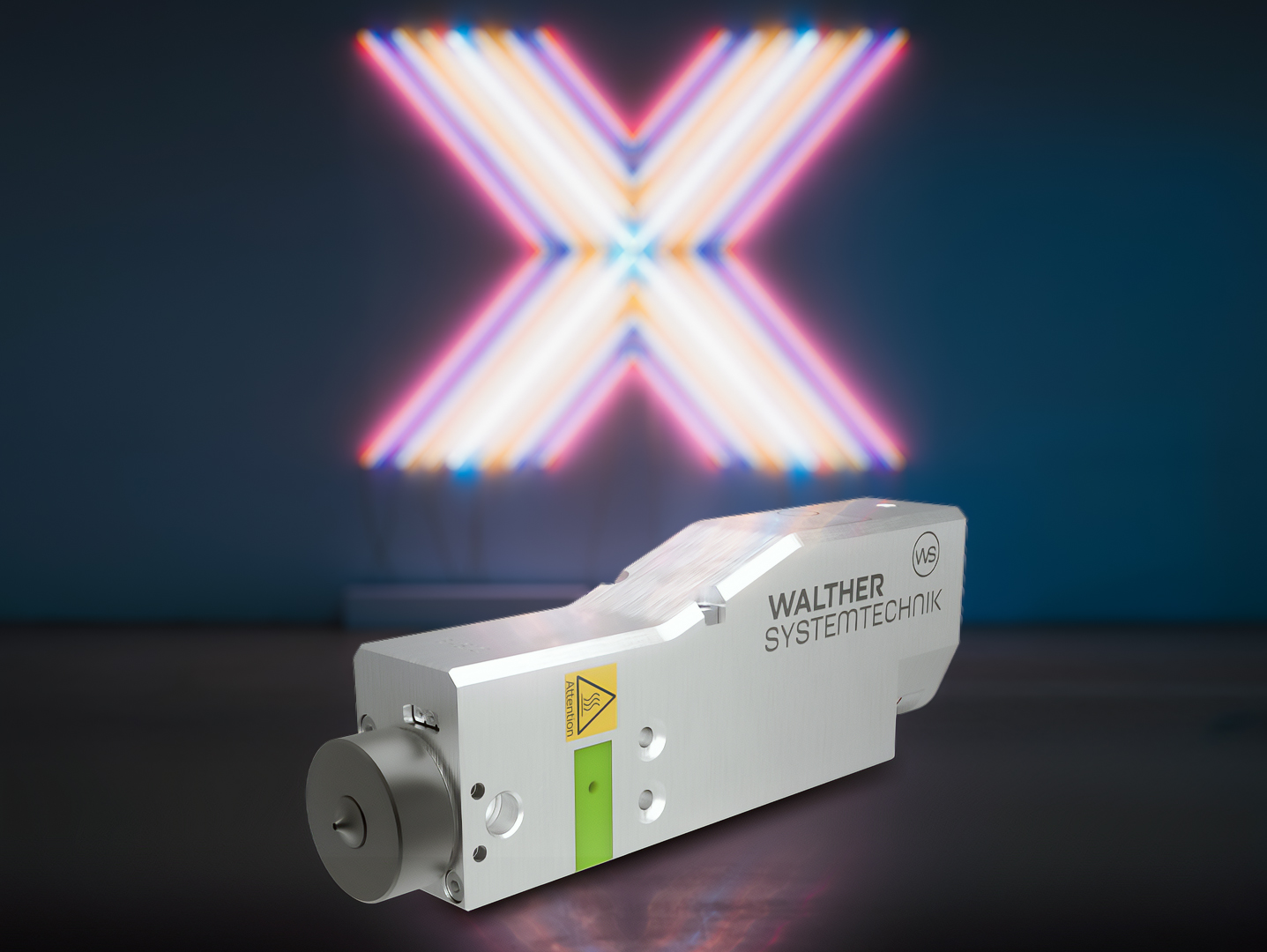

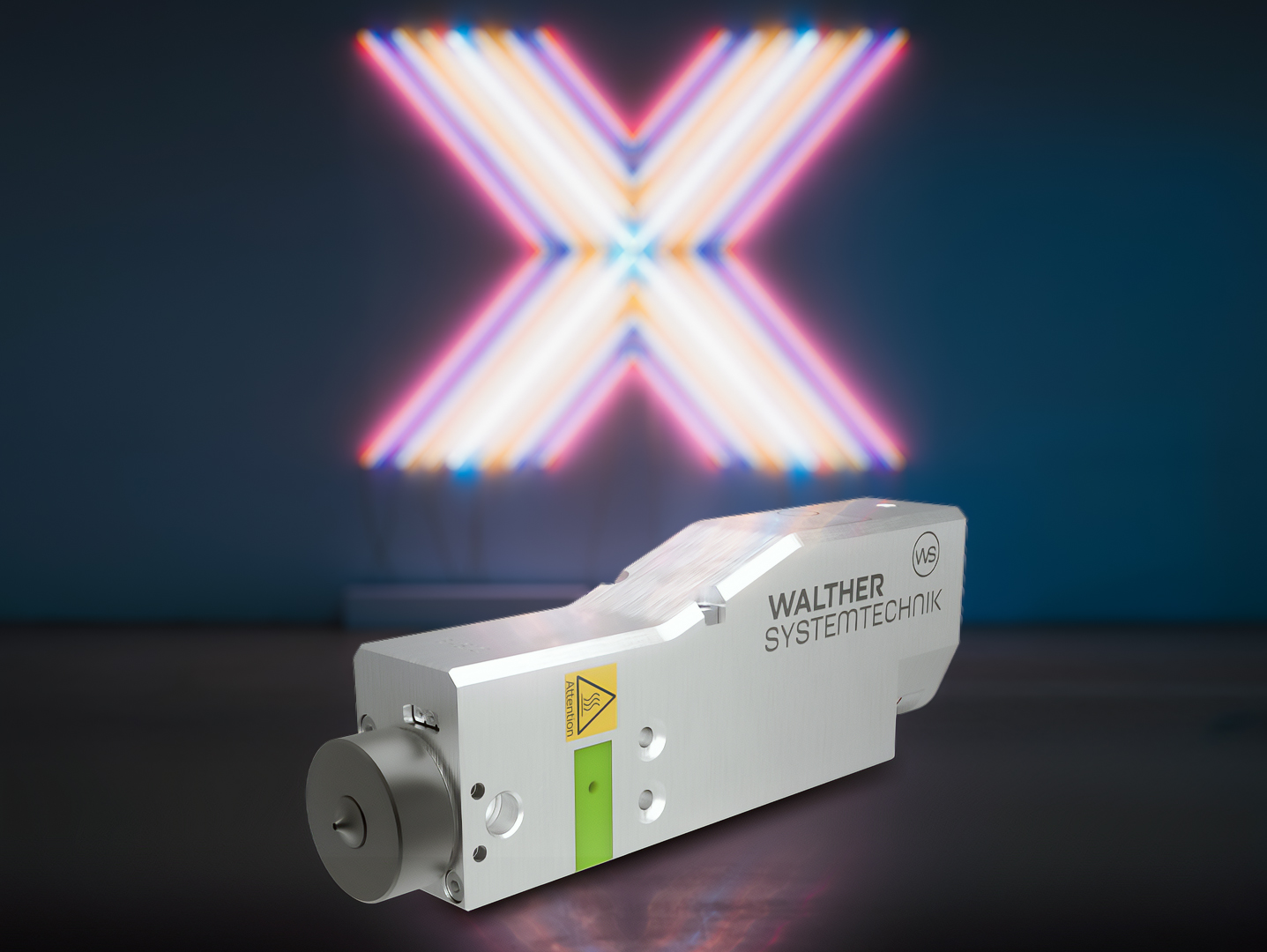

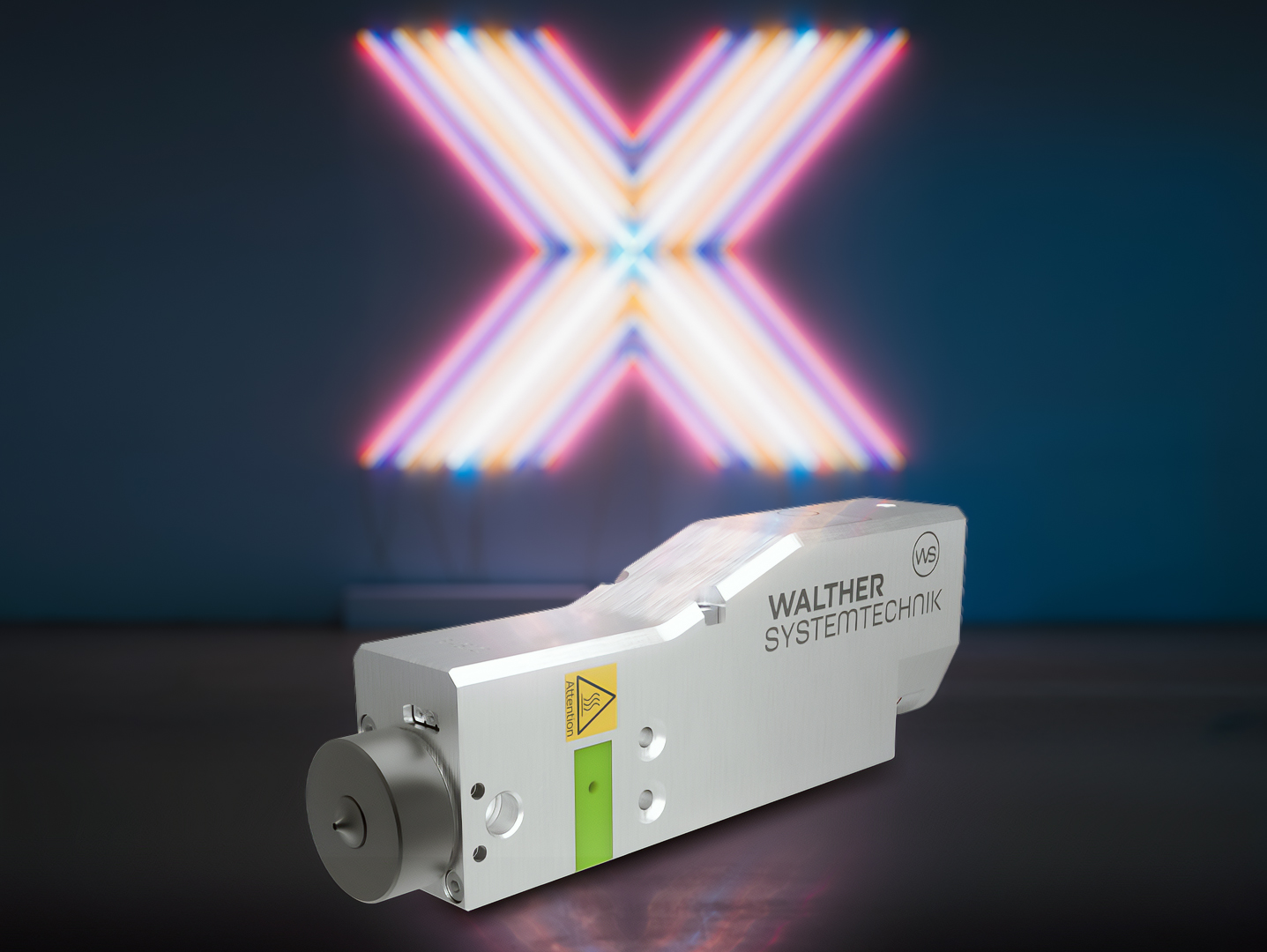

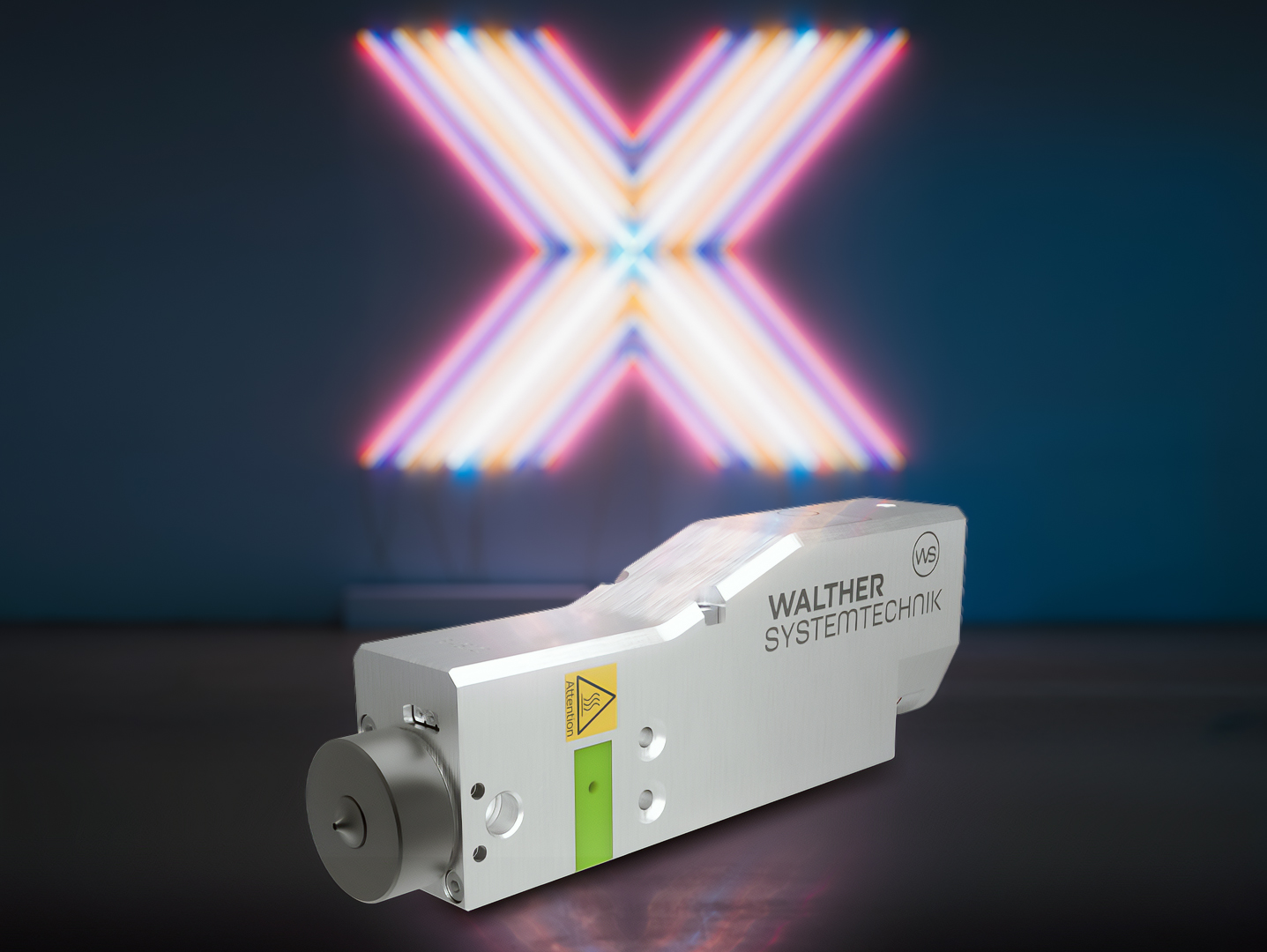

Walther WPV Pulse Valve: An