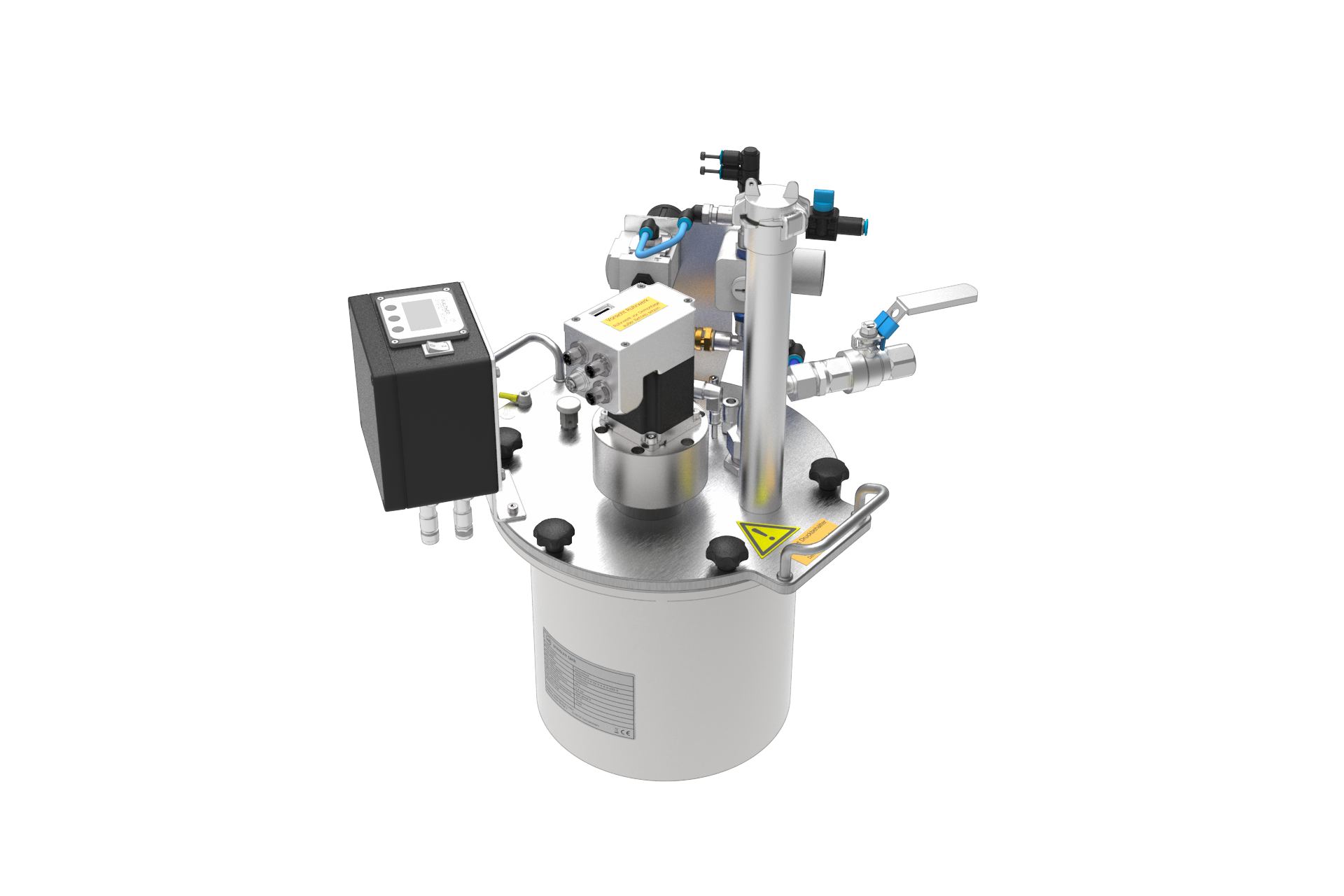

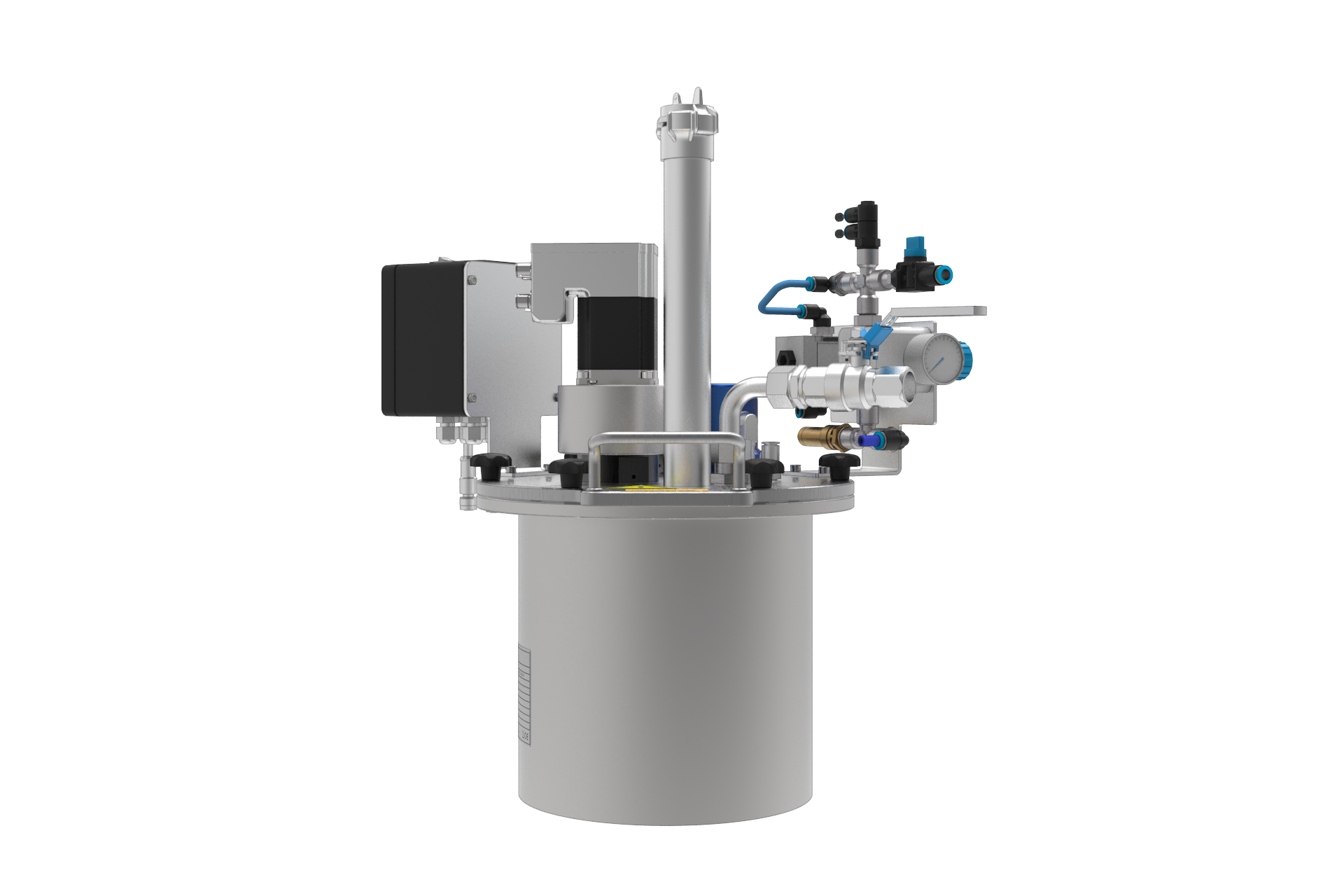

