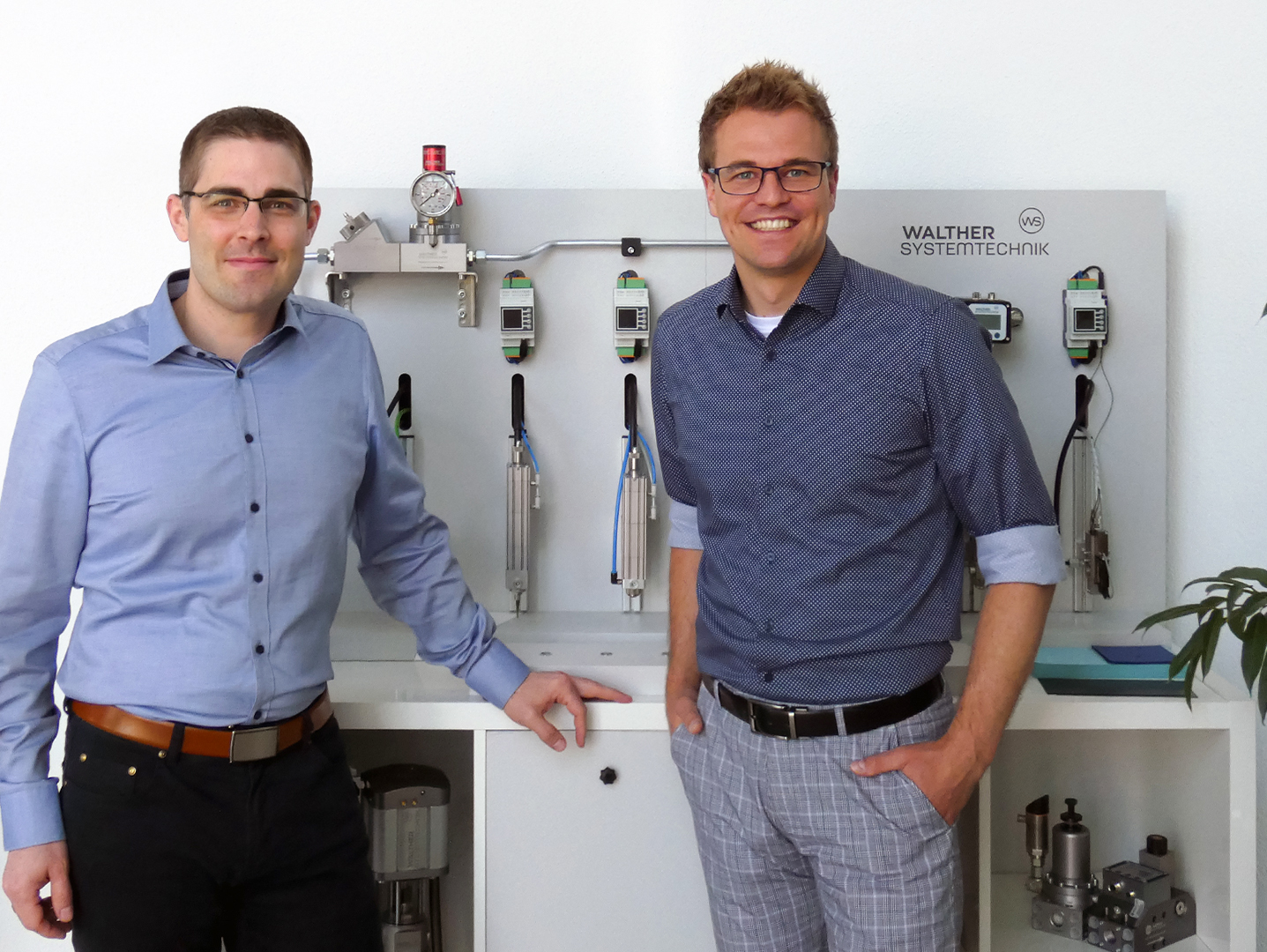

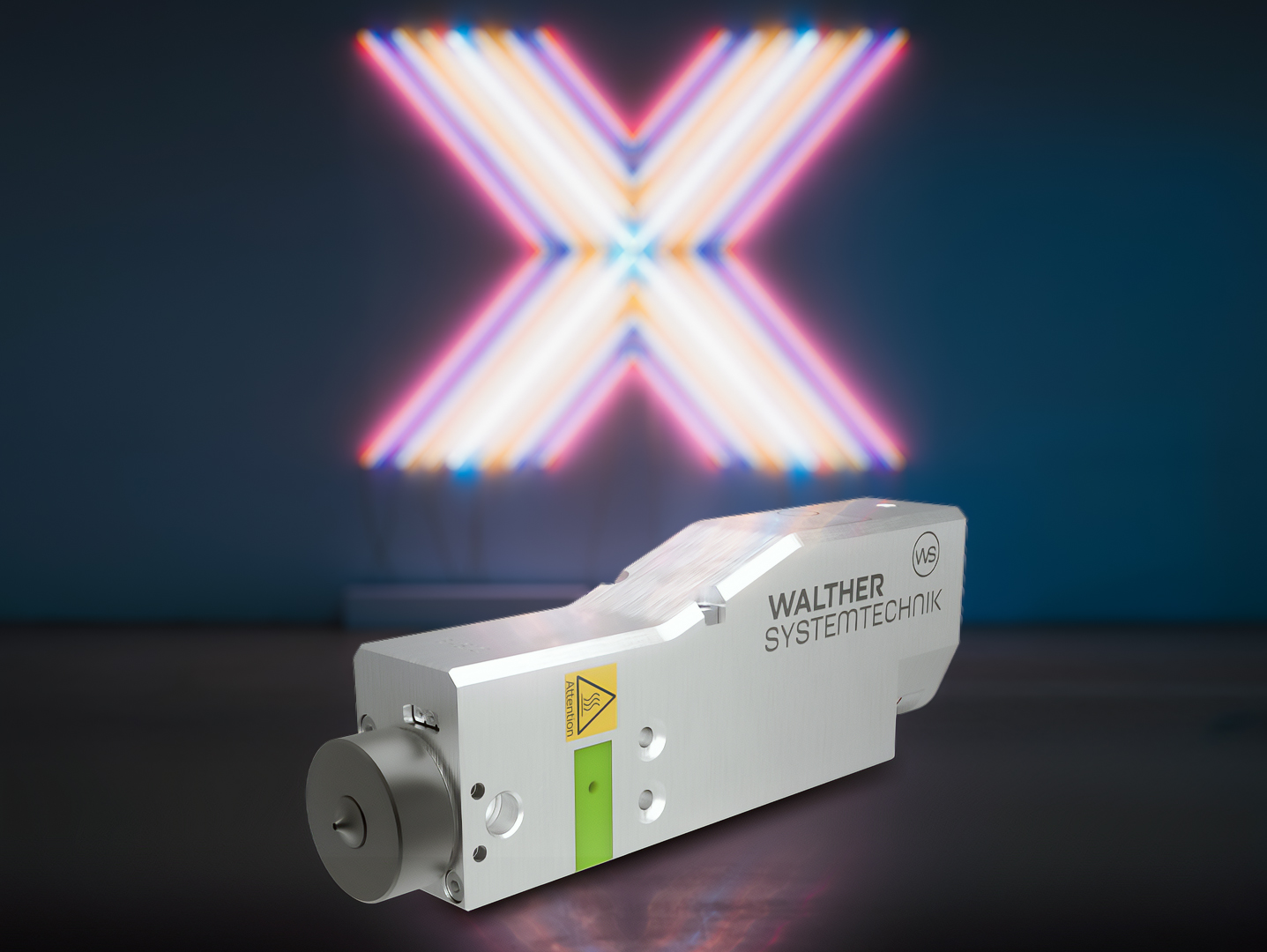

State-of-the-art dosing technology "made in Germany"

