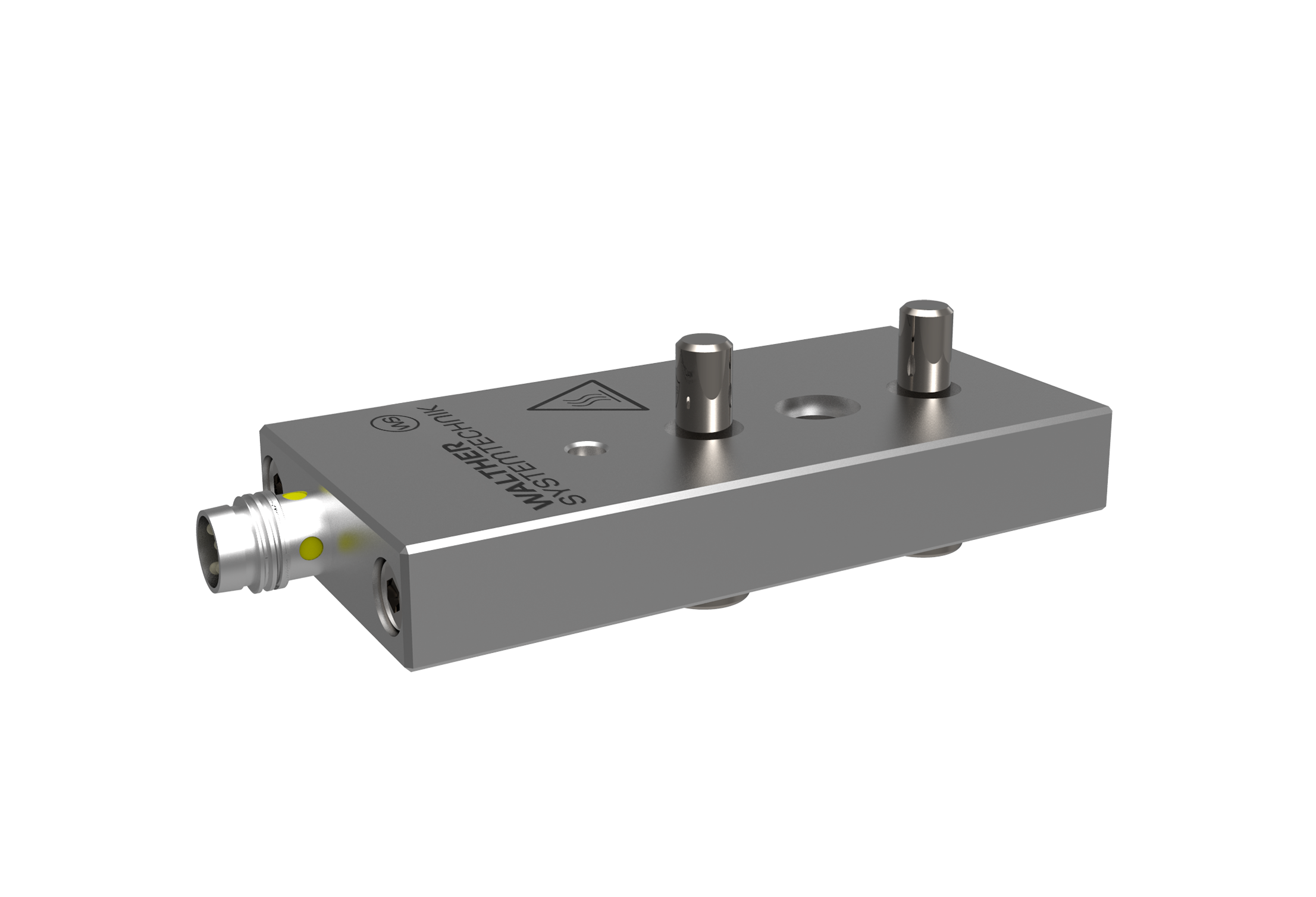

Heating Plate HZP

Walther heating plates are specially designed to control the temperature of application valves. Mounted directly onto the corresponding valve, their specific design ensures optimum heat transfer. This improves the quality and precision of the application, as the temperature has a major influence on the viscosity of the medium.

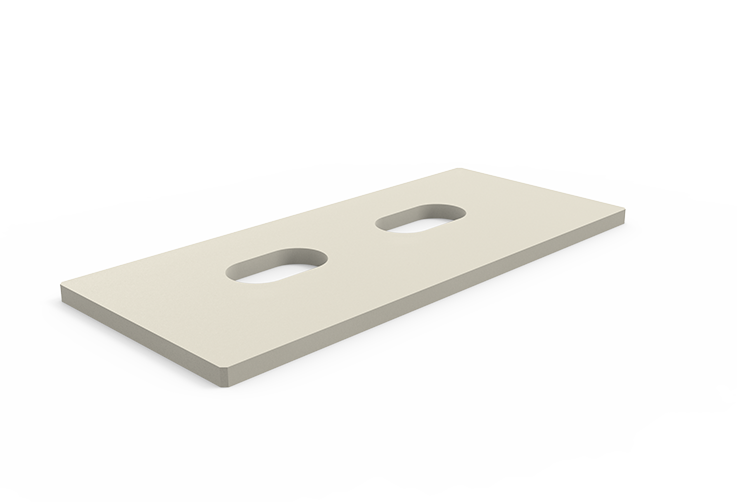

The heating plates have a built-in temperature sensor and a temperature switch that shuts off when the maximum temperature is reached. An LED in the connector indicates when the heating is active. With a heating capacity of 25 [W] at temperatures up to 80 [°C], they keep the temperature of the medium constant regardless of external influences. Optional insulating plates can be used to prevent heat transfer to adjacent components.

Walther valve heating plates are easy to install and operate, increasing the efficiency and safety of your process.

- integrated temperature sensor protects against damages from overheating

- signals for heating process through integrated LED

- integrated PT100 temperature sensor

- operating voltage: 24 [VDC]

- power consumption: 1,04 [A]

- electric connection: M8 4-Pin

- maximum temperature: 90 [°C]

- weight: 0,188 [kg]