innovative evolution in process technology

14 Nov 2023, 14:00:00

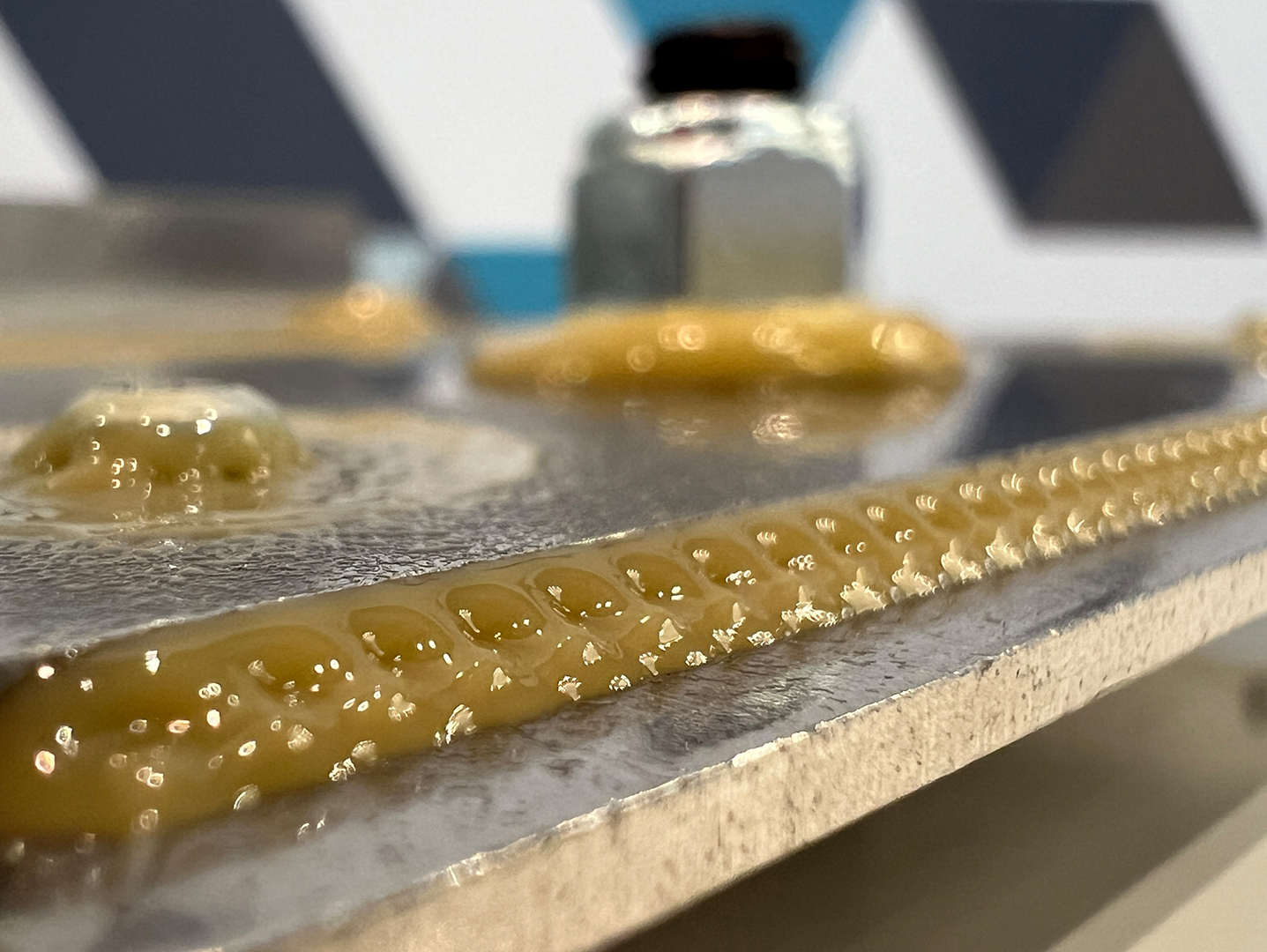

Pulse valves enable contactless dispensing of viscous media with a high level of repeatability. By dispensing individual droplets in rapid succession, even very small quantities can be applied at high frequencies while maintaining consistent precision. This makes pulse valves particularly suitable for applications with high cycle rates, as typically found in series production and automated processes. Even difficult-to-access or uneven component geometries can be handled reliably.

