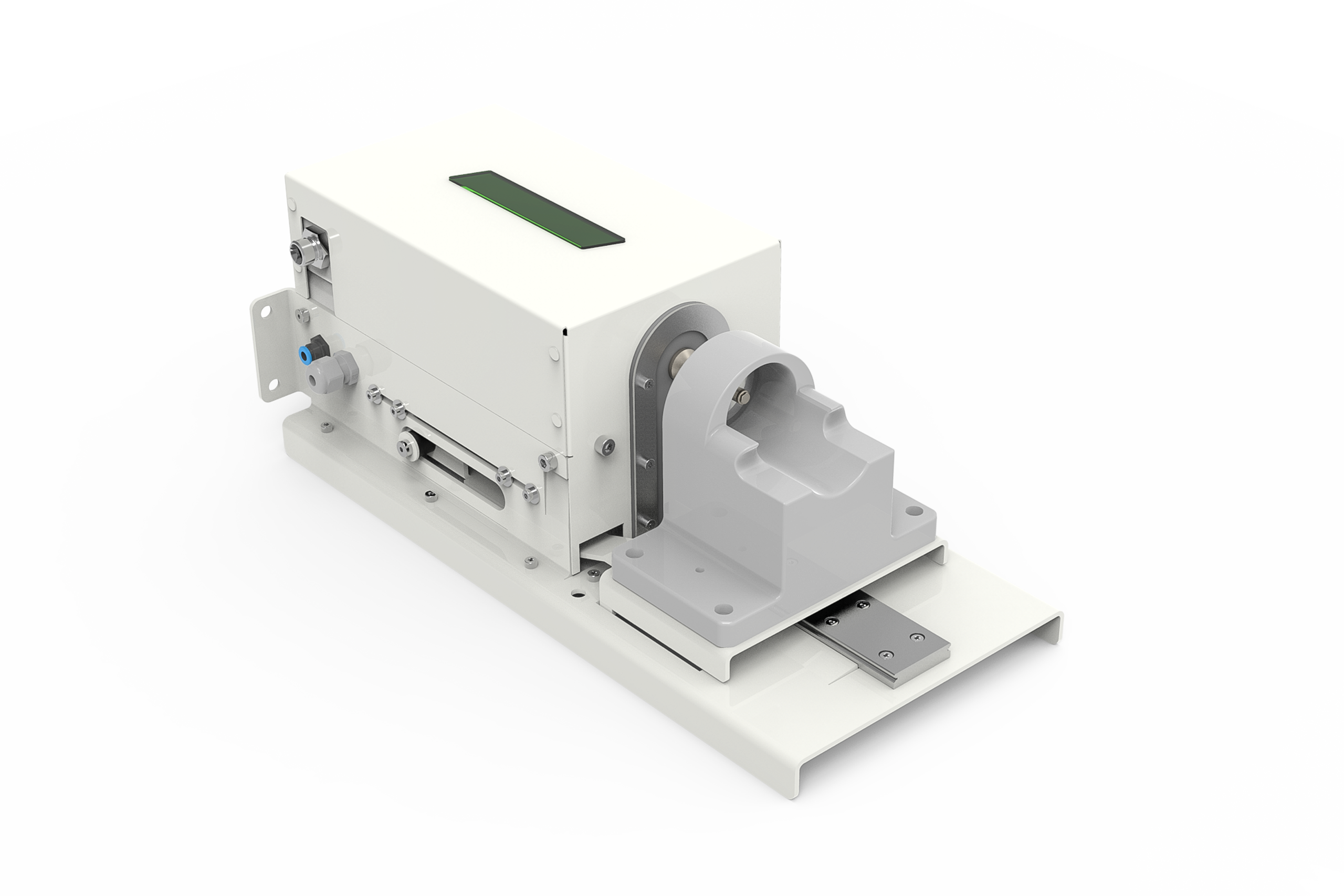

Dosing Device – ReadyLube: Spray!

