Improve your production efficiency and productivity with high-end dispensing technology that gives your manufacturing line the boost it needs.

Welcome to Walther Systemtechnik - your expert in industrial dispensing technology. Discover the perfect solution for your application: Our individually configurable components and systems cover the entire dispensing process chain. From conveying to the precise application of viscous media, we offer customised technologies that make your production processes more efficient and reliable.

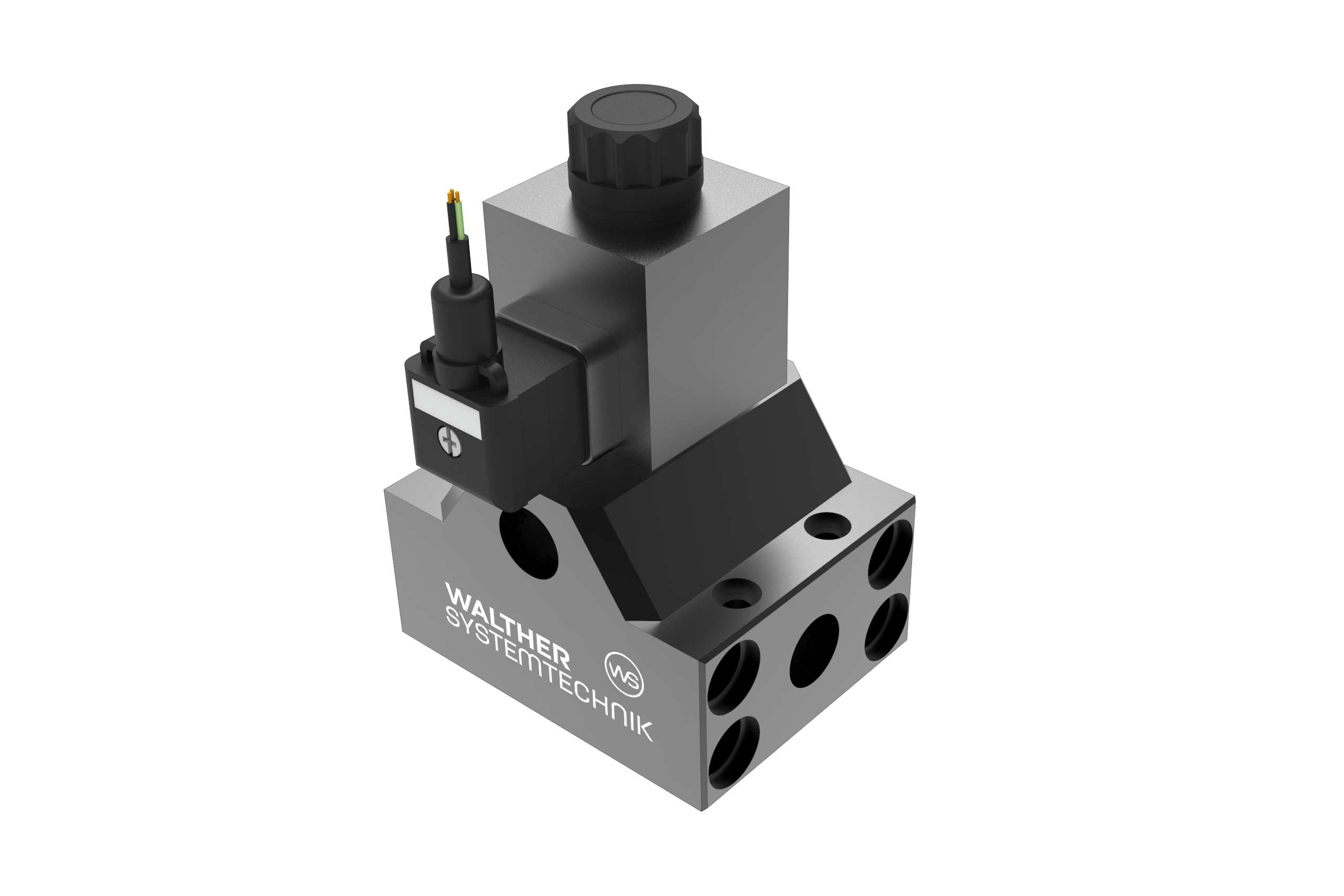

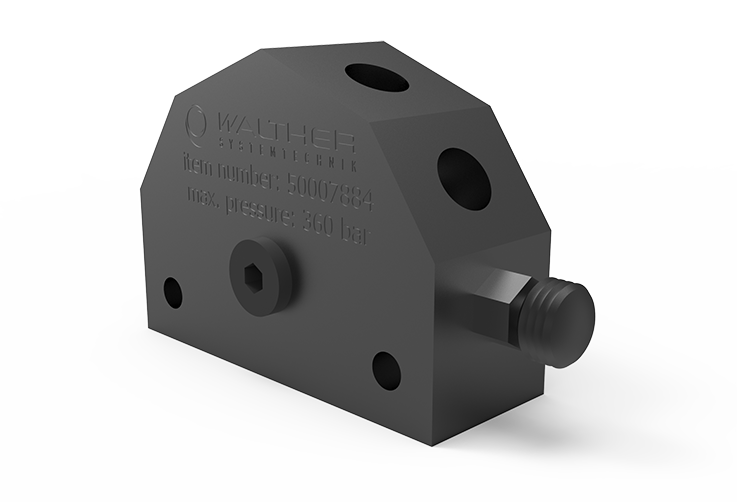

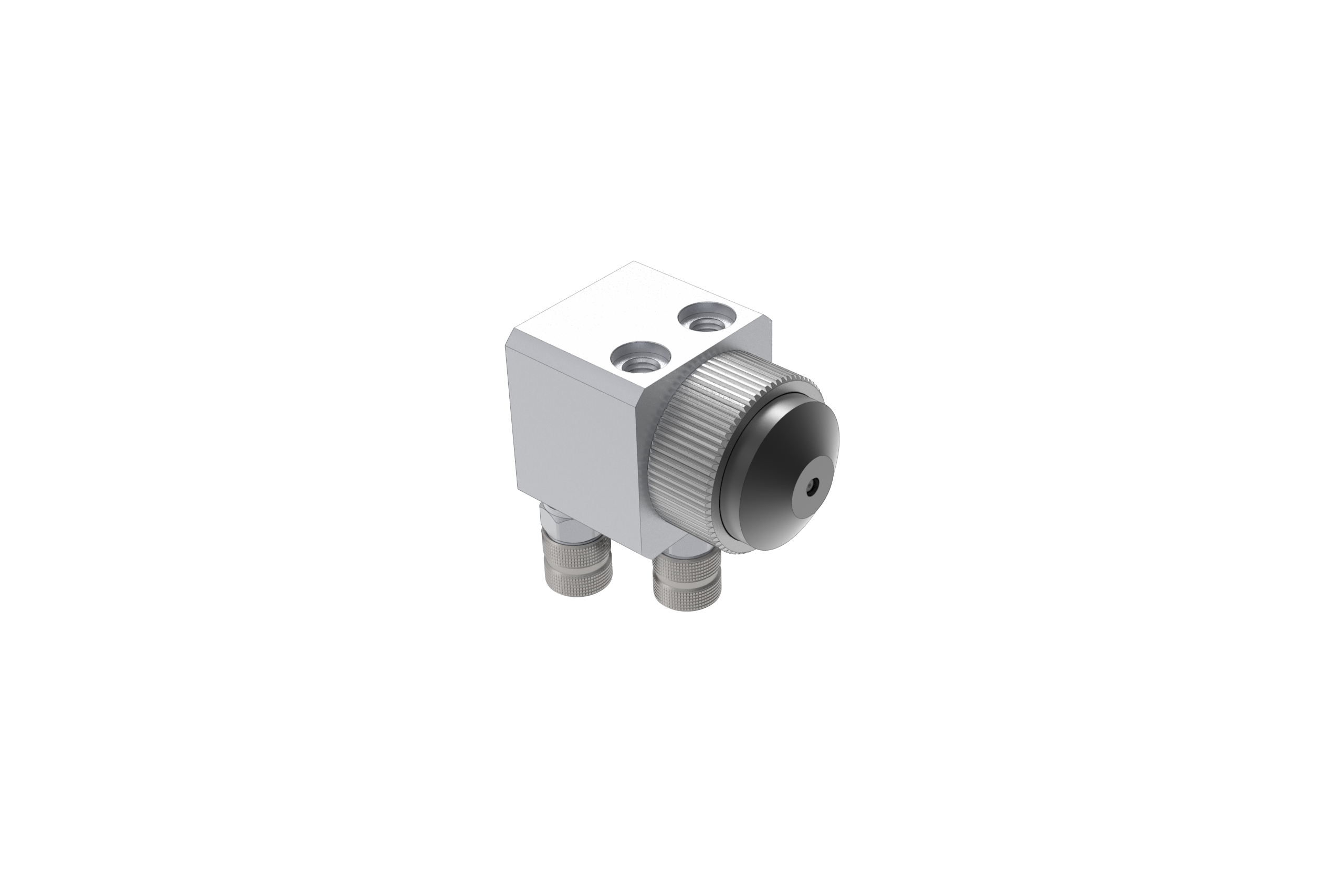

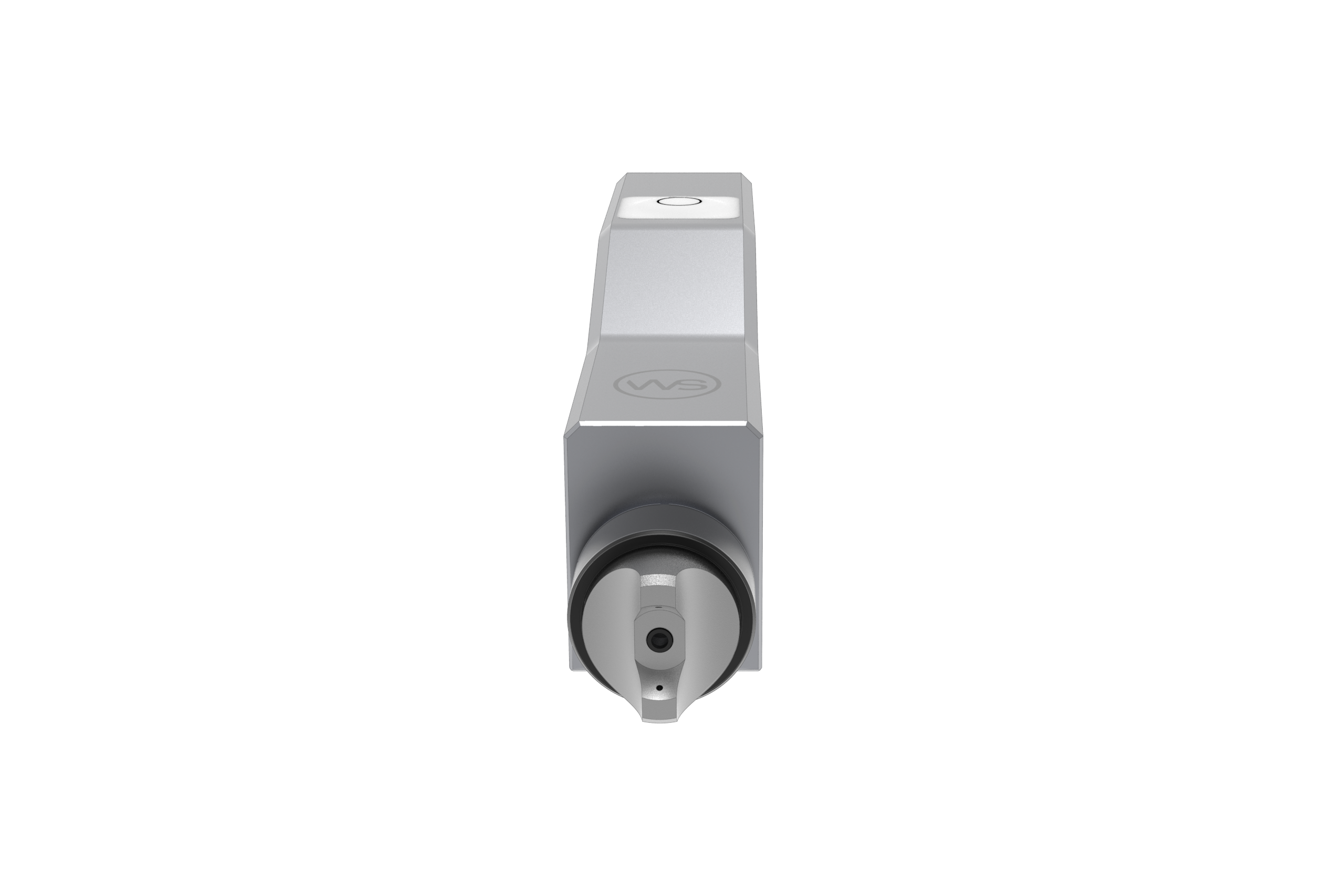

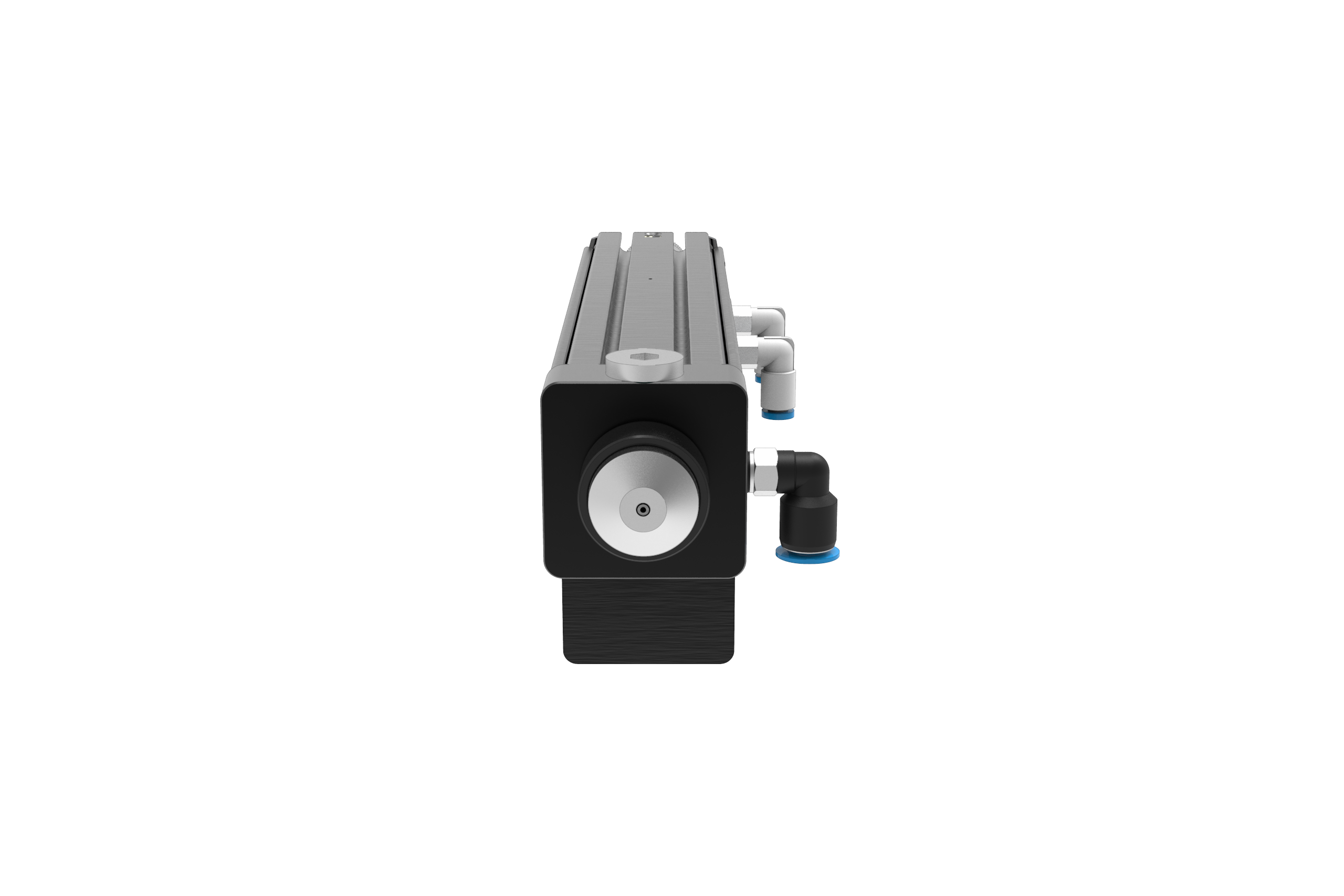

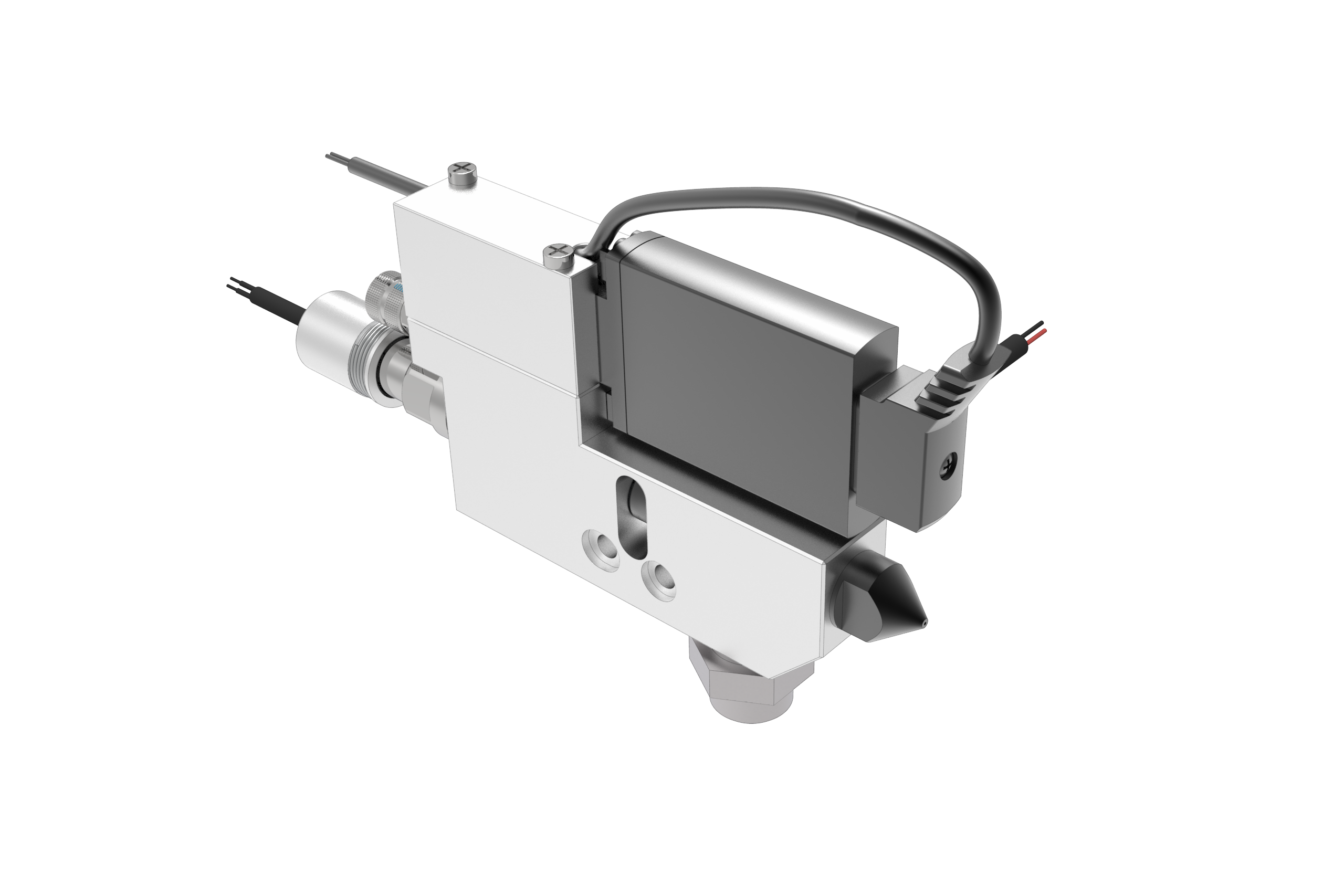

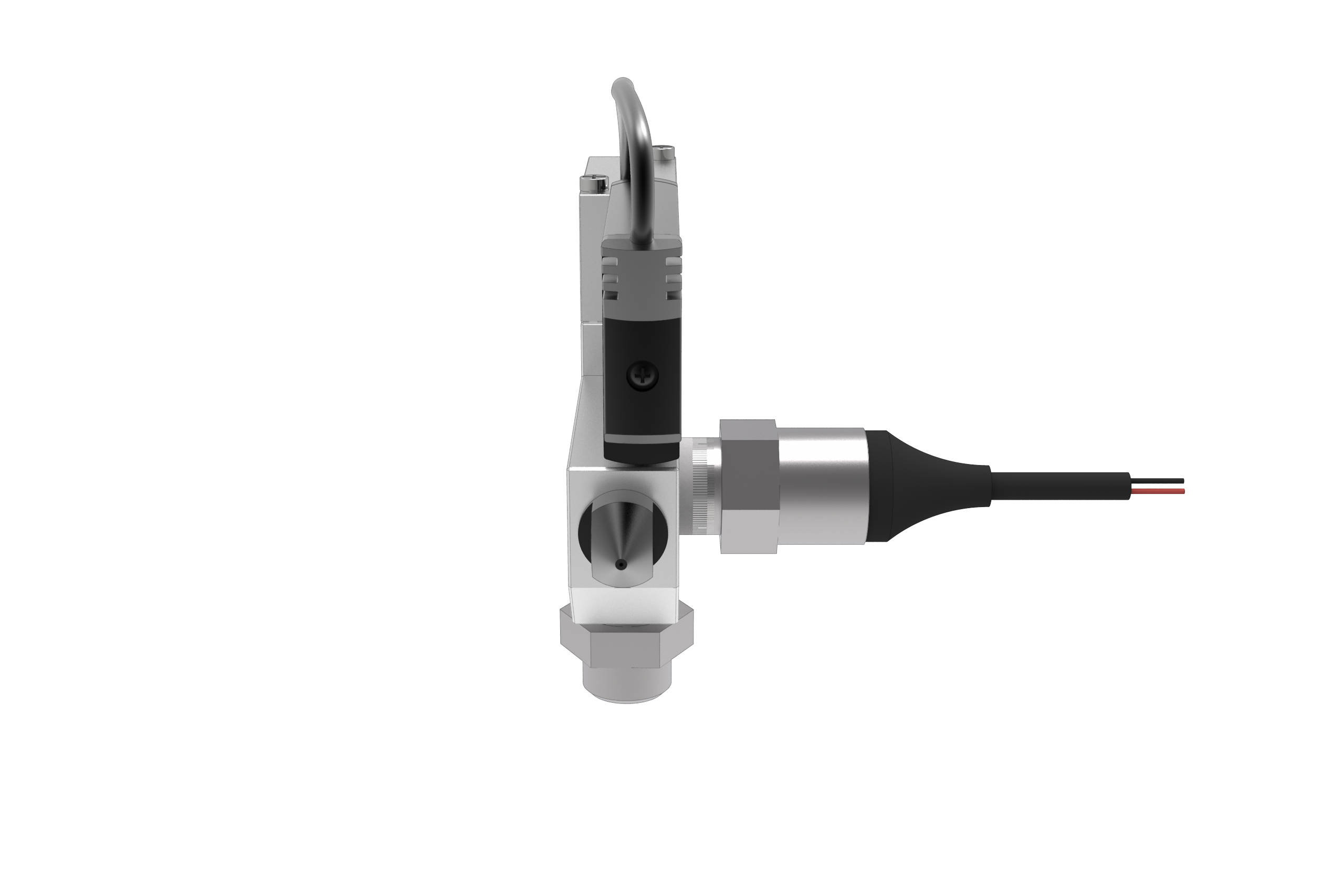

Discover a comprehensive range of proven dispensing components ...

and dispense lubricant such as oil, grease and paste, wax and cavity sealant, preservative, silicone and adhesive, anti-squeak coating, flux, release agent, paint, primer and much more. Divided into four categories, we offer everything you need to design fluid and dispensing systems.

Top sellers. Popular and often ordered:

Dispensing technology highlights:

Dispensing with Walther Systemtechnik: Your dispensing project is in good hands with us.

