Electrical Early-Empty and Empty Detection for Cartridge System

The electrical early-empty and empty detection unit is a functional enhancement for the WKSK cartridge discharge system. It enables reliable fill-level monitoring during operation, ensuring timely cartridge replacement, automated downstream processes and a stable media supply.

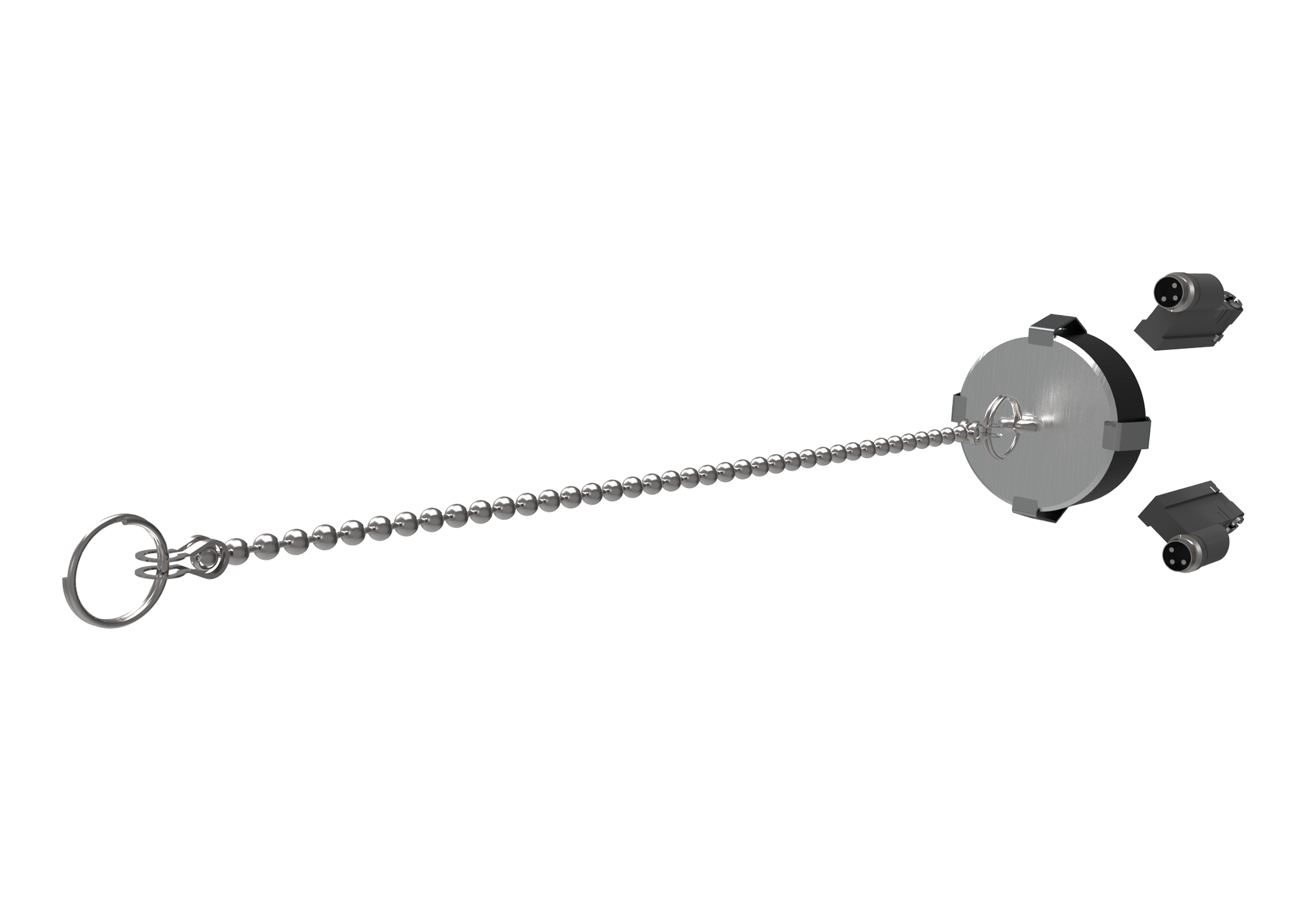

The kit consists of a magnetic attachment with clamping unit and drop chain, as well as two proximity switches. The magnetic attachment is placed on the cartridge lid and guided along the inner cartridge wall by the clamping unit. The two proximity sensors are inserted at staggered positions into the external T-slots of the WKSK base body and fixed in place without tools using a set screw.

The upper sensor detects the approach of the magnet to the end of the cartridge and issues an early-empty signal, e.g. to initiate an upcoming material refill. The lower sensor identifies the completely empty cartridge and generates a clear empty indication. During the next cartridge change, the magnet can be easily removed from the empty cartridge using the drop chain and reused.

The electrical fill-level detection increases process reliability, prevents unplanned downtime and provides the basis for automated operation – particularly in continuously operating dosing and application systems.