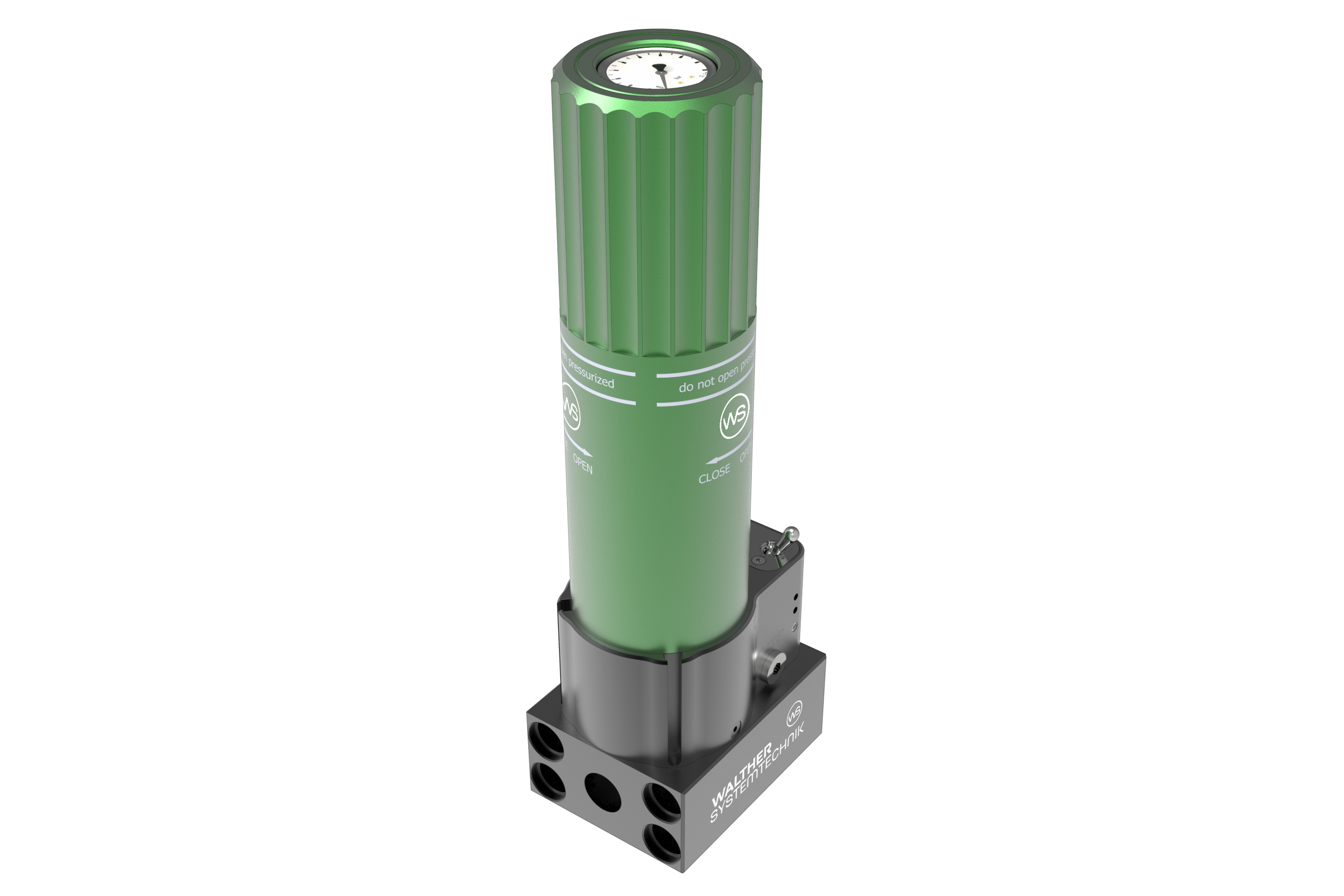

Cartridge Depleting System WKSK

The WKSK cartridge emptying system from Walther Systemtechnik is a compact, robust and process-reliable solution for emptying Euro cartridges in industrial dosing and application environments. Designed for the precise and pressure-controlled dispensing of high-viscosity media such as adhesives, sealants, silicones, greases or waxes, it is suitable for both manual workstations and automated production systems.

The WKSK operates with a closed pneumatic pressure system that presses the cartridge base in a controlled manner towards the outlet. This ensures a constant media flow without pressure fluctuations, regardless of the installation orientation. An integrated pressure regulator with gauge allows precise adjustment of the outlet pressure. With a maximum operating pressure of 10 bar, materials with viscosities of up to 25,000 mPas can be processed safely and uniformly.