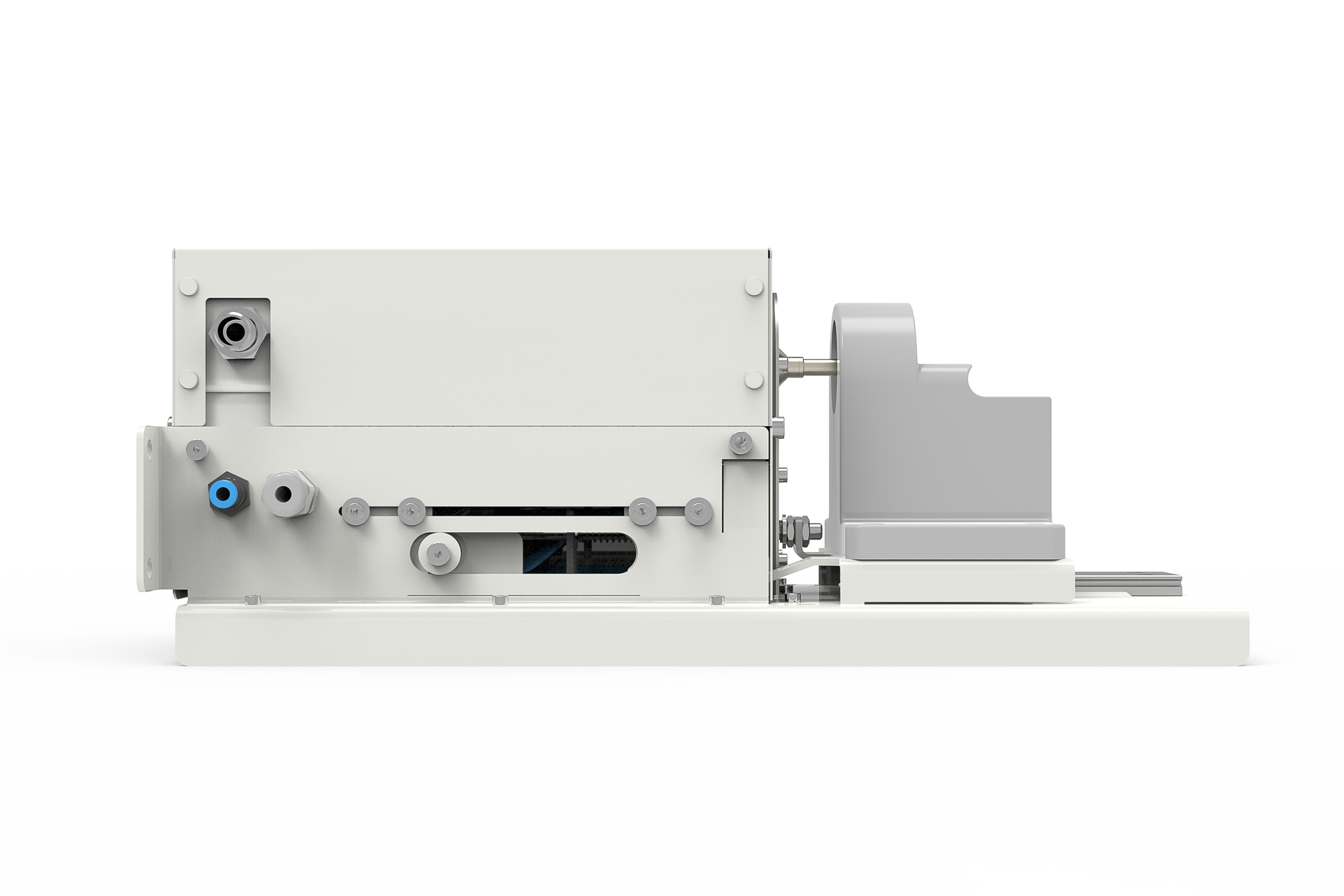

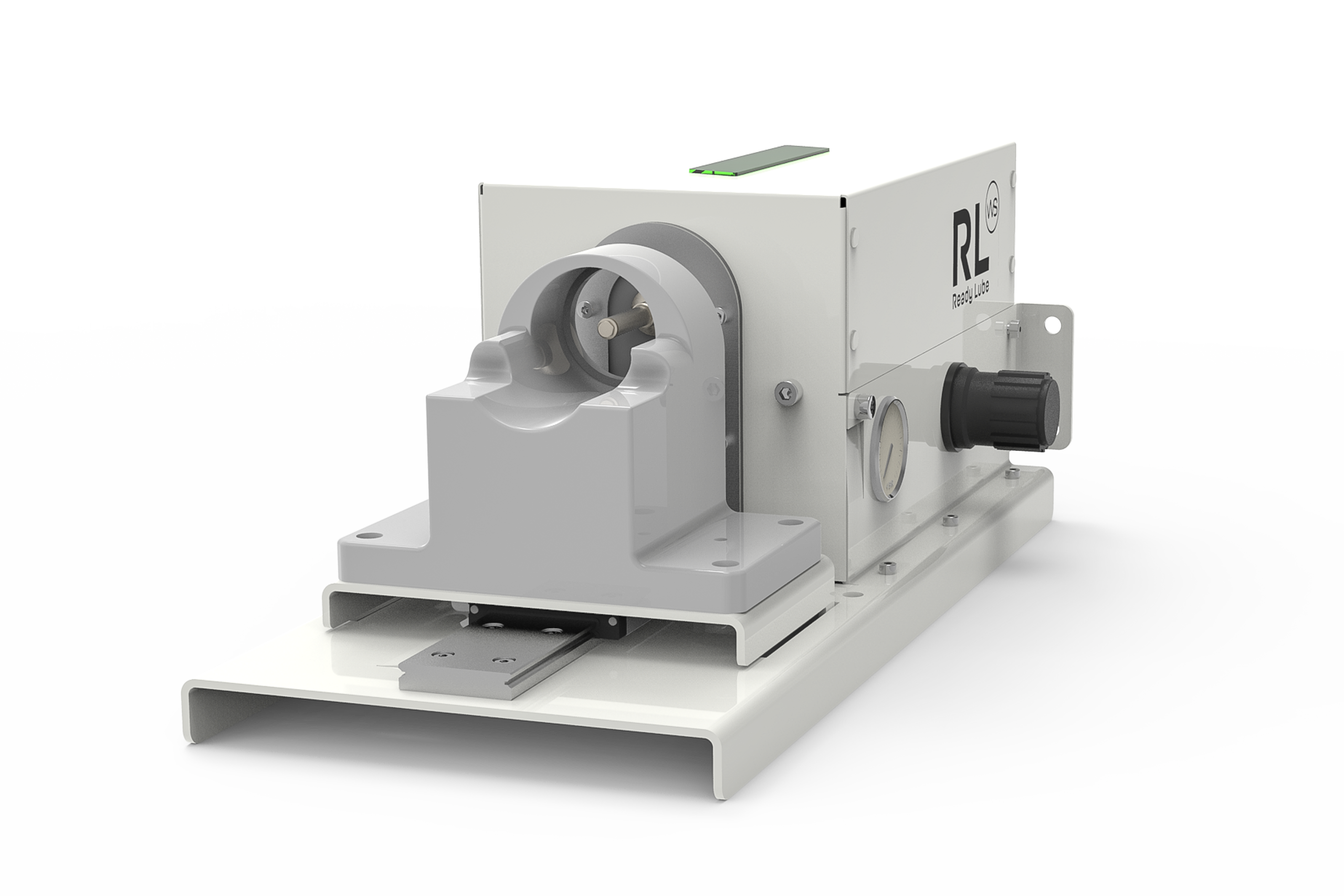

ReadyLube: Spray! is a standardized dosing unit for component-specific, contactless lubricant application in industrial production processes. It enables operator-independent, precise, and repeatable lubrication, sustainably improving product quality, process reliability, and efficiency. Thanks to its compact design and autonomous operation, the dosing unit can be quickly and easily integrated into existing production lines and assembly workstations. Once the media supply and compressed air are connected, ReadyLube is immediately ready for operation.

