Anniversary: 35 years at Walther Systemtechnik

28 Nov 2024, 11:00:00

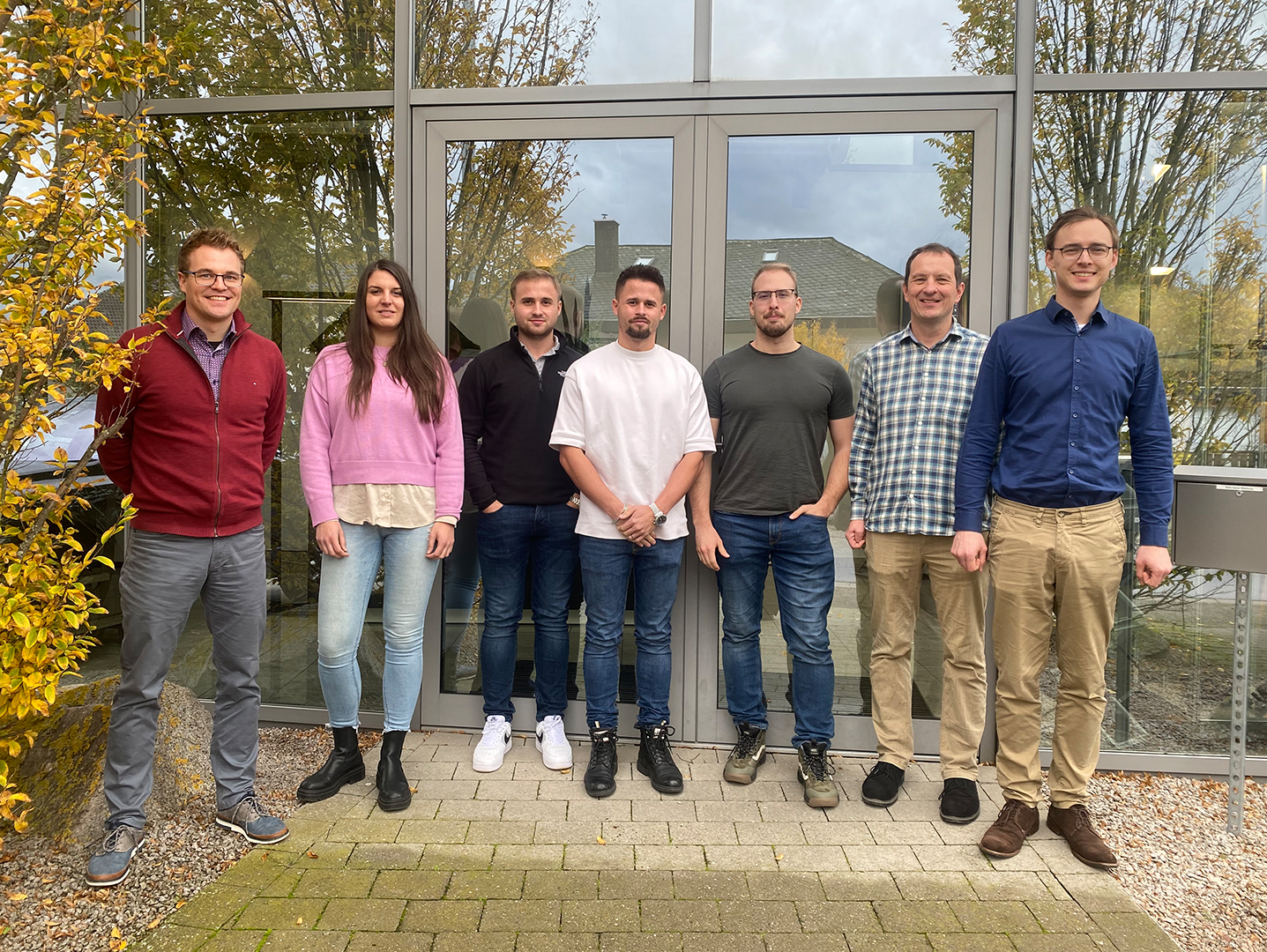

35 years at Walther Systemtechnik is a remarkable milestone. Today, we would like to recognise our colleague Thomas Danz, who has been part of our team for an impressive 35 years.

Thomas began his career at Walther Systemtechnik in design and project engineering. He later moved into field sales, where he demonstrated his technical expertise and strong customer focus. Today, he is a well-established and reliable member of our technical inside sales team.

His extensive knowledge, many years of experience and ongoing commitment make him a highly valued team member. Dear Thomas, thank you for your dedication, reliability and the many years in which you have helped shape Walther Systemtechnik. We look forward to many more shared successes.

Anniversary: 35 years at Walther Systemtechnik

35 years at Walther Systemtechnik is a remarkable milestone. Today, we would like to recognise our colleague Thomas Danz, who has been part of our team for an impressive 35 years.

Thomas began his career at Walther Systemtechnik in design and project engineering. He later moved into field sales, where he demonstrated his technical expertise and strong customer focus. Today, he is a well-established and reliable member of our technical inside sales team.

His extensive knowledge, many years of experience and ongoing commitment make him a highly valued team member. Dear Thomas, thank you for your dedication, reliability and the many years in which you have helped shape Walther Systemtechnik. We look forward to many more shared successes.

Weitere Beiträge

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request