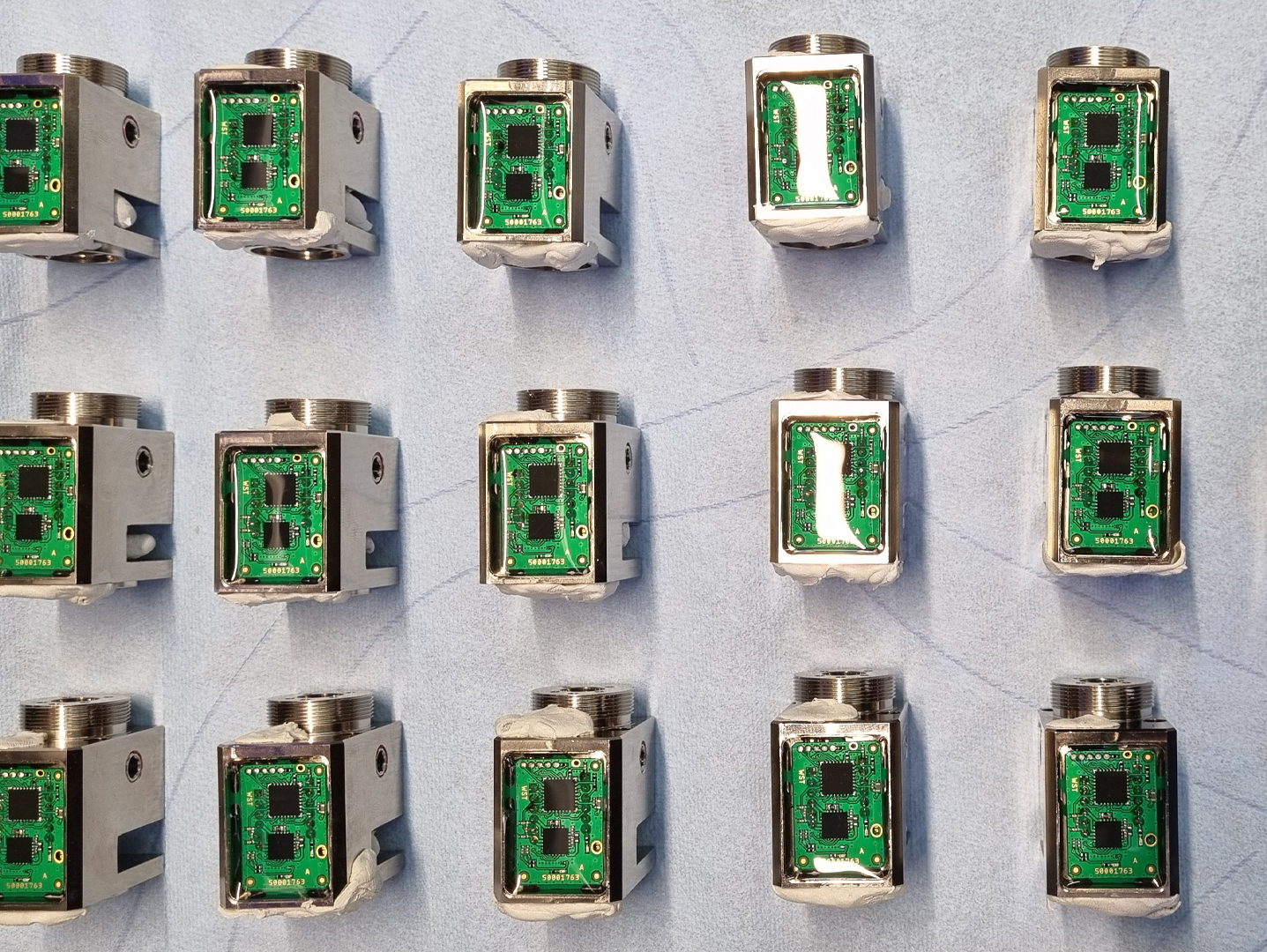

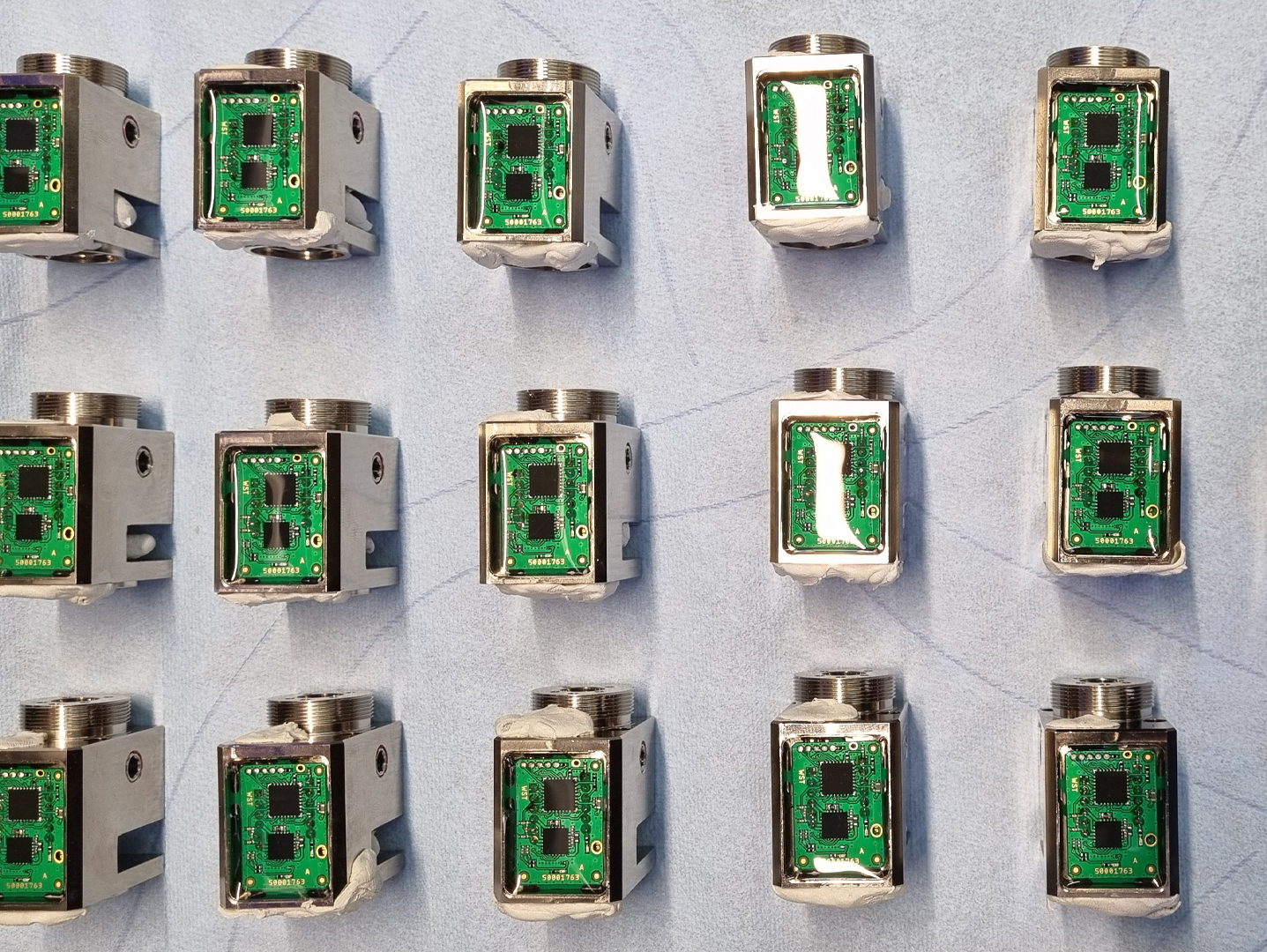

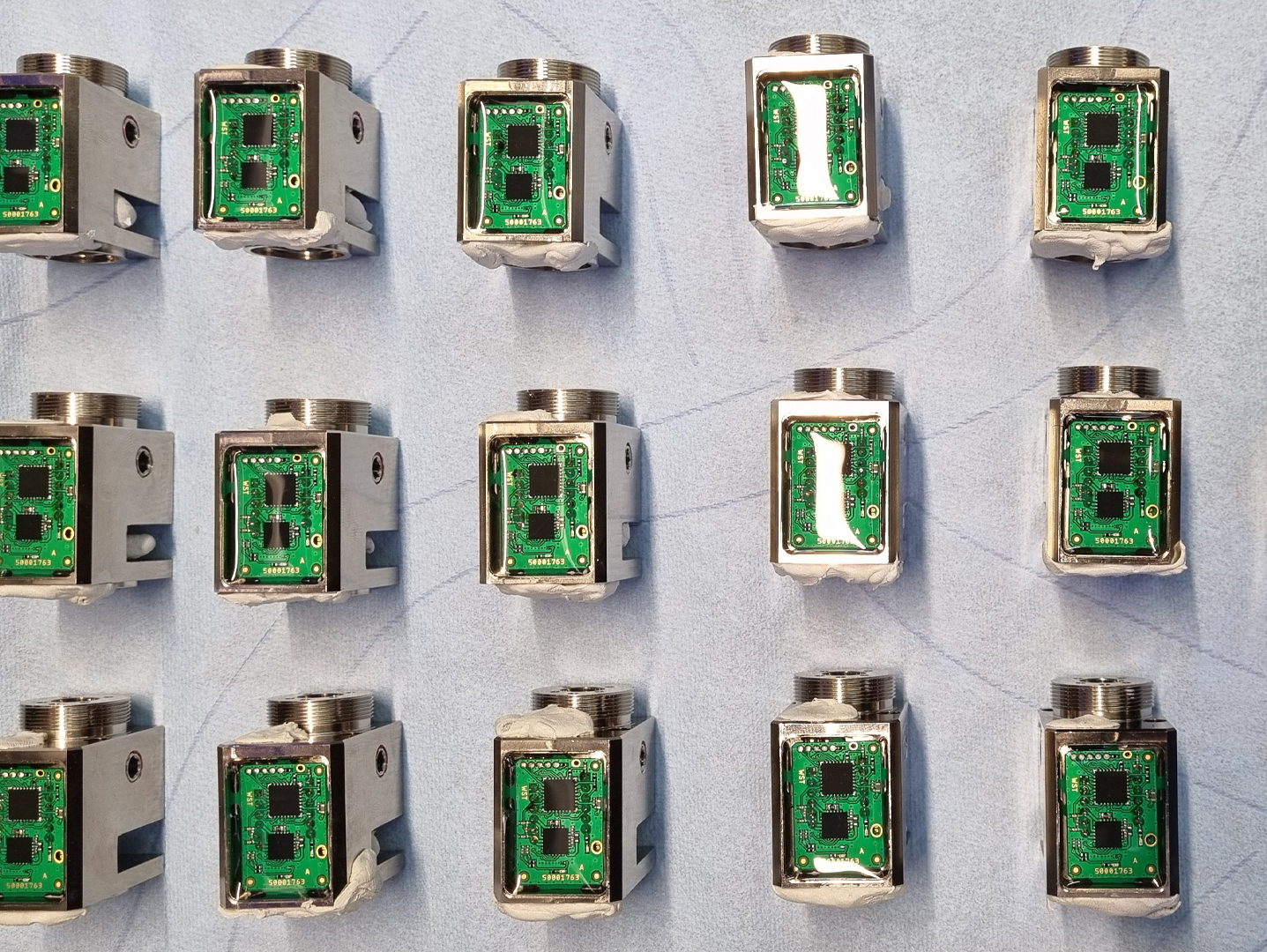

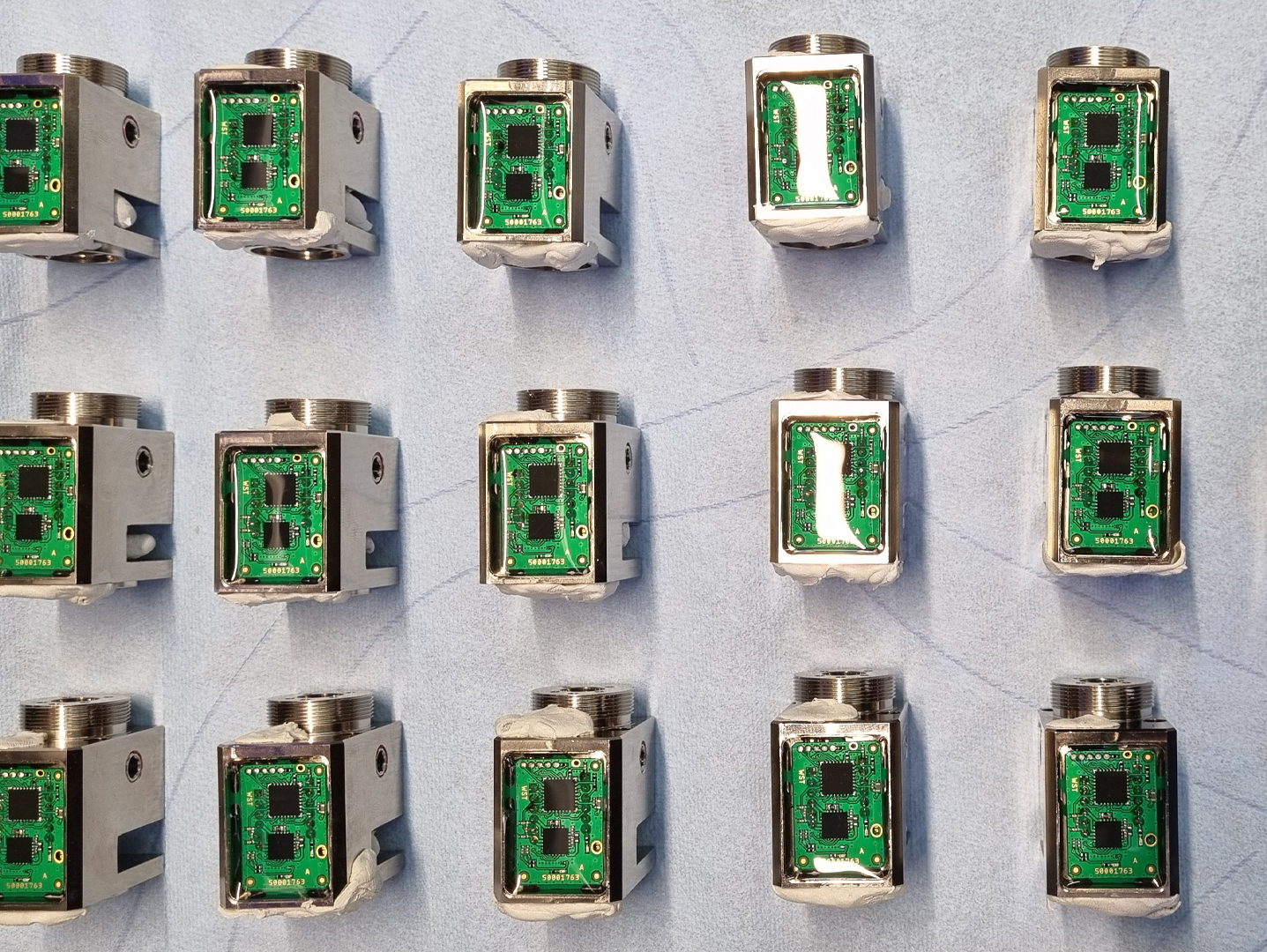

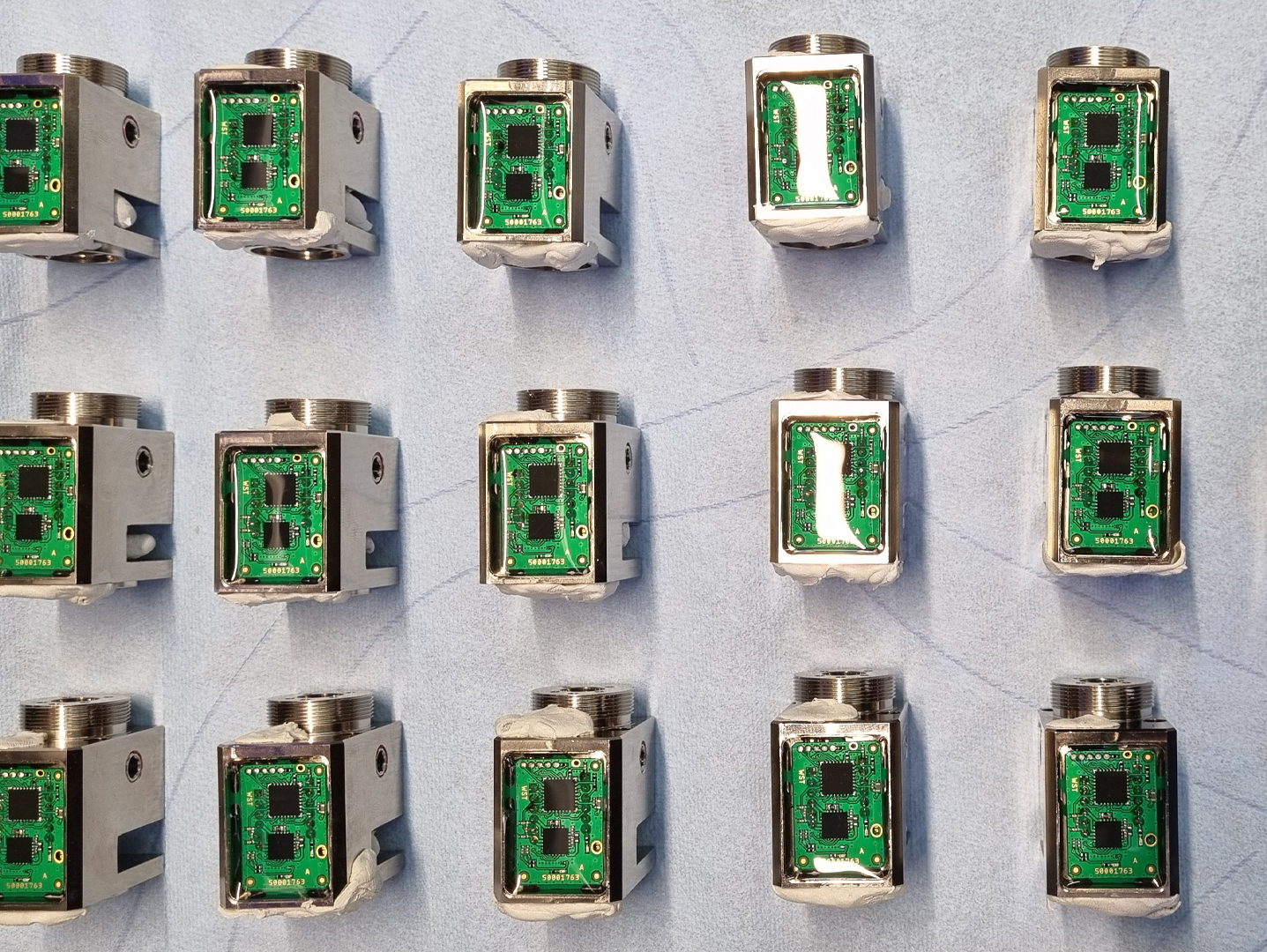

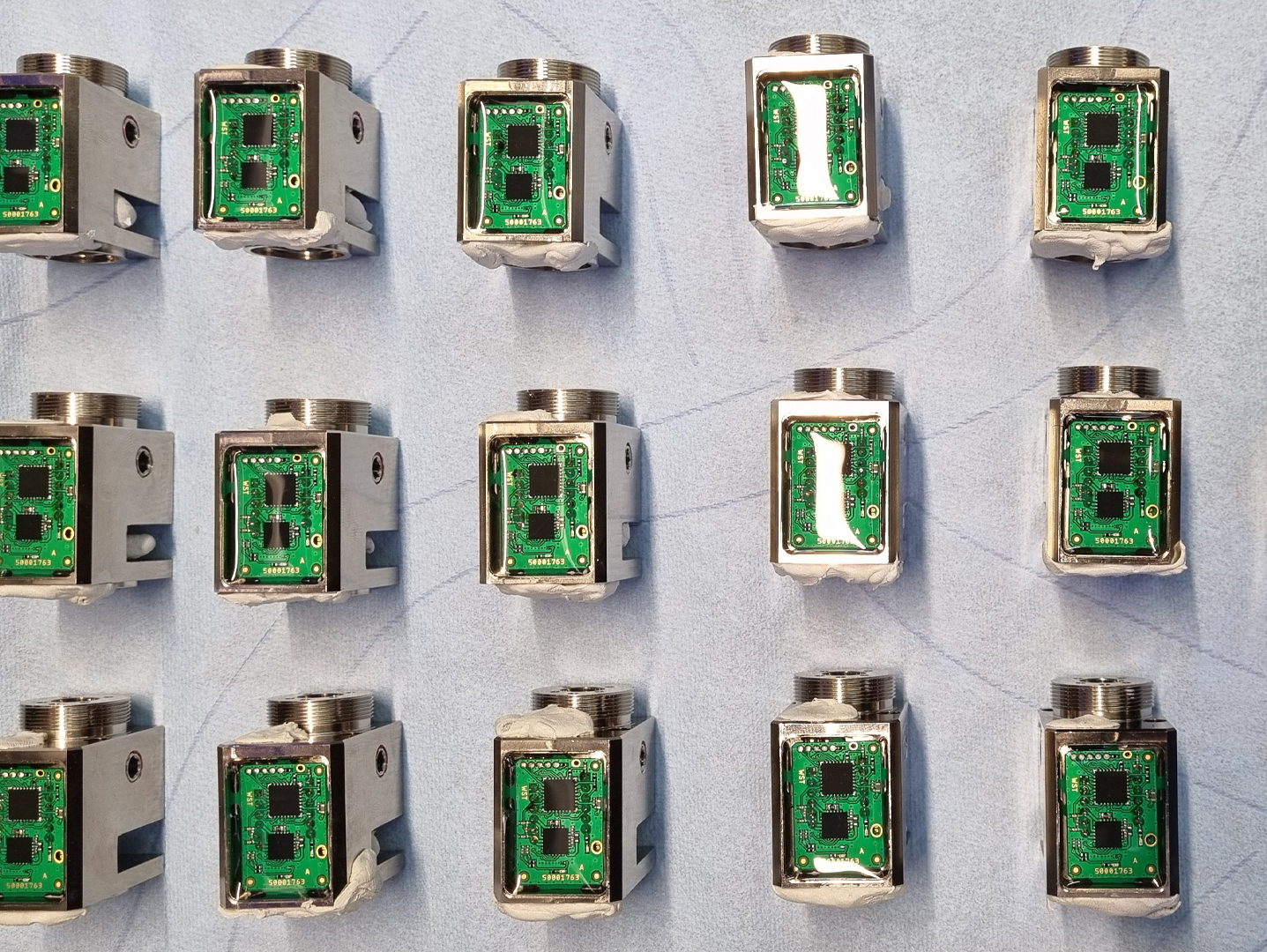