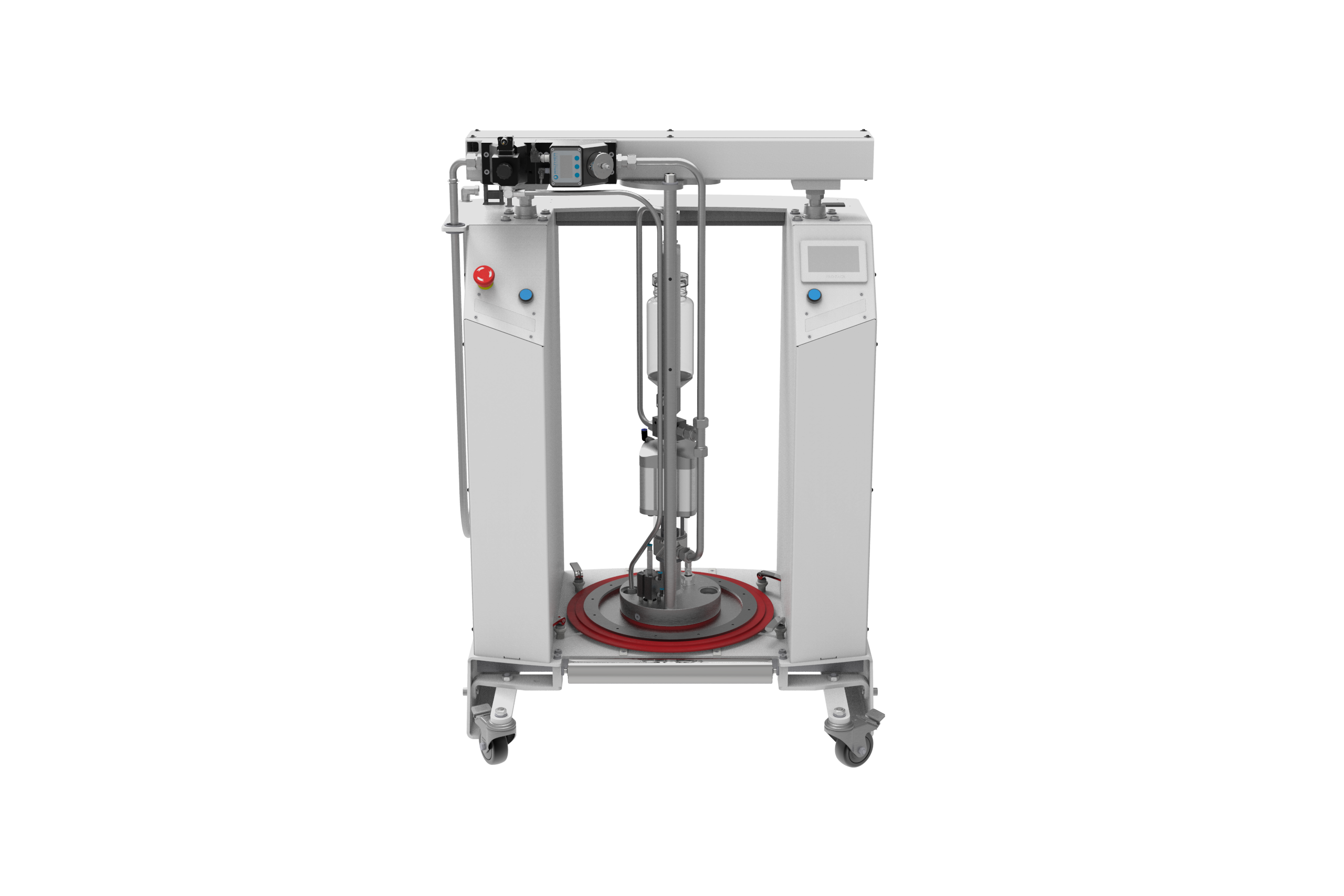

Walther Systemtechnik develops projects and both designs and manufactures components, systems and automated units for conveying, dosing and applying liquid and pasty media.

Like from a one-stop shop, you can get everything from a single source covering the entire dosing process chain, including media characterization, mechanical engineering and automation. In other words: Whether you need sealing, gluing, marking, greasing or oiling, we will assist you in your project from A to Z. Your advantage: You only have one contact person, but many specialists will skillfully take care of your project! Find out more about our range of services ...