How does ReadyLube: Spray! work?

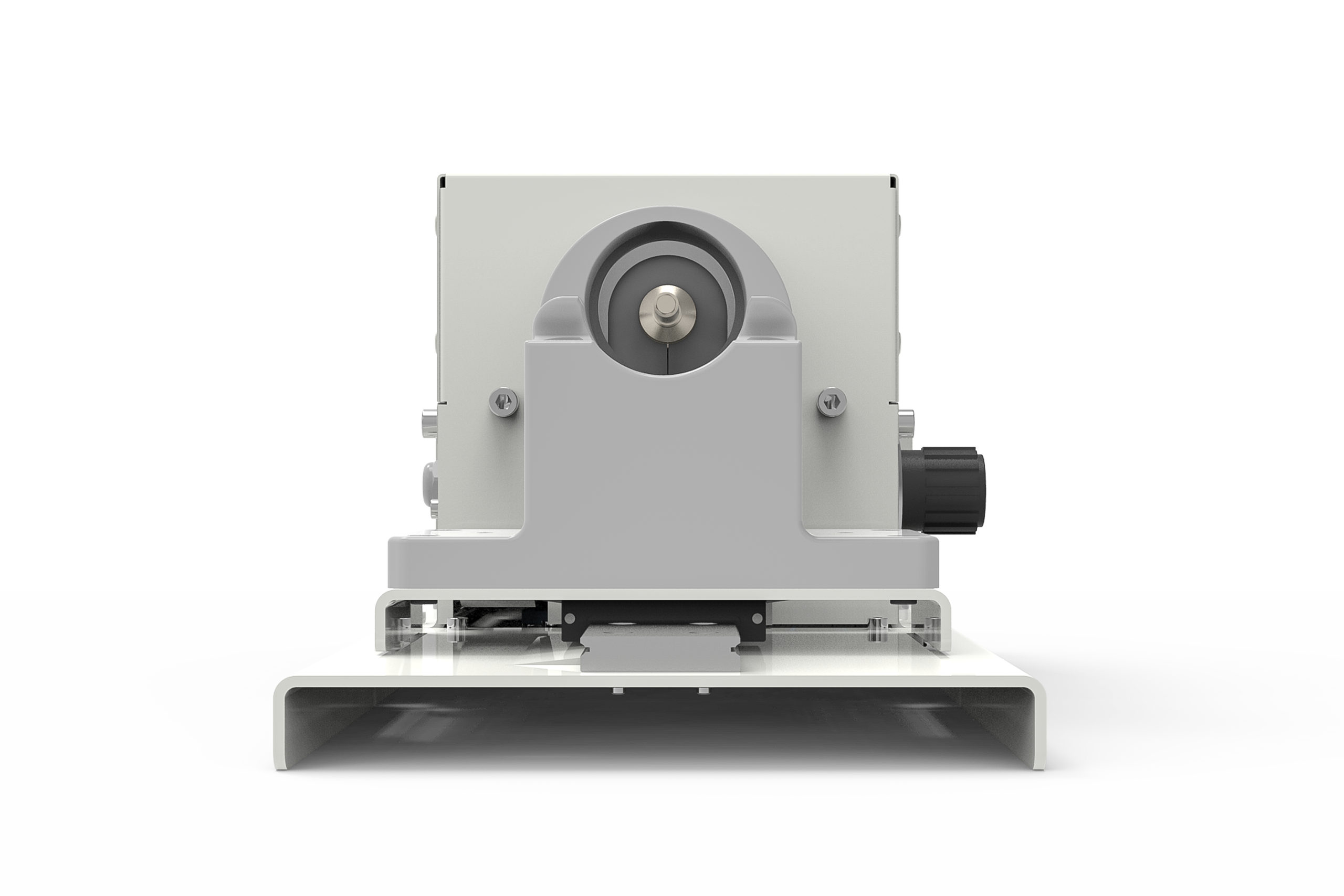

- A dedicated component holder is designed for each part, positioning it precisely in relation to the spray nozzle or nozzle extension.