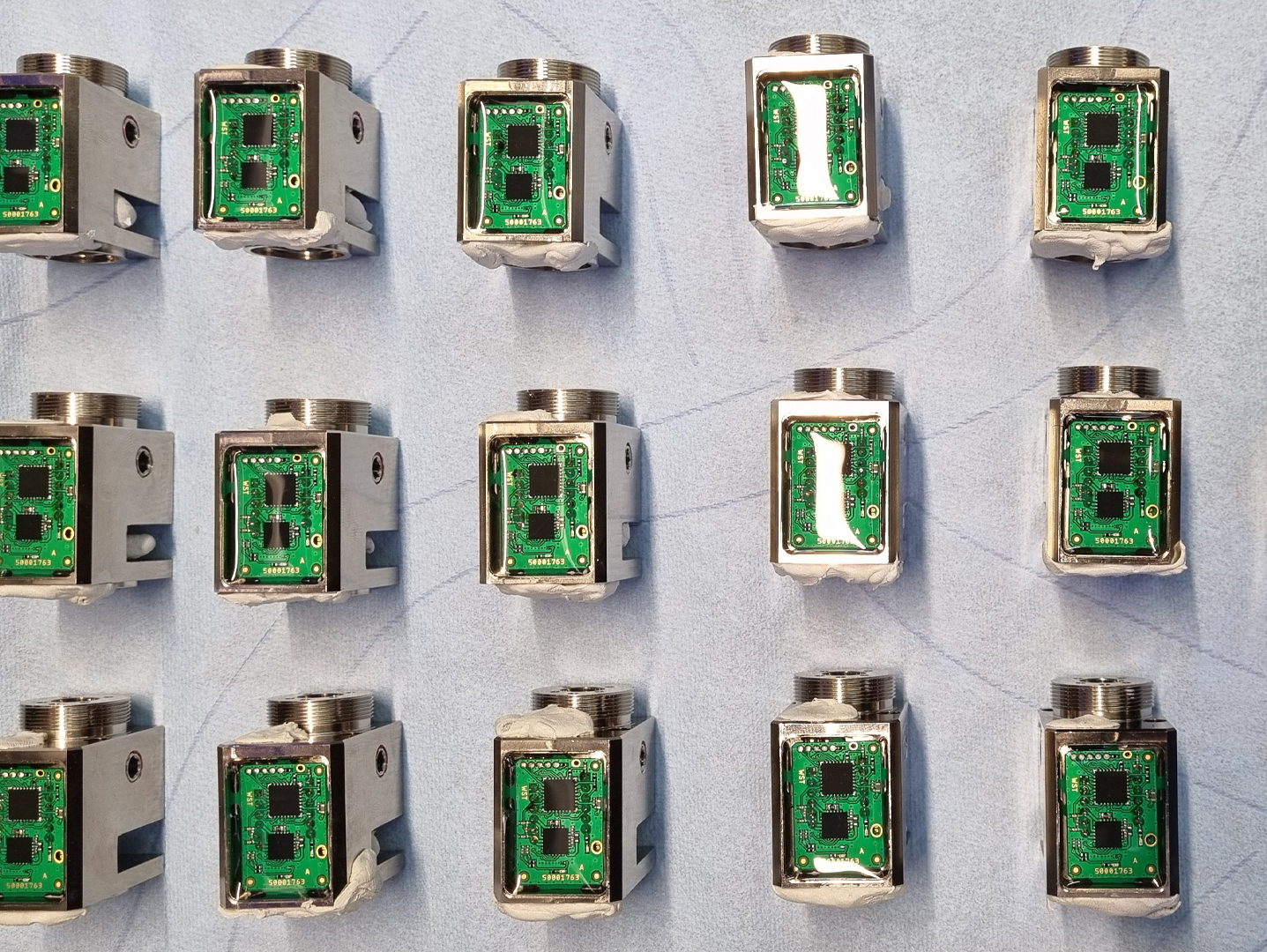

Cured and ready for operation

8 Mar 2024, 10:00:00

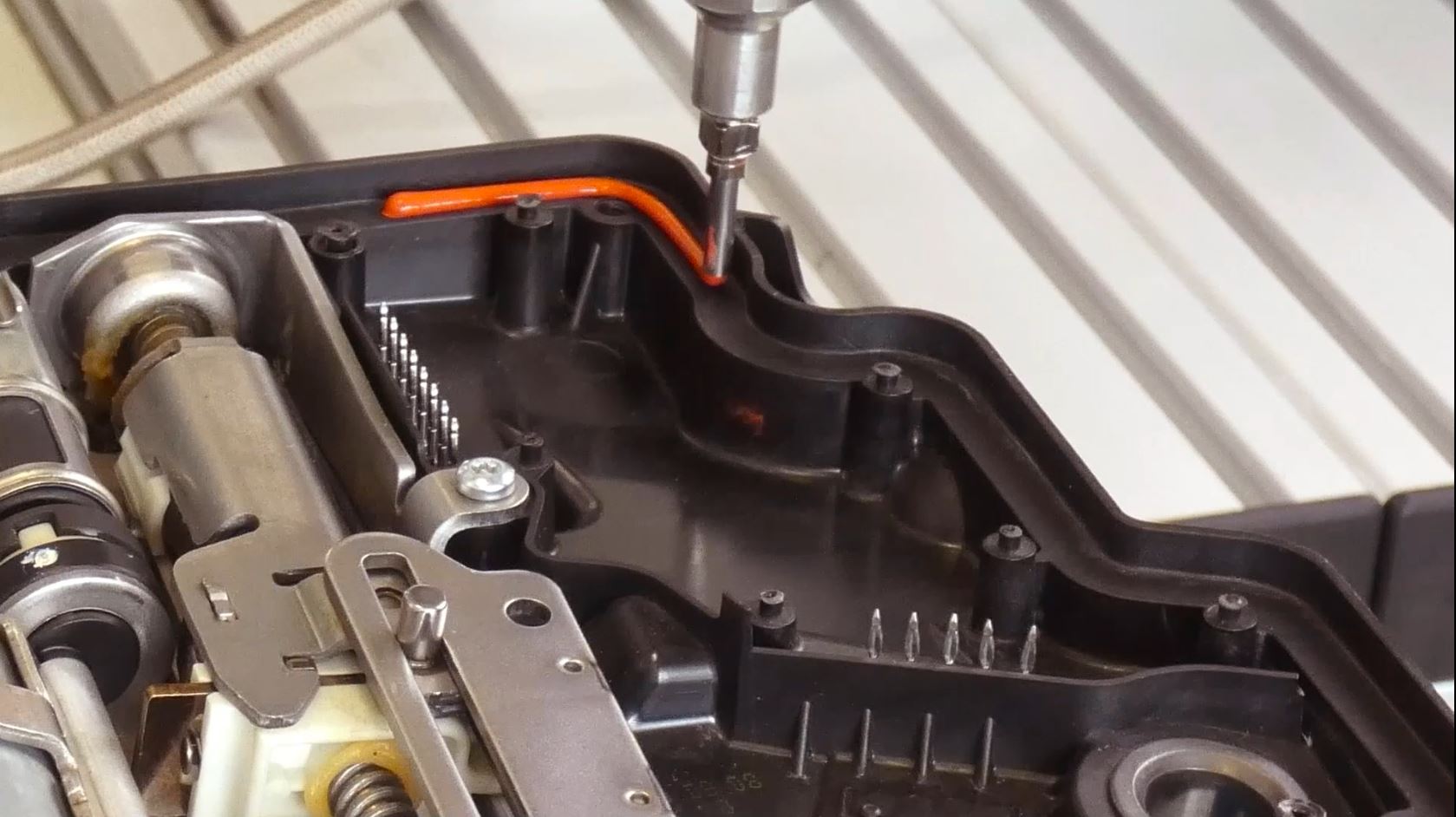

The spray valves of the WSV series are designed for use in industrial production environments with increased mechanical, thermal and environmental loads. For this reason, Walther Systemtechnik deliberately relies on protective methods such as potting of electronic components during the manufacture of the valve assemblies.

The potting process reliably protects the integrated electronics against mechanical impact, moisture, contamination, as well as extreme temperatures and thermal cycling, thereby making a significant contribution to long-term functional reliability.

