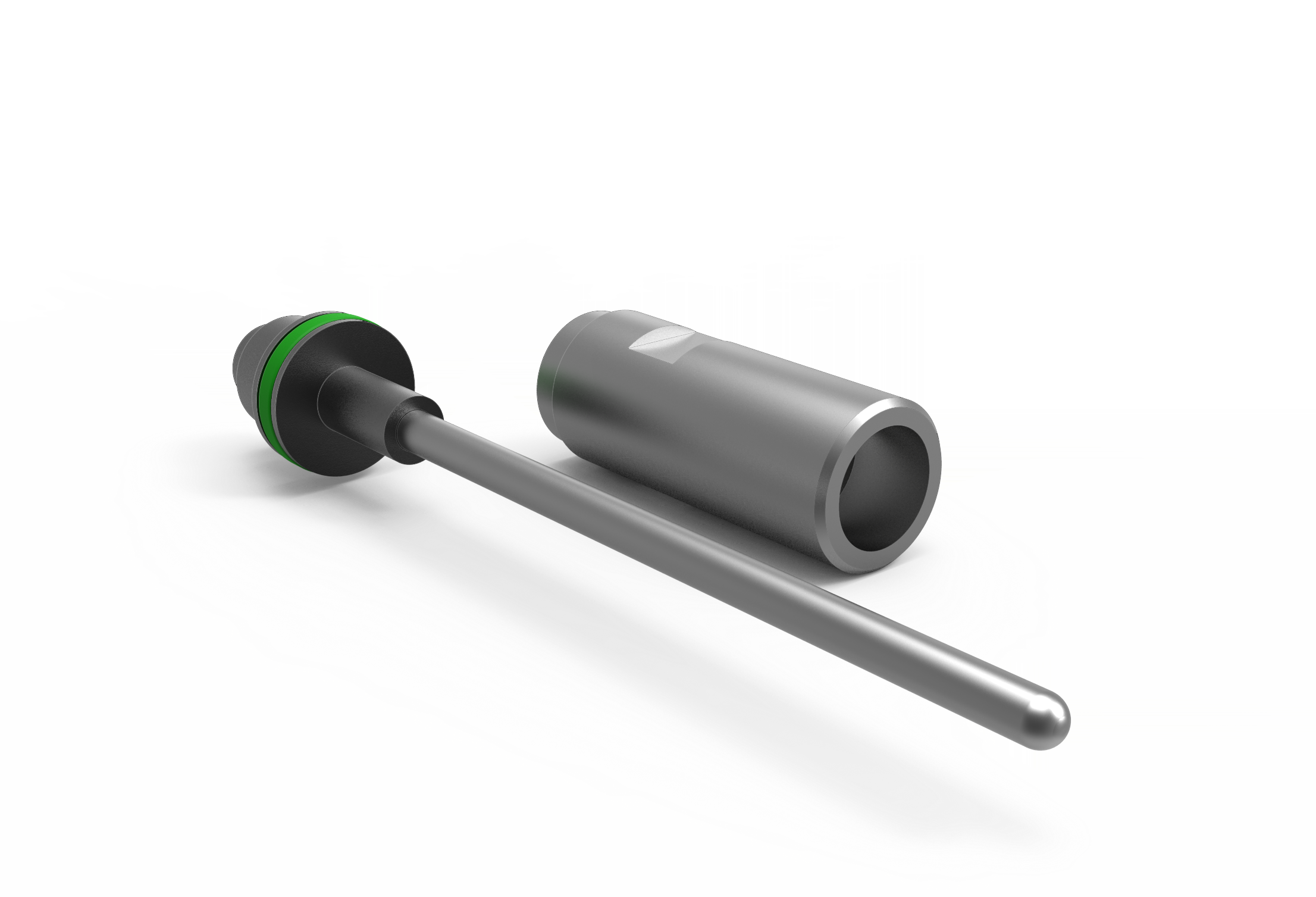

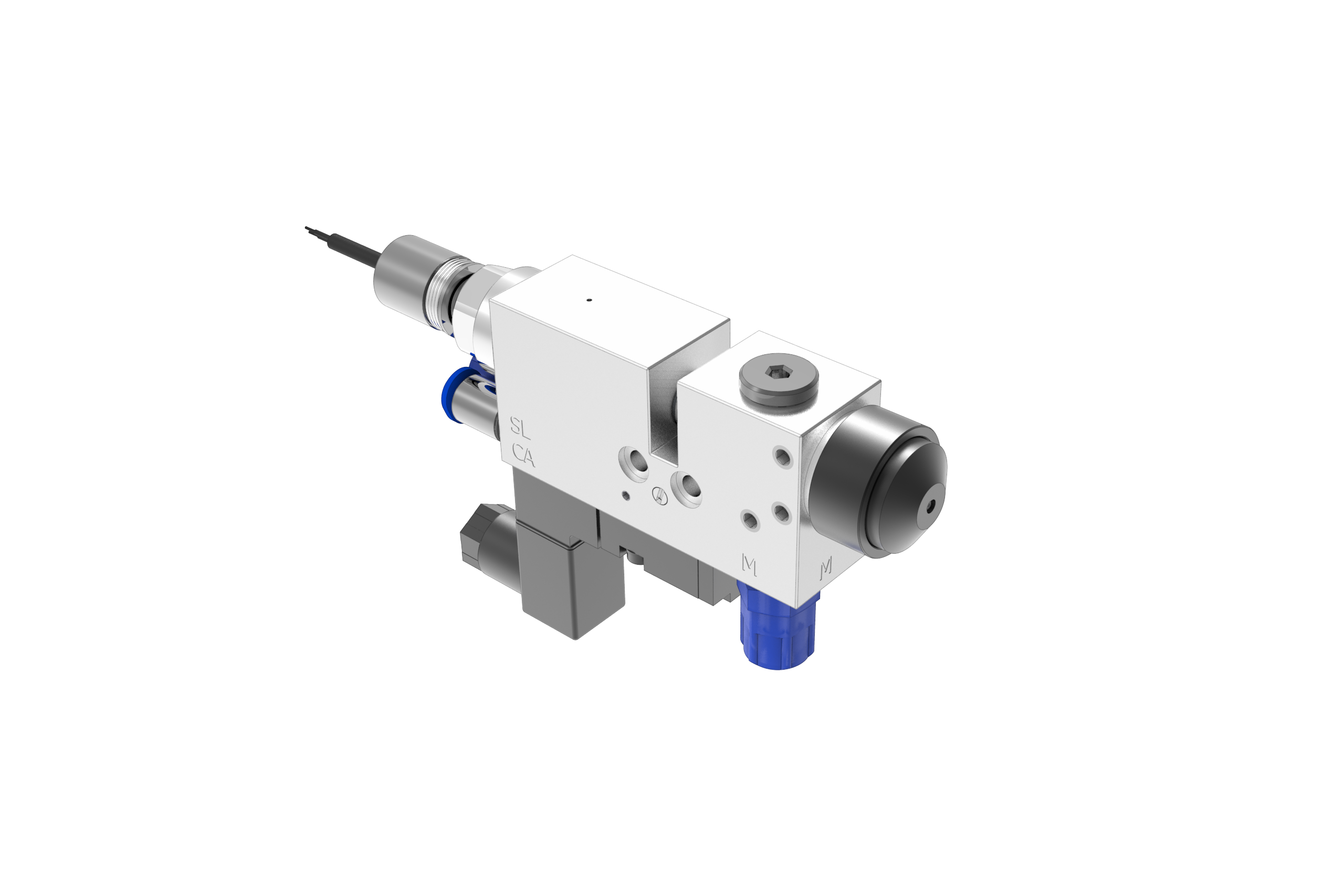

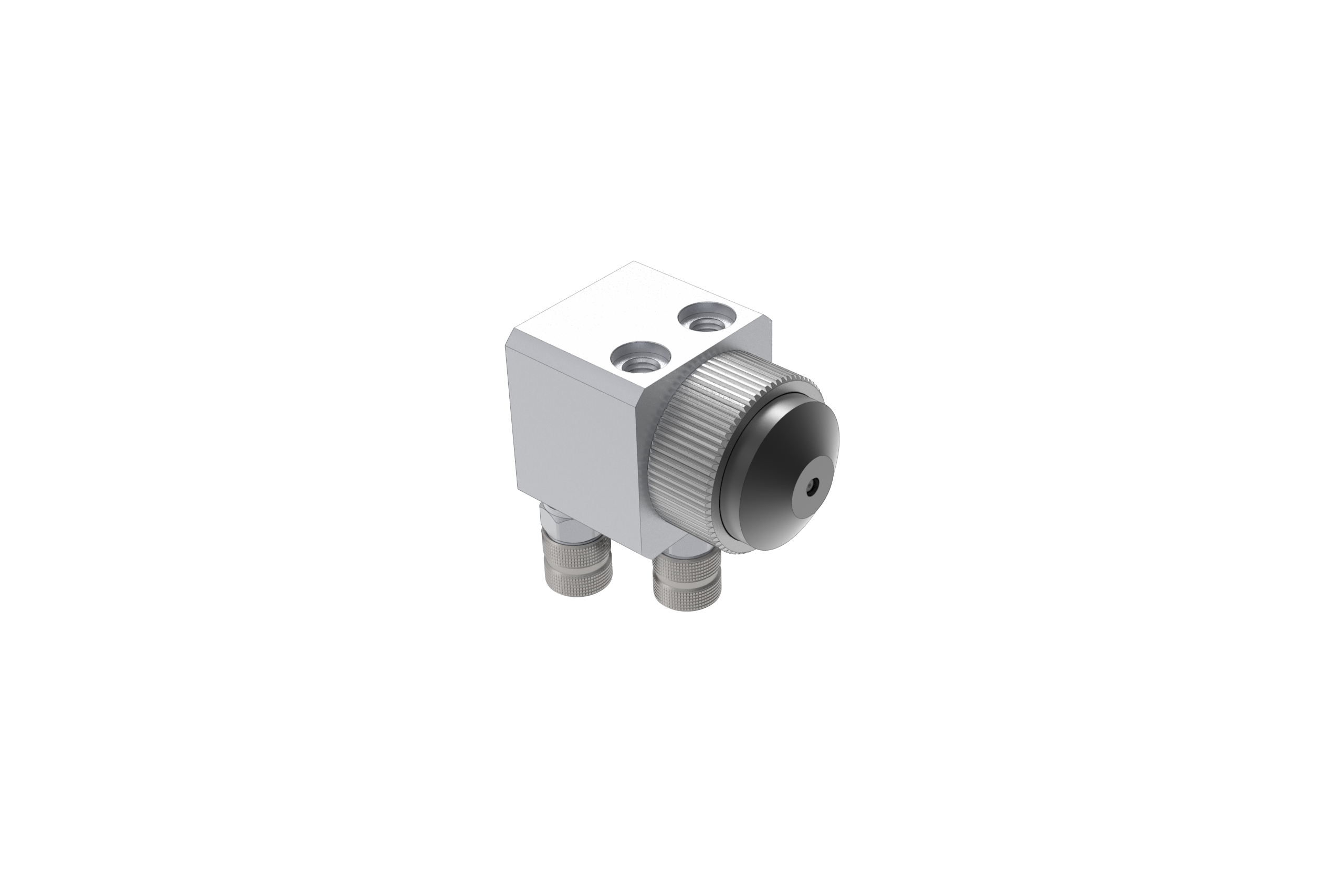

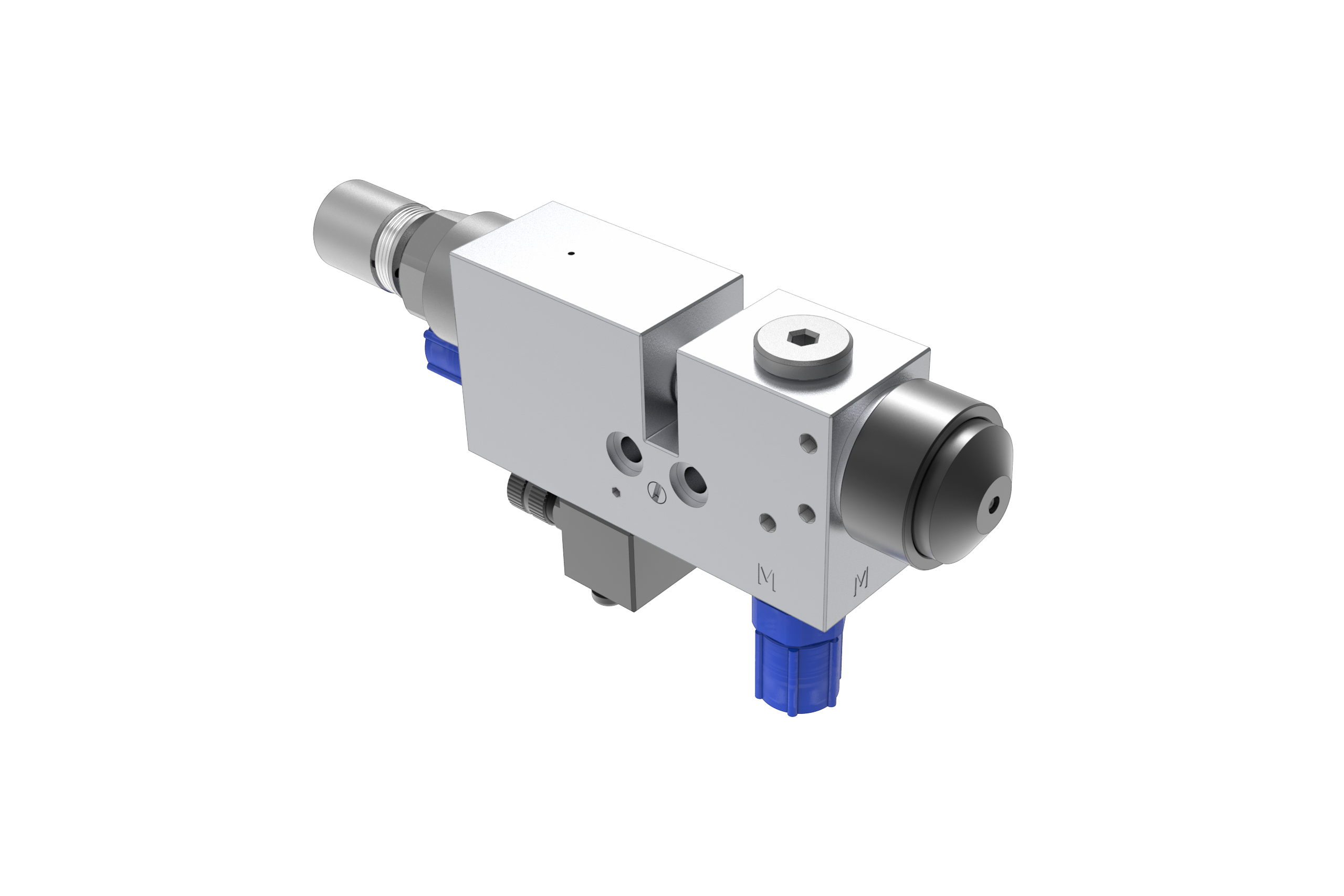