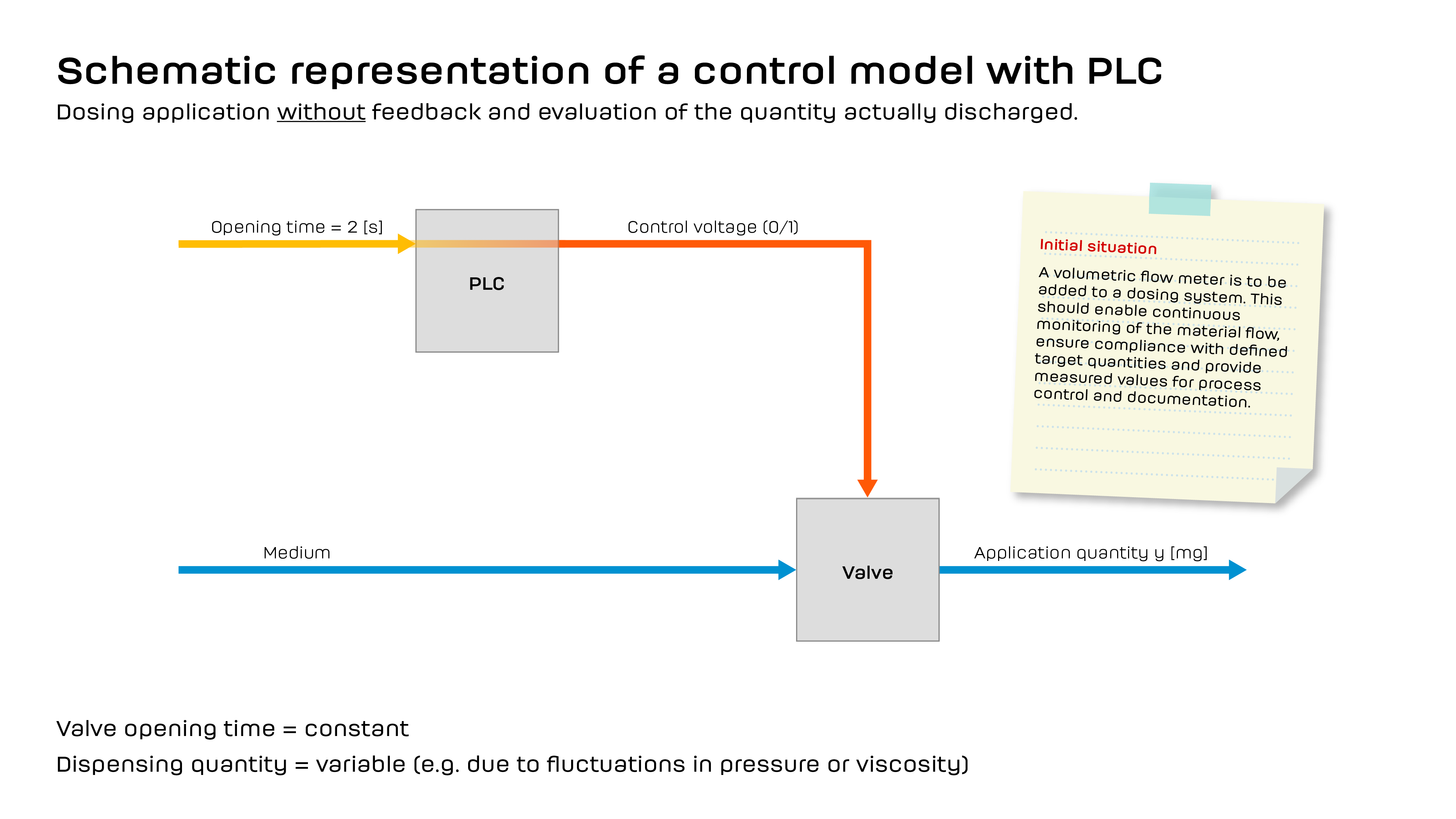

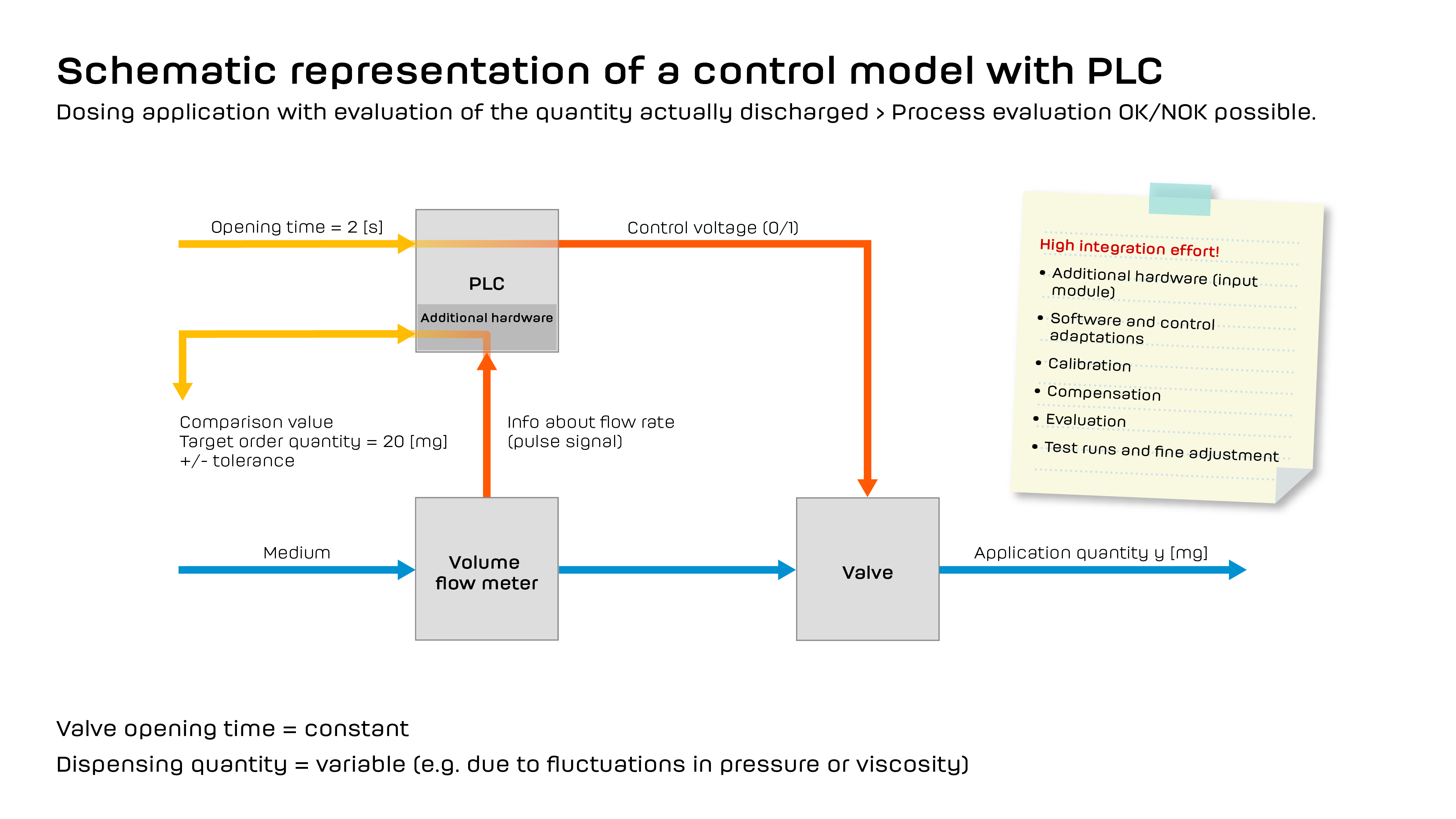

Conventional pulse valve systems, however, are often associated with a high level of integration effort. External control technology, complex programming and additional software increase both investment and commissioning costs and at the same time raise the potential for errors. Against this background, the Walther WPV pulse valve was developed to combine the functional advantages of pulse dispensing with significantly reduced system complexity.