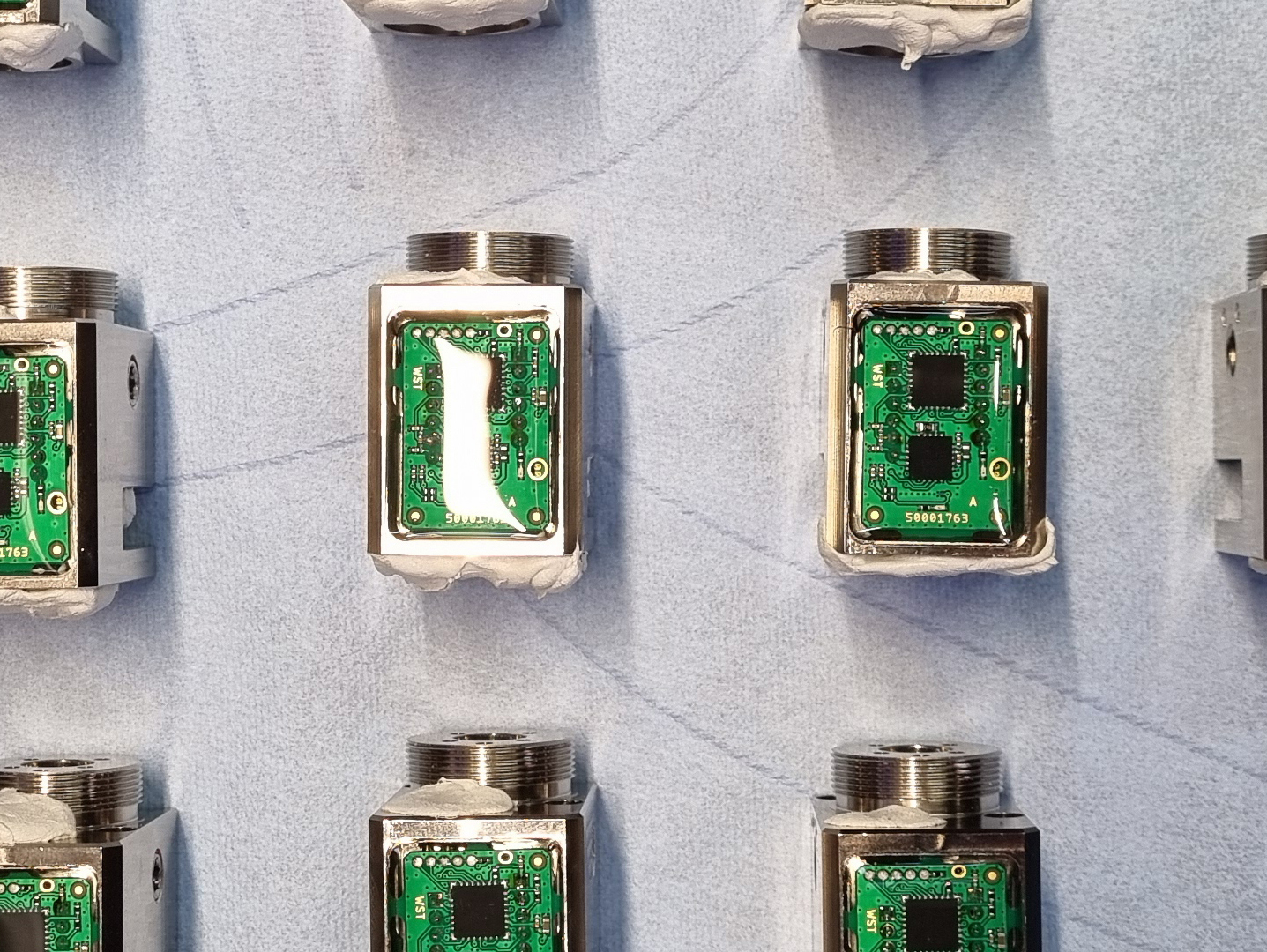

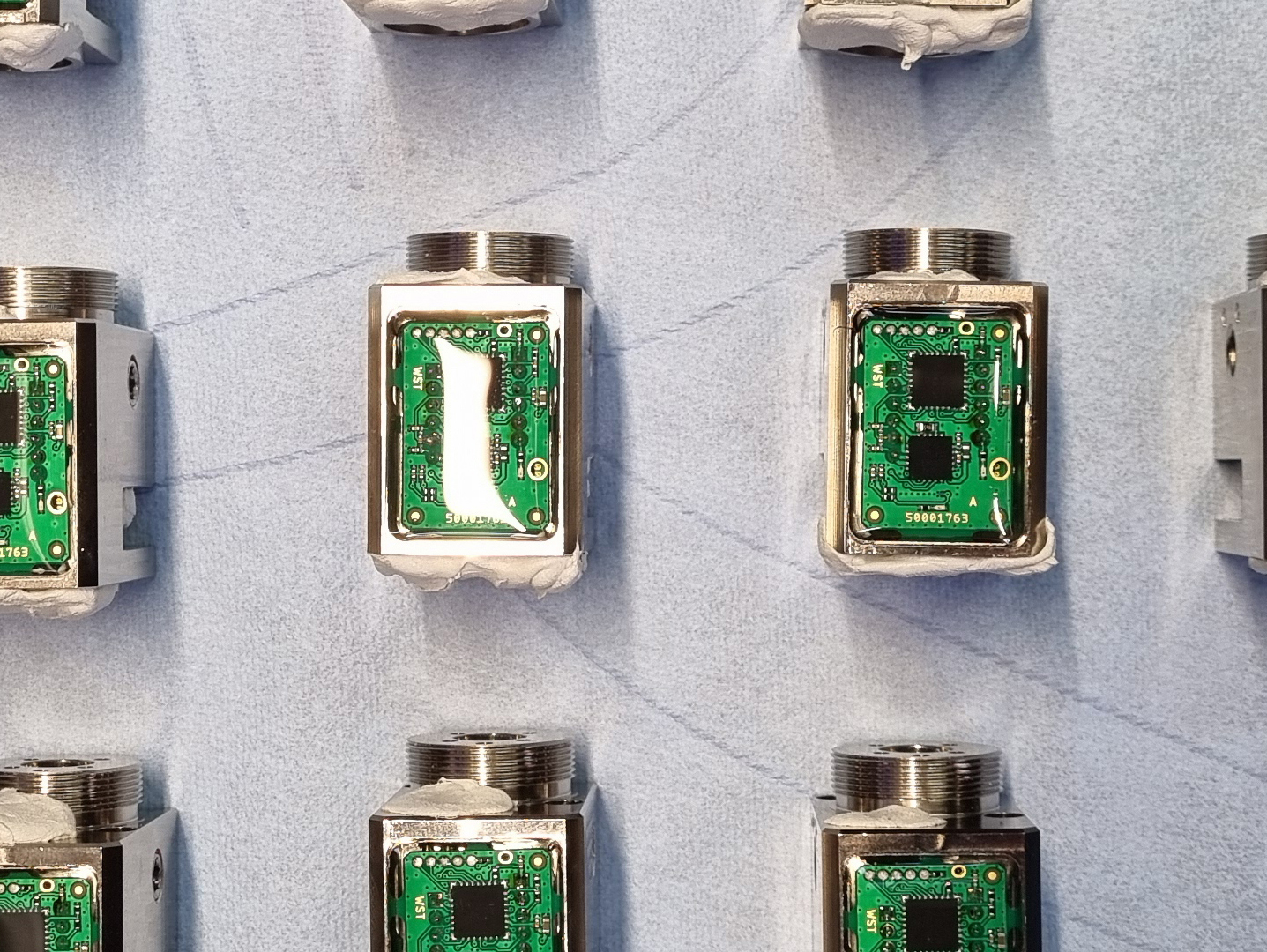

The valve heads shown here have been potted with a high-quality two-component polyurethane resin. After curing, the resin increases the mechanical stability of the assembly and ensures reliable operation of the spray valves even under demanding industrial conditions.