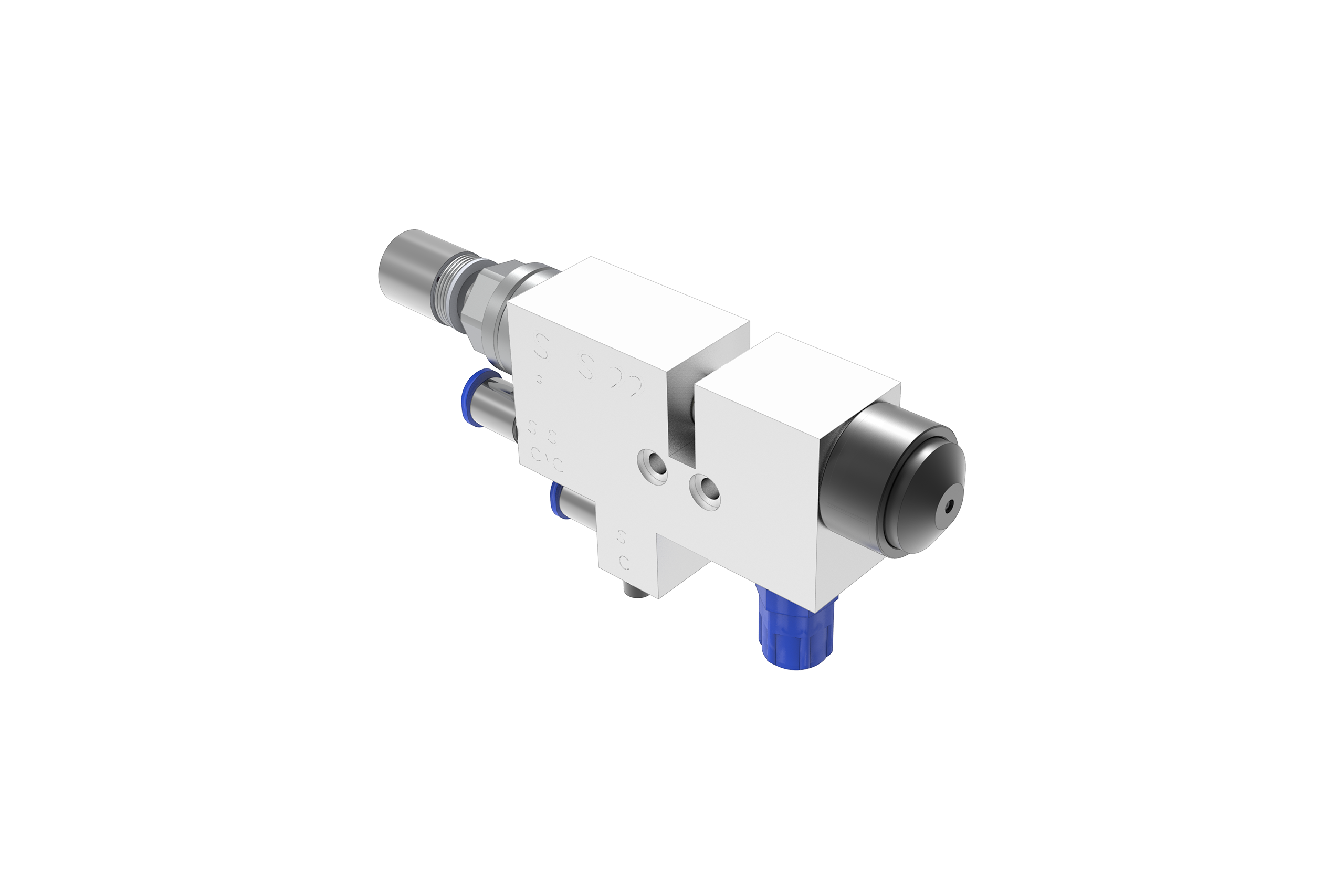

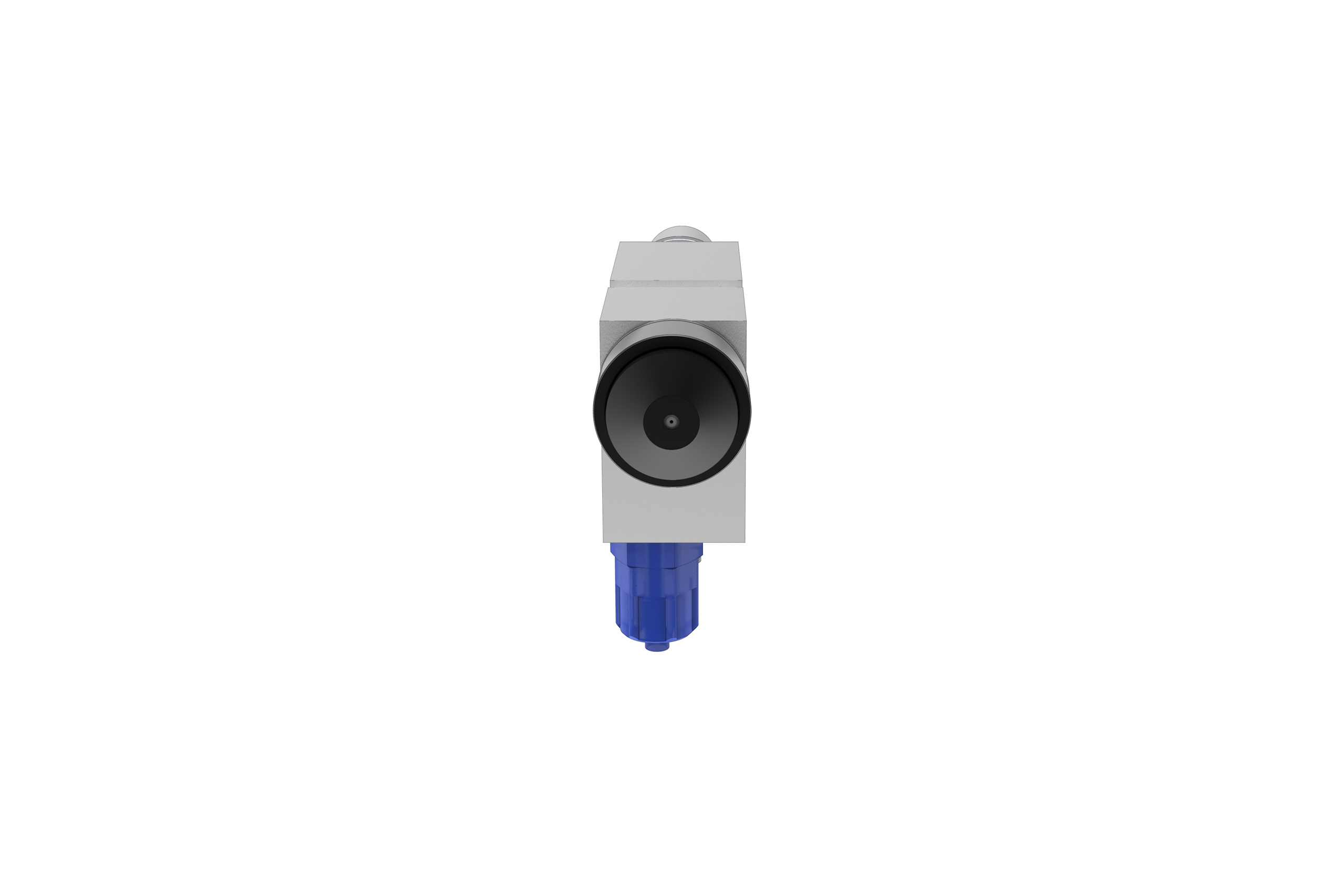

Whether in the production halls of various industries or in specialized workshops, processing and applying liquid and viscous media such as oil, grease, sealant, or adhesive requires special care and the right tools. With our solutions, you rely on reliability, efficiency, and precision – ensuring perfect results for every application. Our products are designed to guarantee the highest accuracy and repeatability in dosing and application while simultaneously boosting productivity. From handheld systems to highly integrative valve technology for fully automated dosing and application processes, to specialized adapters and nozzle extensions, we offer everything you need to process viscous media with process reliability and precision.

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request