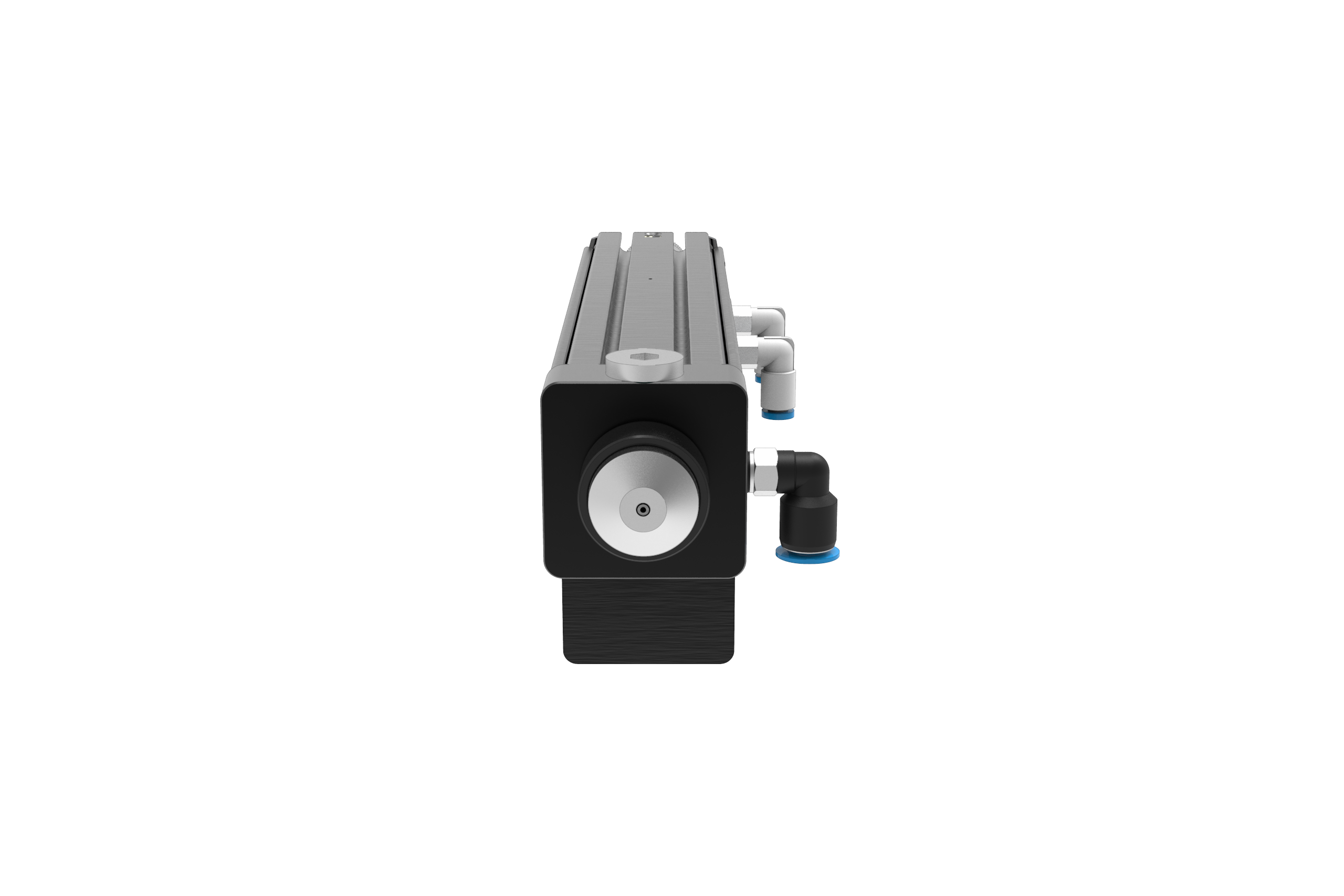

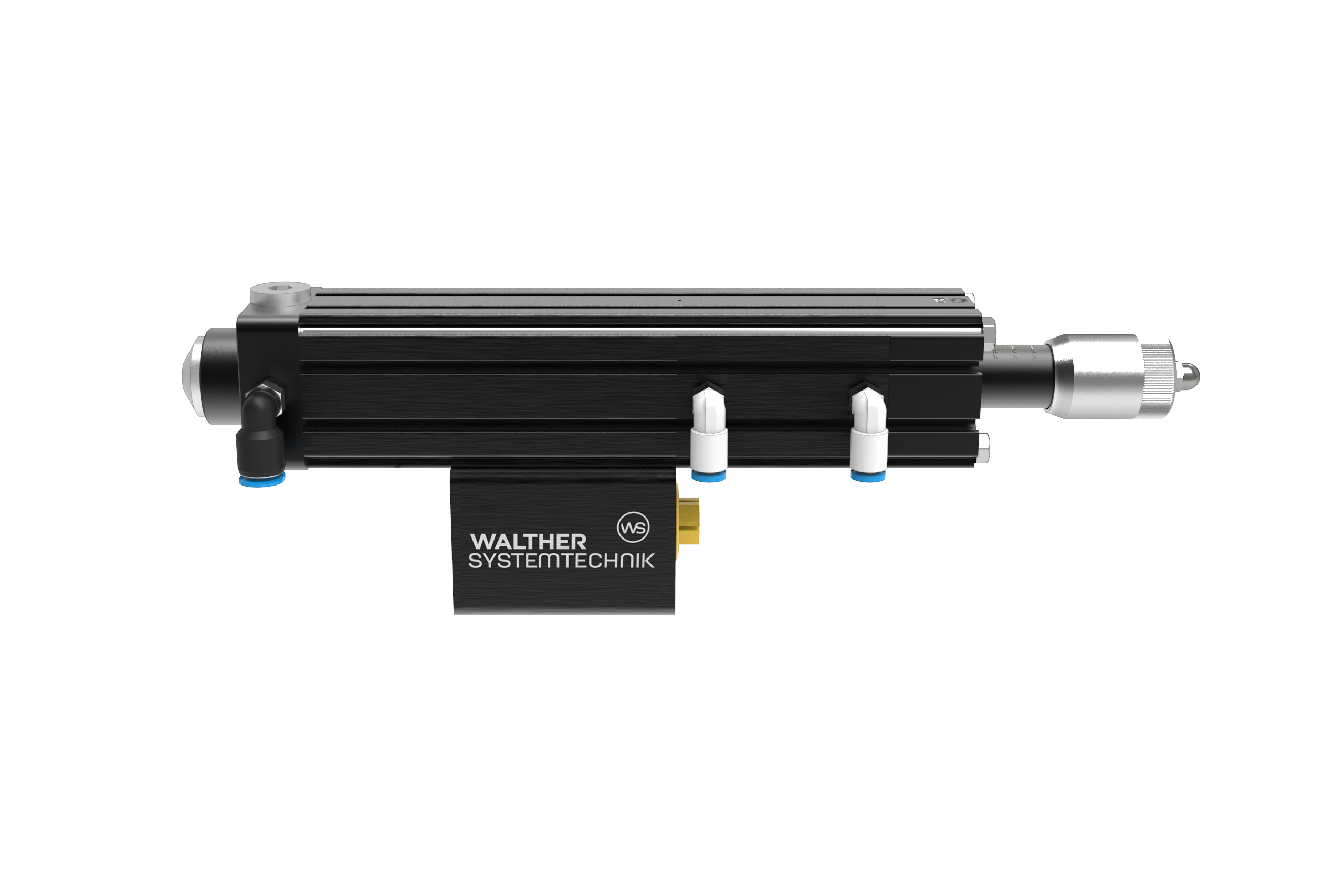

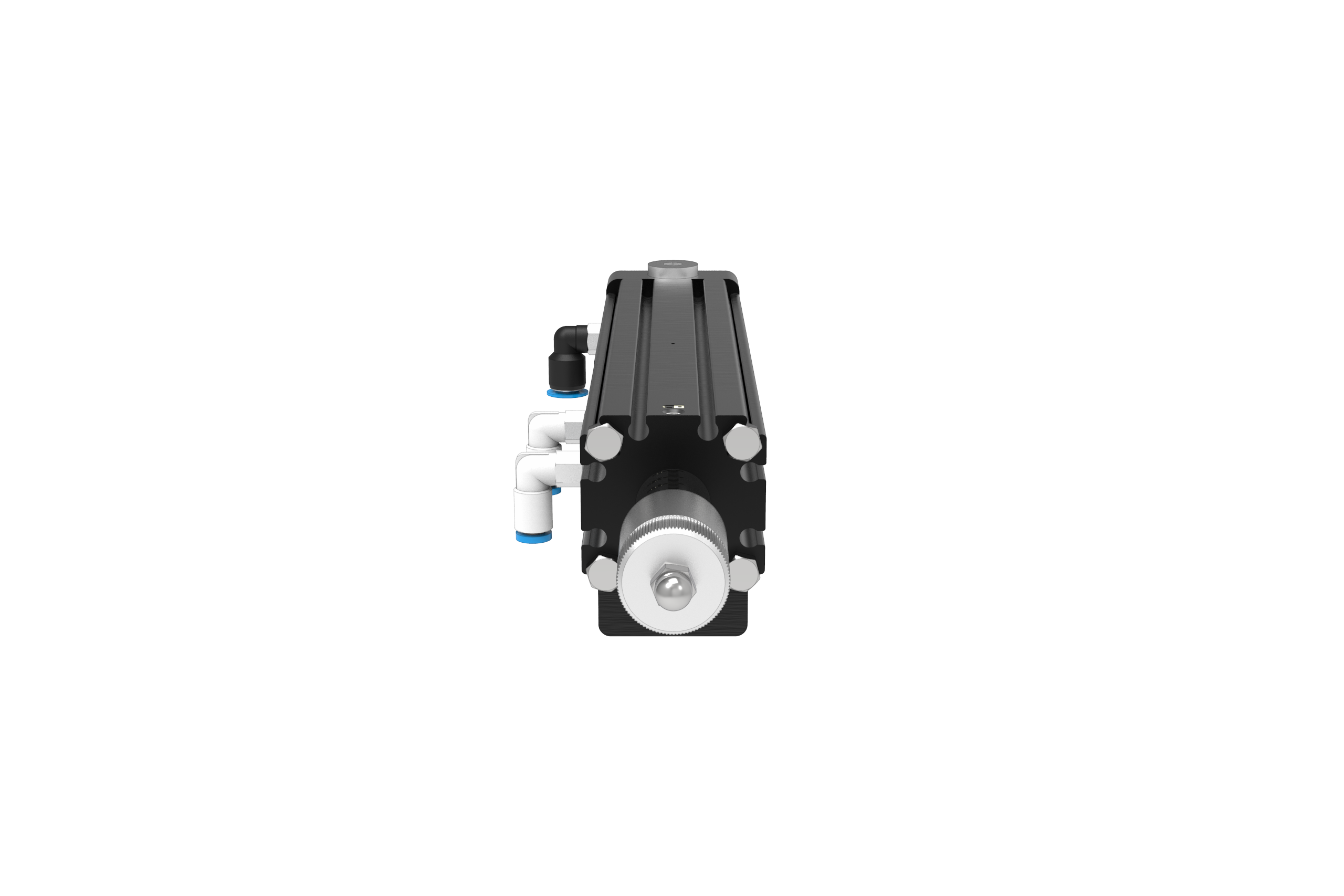

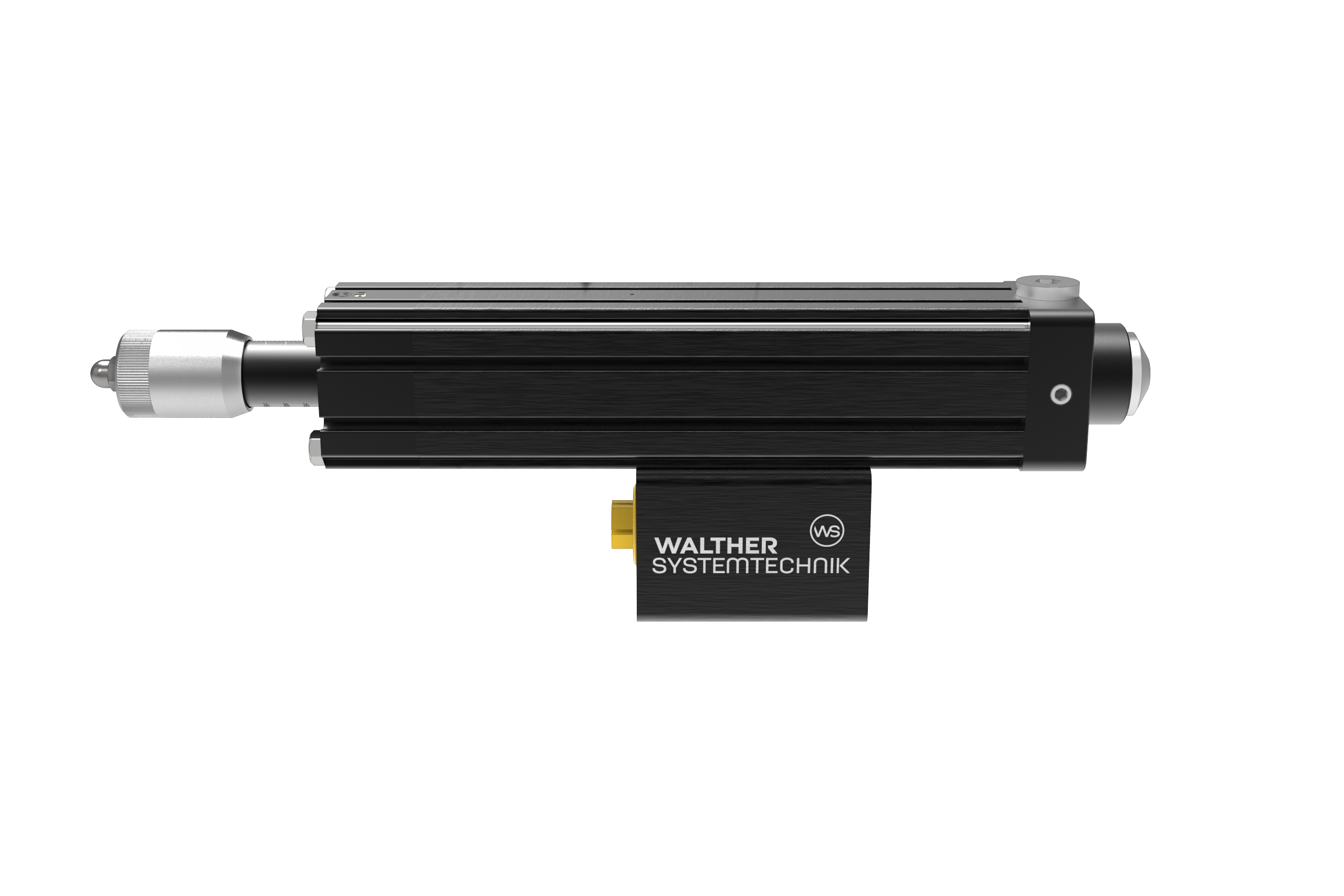

