Pump System WPS PROFESSIONAL

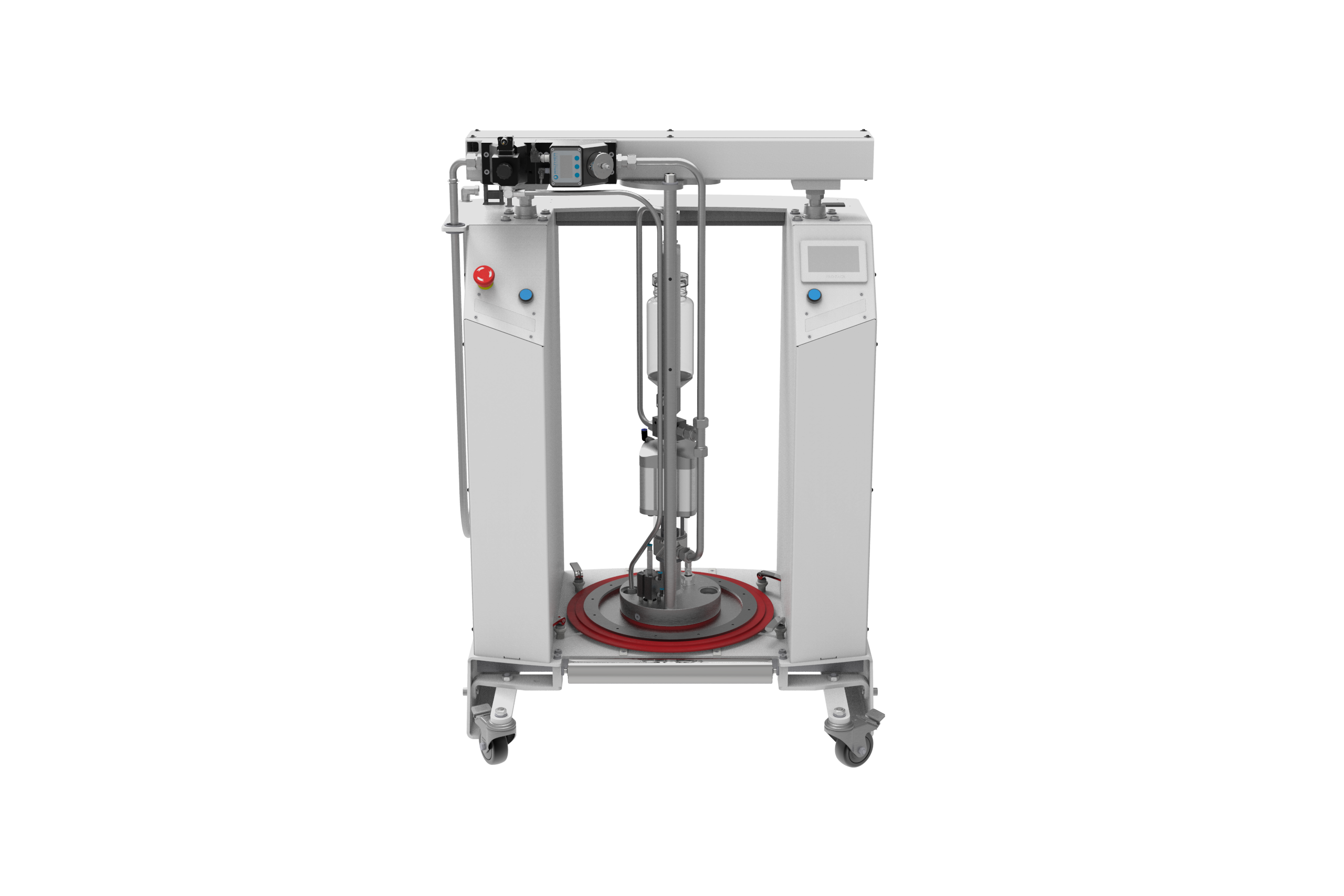

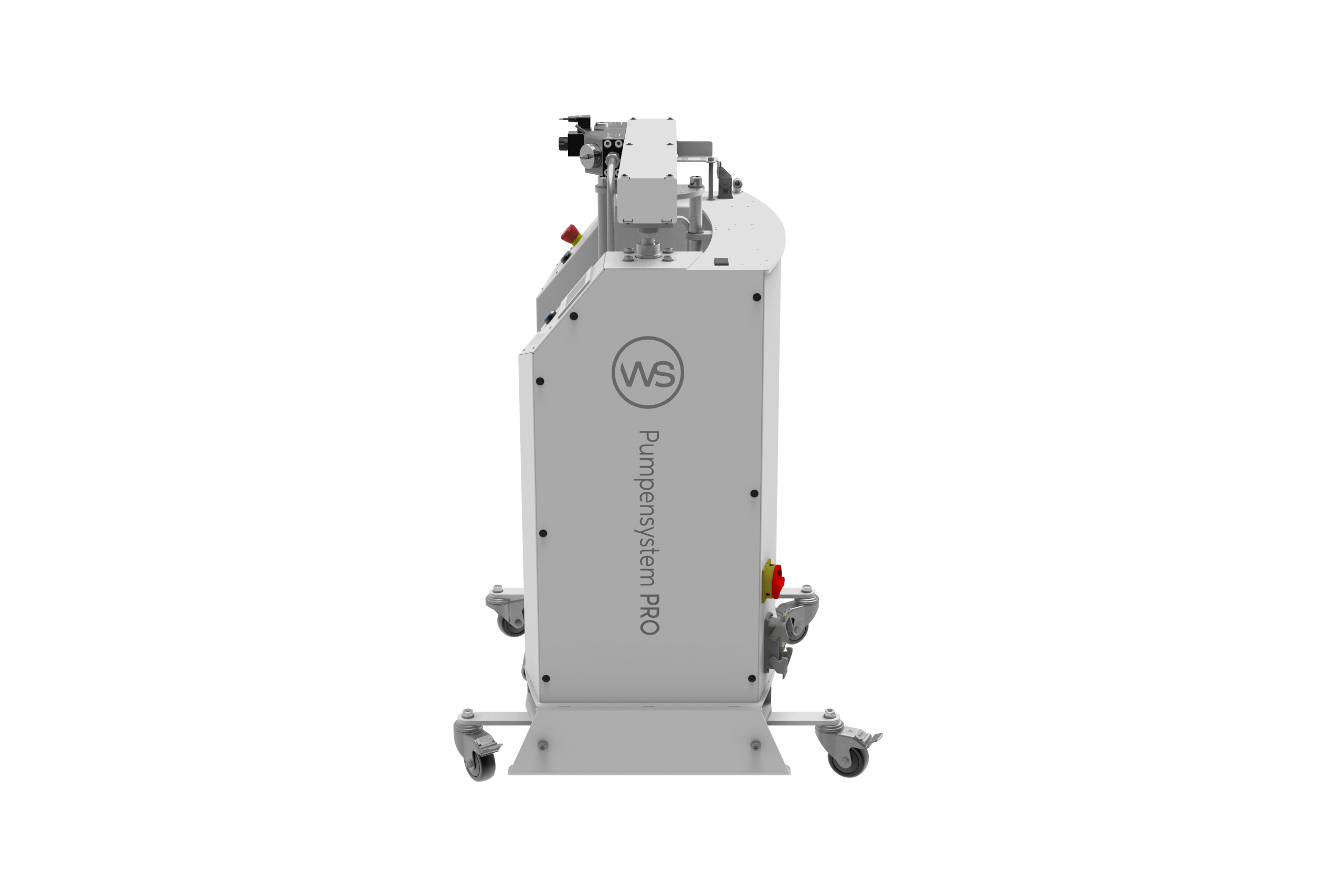

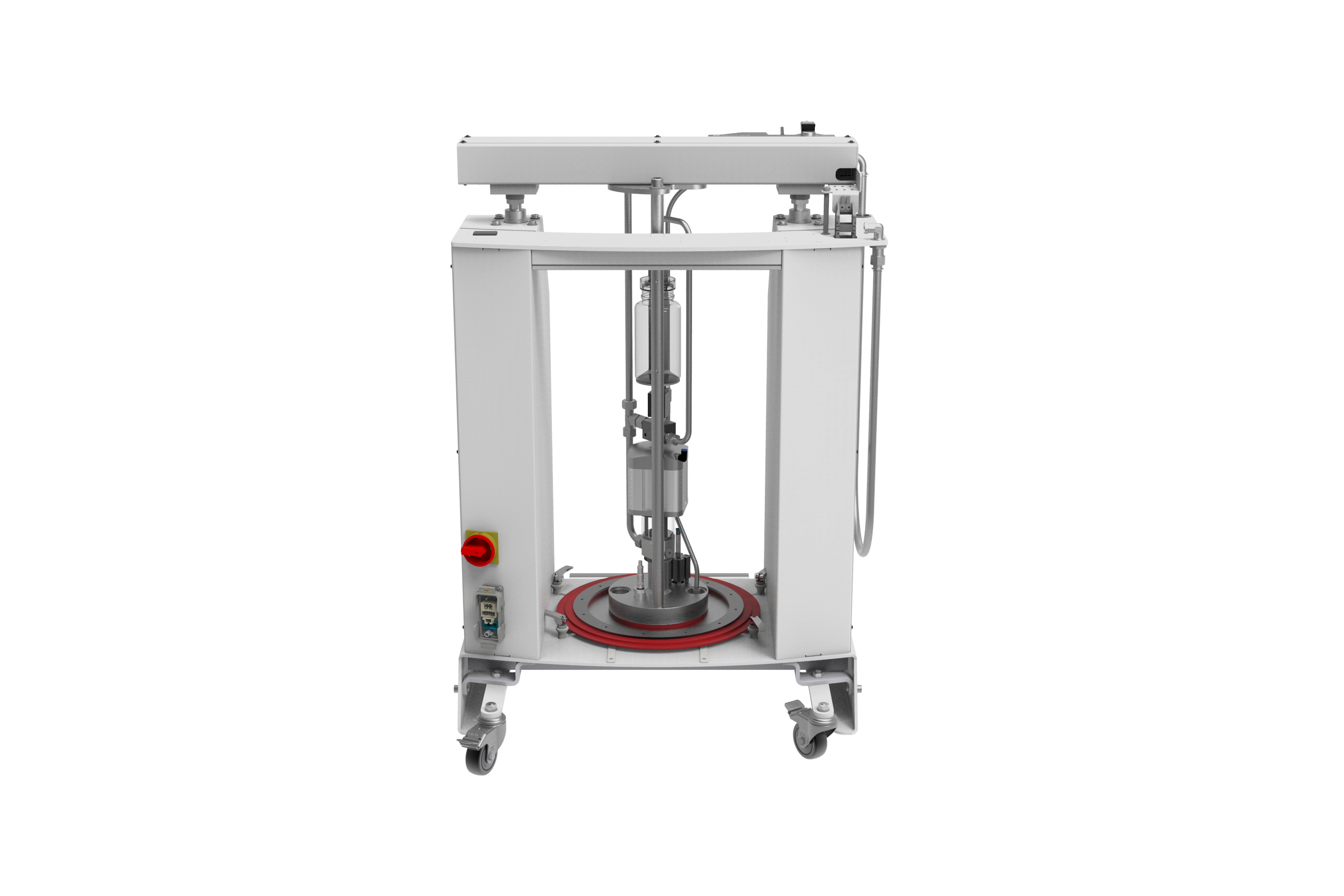

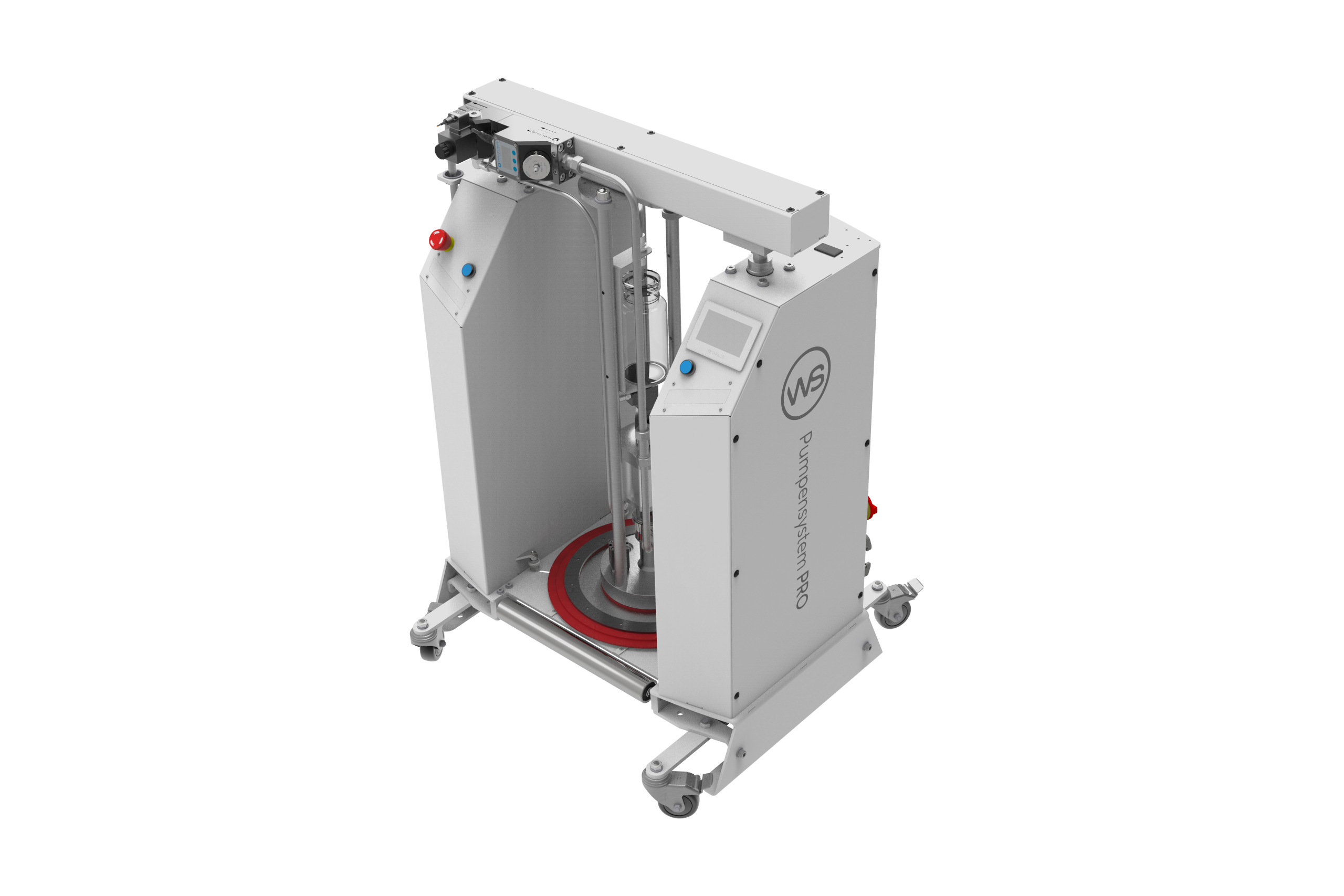

With WPS Professional, the conveying of medium- to high-viscosity materials directly from the original container becomes easier and more process-reliable than ever before. This robust pump system stands out for its high efficiency, durable construction, intuitive operation, and service-friendly maintenance. It provides a reliable foundation for consistent and precise material supply and is designed for continuous industrial use in automated production processes.

The system is operated via an integrated touch panel with a symbol-guided user interface, along with a two-hand control function for safety-critical operations. A guided container change wizard supports the operator step by step throughout the changeover process – including automated venting and automatic retraction of the follower plate from the container. This reduces the risk of operating errors and shortens restart times after a change.

