Handheld System for WSV Spray Valve

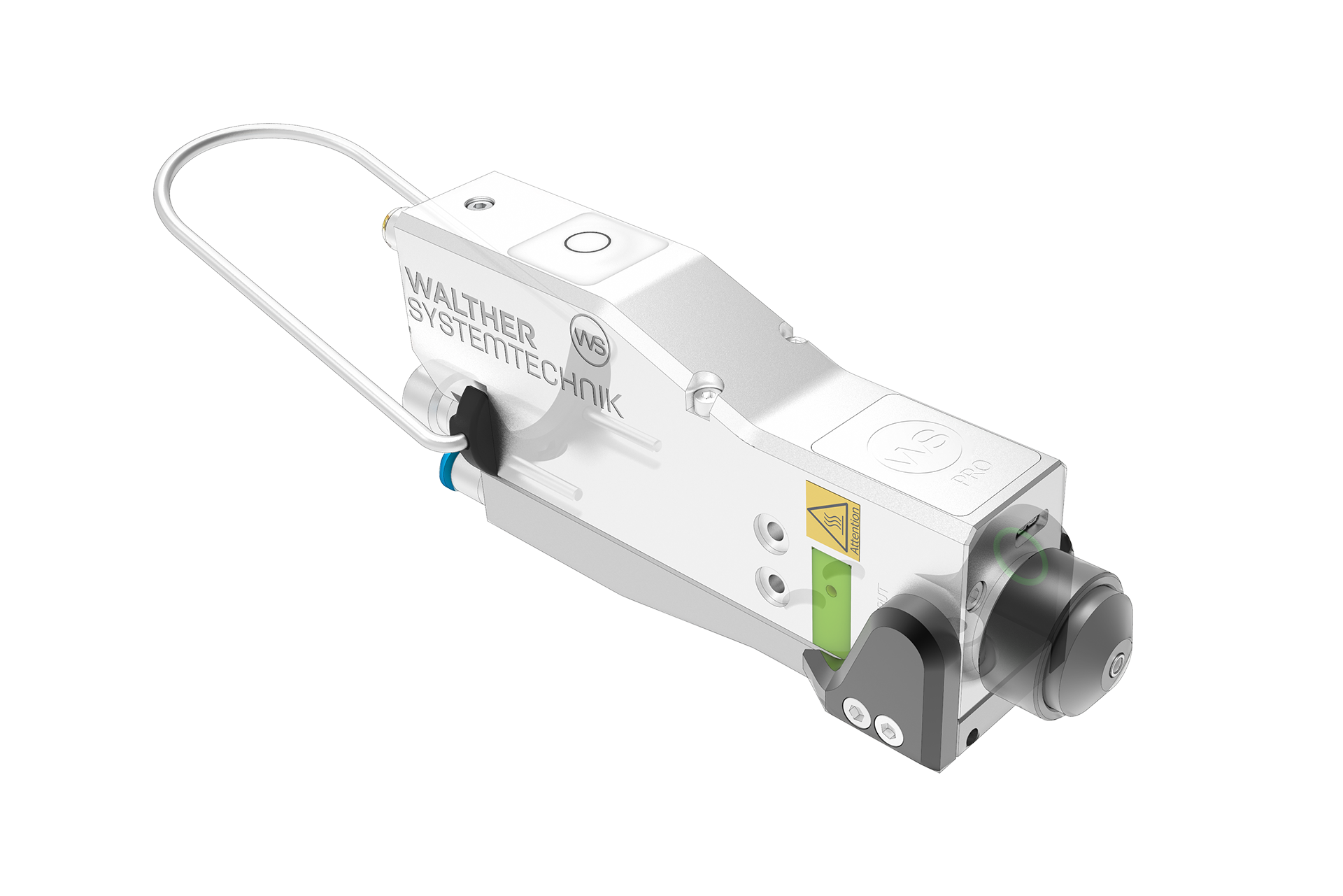

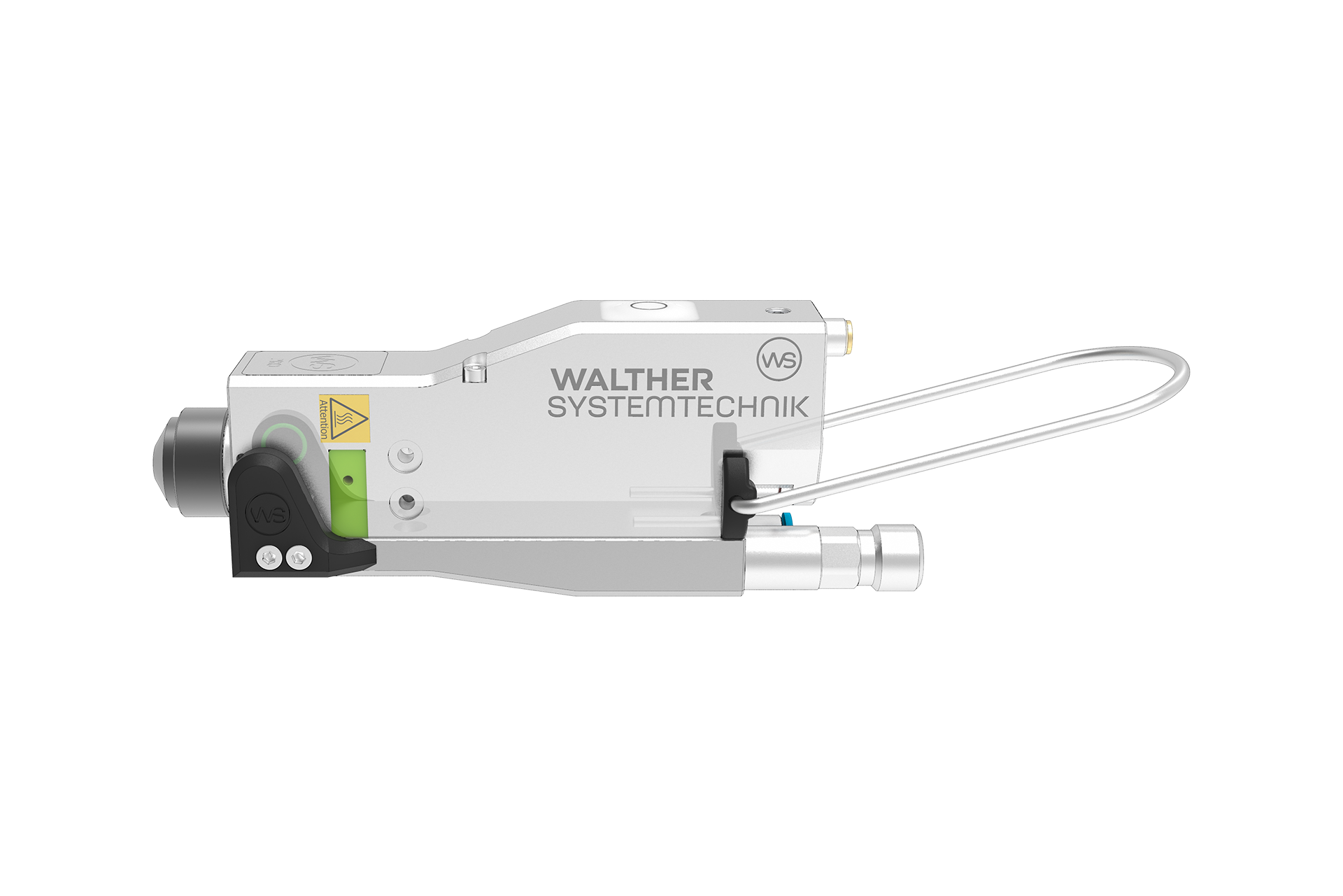

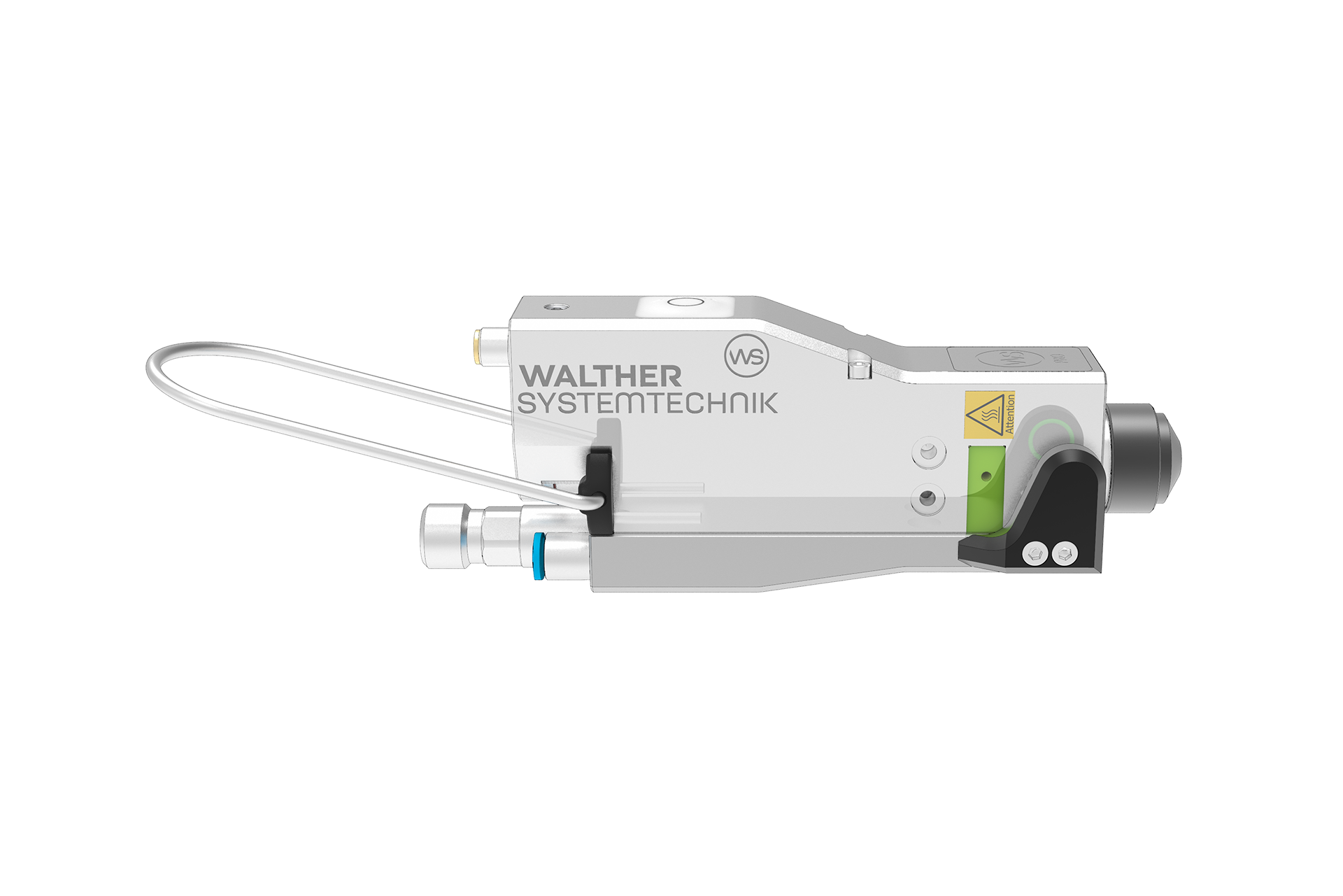

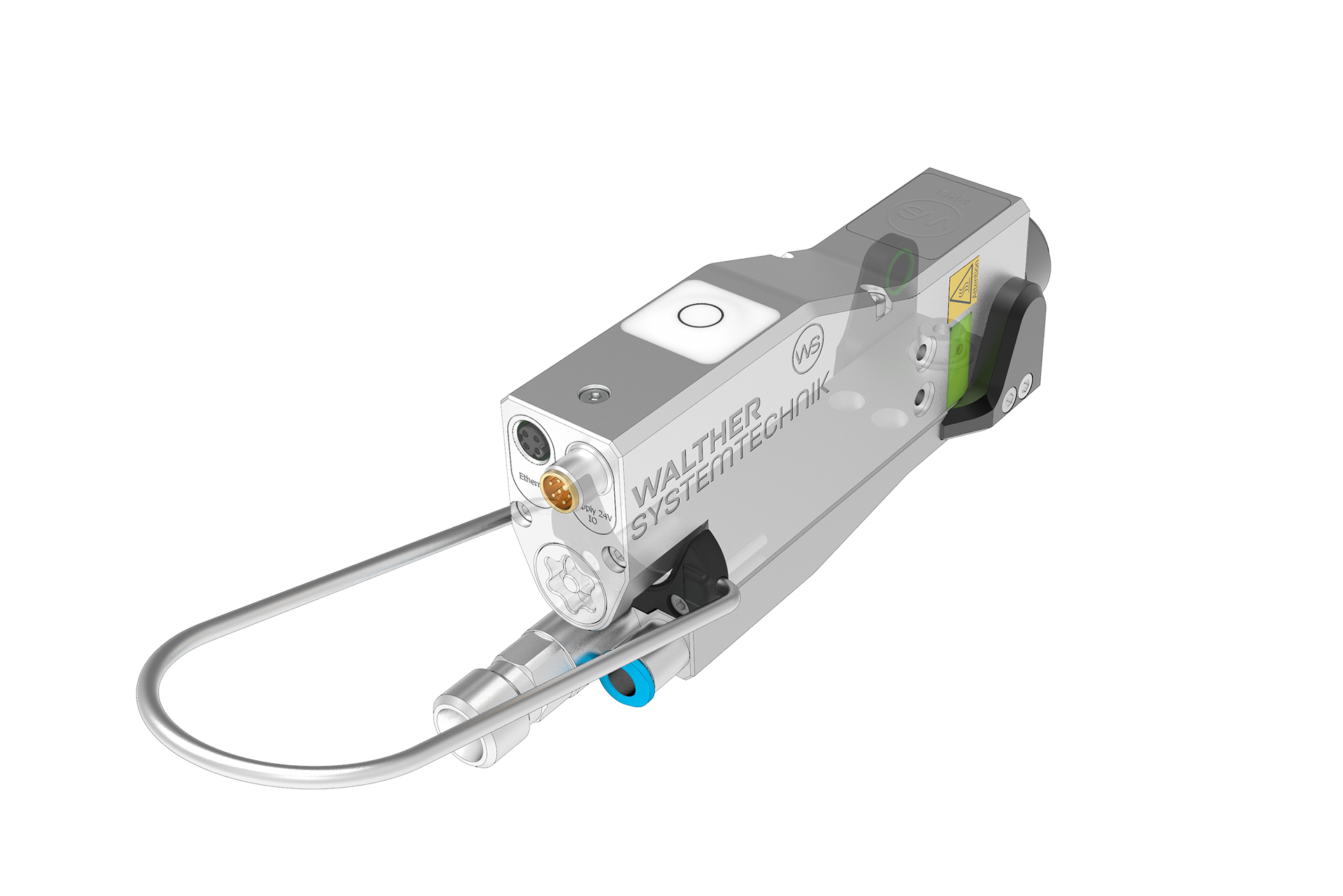

The WSV hand spray system is a ready-to-connect solution for the manual application of viscous media in industrial production environments. It combines the proven valve technology of the electrically actuated Walther spray valve WSV with an ergonomically designed hand module, enabling flexible use in assembly processes, rework operations, or prototype construction. Designed for use outside automated production lines, the system delivers reproducible spray application with optional process monitoring and documentation via Modbus TCP.