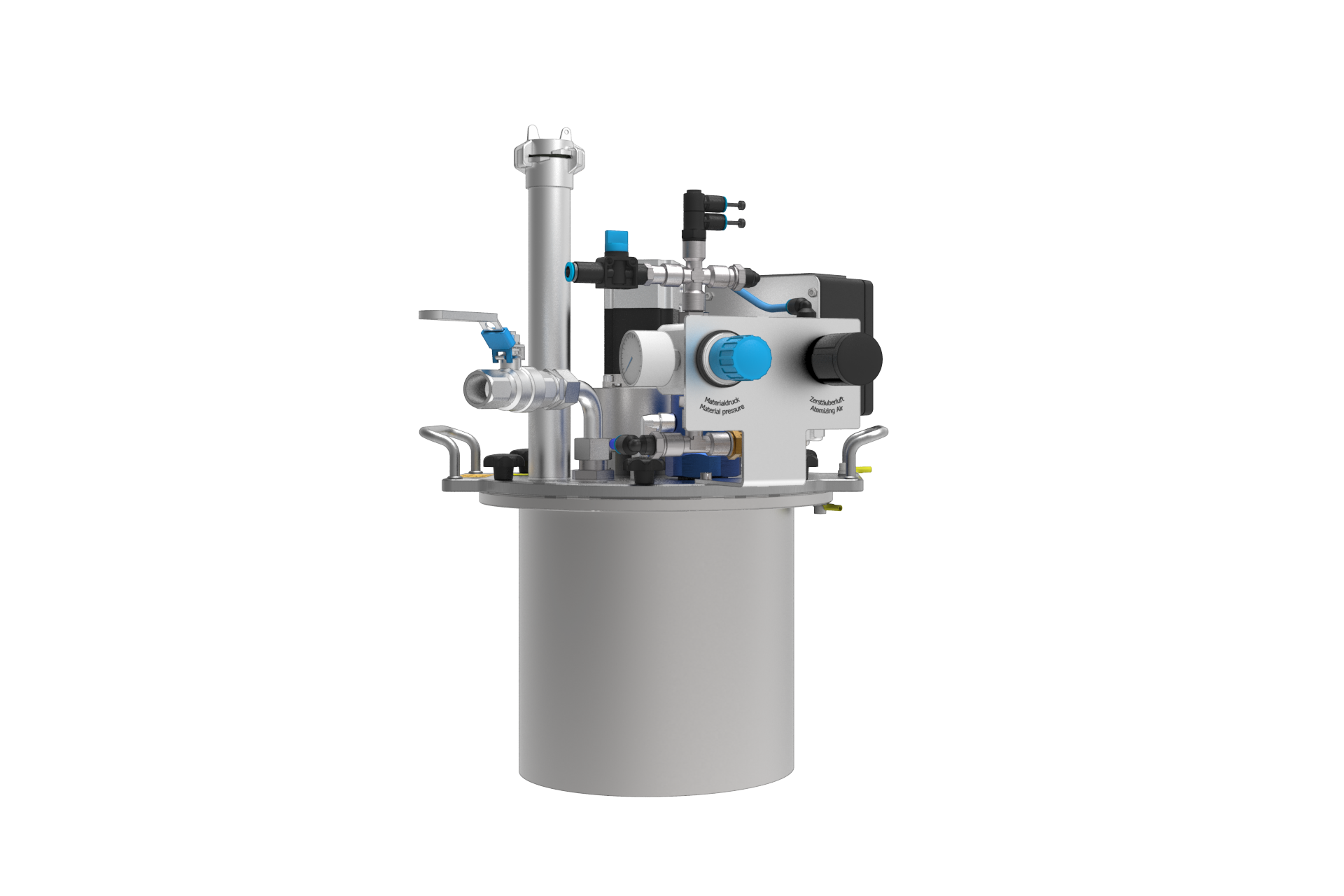

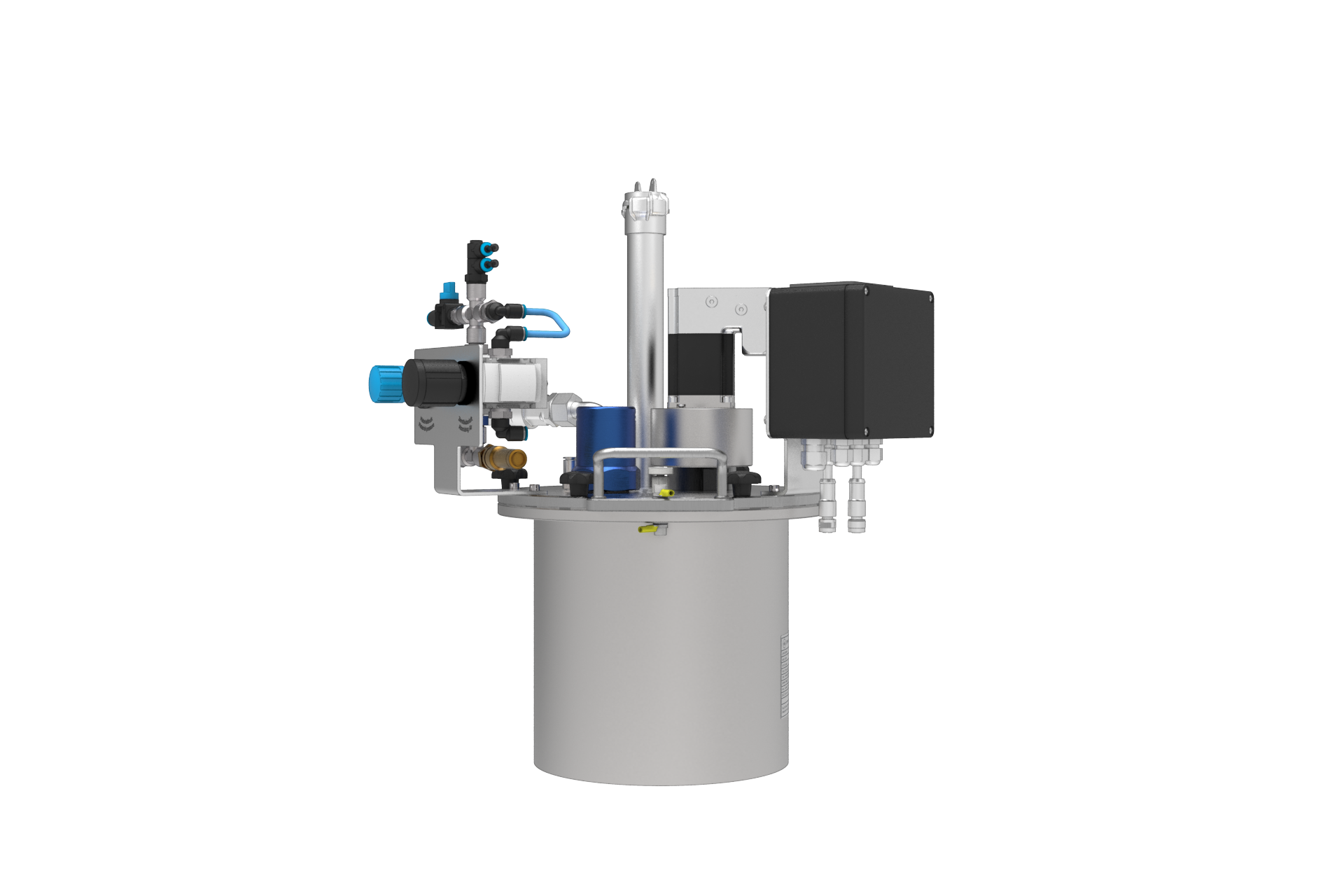