- The holder is fixed on a component slide and then moved towards the valve.

- Once the component reaches the defined position, the contact sensor in the slide automatically triggers the spraying process.

- Within milliseconds, the lubricant is applied. The dosing quantity can be individually adjusted.

- After dosing, the component is removed from the holder and can be processed immediately. Alternatively, component feeding and removal can be automated, e.g., by a robot.

Spray Process in Detail

- ReadyLube: Spray! uses nozzle extensions as an integral part of the system to apply the lubricant to the component.

- By controlling the spray impulse, the lubricant is precisely applied to defined locations.

- The combination of an individually adjustable spray duration and the precise linear movement of the component on the slide enables exact control of lubricant application.

- Point-based lubricant application occurs when the component remains stationary during the spray impulse.

- A line-based application is achieved when the component moves on the slide during spraying, ensuring even distribution along a defined path.

Applications: Due to its contactless application, ReadyLube: Spray! is particularly suitable for delicate or complex-shaped components. To meet diverse requirements, various types of nozzle extensions and application methods are available. These are suitable for specific applications such as targeted coating of hard-to-reach areas, radial internal wetting of bores or hollow bodies, segmented or full-surface media application. By selecting the appropriate nozzle extension, spray angle, immersion depth, spray distance, spray shape, and spray pattern can be optimally adapted to the component geometry. This ensures optimal lubricant distribution while reducing media consumption and minimizing unwanted mist formation.

Flexibility & Cost-Effectiveness: Thanks to easily interchangeable component holders, replaceable nozzle extensions, and individually adjustable parameters, ReadyLube: Spray! can be flexibly adapted for different component series. This makes it particularly economical for small-series production and use in variable production processes.

