WMAV – developed for reliable pressure-time-based dosing of reactive media

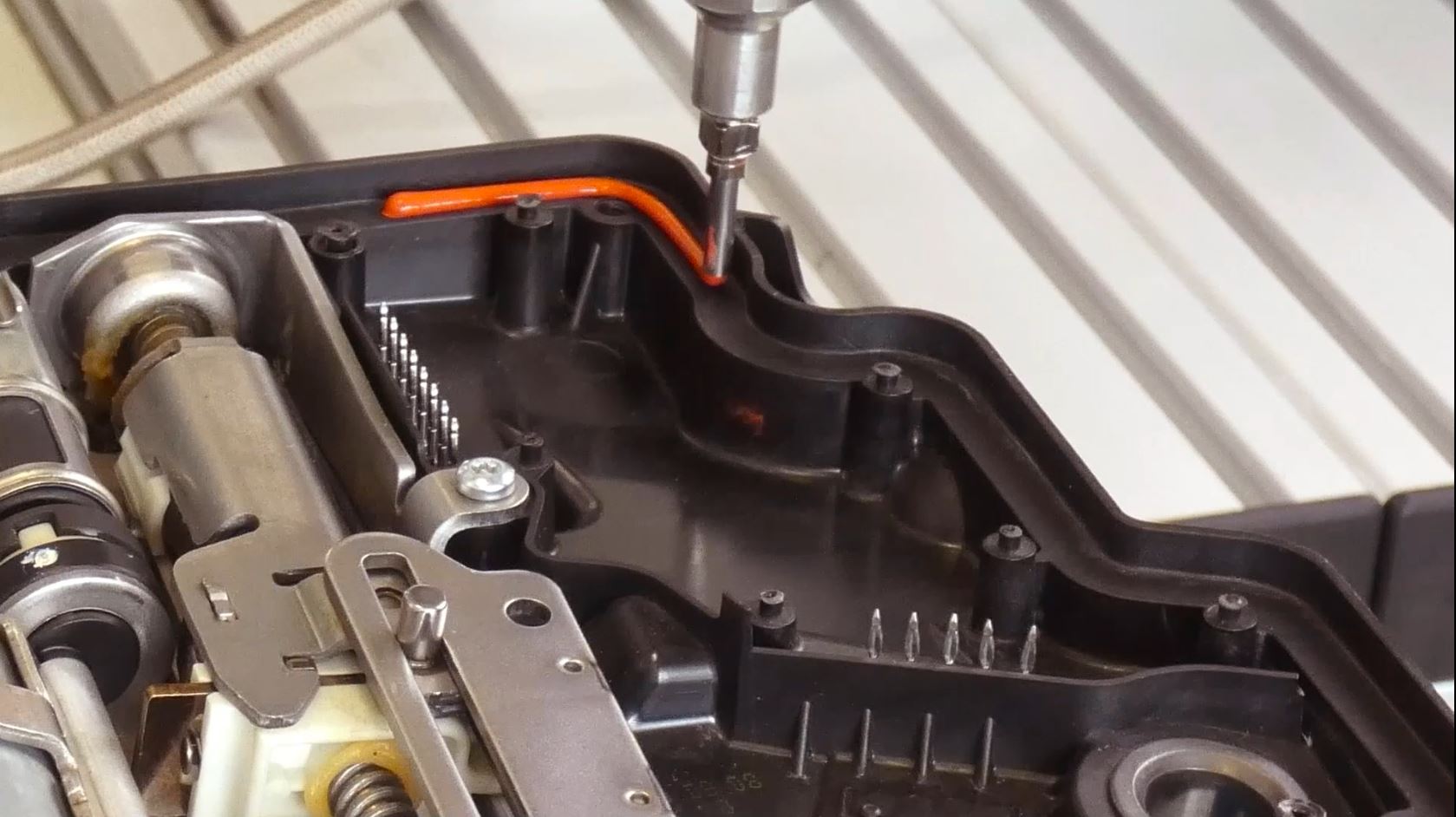

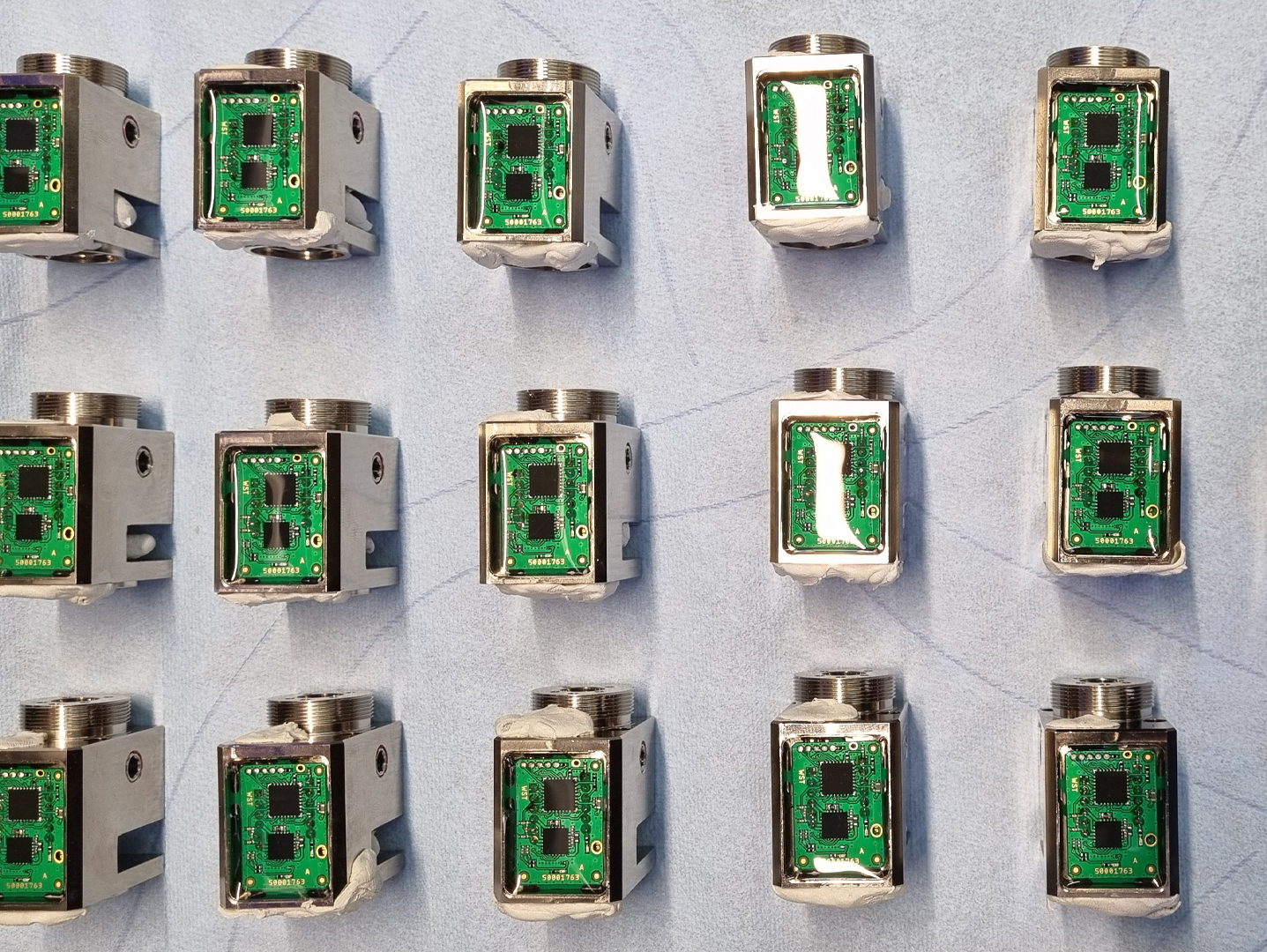

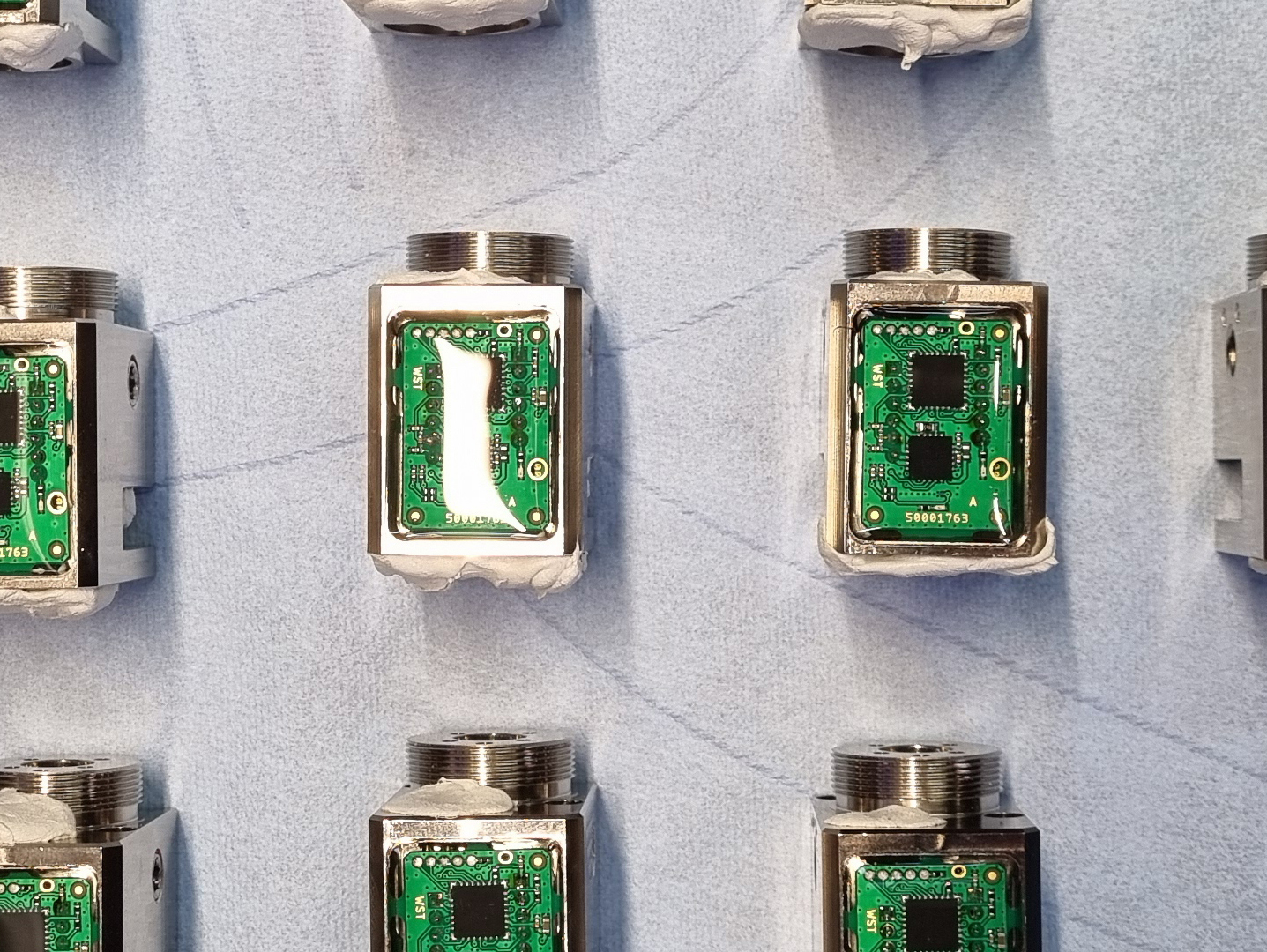

The clean and precise application of reactive media such as adhesives places high demands on dosing technology. With the membrane outlet valve WMAV, Walther Systemtechnik expands its valve portfolio with a solution designed for pressure-time-based dosing of such media.

The compact, pneumatically actuated valve can be integrated into production environments with limited installation space. The specially designed membrane construction prevents ambient air from entering the media chamber and thus supports stable processing of reactive media. The integrated snuffback effect ensures a clean cut-off during media application and reduces dripping.