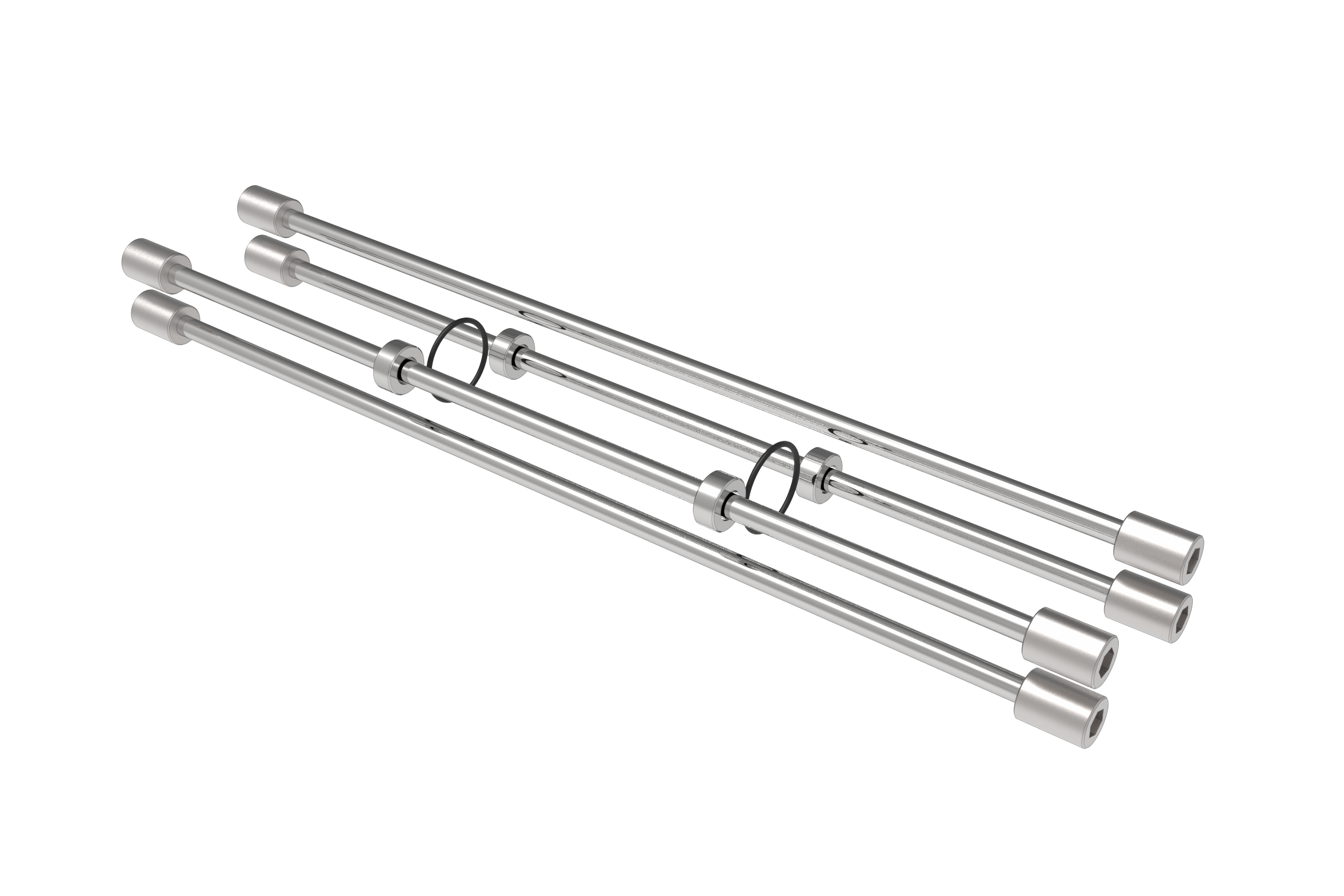

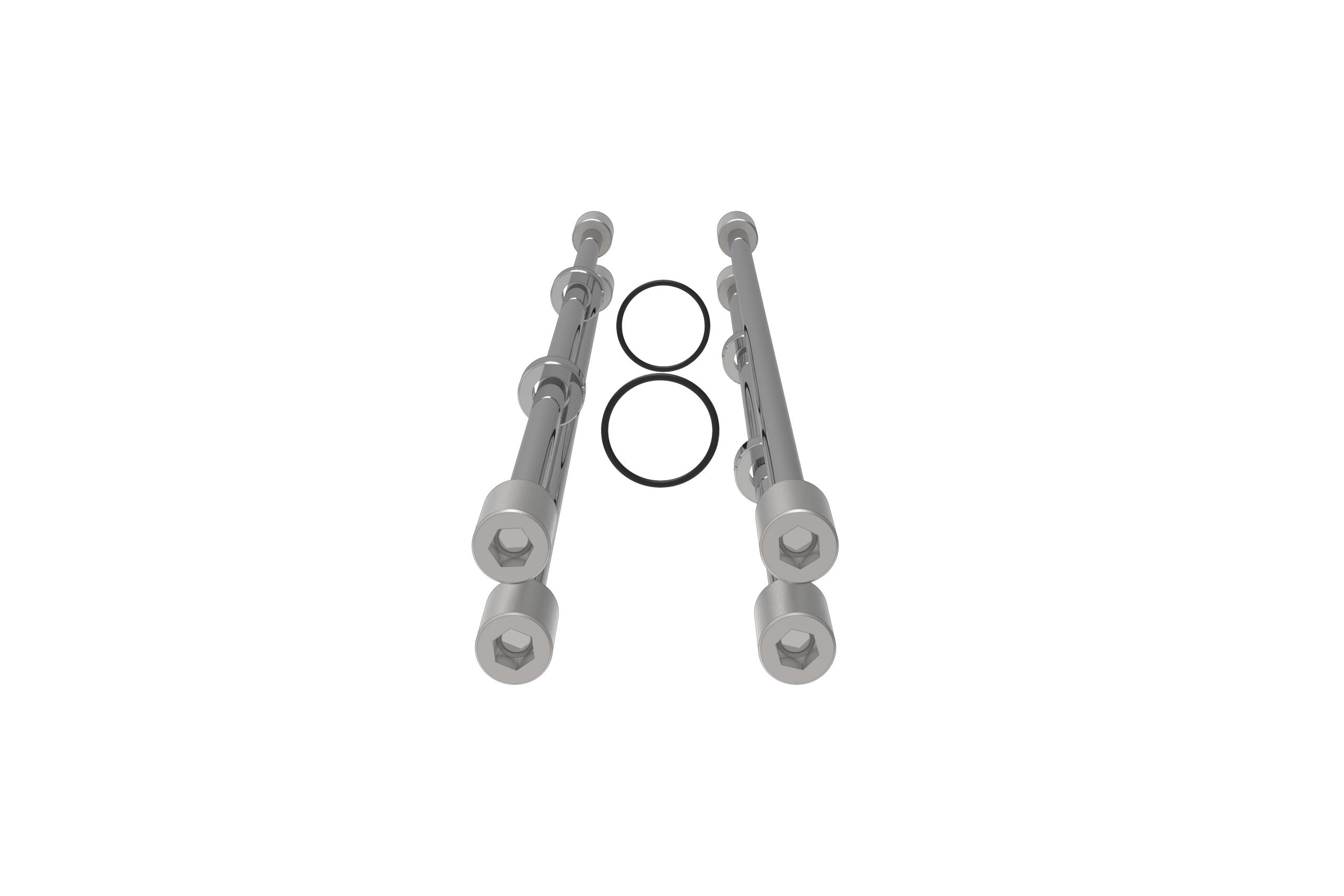

As standard, the WKSK is designed for Euro 1 plastic cartridges (Ø 46.2 mm, S15x2.5 thread). With the interchangeable cartridge adapter, it can also be used with Euro 2 aluminium cartridges (Ø 46.8 mm, M15x1 thread) without compromising system integrity or performance.