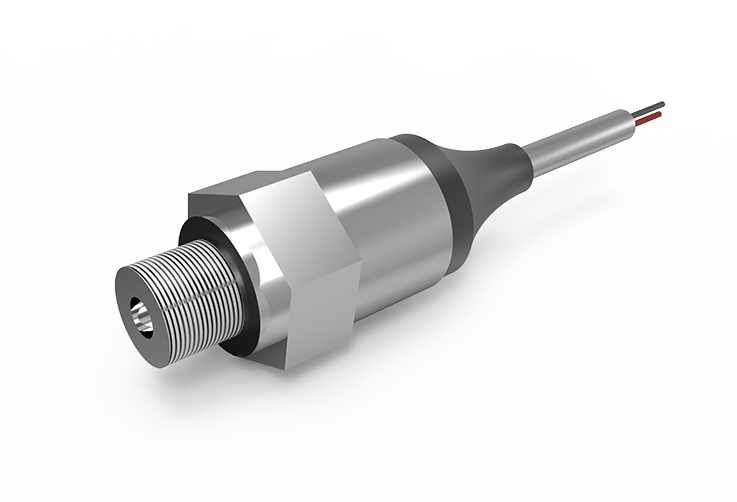

Walther Volume Spray Valve WSDV

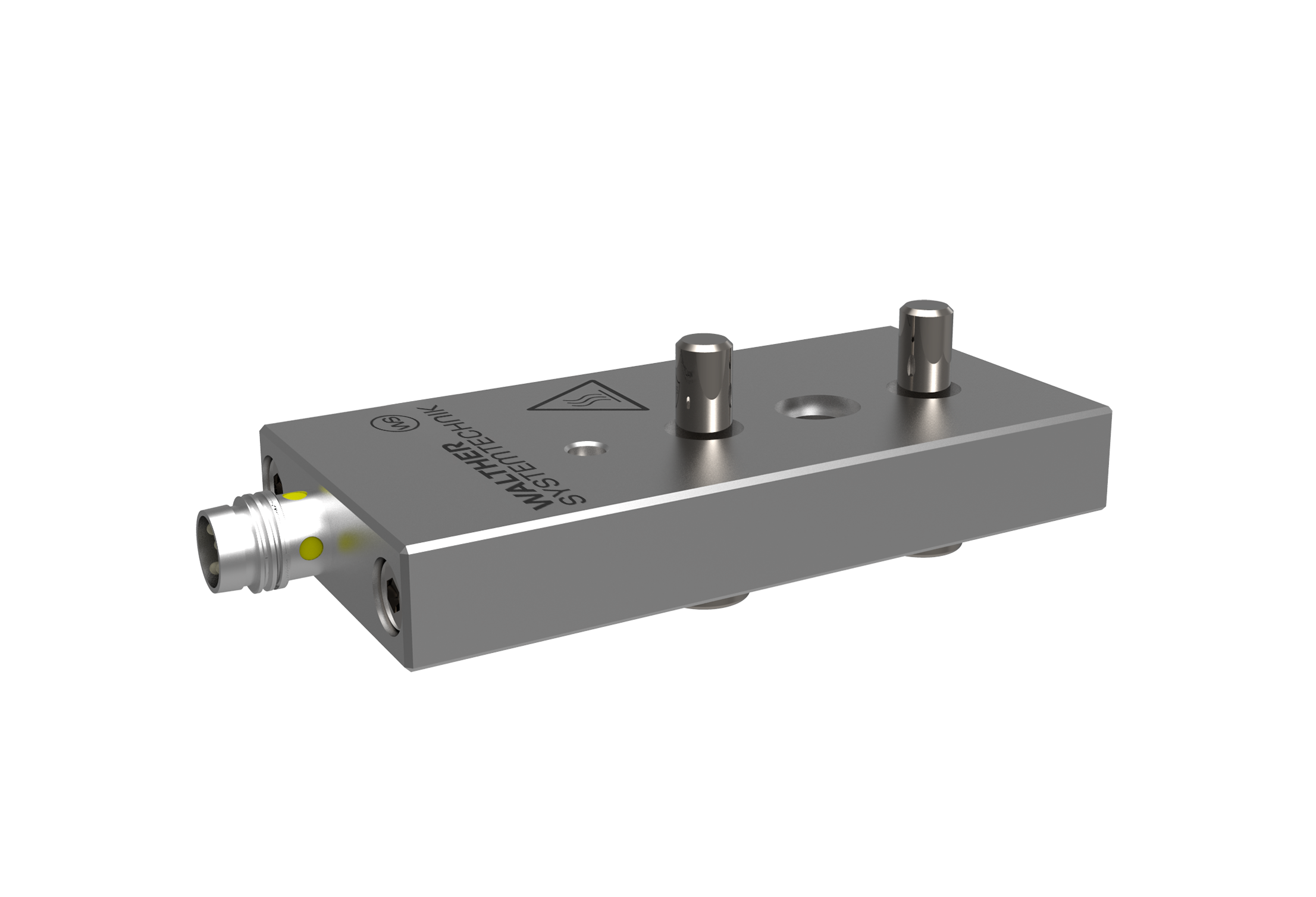

Spraying or volumetric dosing – why not both? With the Volume Spray Valve WSDV, you can spray viscous media precisely and repeatedly in defined quantities without contact and on larger surfaces. The spray valve comes in four different sizes and allows you to adjust medium volumes of up to 6000 mm³ via an adjusting screw for the pre-set dosing range.

Thanks to the volumetric dosing, there are no deviations in the medium characteristics. The special construction of the valve also produces a back suction effect at the end of the spraying process. This will keep the production area clean as there is no dripping before or after.

