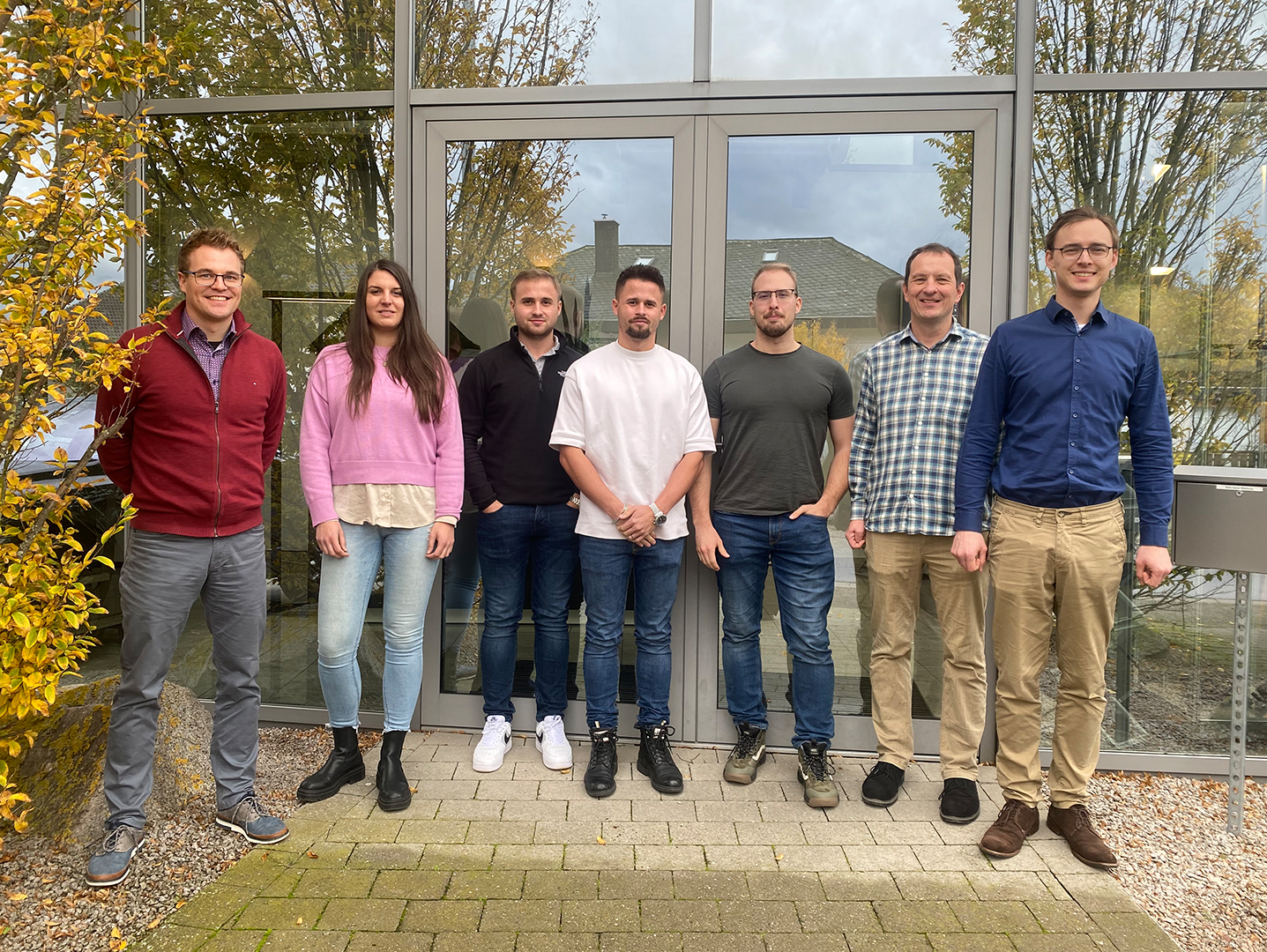

From Action to Relaxation: A Day of Team Spirit for Project Management and Engineering!

Instead of planning and designing dosing systems, the colleagues from Project Management and Engineering enjoyed a day filled with action, relaxation, and indulgence. The team experienced an unforgettable team event that brought their cohesion to a whole new level. The day kicked off with an exciting paintball competition, where not only tactical skills and communication abilities were put to the test, but also the participants' sportsmanship.

After the action, a relaxing wagon ride through the picturesque Palatinate countryside followed, offering plenty of time for conversation, shared laughter, and appreciation of the beautiful scenery. The event concluded at a local winery, where the team reminisced about the day's experiences over fresh grape juice and delicious finger food, recharging for the challenges ahead.

A heartfelt thank you goes out to everyone who organized and participated in this event. Such shared experiences strengthen team spirit and prepare us well for future tasks!

From Action to Relaxation: A Day of Team Spirit for Project Management and Engineering!

Instead of planning and designing dosing systems, the colleagues from Project Management and Engineering enjoyed a day filled with action, relaxation, and indulgence. The team experienced an unforgettable team event that brought their cohesion to a whole new level. The day kicked off with an exciting paintball competition, where not only tactical skills and communication abilities were put to the test, but also the participants' sportsmanship.

After the action, a relaxing wagon ride through the picturesque Palatinate countryside followed, offering plenty of time for conversation, shared laughter, and appreciation of the beautiful scenery. The event concluded at a local winery, where the team reminisced about the day's experiences over fresh grape juice and delicious finger food, recharging for the challenges ahead.

A heartfelt thank you goes out to everyone who organized and participated in this event. Such shared experiences strengthen team spirit and prepare us well for future tasks!

Weitere Beiträge

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request