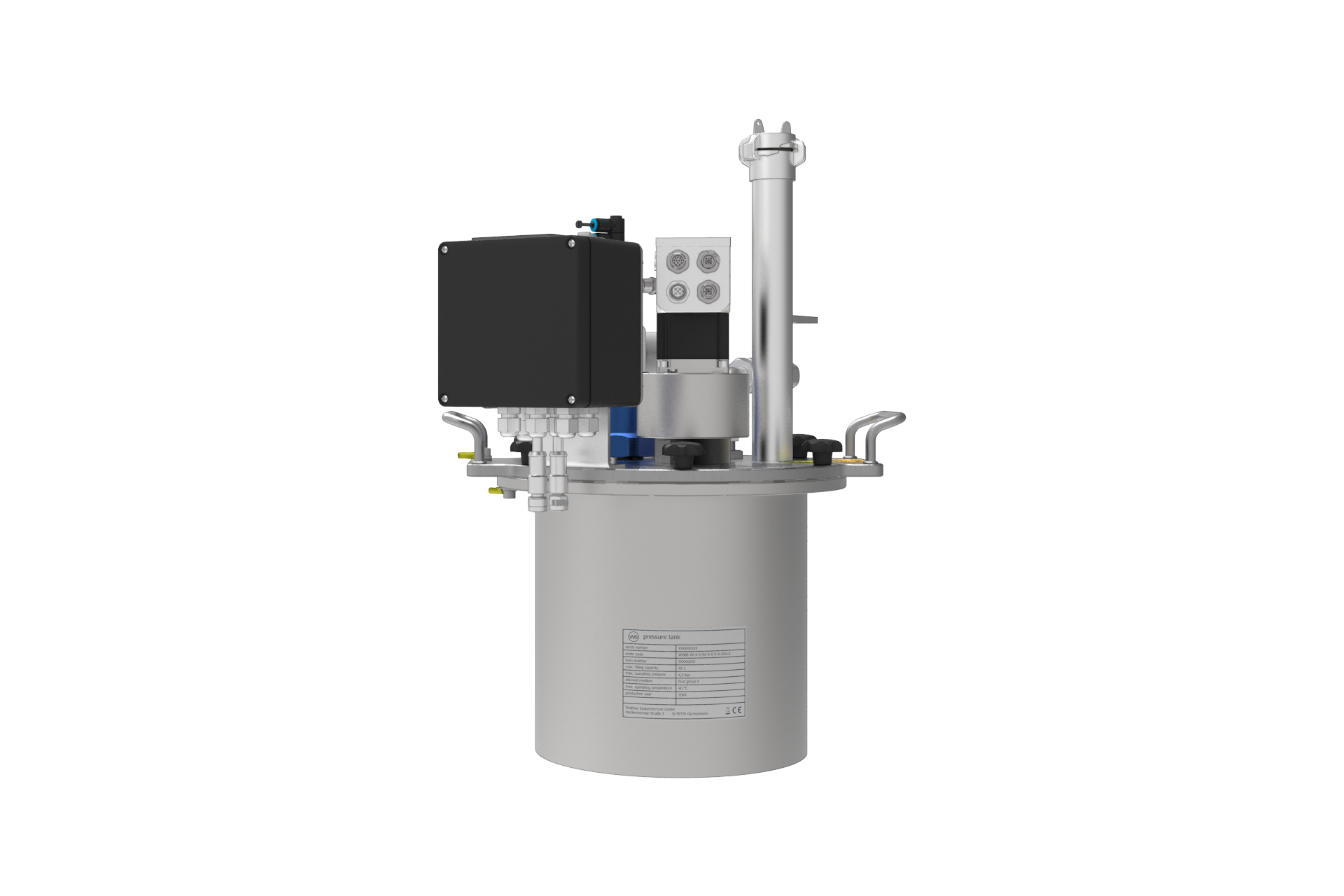

Presssure Container System WDBS

The Walther Pressure Container System WDBS is the state-of-the-art solution for the provision and pulsation-free supplying of low to medium viscous media, such as paints, lacquers, oils, fluxing agents, primers etc.