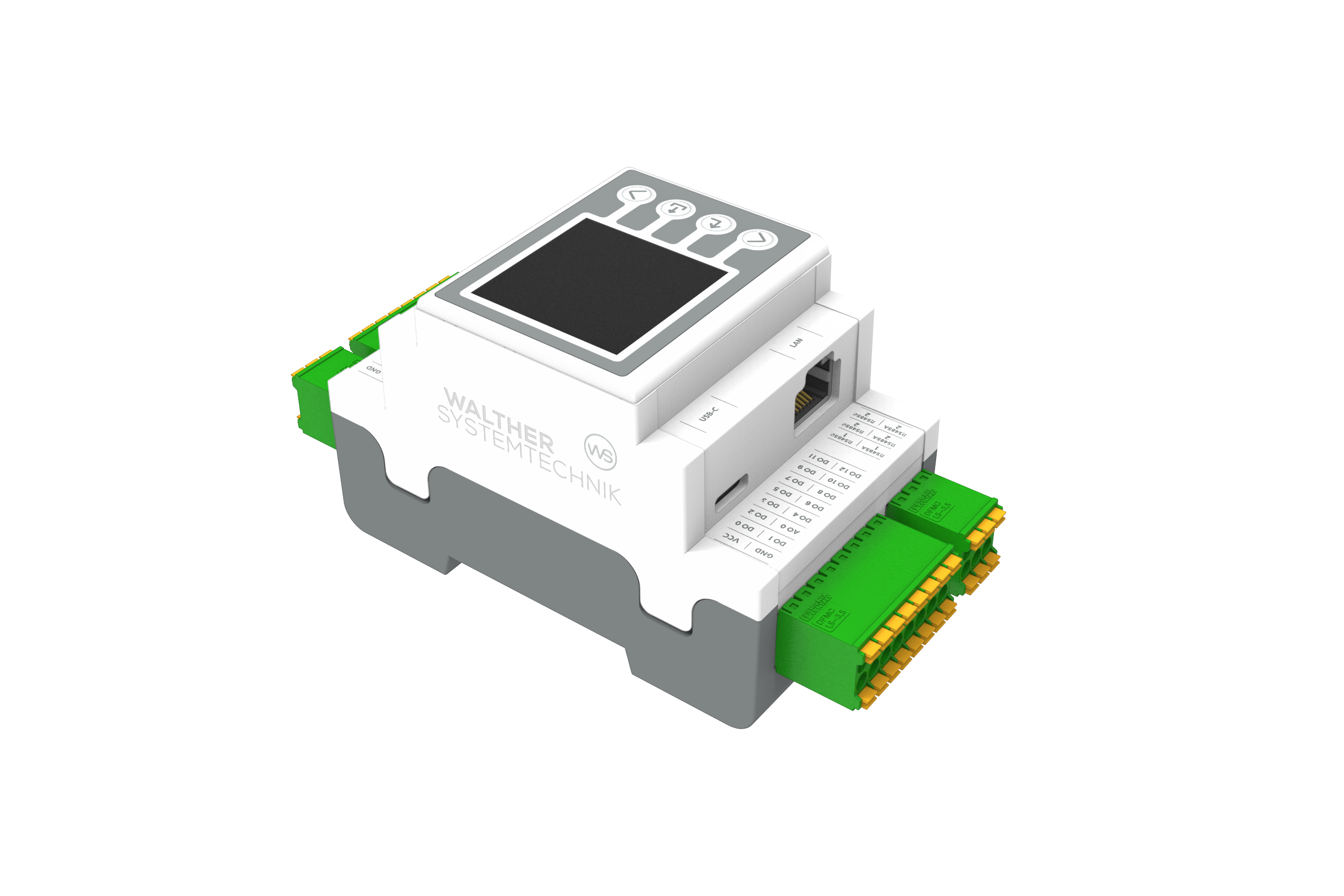

An external 5/2-way valve is used for controlling the WSDV Spray Valve. Atomizer air is controlled by a 3/2-way valve and is independent from controlling the doing piston.

Valves of the WSDV series are characterized by a high reliability and very little maintenance effort: Modern sealing elements guarantee a long life even with high inlet pressures of up to 200 bar.

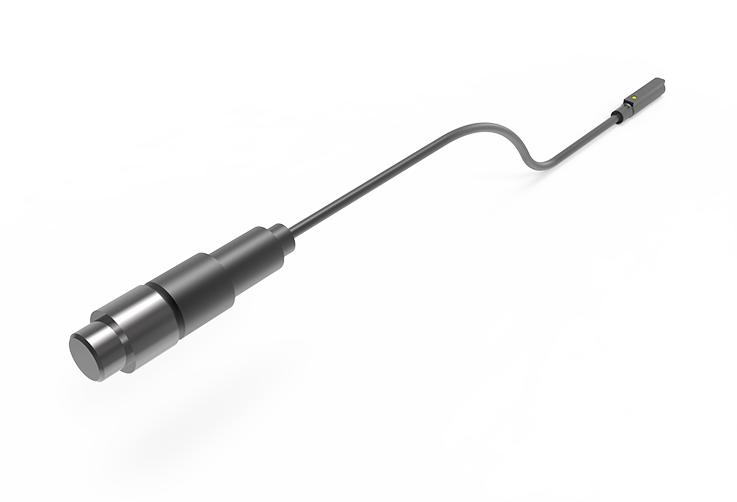

You can use the WSDV for manual application as well as integrated into a fully automated process. Additional accessories for process monitoring are screw-on pressure sensors, a needle stroke sensor or a valve heating.

- highest process reliability even with minimal spray quantities

- suitable for input pressures up to 200 [bar]

- opportunity for implementing process control in conjunction with the WALTHER Valve Controller

- inlet pressure (pneumatic): 5.0 to 8.0 [bar]

- inlet pressure (medium): 5 to 200 [bar]

- dosing quantity:

>> VAR "020": 0.01 to 0.2 [ml]

>> VAR "200": 0.1 to 2 [ml]

>> VAR "600": 1 to 6 [ml]

- weight:

>> VAR "020": 0.182 [kg]

>> VAR "200": 0.868 [kg]

>> VAR "600": 0.891 [kg]

- dimensions (l x w x h):

>> VAR "020": 135 x 23 x 51 [mm]

>> VAR "200": 246 x 36 x 77 [mm]

>> VAR "600": 246 x 36 x 77 [mm]