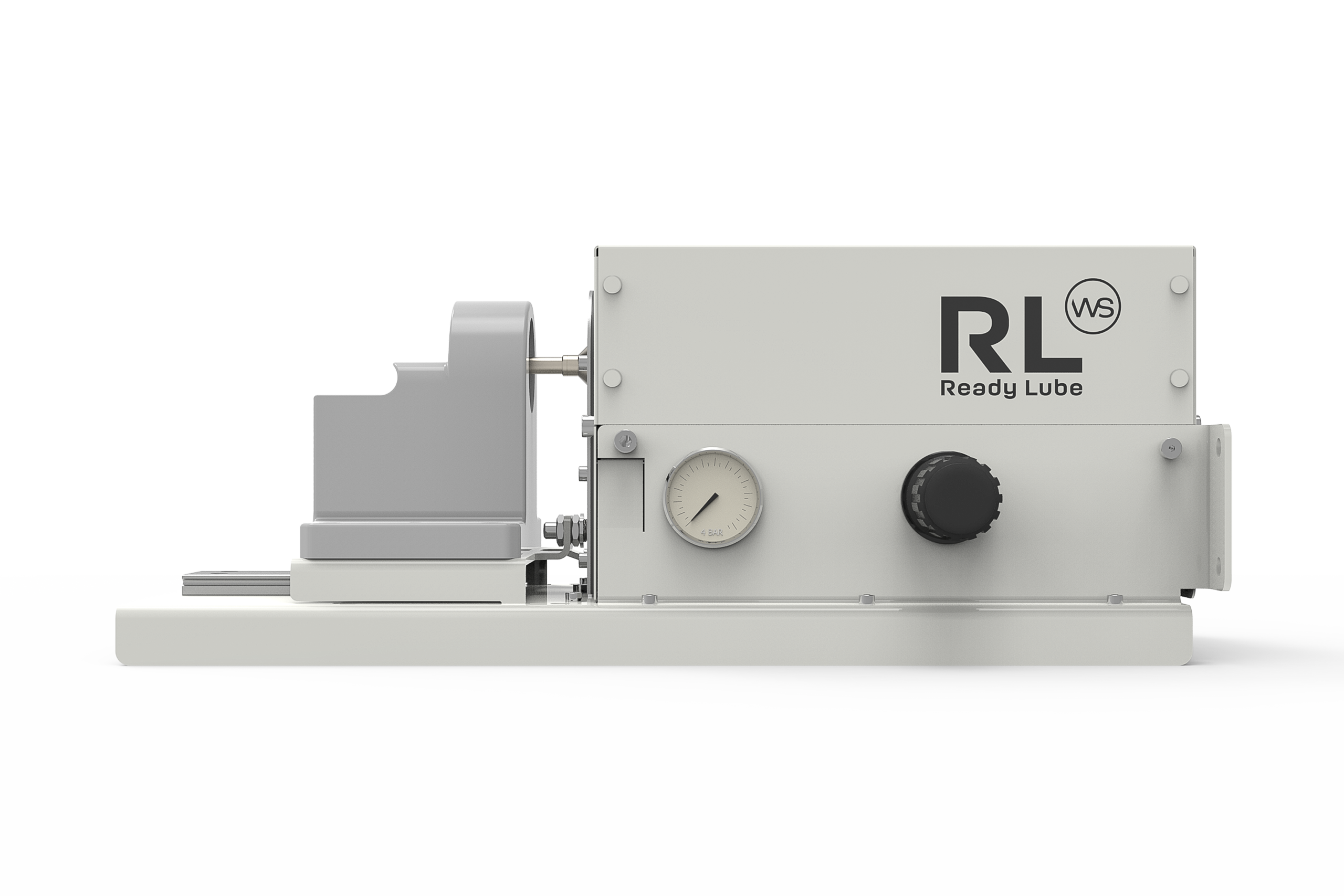

ReadyLube: Spray! is available in three versions...