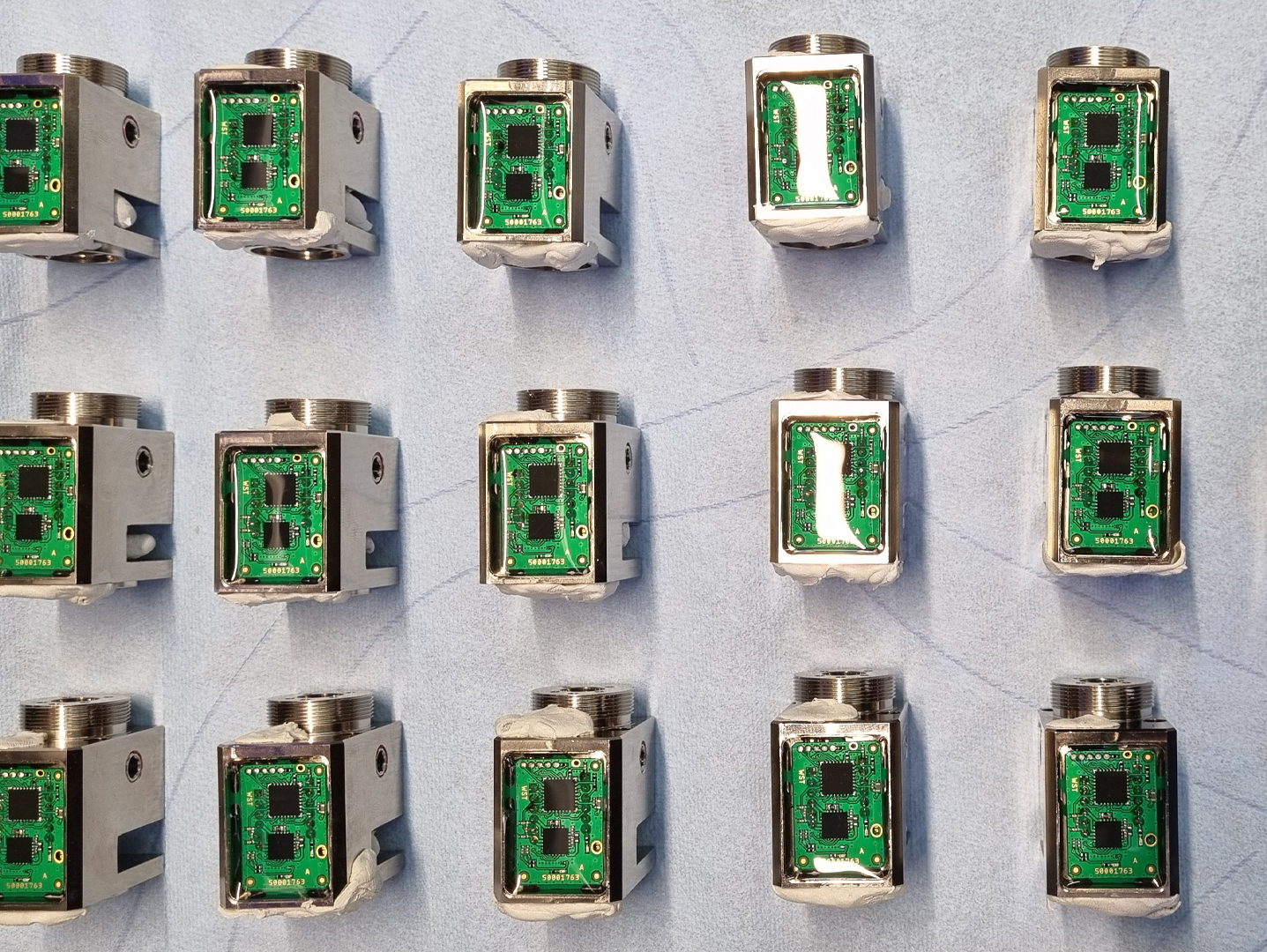

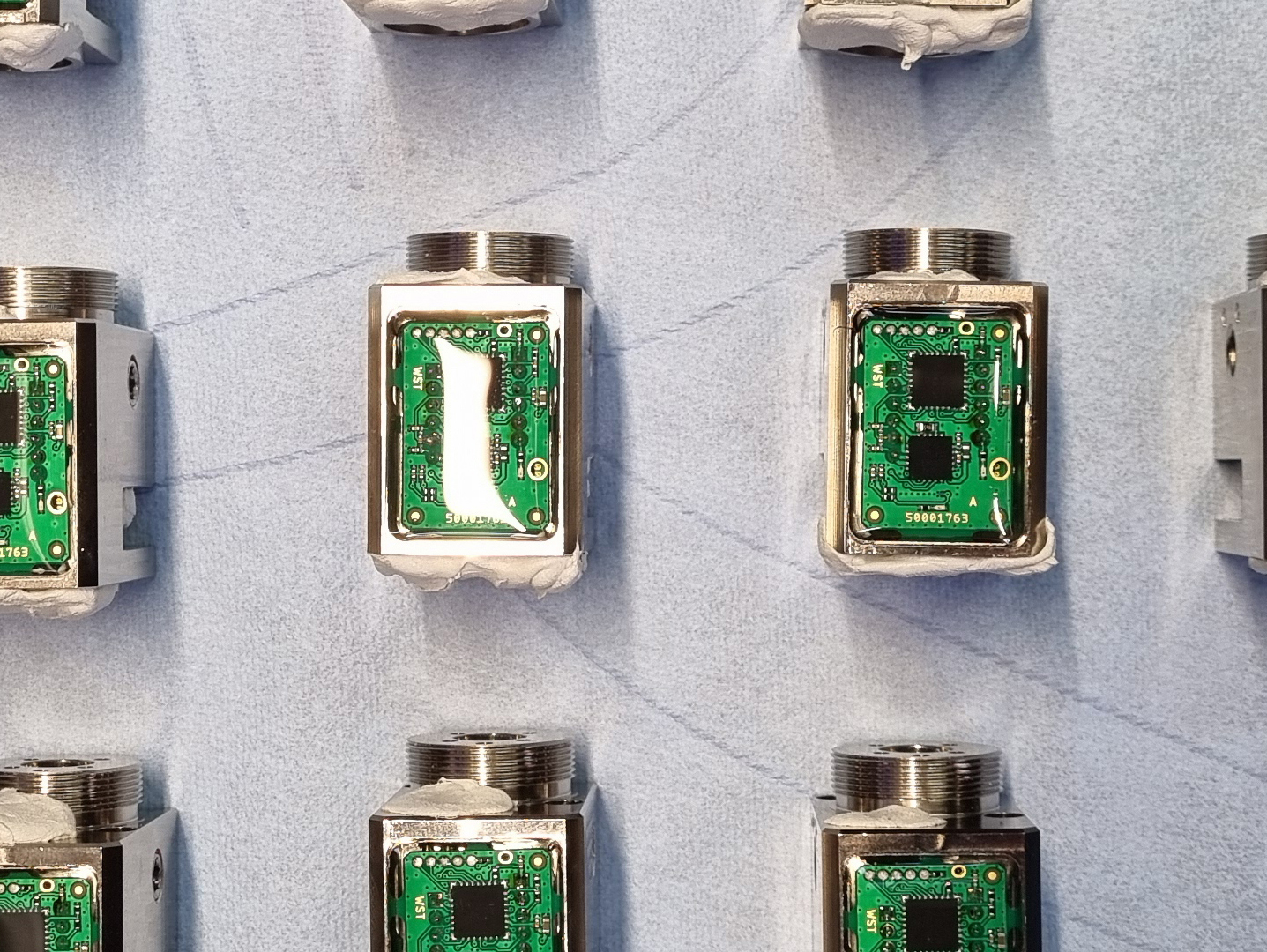

Walther Systemtechnik GmbH has been a reliable partner for the precise dosing and application of liquid and paste-like media for more than three decades. Our focus is on process reliability, precise application quantities and pinpoint application. Our headquarters is located in Germersheim, Germany.

Due to our expertise, we have established ourselves as a competent specialist in various branches of industry. Our dosing technology and dosing systems are used in the automotive, pharmaceutical, food, rubber, chemical and metal processing industries as well as in many other sectors. We always attach great importance to the individual requirements and needs of our customers.

With an experienced team of design engineers and state-of-the-art production and assembly in machine and fixture construction, we offer customised and integrated solutions worldwide. Customer satisfaction and the maintenance of long-term partnerships are our top priorities.