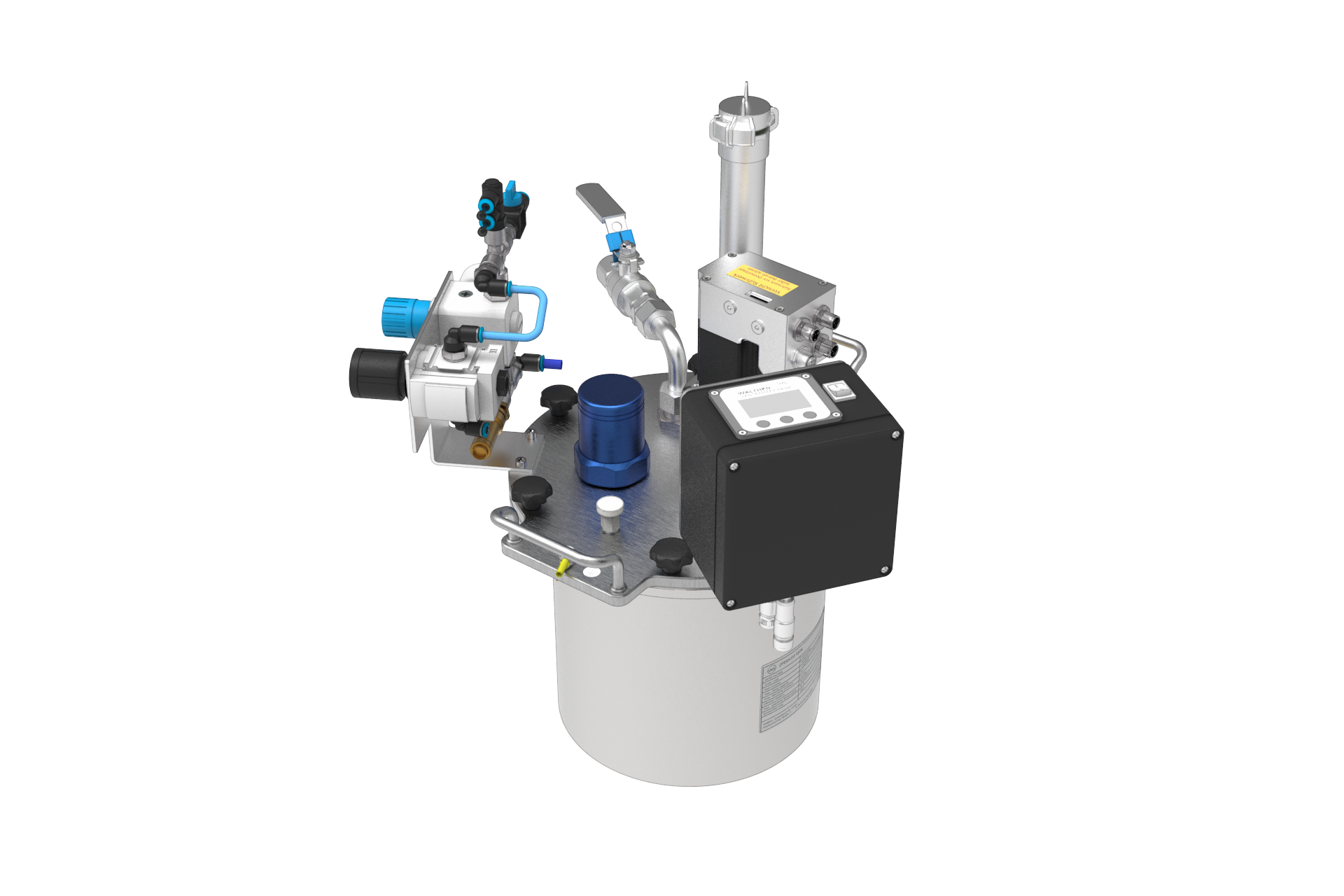

By means of compressed air, the supplied medium will be pressurized in the pressure container. From there, it will flow pneumatically via a riser pipe or riser hose to the medium outlet which is secured by a check valve (optional). The WDBS can function as a supply system for 1K- and 2K-dosing systems, or as an autonomous system together with dosing, outlet, or spray valves.

An integrated control unit will be used for selecting the stirrer mode and monitoring the filling level, as well as directly controlling a process valve. The control unit offers various setting options for the stirrer and the valve and communicates status messages for the filling level sensor, the stirrer, and the valve via DIOs and fieldbus.