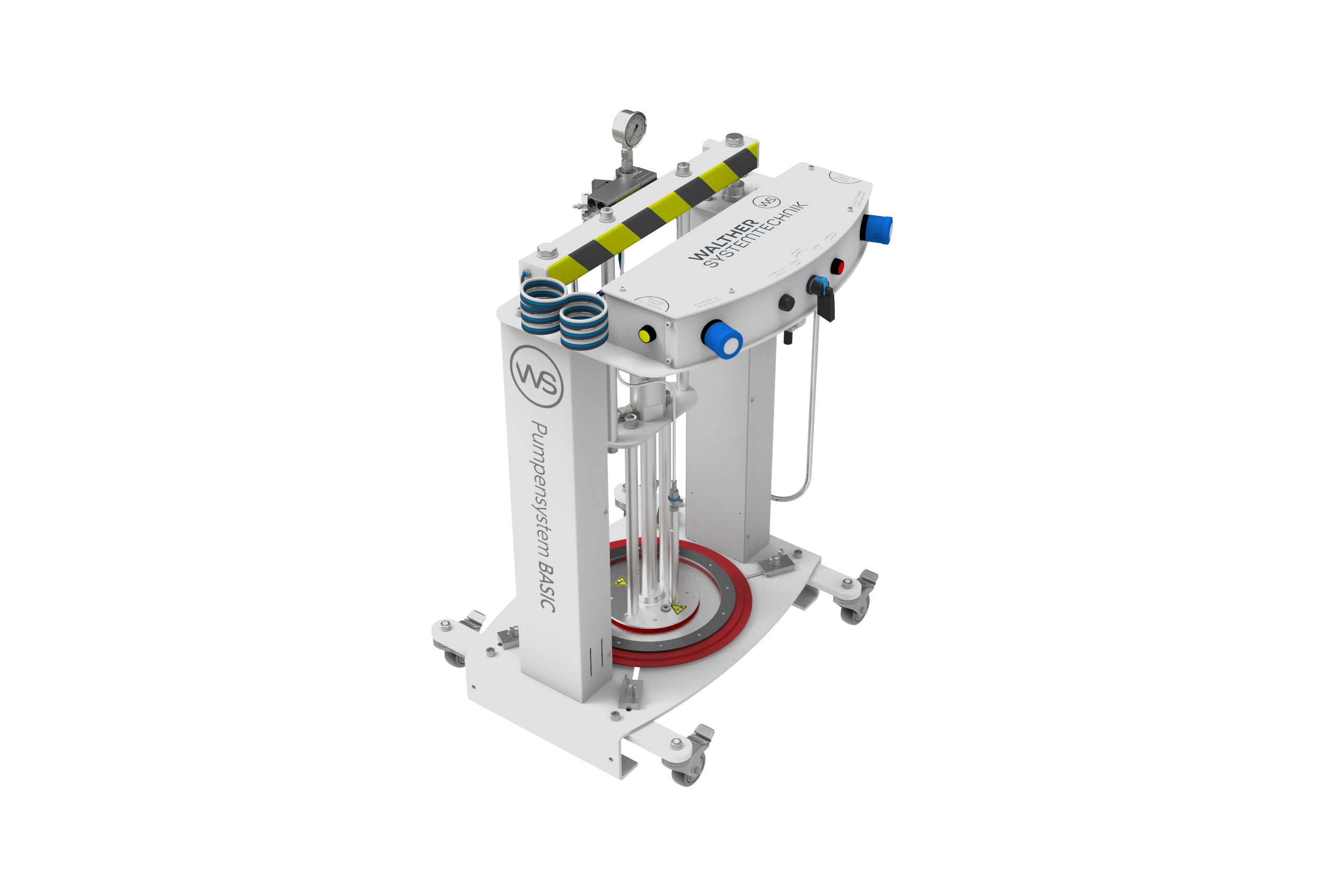

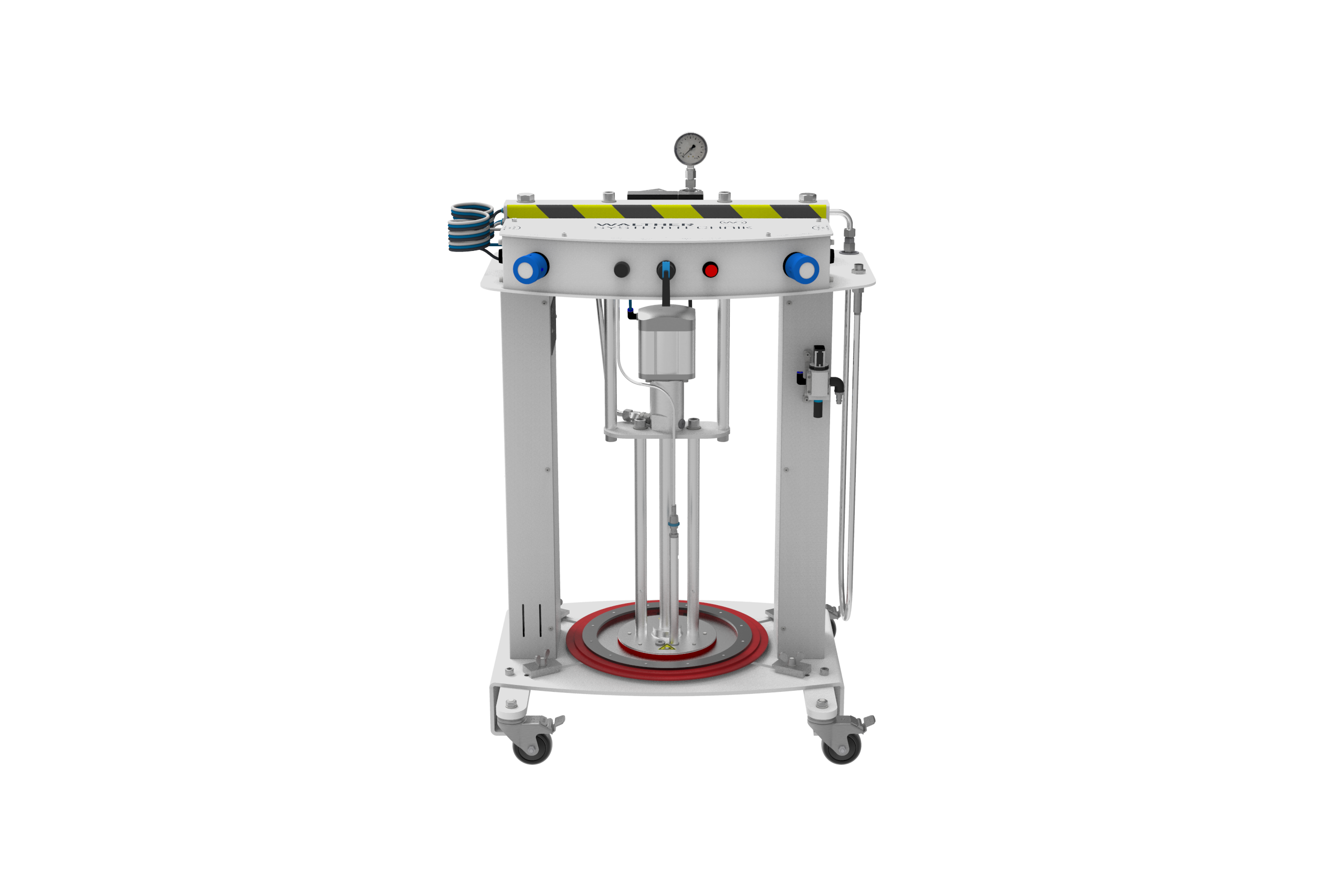

Metering and dispensing systems, perfectly customised to your processes.

