Lubrication of rolling bearings: Project completed ...

16 Jan 2024, 09:00:00

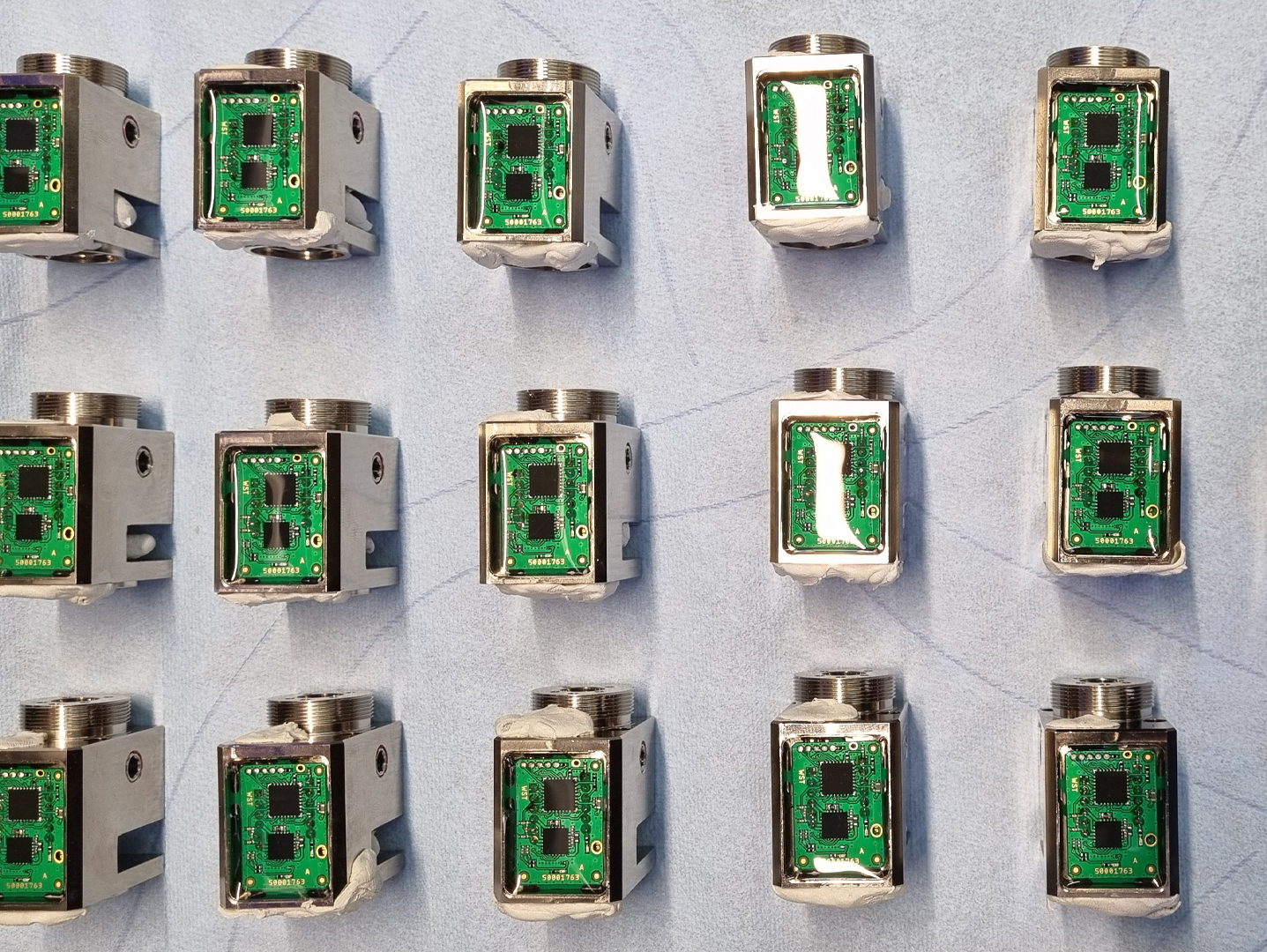

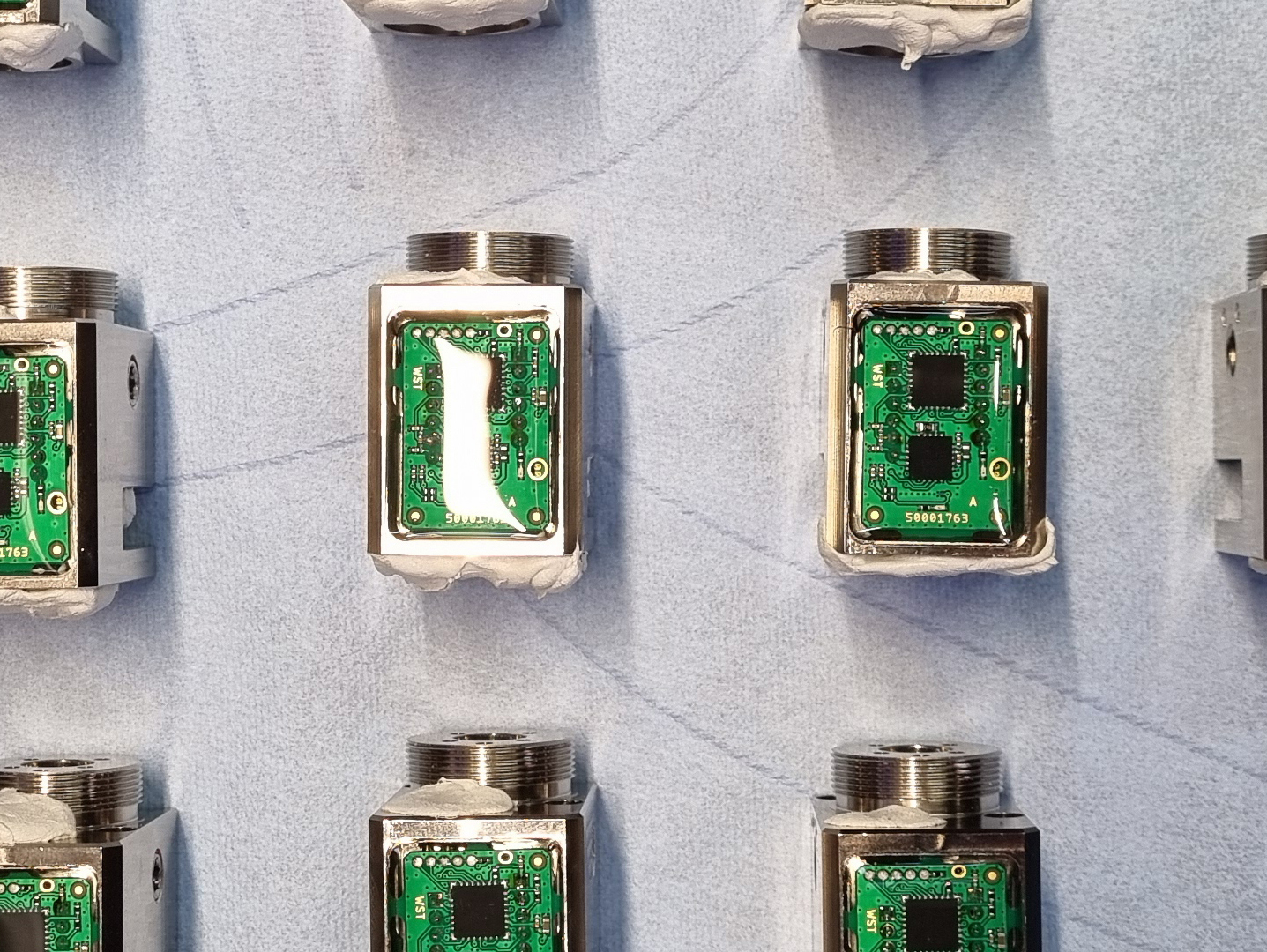

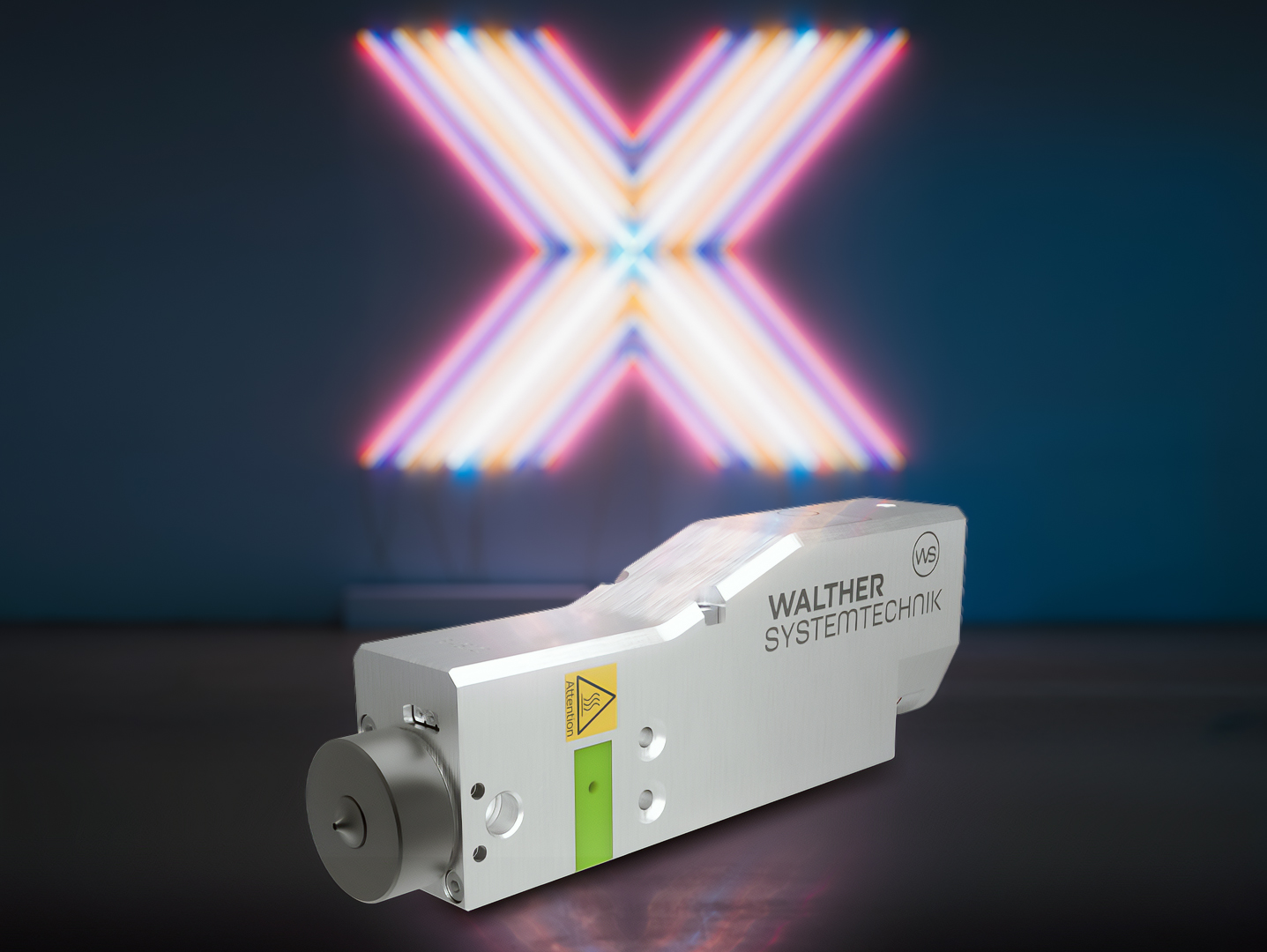

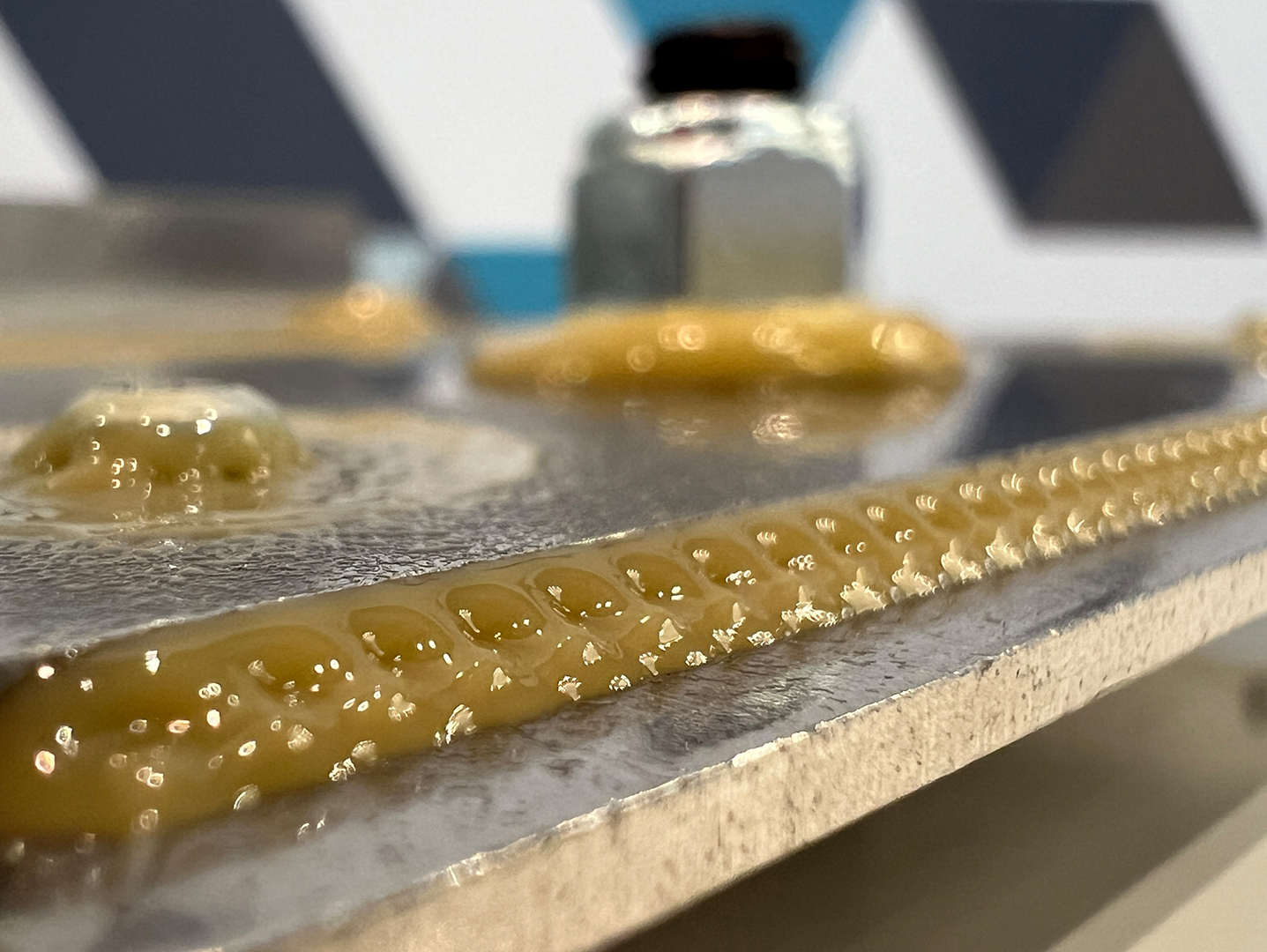

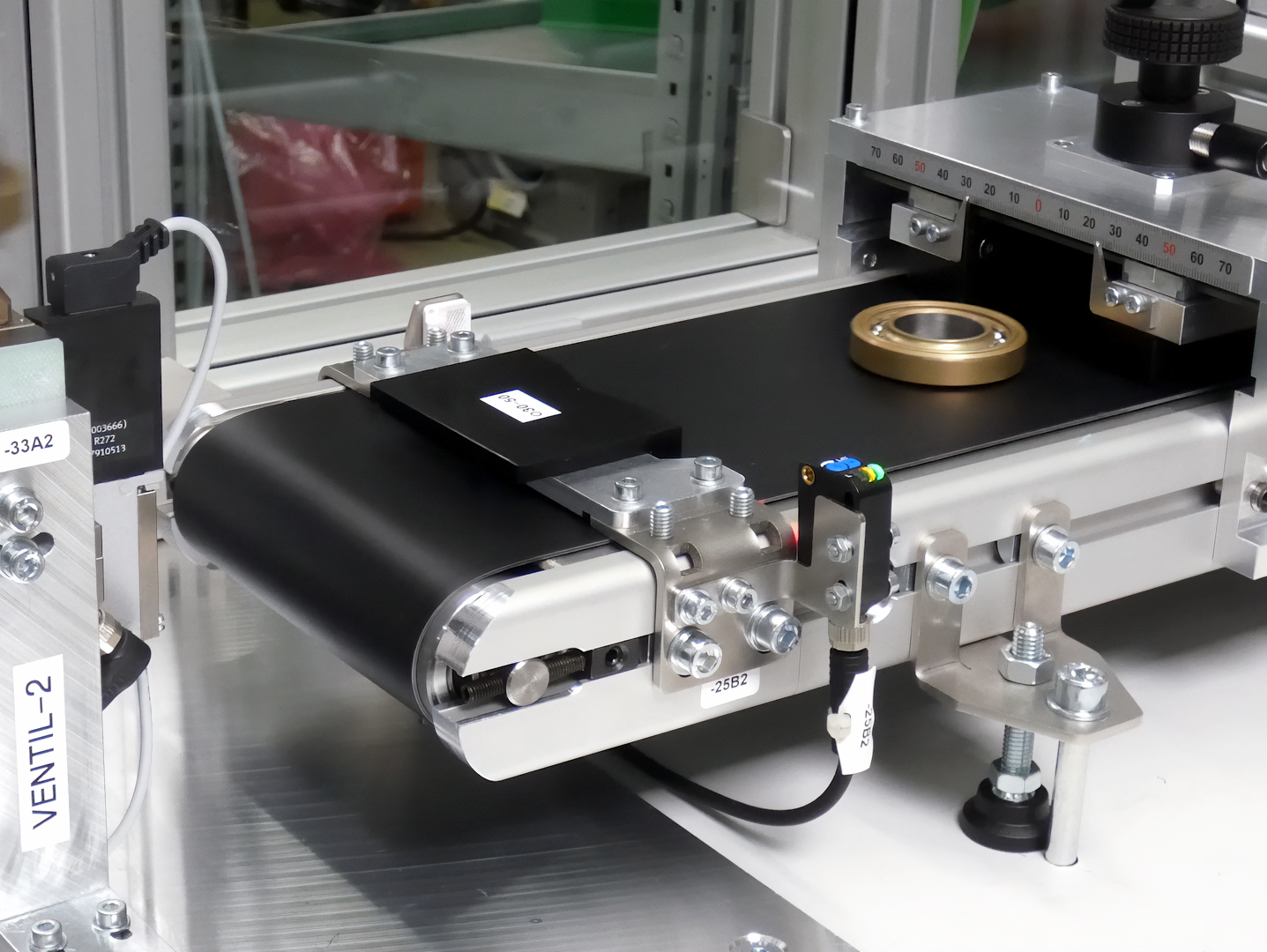