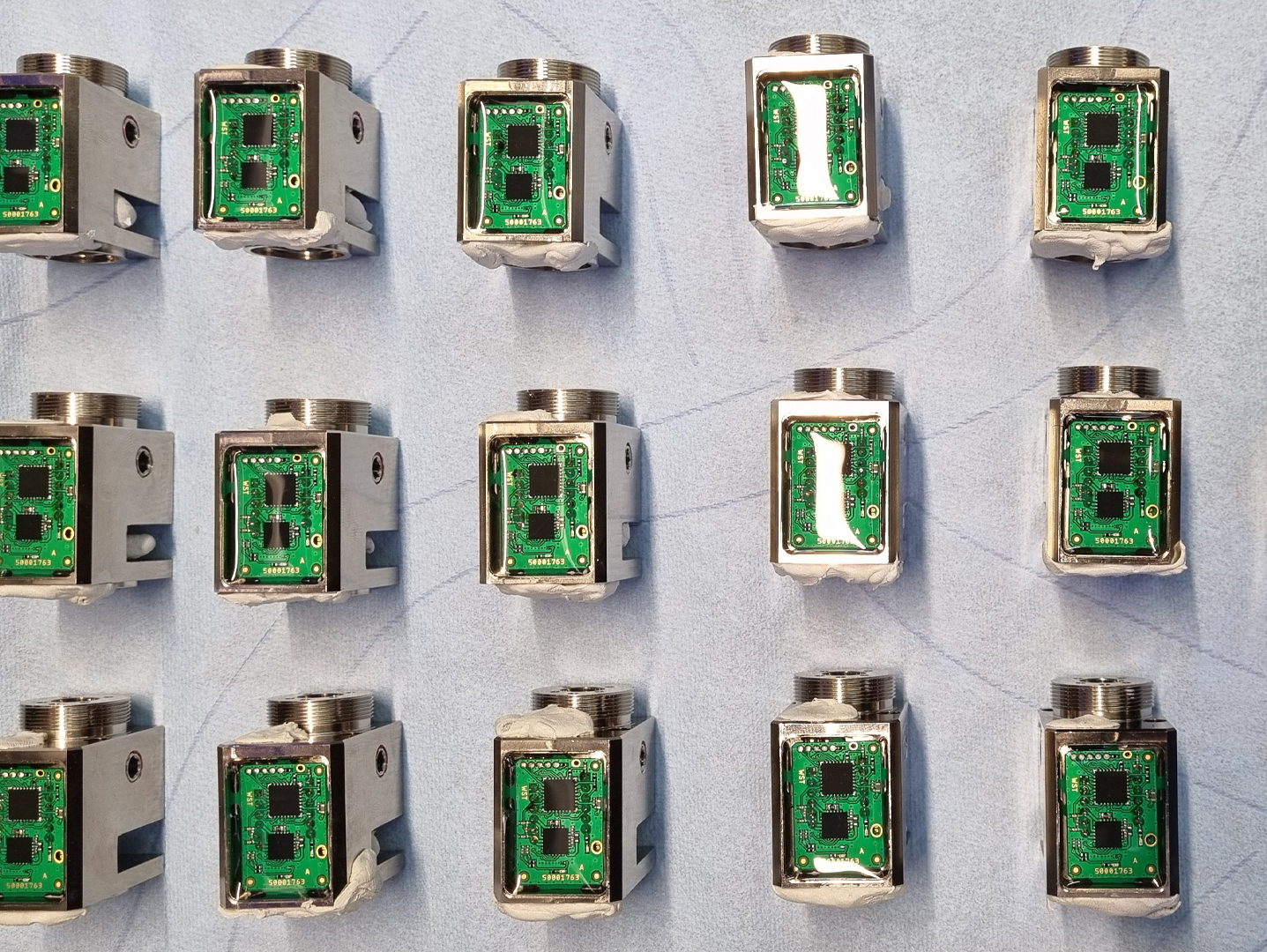

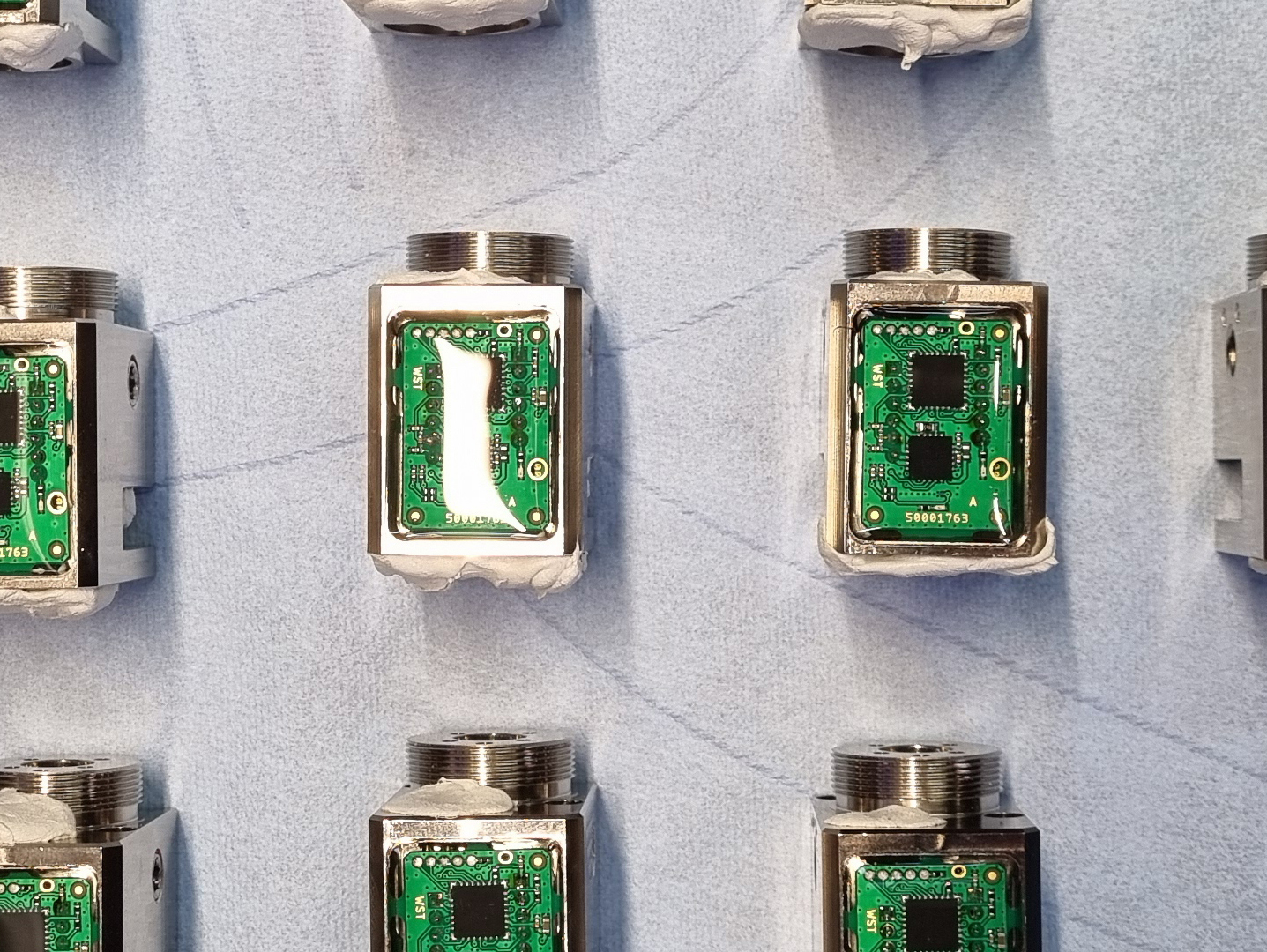

Functional integration instead of external control: the WPV pulse valve is characterised by a high degree of functional integration within a compact design. Control, monitoring and process evaluation are integrated directly into the valve. No additional external control system, dedicated software or programming effort is required. Operation consistently follows the principle of “parameterising instead of programming” – from commissioning through to ongoing process monitoring.