Adjustable follower plate pressure ensures that the material is fed to the pump inlet under uniform pressure – even with highly viscous greases or pasty compounds. This prevents air pockets and improves suction performance, especially with contoured or conical containers featuring indentations or varying diameters. The material is conveyed gently and evenly. Thanks to the form-fitting follower plate guidance, nearly complete emptying of the container is possible.

Comprehensive process monitoring: A continuous fill level monitoring system tracks the media level in the container and automatically stops the pumping process once the minimum level is reached. This reliably prevents air intake and the resulting system downtime, complex venting procedures, and material losses. Warnings are issued via the touch display (visual), an optional acoustic signal, and an LED indicator on the system. In addition, the contamination level of the integrated filter system is continuously monitored and displayed.

Connected functionality: WPS Professional features an integrated bus system (Modbus TCP) for seamless integration into higher-level control architectures. Digital input and output interfaces allow straightforward communication with existing automation environments. All process parameters – including material pressure, follower plate pressure, container level, operating hours, and cycle count – are available for remote visualization and diagnostics. Three freely configurable digital alarm outputs enable targeted monitoring of system states and threshold violations.

Design and serviceability: The pump system is available in two sizes for containers ranging from 14 to 180 liters. The mobile version features castors for flexible on-site use. The system is designed to allow optional functions such as an external emergency stop for safety-related shutdown of connected components, a container scanner for process data transfer via QR code, and an acoustic empty-container alarm to be integrated as needed. At the same time, all key components are easily accessible for maintenance.

Note: For applications involving filled, sedimentation-prone or phase-separating media, the WPS Pro pump system with integrated homogenisation function is available >>

- operation through HMI with clear pictograms

- automated container replacement-wizard guides the worker step by step

- automated venting after container replacement

- continuous monitoring of contamination status of integrated filter system

- BUS system for an operation with superordinate control units

- freely configurable, digital alarm outlets

- continuous monitoring and providing of different process parameter (pressure, filling level, operation time, follower plate pressure)

- expandible by various options

- process pressure: max 150 [bar]

- supplied volume: max. 1500 [cm³/min]

- pneumatic inlet pressure: max.6 [bar]

- follower plate pressure: max. 6 [bar]

- container sizes: 14 to 180 [l]

- container outside diameter:

>> size 3: max. 585 [mm]

- container height:

>> size 3: max. 930 [mm]

- dimensions (w x d) - mobile version:

>> size 3: 1,032 x 700 [mm]

- height - mobile version:

>> size 3: min. 1,440 - max. 2,390 [mm]