Can't get enough of our dispensing technology? Keep up to date and become a fan.

For more articles, visit Dispensing Technology today or follow us on facebook, instagram, linkedin and other social media channels.

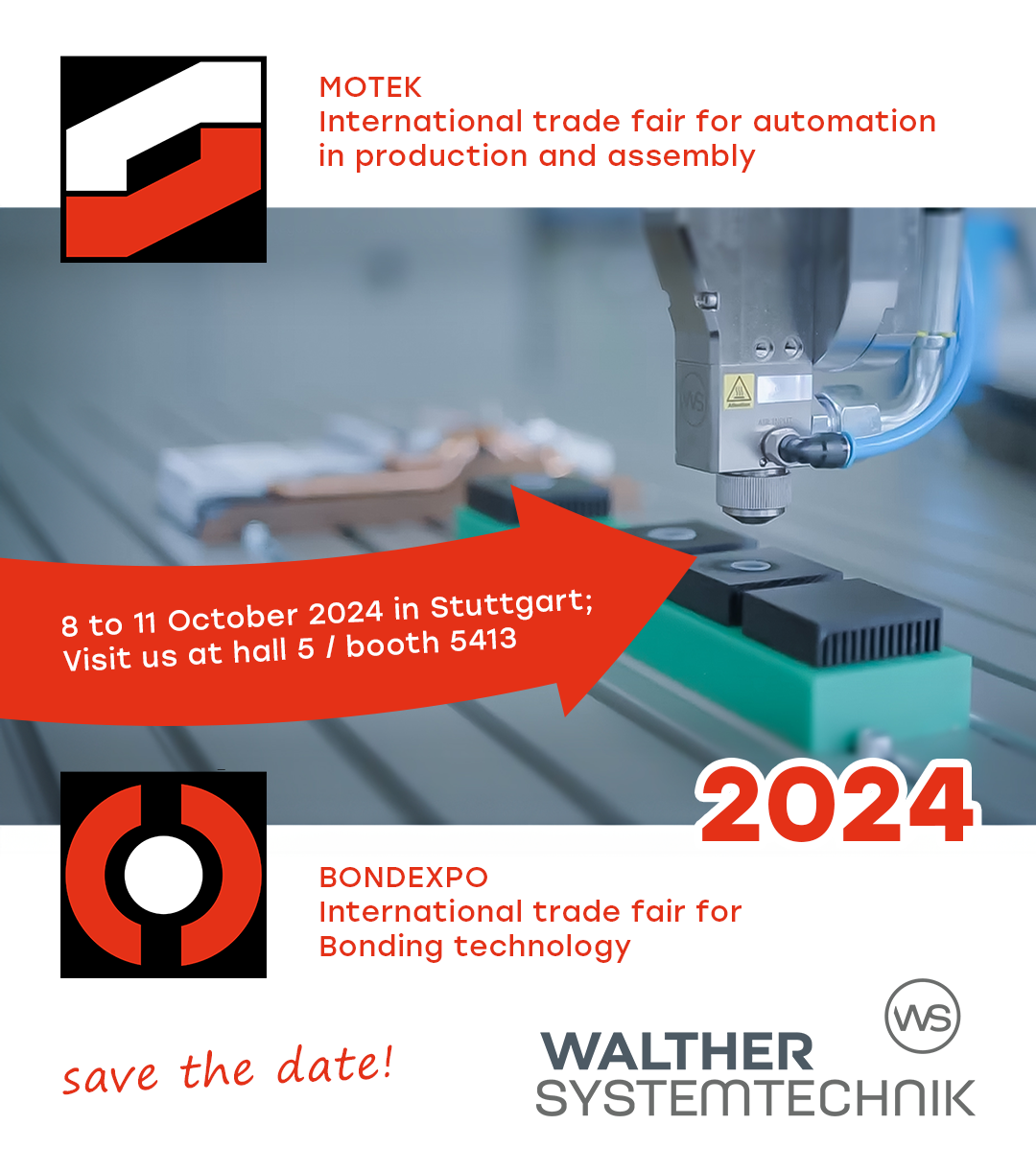

Experience dispensing technology live: Trade fairs and events

Lubricant Expo North America

Detroit / Michigan, Huntington Place

19 - 21 March 2024

Hall 1 / Stand 225

Organiser's page >>

The Battery Show Europe

Stuttgart, Trade Fair Centre

18 - 20 June 2024

Hall 4 / Stand C07

Organiser's page >>

Motek / Bondexpo

Stuttgart, Trade Fair Centre

08 - 11 October 2024

Hall 5 / Stand 5413

Organiser's page >>