BASIC Version: Compact, ready-to-use dosing unit

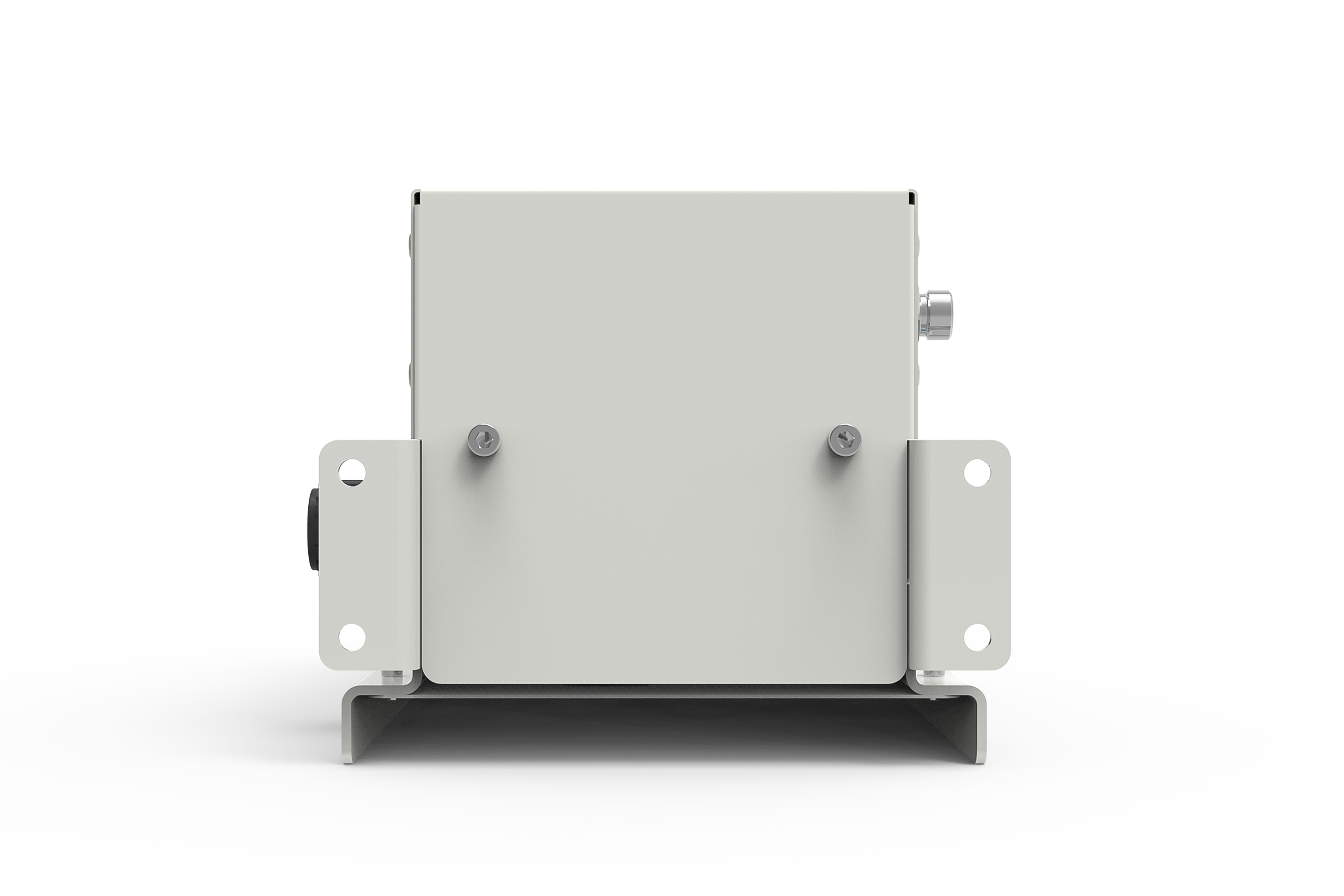

- Robust dosing unit with an integrated spray valve, ready for direct installation

- Easy integration, requiring only media supply and compressed air connection

- Immediate operational readiness without complex commissioning

- Automatic activation via component positioning

- Custom component holder, tailored to specific components

- Freely selectable nozzle extension, adapted to the application

- Adjustable lubricant quantity via spray duration and valve opening width

- Integrated process control with visual indication for readiness and IO/NIO notifications

- Interfaces for process communication: 3 digital outputs (readiness, IO/NIO signal, start signal), 1 digital input (external start signal)

- Flexible start options: Manual activation; alternatively, dosing can be triggered via an external control signal

- Advanced integration into higher-level control systems and step-sequence-controlled production liness

ADVANCED Version: All features of the BASIC version plus valve heating package

- Valve heating for media temperature control

- Integrated temperature regulation

PROFESSIONAL Version: All features of the BASIC and ADVANCED versions plus pressure sensing package