All media-contacting components are made of stainless steel and PTFE and are designed for use with corrosive media. This contributes to low wear and stable valve operation.

The WMAV is optionally available with features such as piston position sensing, a pressure sensor and valve heating. These options extend the range of applications for different dosing tasks.

The WMAV therefore represents a compact valve solution for production environments in which reactive media must be dosed reliably and reproducibly.

WMAV – developed for reliable pressure-time-based dosing of reactive media

The clean and precise application of reactive media such as adhesives places high demands on dosing technology. With the membrane outlet valve WMAV, Walther Systemtechnik expands its valve portfolio with a solution designed for pressure-time-based dosing of such media.

The compact, pneumatically actuated valve can be integrated into production environments with limited installation space. The specially designed membrane construction prevents ambient air from entering the media chamber and thus supports stable processing of reactive media. The integrated snuffback effect ensures a clean cut-off during media application and reduces dripping.

All media-contacting components are made of stainless steel and PTFE and are designed for use with corrosive media. This contributes to low wear and stable valve operation.

The WMAV is optionally available with features such as piston position sensing, a pressure sensor and valve heating. These options extend the range of applications for different dosing tasks.

The WMAV therefore represents a compact valve solution for production environments in which reactive media must be dosed reliably and reproducibly.

Weitere Beiträge

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request