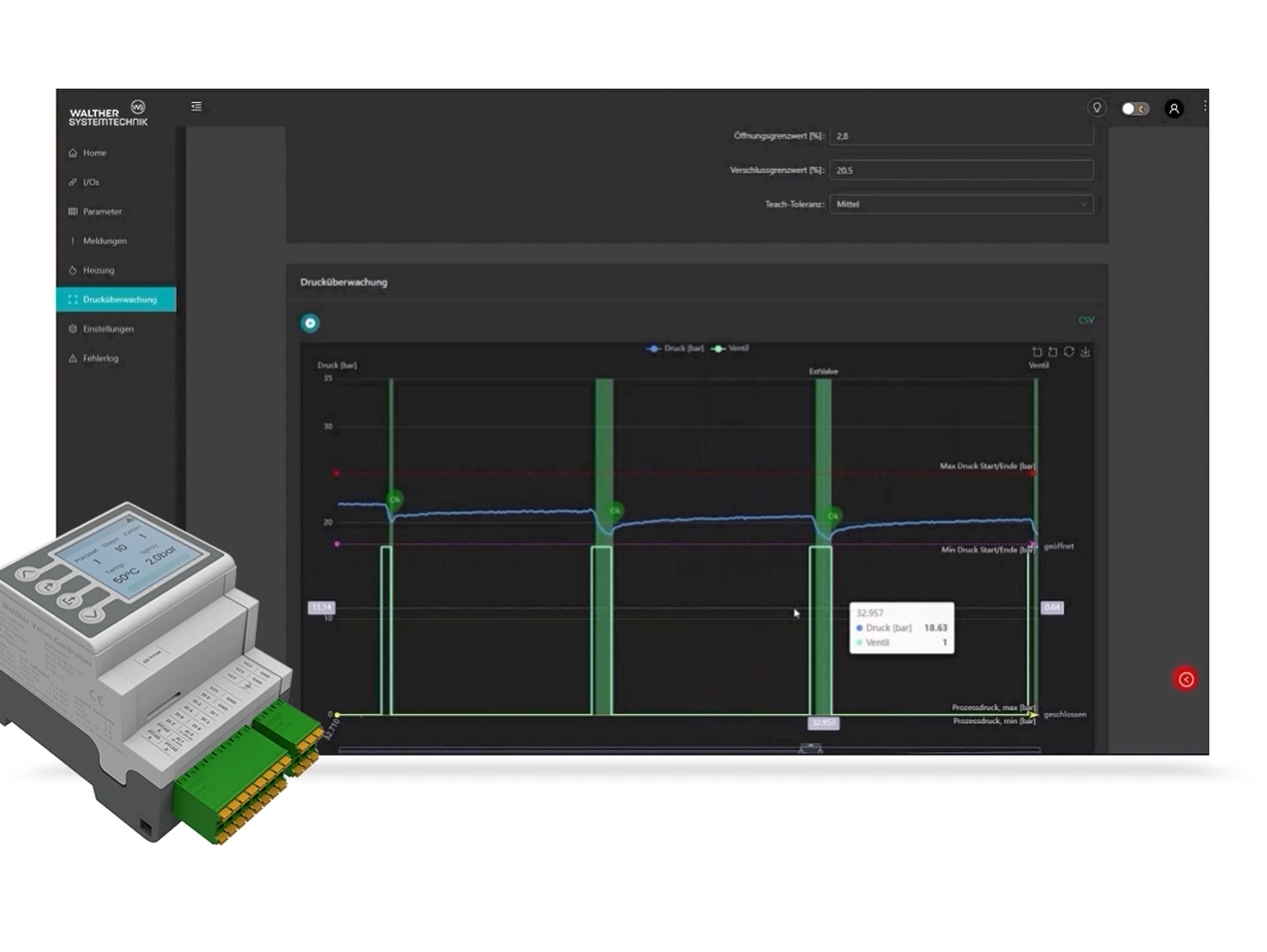

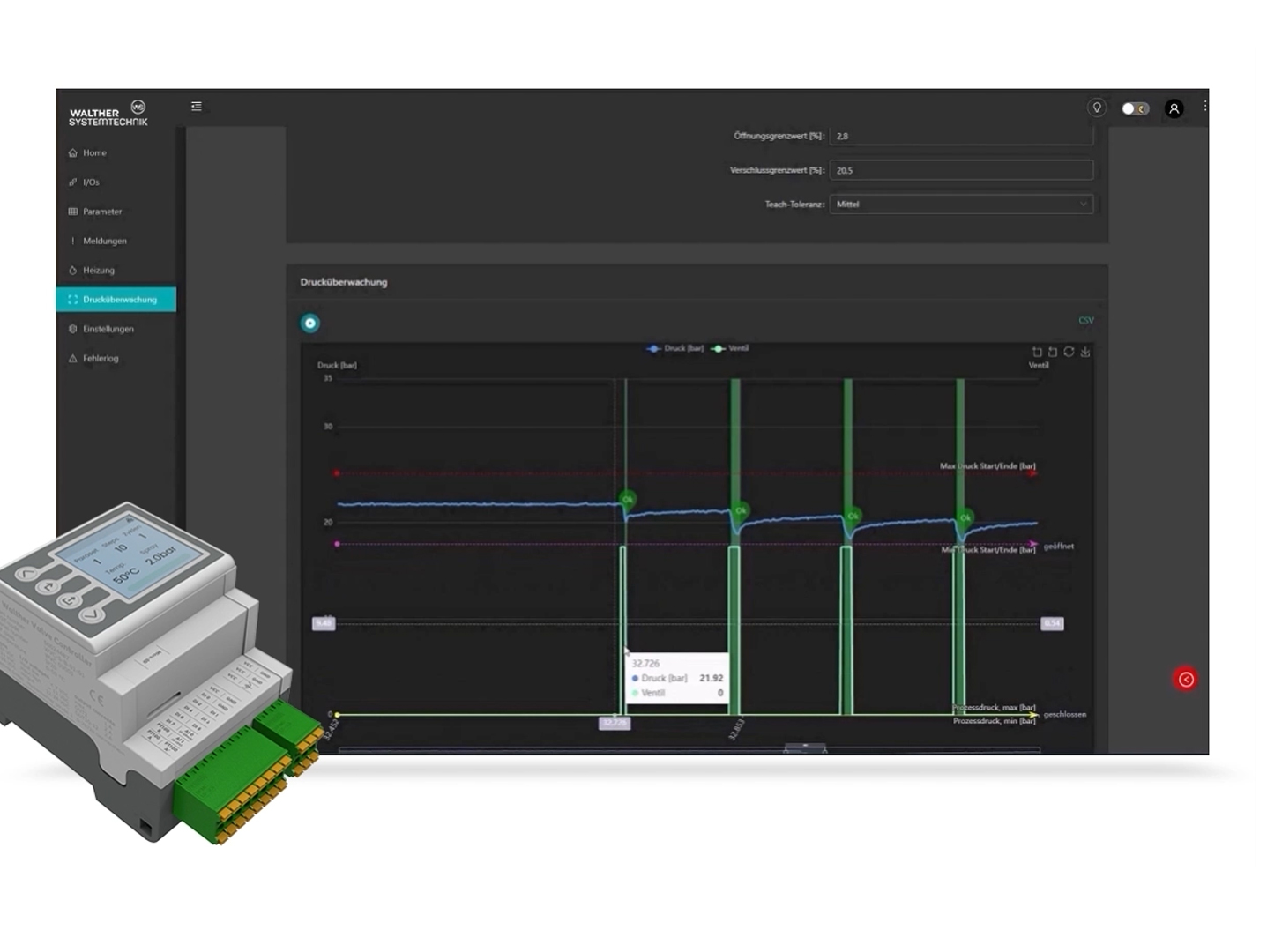

Access to the valve’s own dashboard is provided via a web interface. Functions such as remote parameterisation and remote diagnostics enable flexible adjustment of process parameters as well as rapid analysis of process conditions. In addition, peripheral components can be controlled and evaluated without the need for a higher-level control system.

Equipment and operating concept: the standard equipment of the WPV includes an integrated pressure sensor, a valve heating system with temperature control, as well as analogue and digital inputs and outputs for connecting external components. Fully electric operation eliminates the need for compressed air lines, reduces installation effort and space requirements, and lowers operating costs.

By combining contactless dispensing with integrated control and monitoring technology, the WPV opens up new possibilities for efficient, highly automated dispensing processes while at the same time reducing overall system complexity.

Process control and expandability: multiple parameter sets can be stored and process-relevant variables documented. This has a positive effect on process capability, overall equipment effectiveness (OEE) and product quality. In addition, software add-ons can be activated retrospectively as required to flexibly address future requirements.

Walther WPV Pulse Valve: An innovative evolution in process technology

Pulse valves enable contactless dispensing of viscous media with a high level of repeatability. By dispensing individual droplets in rapid succession, even very small quantities can be applied at high frequencies while maintaining consistent precision. This makes pulse valves particularly suitable for applications with high cycle rates, as typically found in series production and automated processes. Even difficult-to-access or uneven component geometries can be handled reliably.