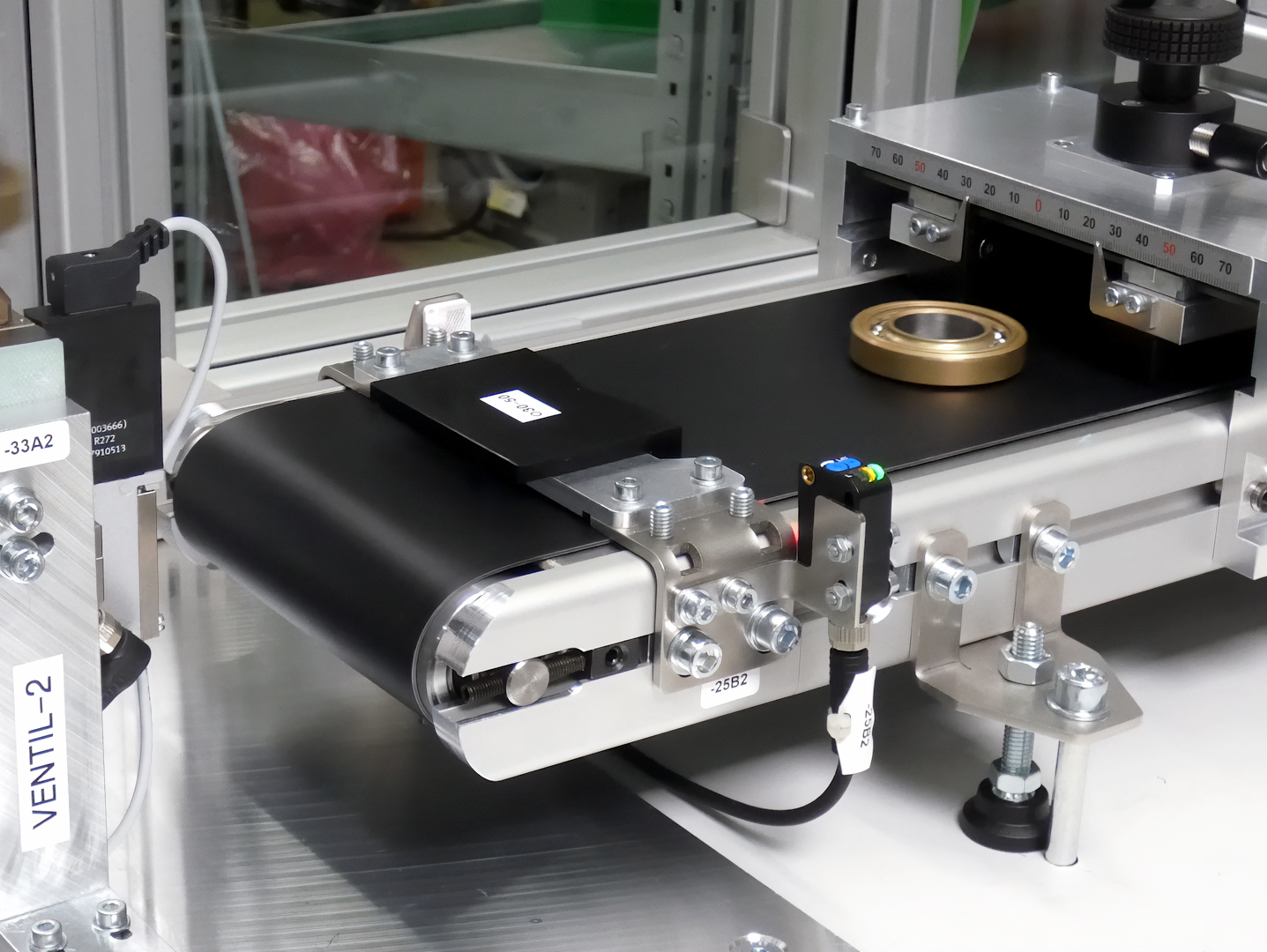

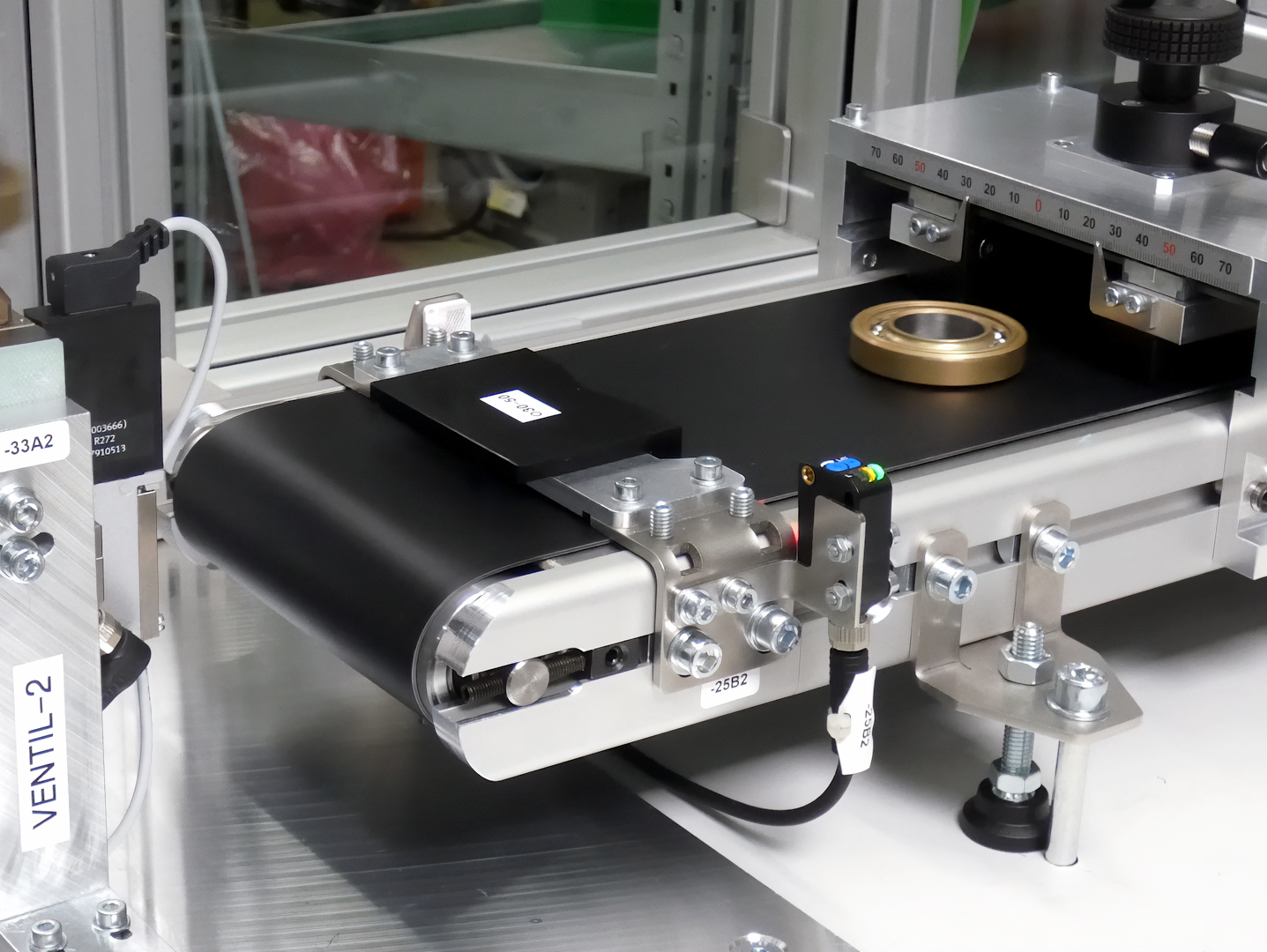

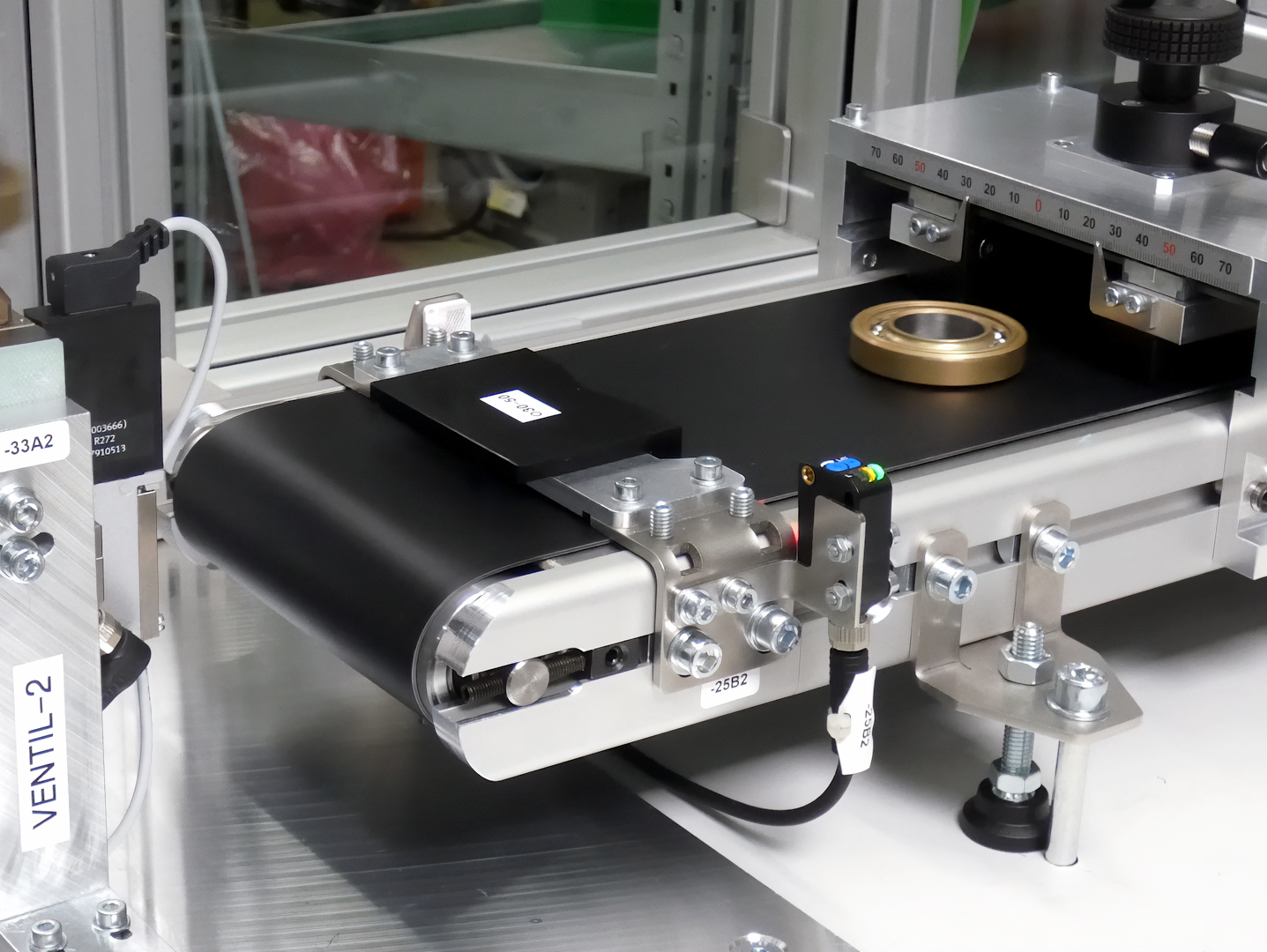

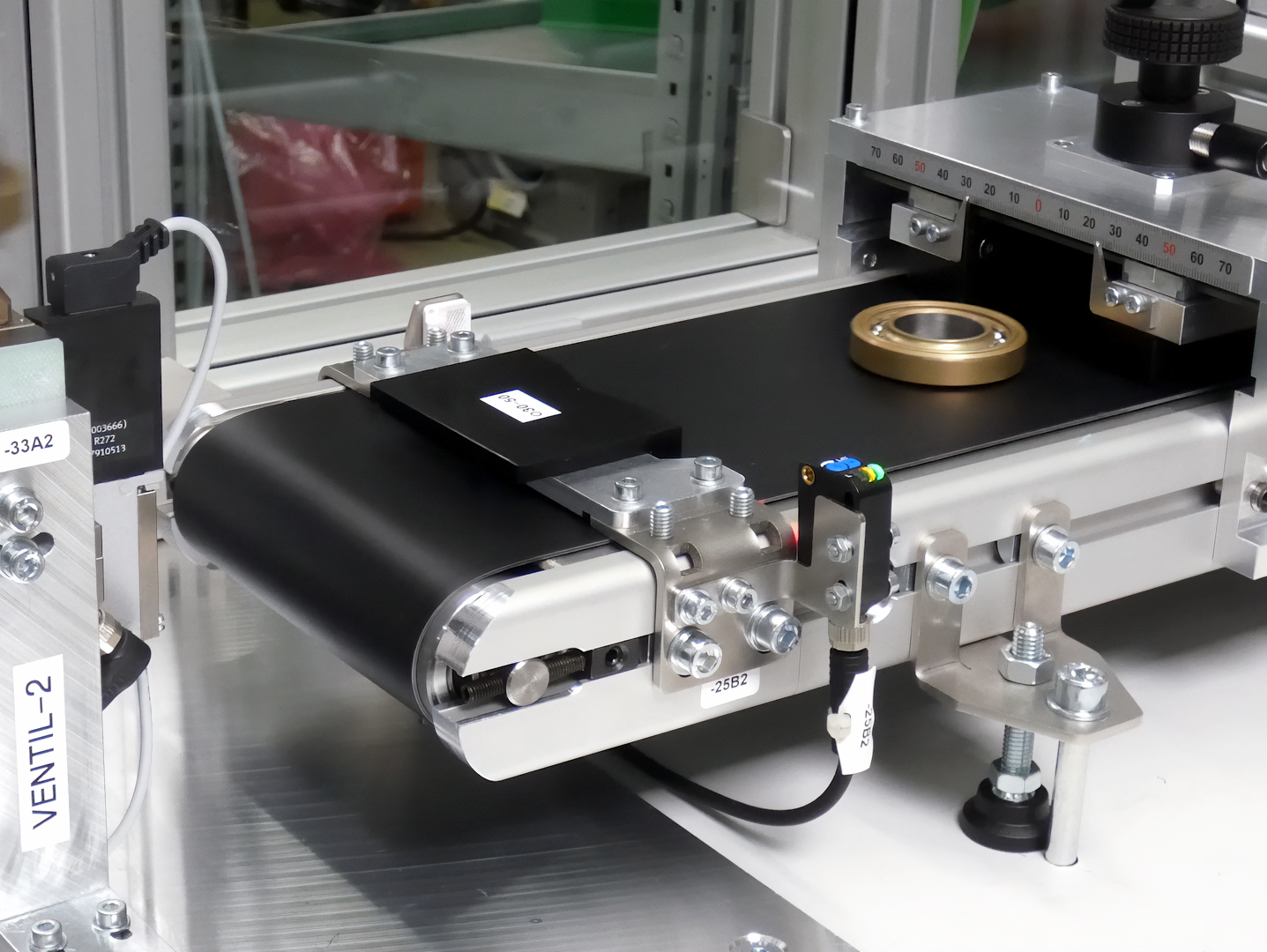

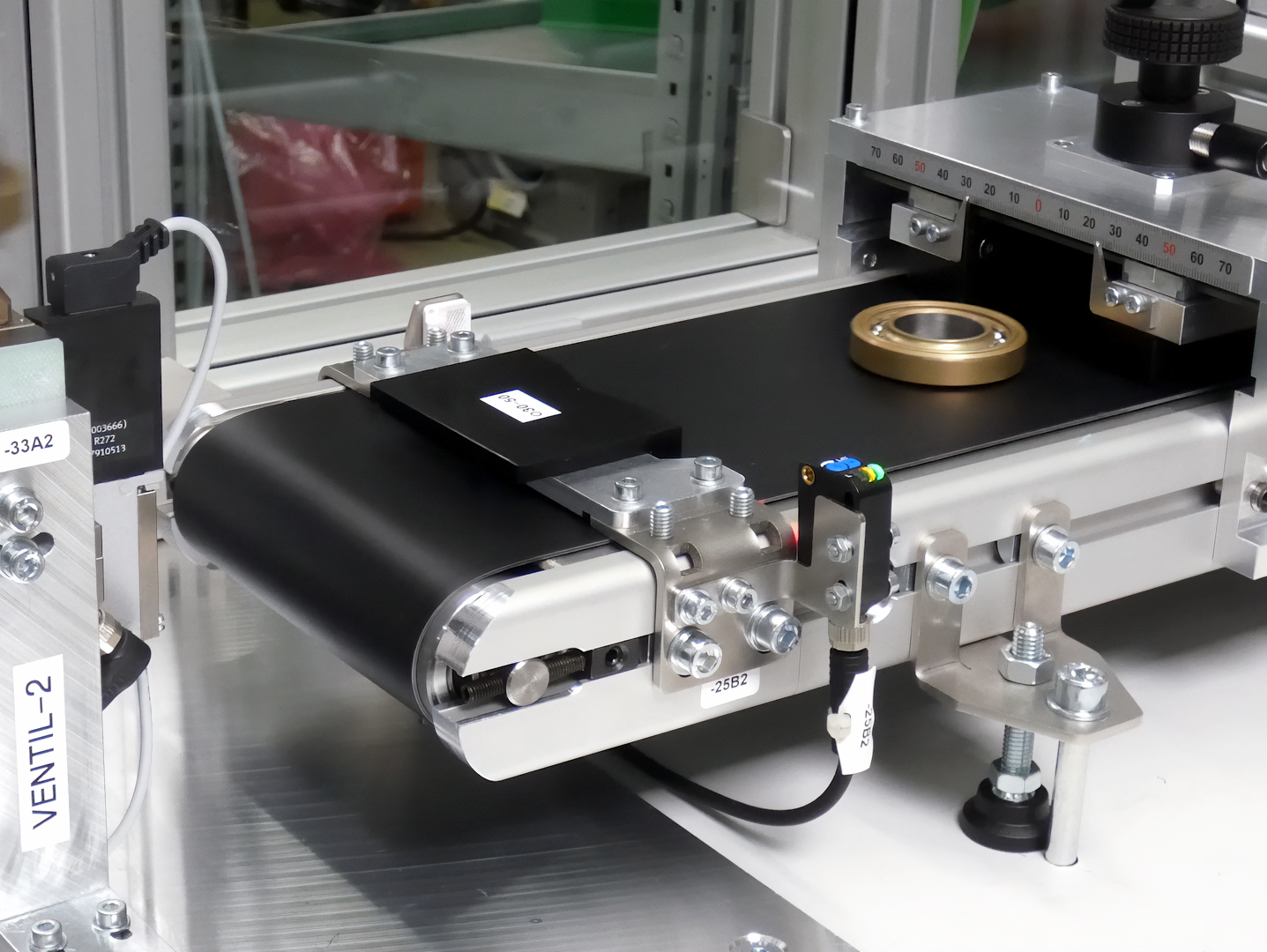

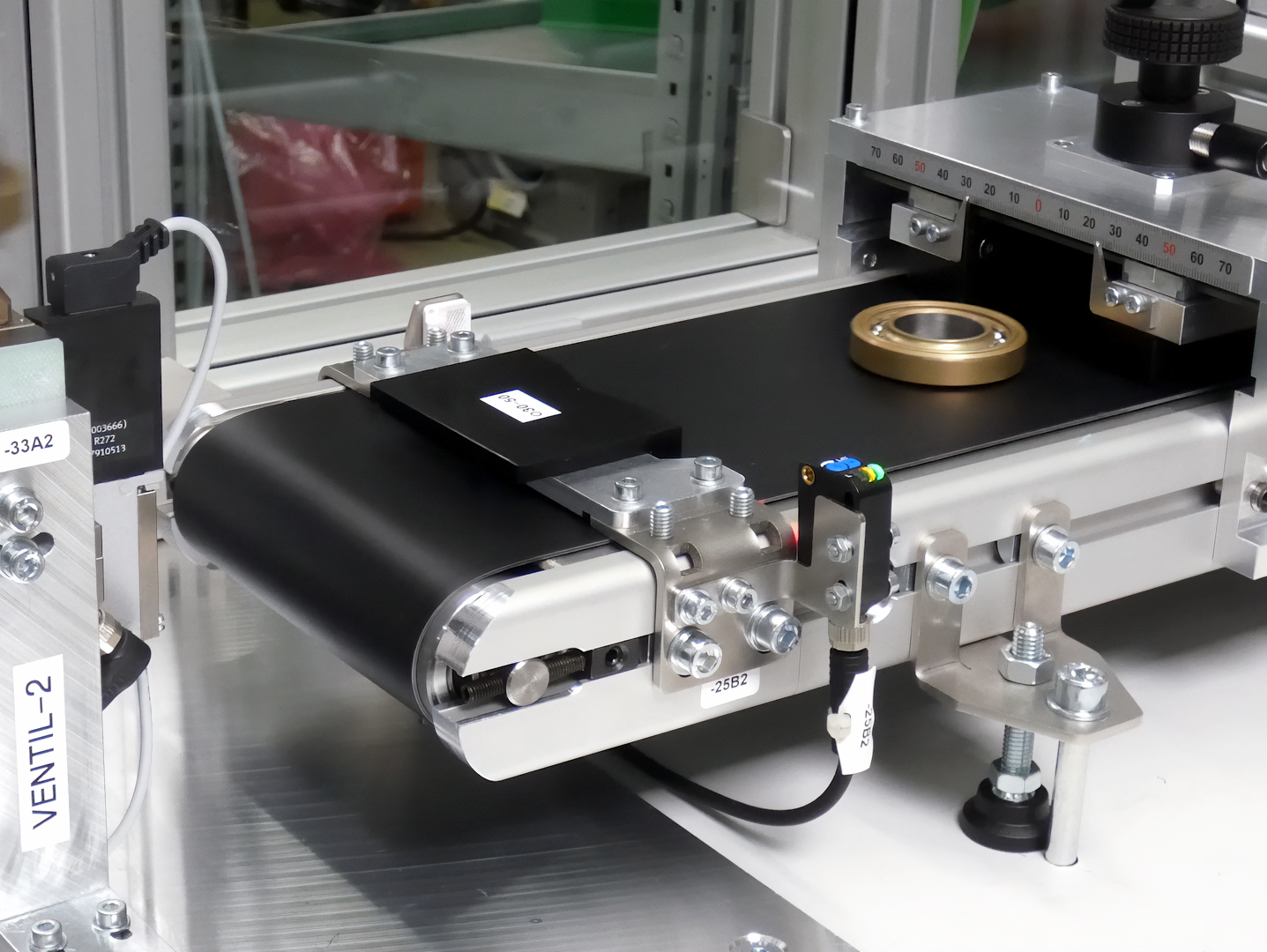

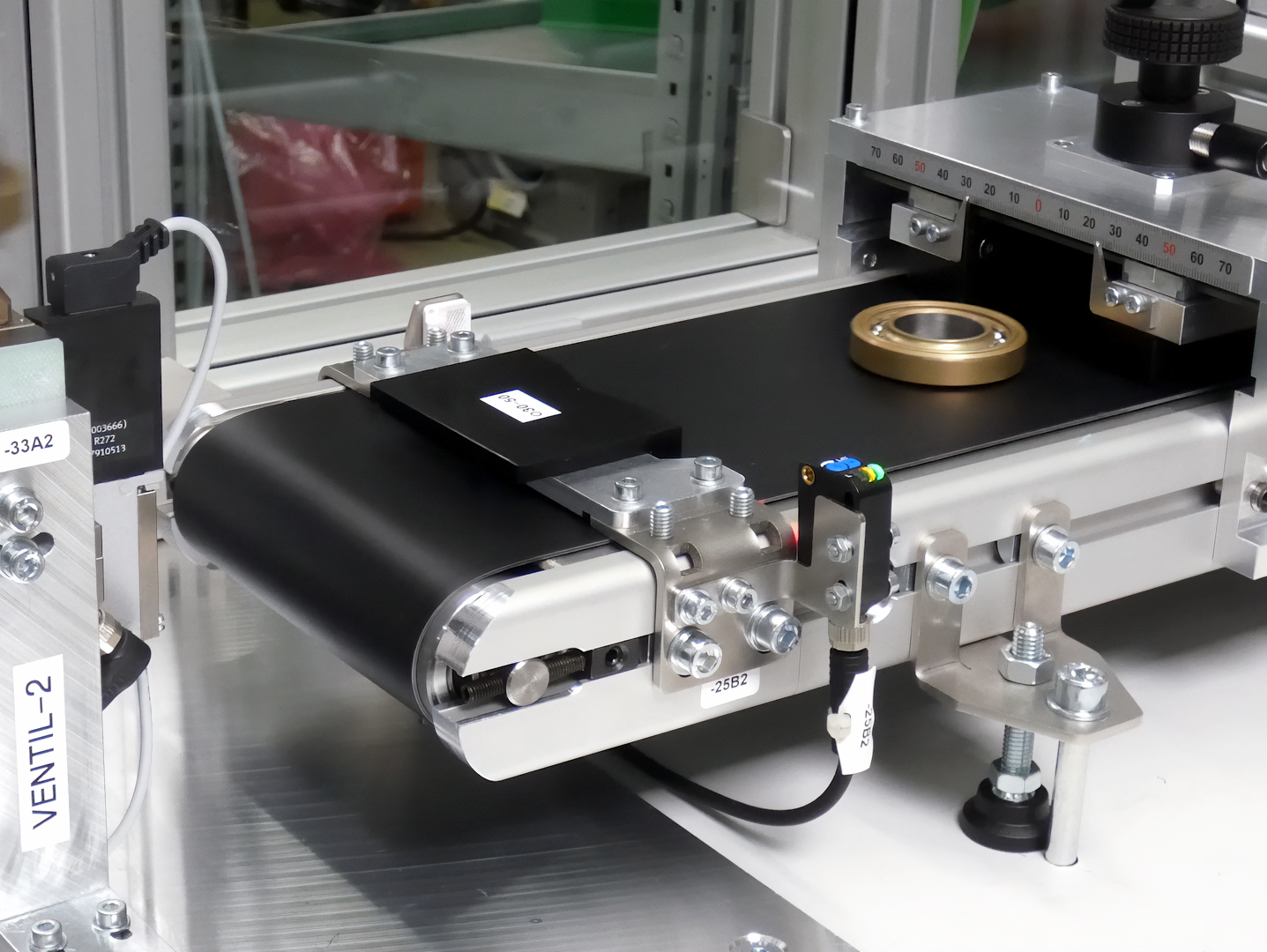

We have developed an advanced lubricant application system for rolling bearings that precisely addresses the challenges of component lubrication. Through the use of pulse valves, the system offers a pinpoint solution for component lubrication requirements, especially for small batch sizes with a high number of variants. It has been designed to enable fast and efficient adaptation to different production needs in bearing manufacturing by integrating automation, low set-up effort, recipe management and process control.

- Flexibility and adaptability: The system allows quick adaptation to different bearing dimensions and types by simply changing the gripper jaws.

- Automated processes: The manual insertion of the rolling bearings is supplemented by a fully automated process that includes component pick-up, alignment and lubricant application on one or both sides, as well as component removal. This ensures consistently high quality and reproducibility.

- Recipe management: The ability to store and recall lubricant recipes and application programmes specific to different bearing types not only improves production efficiency, but also ensures that each bearing type is treated according to its particular requirements.