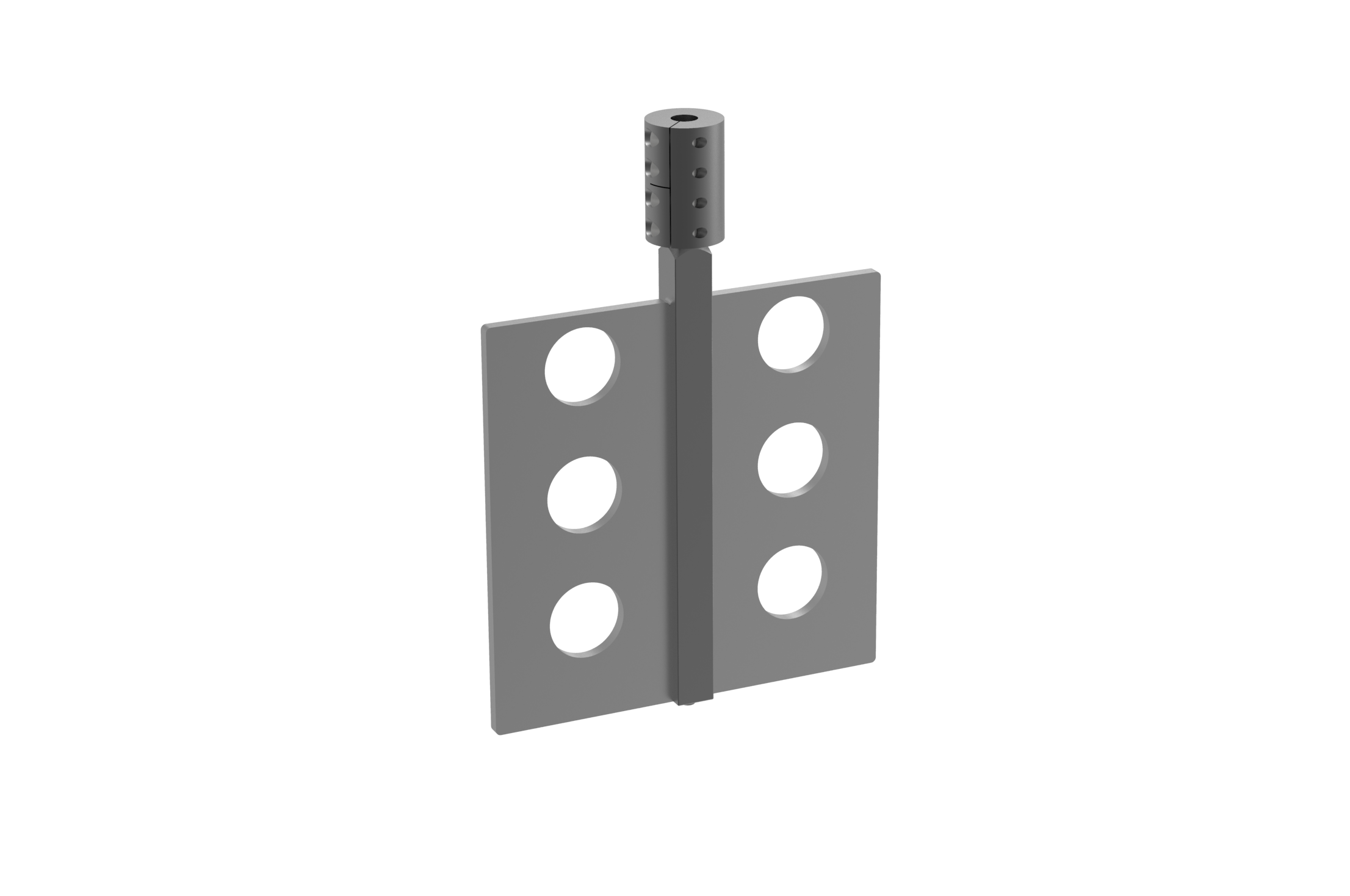

The Walther Pressure Container System has different container sizes from 2 to 40 liters, a filling level sensor with a floating switch, an ultrasound, or capacitive probe, as well as an electric or pneumatic stirrer and thereby offers a large number of design options and very flexible configuration possibilities.