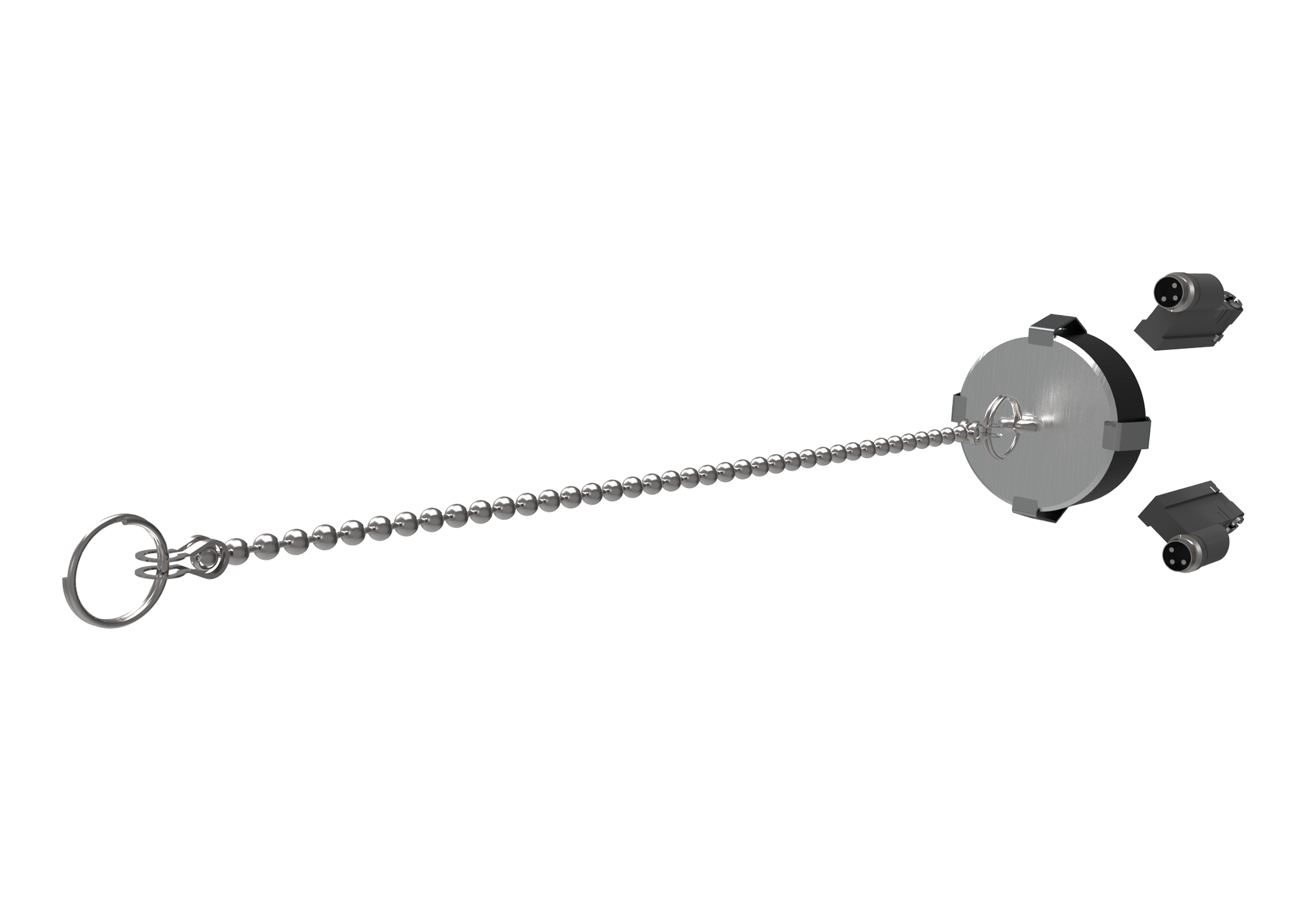

For quick and tool-free cartridge replacement, it is sufficient to switch off the device; system pressure is automatically released. If the cartridge holder is accidentally opened under pressure, integrated safety vents ensure controlled depressurisation.

For applications involving very viscous media or vertical installation, the WKSK is also available with mechanical spring assistance. This provides additional feed force and reduces the load on the pneumatic system. An optional electronic pre-empty and empty indication is also available. Two proximity sensors monitor the cartridge fill level and indicate when a replacement is required – a key advantage for continuously automated processes.

As part of the Walther MODULAR system, the WKSK can be flexibly combined with other functional modules using standardised connector kits. A particular highlight is its cascading capability: Multiple emptying units can be combined into a linear feed unit to ensure uninterrupted media supply.

Thanks to its slim design, the WKSK can be installed in a space-saving manner within or alongside dosing cells, robot stations or automated handling systems. With compact dimensions of 102 × 79 × 316 mm (without spring assistance) and self-contained operation, it is ideally suited for use in confined spaces and highly automated production environments requiring maximum reliability, efficiency and process stability.

- compact, user-friendly, and process-secure emptying of plastic and aluminum Euro cartridges

- suitable for use in highly automated manufacturing and assembly systems

- uninterrupted media supply through cascading

- secured against air ingress into the fluid system

- inlet pressure (pneumatic): max. 10 [bar]

- operating temperature: 4 to 50 [°C]

- weight: 2,35 [kg]

- dimensions (l x w x h): 102 x 79 x 316 [mm]

- cartridge connection thread:

>> plastic: S15 x 2,5

>> aluminium: M15 x 1

- diameter cartridge:

>> plastic: Ø 46,2 [mm]

>> aluminium: Ø 46,8 [mm]

- length of cartridge: 215 - 216 [mm] (with or without flange)

- Walther Module length: 2 [TE]