Conventional pulse valve systems, however, are often associated with a high level of integration effort. External control technology, complex programming and additional software increase both investment and commissioning costs and at the same time raise the potential for errors. Against this background, the Walther WPV pulse valve was developed to combine the functional advantages of pulse dispensing with significantly reduced system complexity.

Functional integration instead of external control: the WPV pulse valve is characterised by a high degree of functional integration within a compact design. Control, monitoring and process evaluation are integrated directly into the valve. No additional external control system, dedicated software or programming effort is required. Operation consistently follows the principle of “parameterising instead of programming” – from commissioning through to ongoing process monitoring.

Access to the valve’s own dashboard is provided via a web interface. Functions such as remote parameterisation and remote diagnostics enable flexible adjustment of process parameters as well as rapid analysis of process conditions. In addition, peripheral components can be controlled and evaluated without the need for a higher-level control system.

Equipment and operating concept: the standard equipment of the WPV includes an integrated pressure sensor, a valve heating system with temperature control, as well as analogue and digital inputs and outputs for connecting external components. Fully electric operation eliminates the need for compressed air lines, reduces installation effort and space requirements, and lowers operating costs.

By combining contactless dispensing with integrated control and monitoring technology, the WPV opens up new possibilities for efficient, highly automated dispensing processes while at the same time reducing overall system complexity.

Process control and expandability: multiple parameter sets can be stored and process-relevant variables documented. This has a positive effect on process capability, overall equipment effectiveness (OEE) and product quality. In addition, software add-ons can be activated retrospectively as required to flexibly address future requirements.

Weitere Beiträge

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request