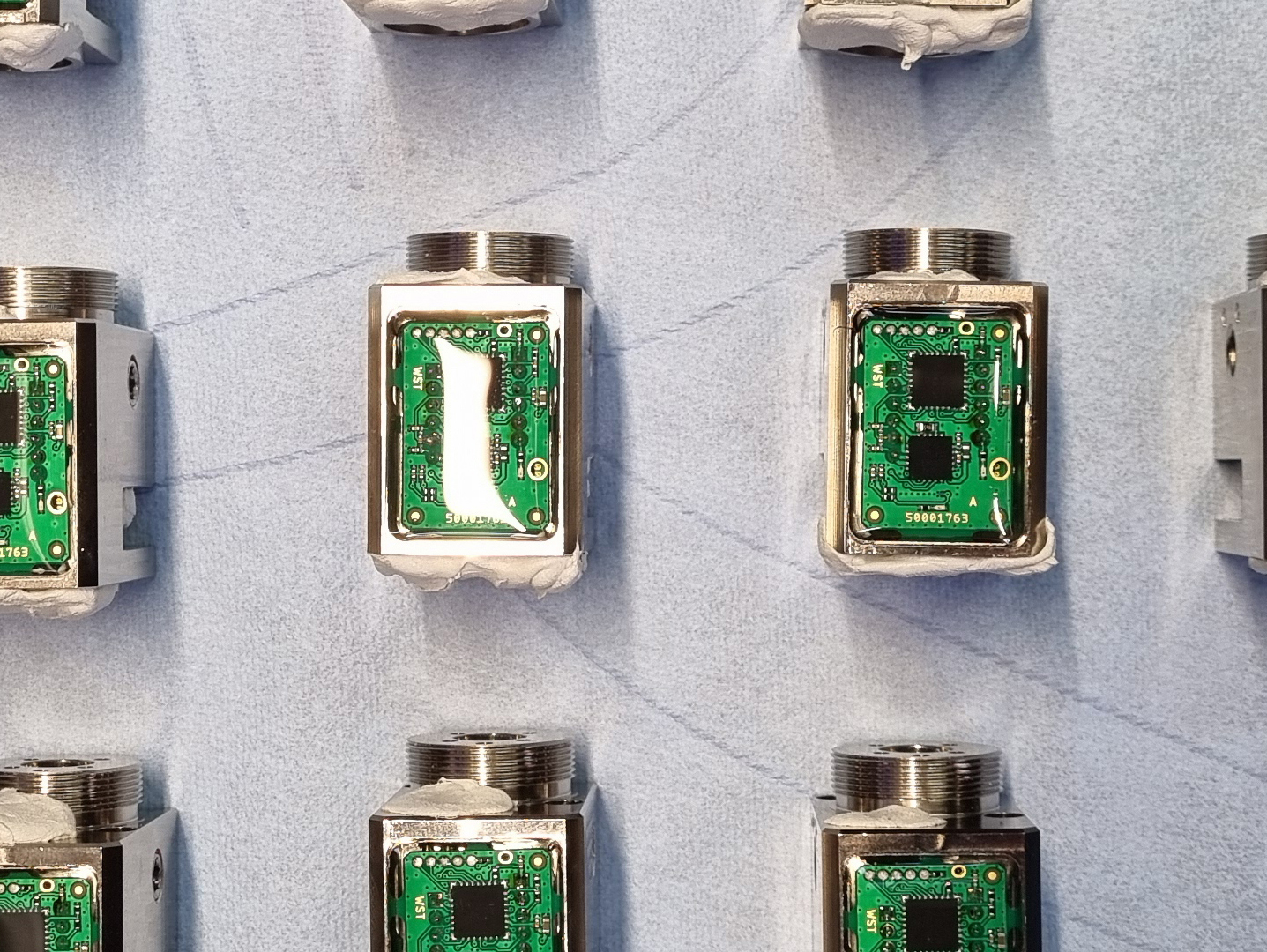

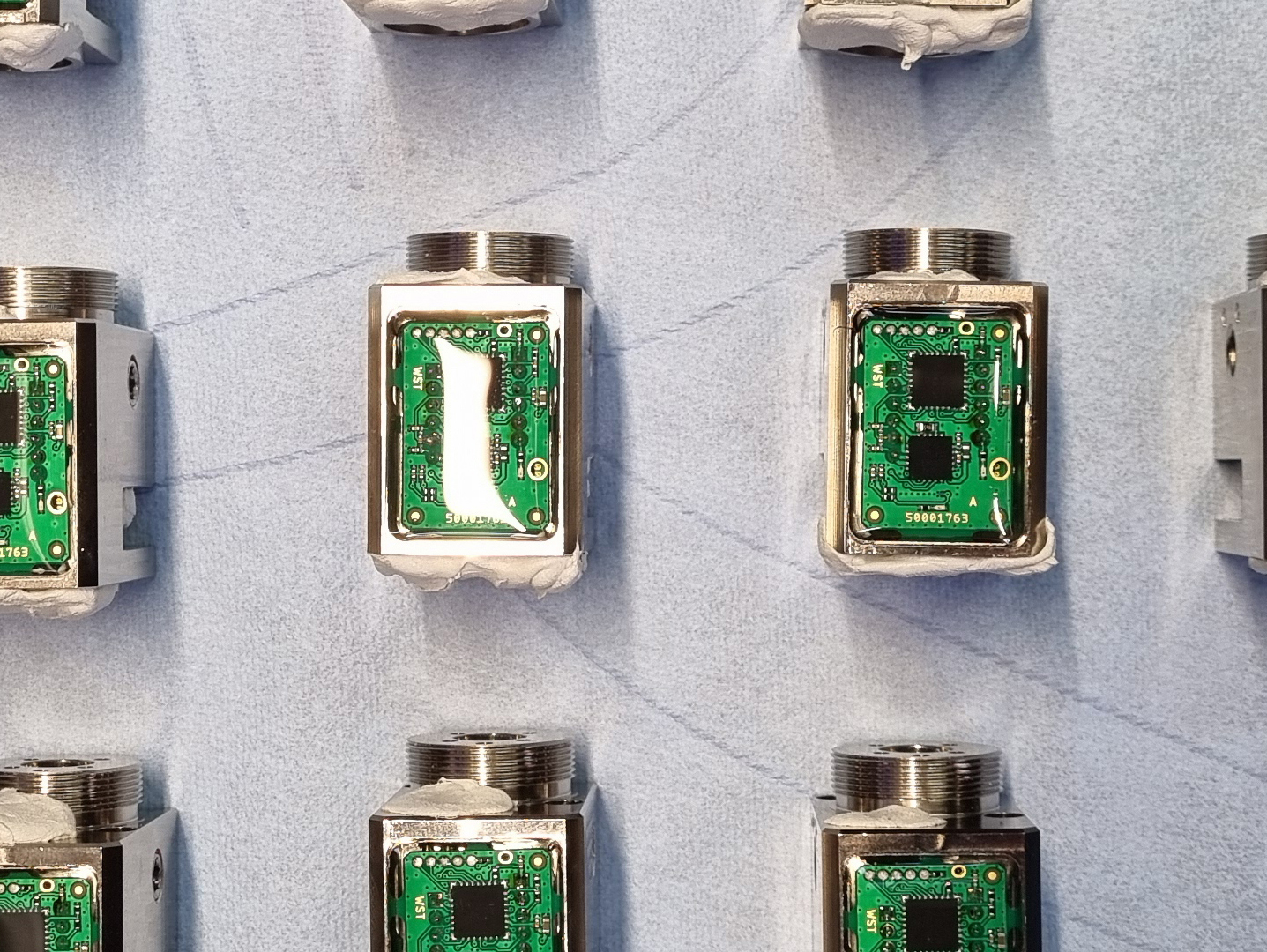

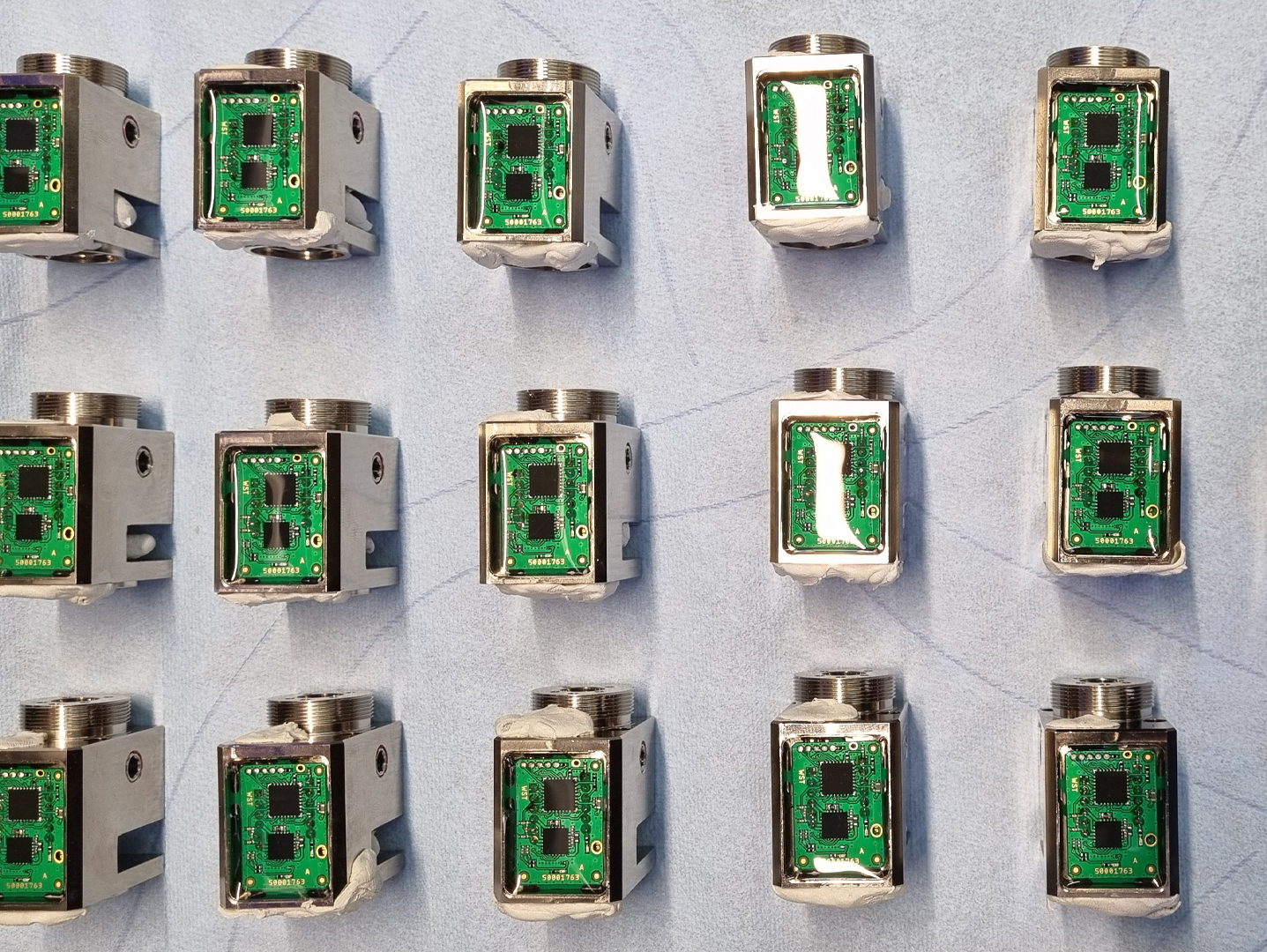

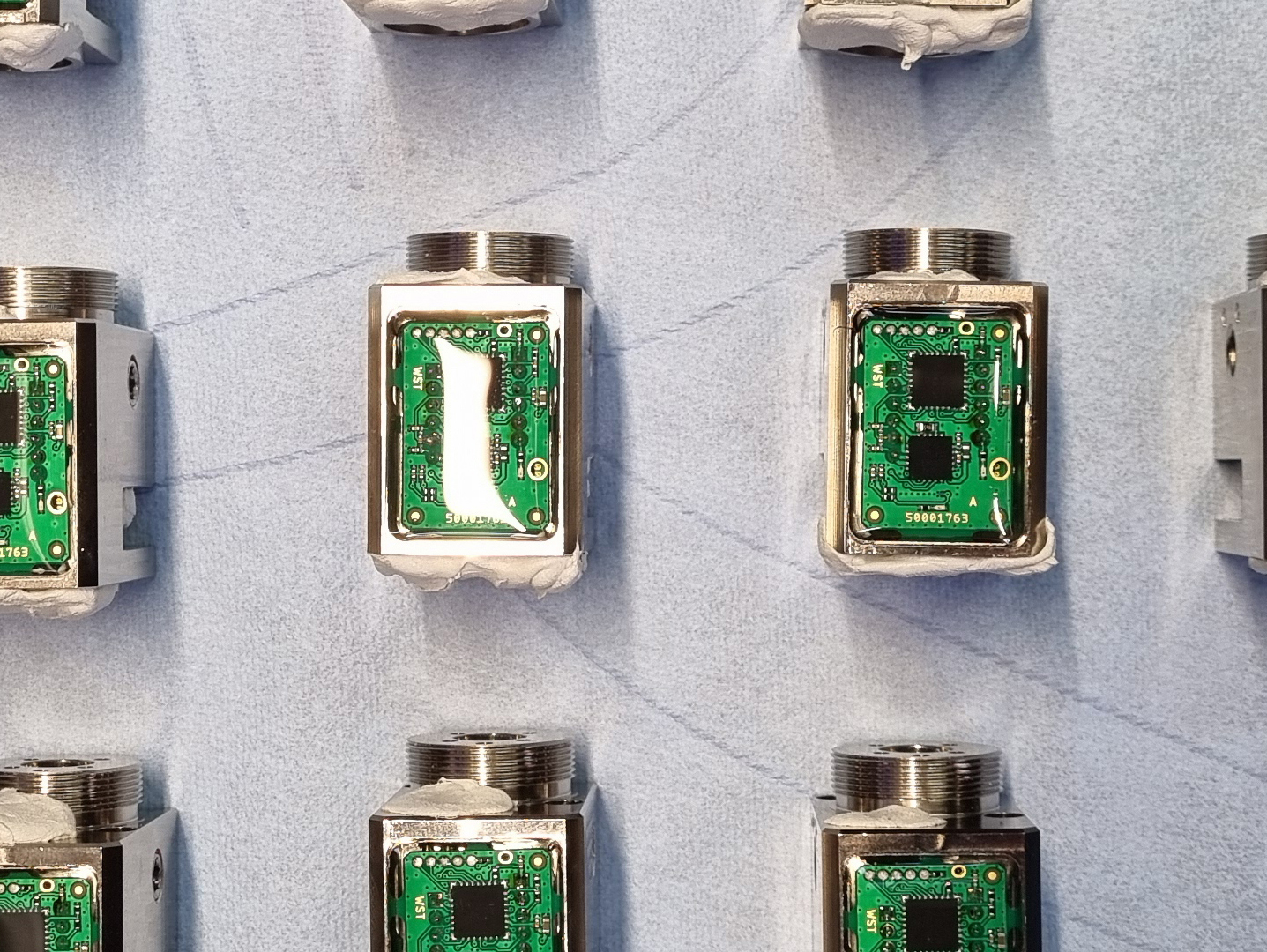

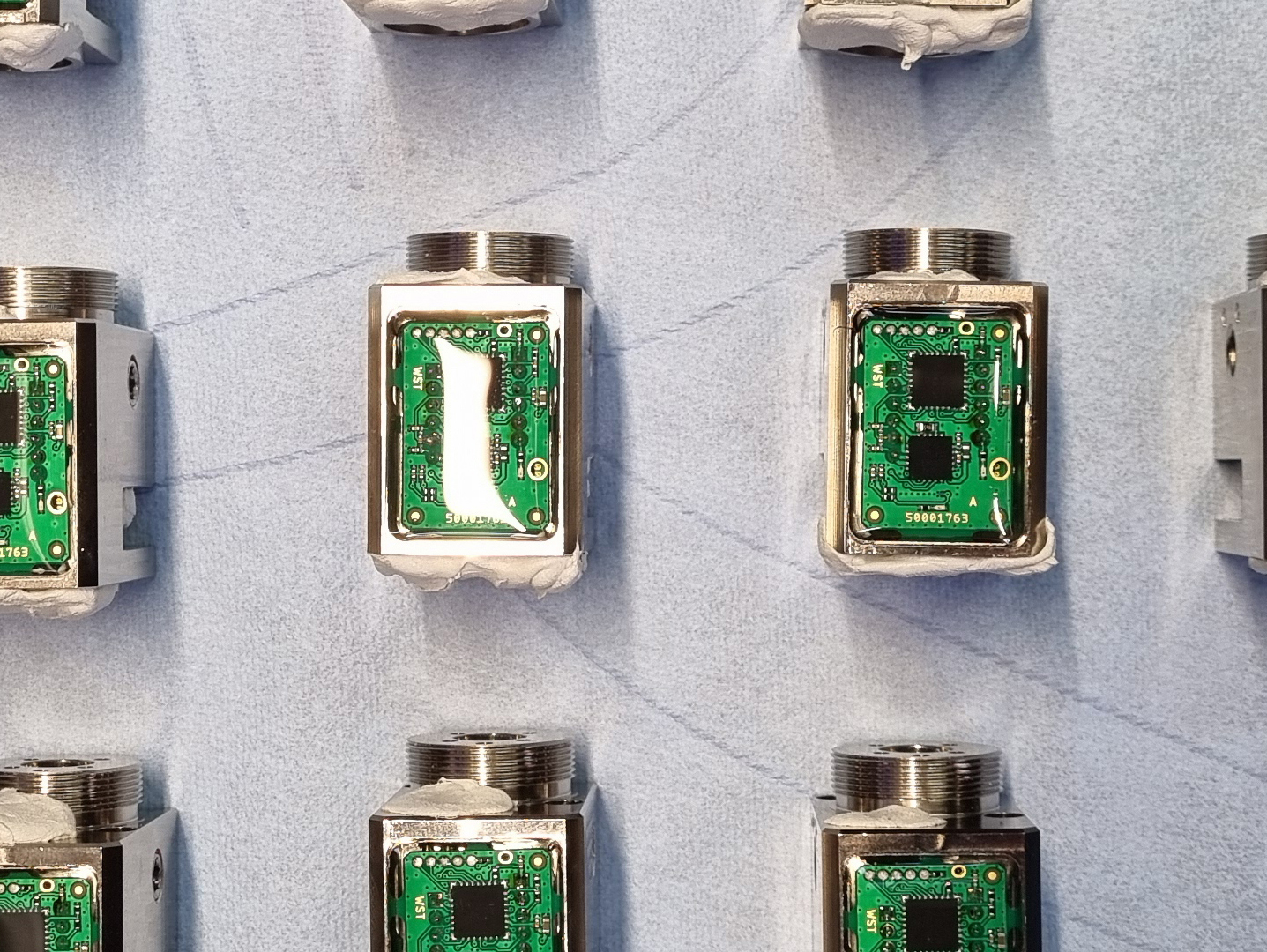

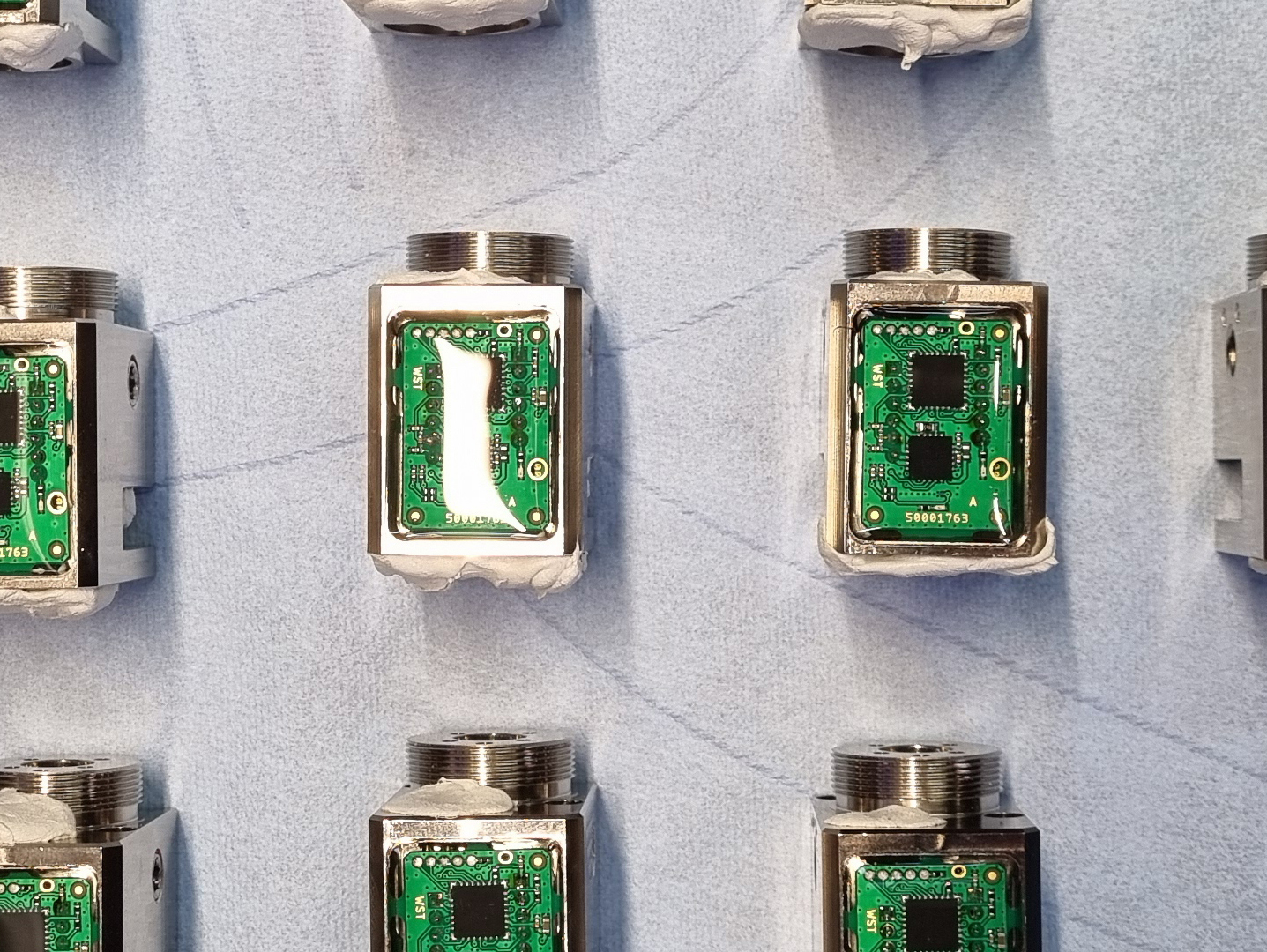

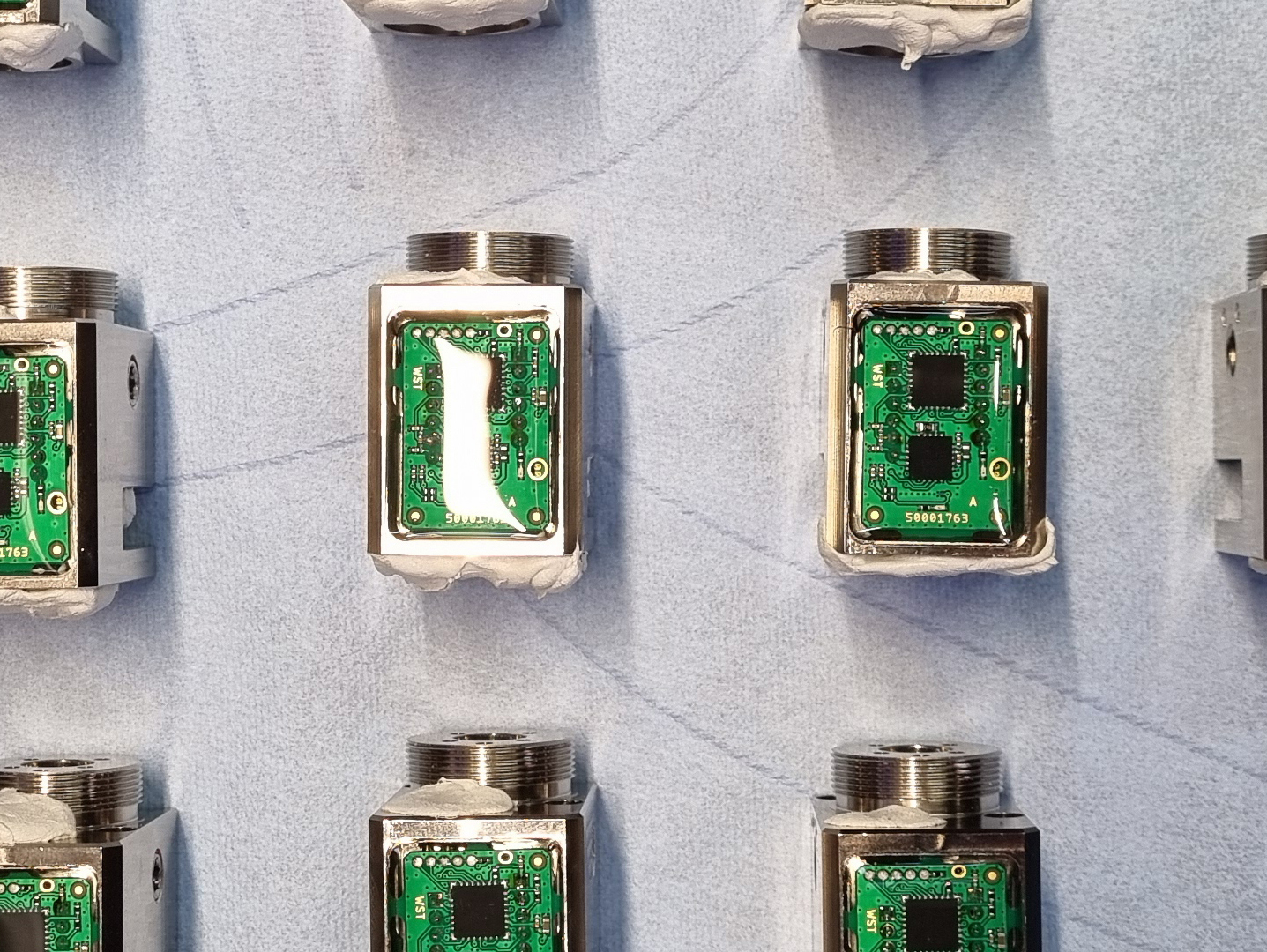

Cured and ready for operation

The spray valves of the WSV series are designed for use in industrial production environments with increased mechanical, thermal and environmental loads. For this reason, Walther Systemtechnik deliberately relies on protective methods such as potting of electronic components during the manufacture of the valve assemblies.

The potting process reliably protects the integrated electronics against mechanical impact, moisture, contamination, as well as extreme temperatures and thermal cycling, thereby making a significant contribution to long-term functional reliability.

The valve heads shown here have been potted with a high-quality two-component polyurethane resin. After curing, the resin increases the mechanical stability of the assembly and ensures reliable operation of the spray valves even under demanding industrial conditions.

Weitere Beiträge

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request