At the core of the system is the intelligent spray valve WSV, which operates without external control devices. Parameter configuration is handled via a web-based dashboard accessible through the integrated Ethernet interface. The built-in controller allows precise adjustment of spray durations, needle opening intervals, and spray cycles. Depending on the version, media temperature regulation and process pressure monitoring are also available. Pre- and post-air timings can be individually configured to control the spray pattern effectively and prevent dripping, overspray, stringing, or buildup at the nozzle. A built-in pushbutton on the top of the valve acts as a direct trigger for the spray process—eliminating the need for a separate hand or foot switch. However, an external trigger can be connected if required.

The hand module features a robust suspension bracket that allows mounting to a balancer or spring retractor. This suspension reduces physical strain and supports ergonomic, fatigue-free operation. The grip is ergonomically shaped to ensure safe and precise handling, even during prolonged use, and helps minimize user errors due to fatigue or declining concentration.

The hand spray system is available as an add-on kit for all common versions of the WSV – from the Basic model with simple control logic to the Professional version with integrated media temperature control and process pressure monitoring. These can be extended via software add-ons, such as multi-parameter sets, needle stroke monitoring, or Ethernet bus integration. The digital architecture also enables seamless integration into worker assistance systems, ideal for use at assembly stations with mandatory process documentation or guided task sequences. This makes the WSV hand spray system an excellent solution for manual rework stations, small-series production environments, and digitally networked manufacturing setups that demand precision, flexibility, and process control.