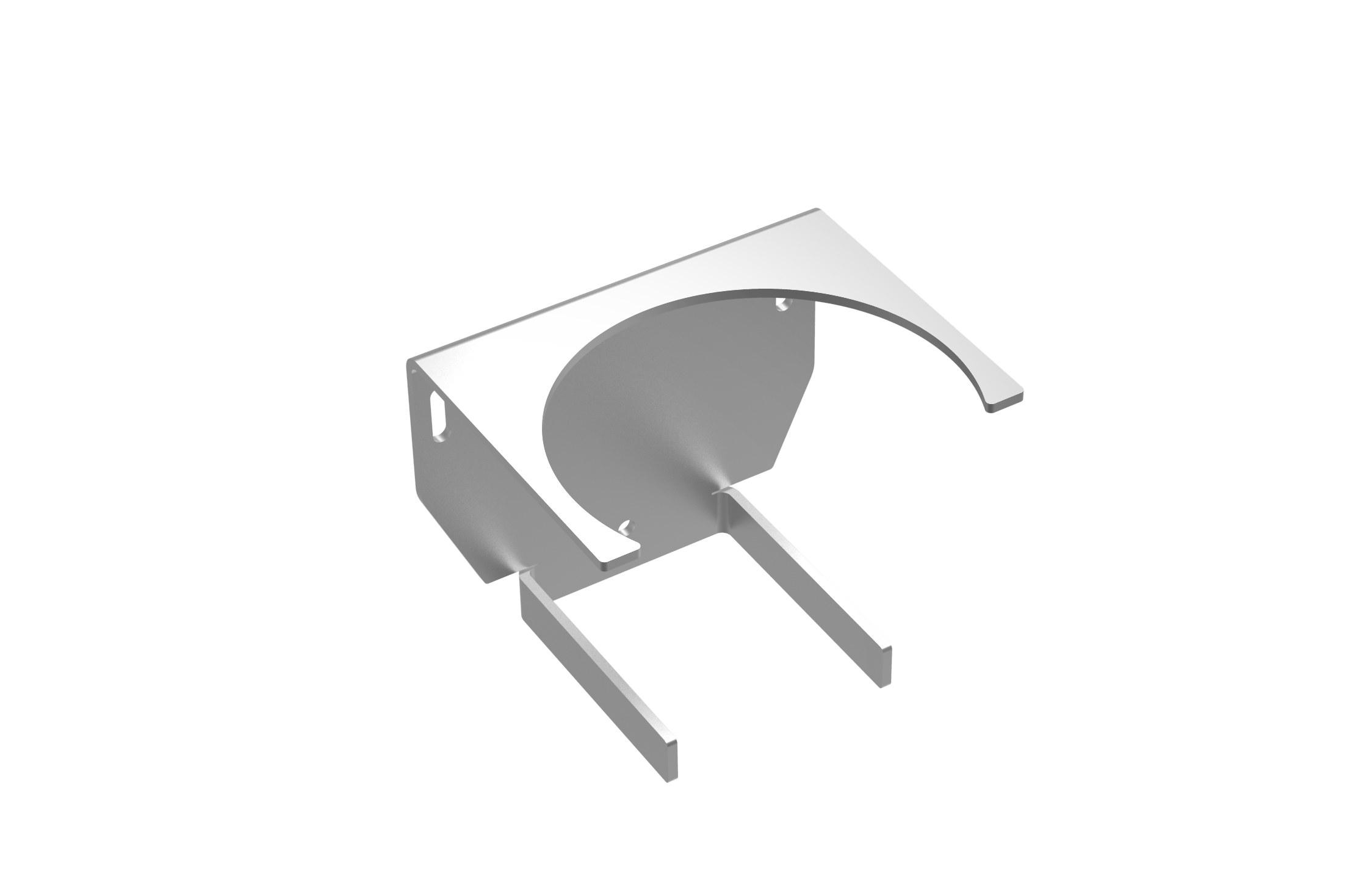

As a standard, all medium-touching components are made from stainless steel. Also as a standard, a stainless steel funnel can be used for filling the container without opening the lid. With its high functionality, easy and intuitive operation, and high durability, our pressure container system meets all industrial requirements and will reliably support you in your production processes.

- flexibility for individual requirements, ranging from 2 to 40-liter container sizes, and numerous options for customization

- integrated control for agitator, level sensor, and process valve

- high connectivity for providing process parameters and notifications

- simple direct operation of the system and connected peripheral elements

- operating pressure: max. 2,5/4,5/6 [bar]

- viscosity range: 1 [mPa s] to 50.000 [mPa s] (with self-leveling medium)

- RPM Stirrer: max. 250 [U/min]

- pneumatic connection Ø: 8 [mm]

- connection medium outlet: G1/2"

- operating temperature: -10 bis +40 [°C]

- operating voltag: 24 [V DC]

- container sizes [Ø x H]:

>> WDBS-05 - 503 x 510 [mm]

>> WDBS-12 - 503 x 680 [mm]

>> WDBS-25 - 650 x 600 [mm]

>> WDBS-40 - 650 x 750 [mm]