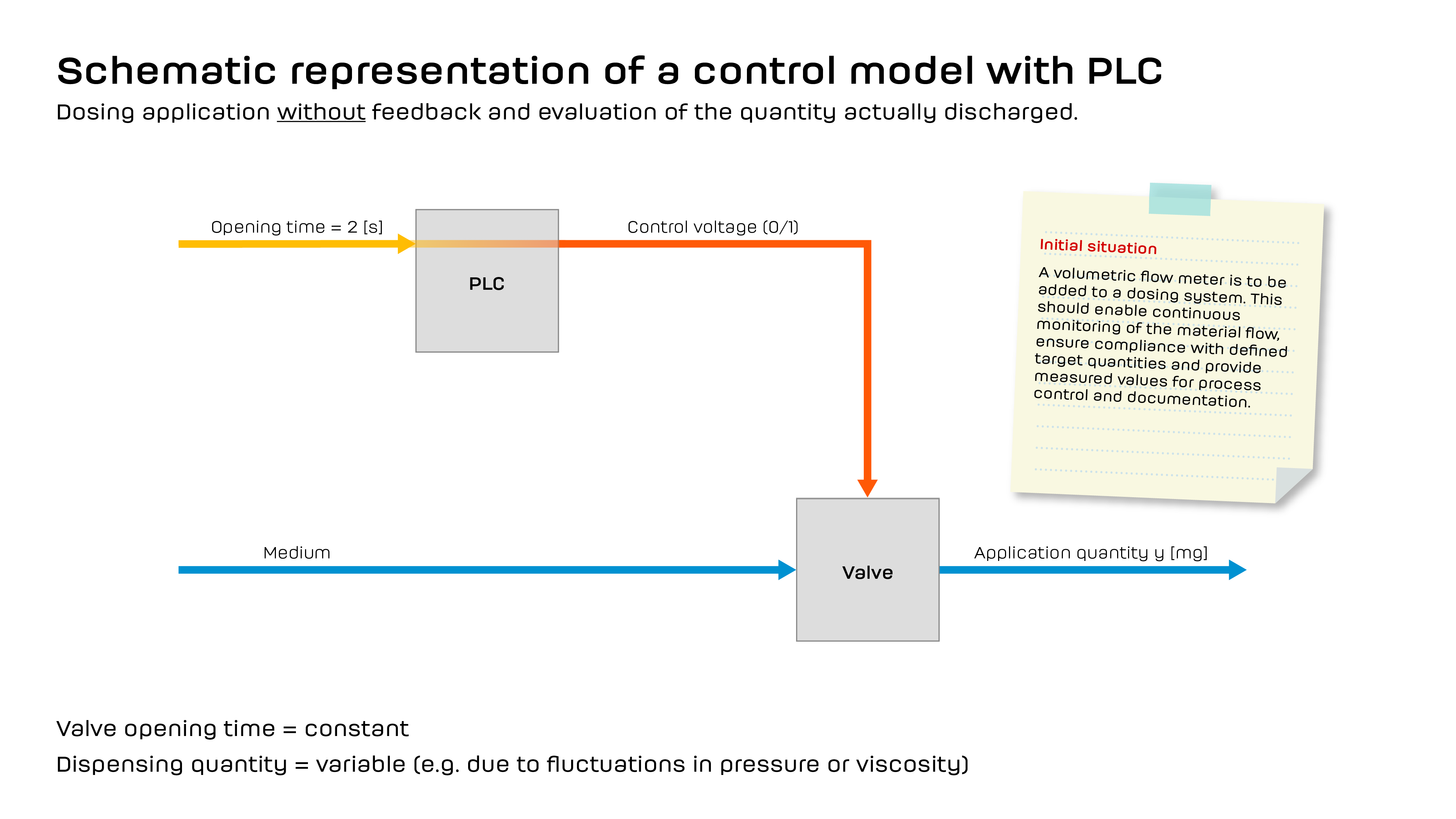

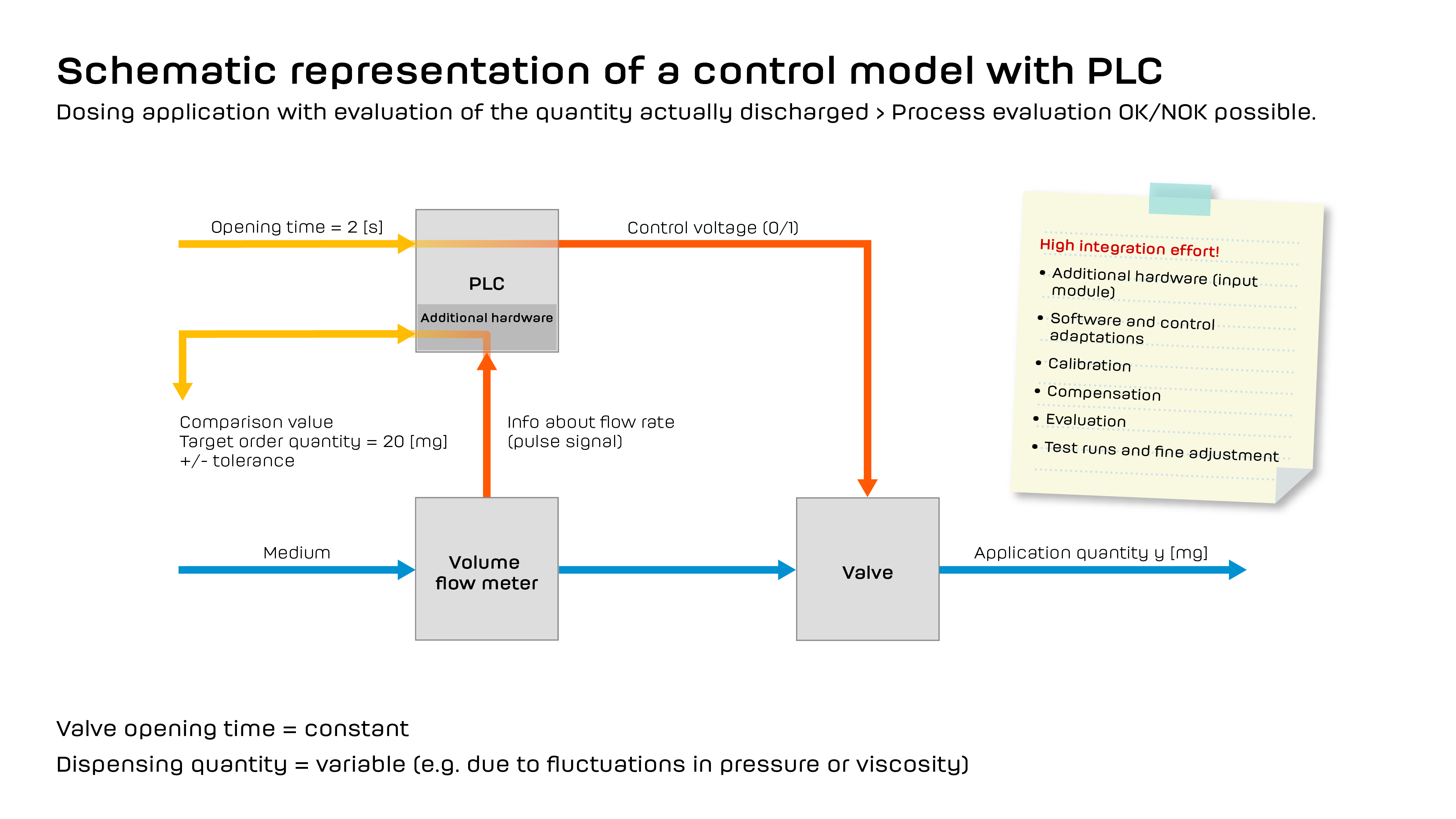

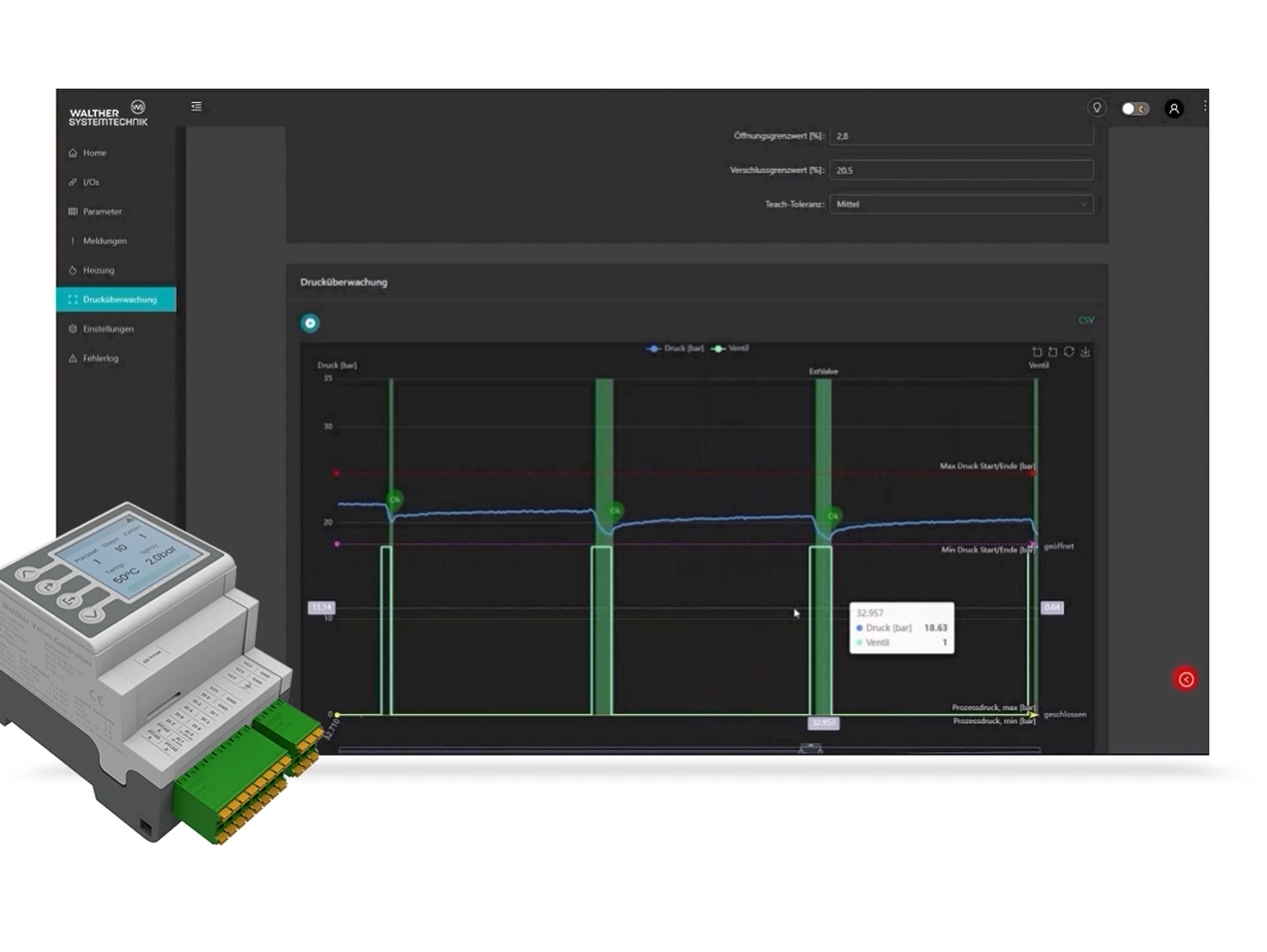

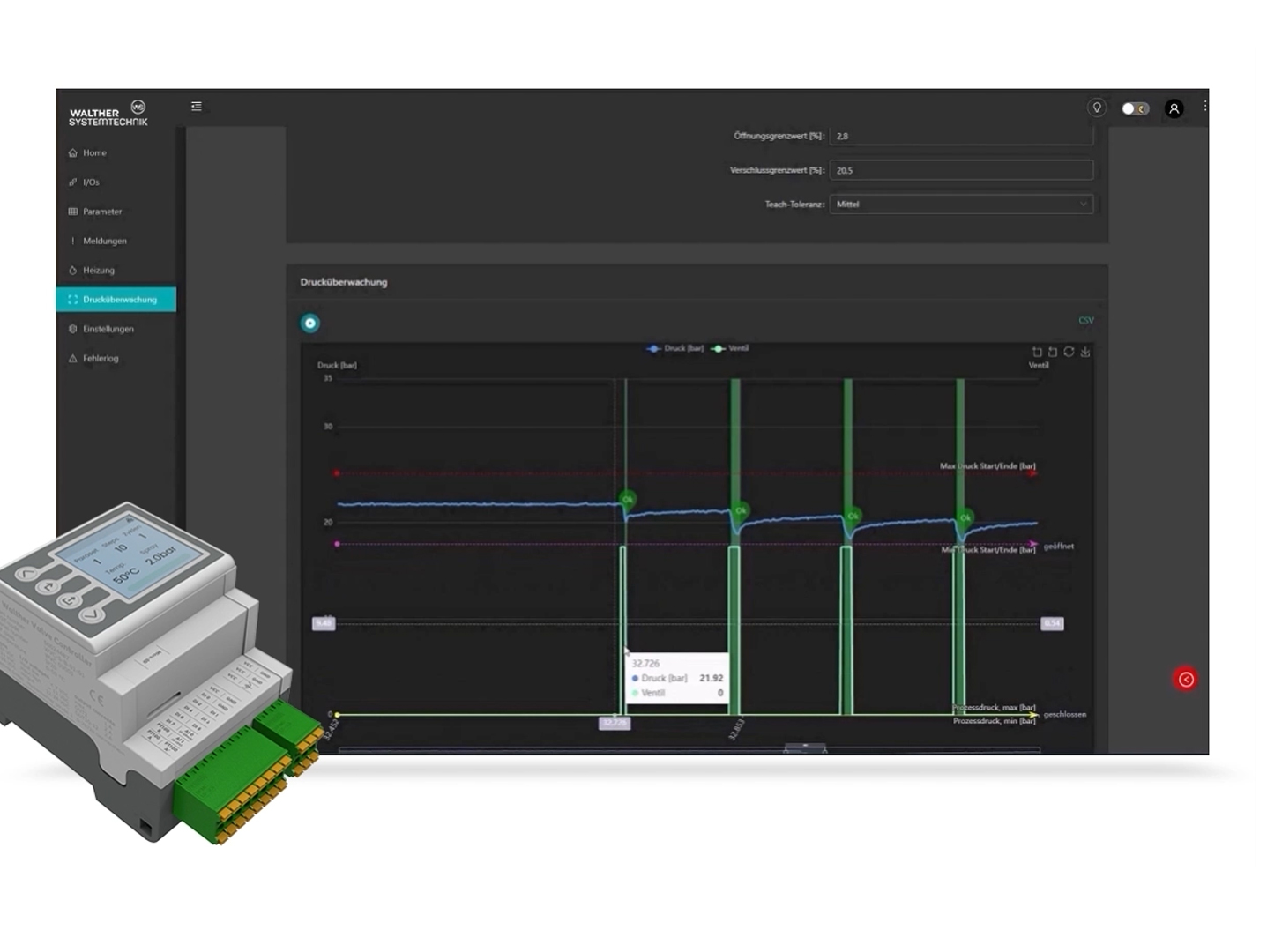

- Process control: Integrated monitoring functions monitor and ensure precise lubricant application, ensuring accurate dosing and high process reliability.

Lubrication of rolling bearings: Project completed ...

We have developed an advanced lubricant application system for rolling bearings that precisely addresses the challenges of component lubrication. Through the use of pulse valves, the system offers a pinpoint solution for component lubrication requirements, especially for small batch sizes with a high number of variants. It has been designed to enable fast and efficient adaptation to different production needs in bearing manufacturing by integrating automation, low set-up effort, recipe management and process control.

- Flexibility and adaptability: The system allows quick adaptation to different bearing dimensions and types by simply changing the gripper jaws.

- Automated processes: The manual insertion of the rolling bearings is supplemented by a fully automated process that includes component pick-up, alignment and lubricant application on one or both sides, as well as component removal. This ensures consistently high quality and reproducibility.

- Recipe management: The ability to store and recall lubricant recipes and application programmes specific to different bearing types not only improves production efficiency, but also ensures that each bearing type is treated according to its particular requirements.

- Process control: Integrated monitoring functions monitor and ensure precise lubricant application, ensuring accurate dosing and high process reliability.

Weitere Beiträge

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request