- Monitoring of the process pressure profile during a spraying process

- Evaluation of characteristic pressure profiles

Additional information on the ReadyLube product line can be found here >>

- Automated, repeatable component lubrication for maximum process reliability

- Interchangeable, specific component holder for flexible applications

- Easy integration into existing assembly workstations and production lines

- Immediately operational after connecting the media supply and compressed air

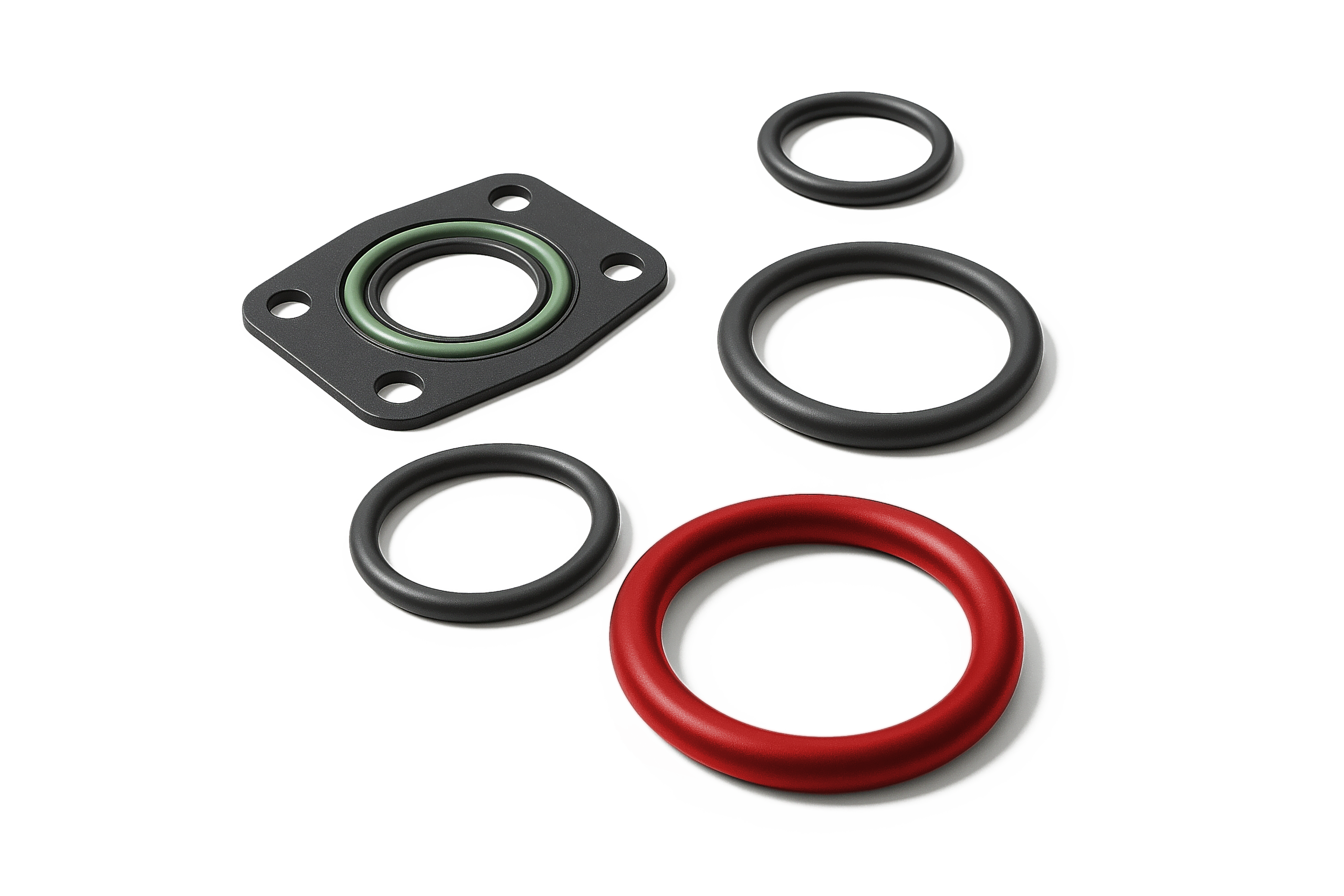

- Robust design for long service life and minimal maintenance effort

- Suitable for low- to high-viscosity lubricants (oils and greases)

- Inlet pressure range: max. 50 bar

- Media: Greases and oils

- Media connection: 10 L

- Air connection: 6 mm

- Air pressure: 4-10 bar

- Nozzle extension: Freely selectable, depending on the component to be lubricated

- Dimensions LxWxH (mm): 465 / 200 / 180

- ADVANCED version: additionally equipped with an integrated IO/NIO display for process monitoring