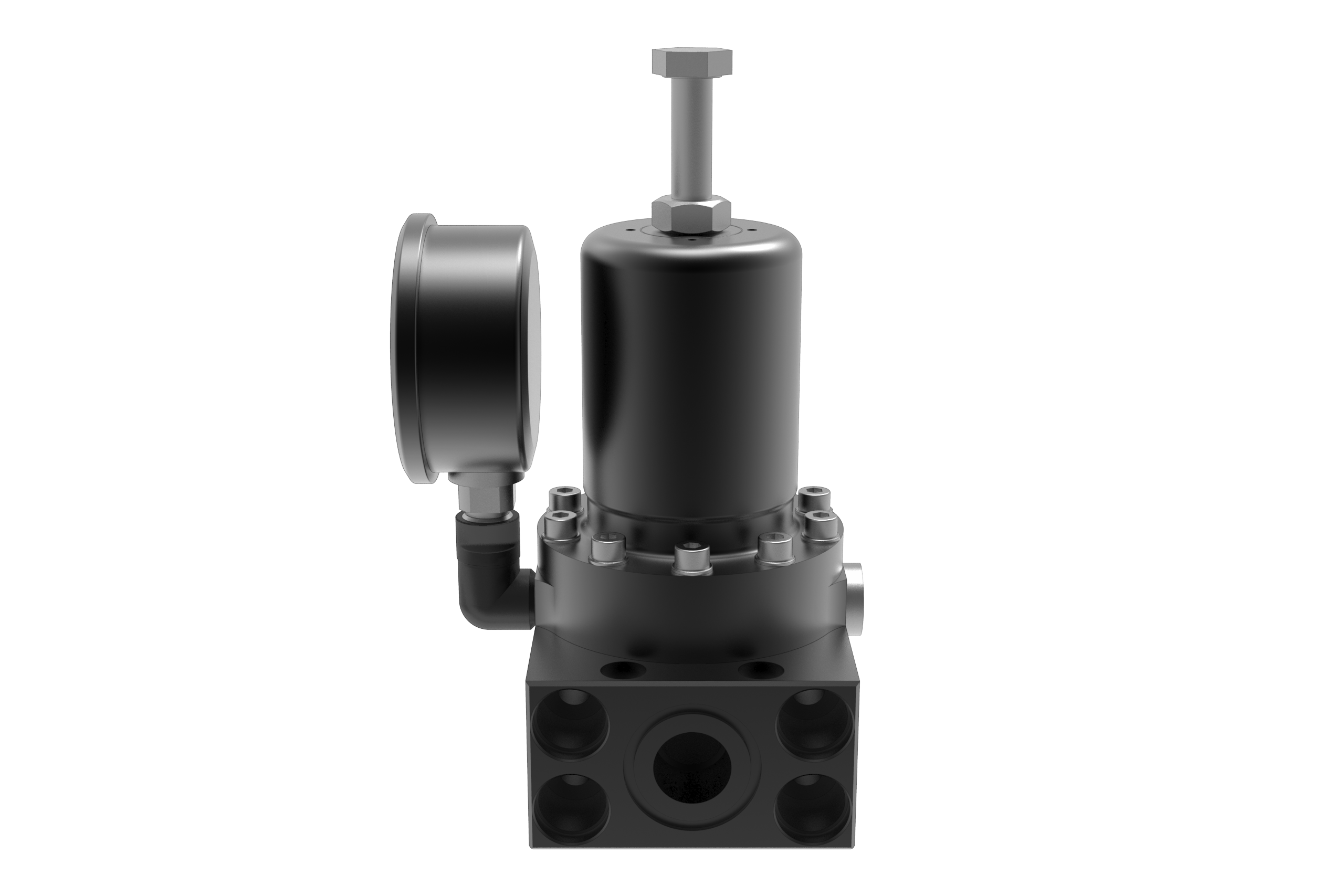

Material Pressure Regulator WMDR

The WMDR-50 material pressure regulator from Walther Systemtechnik is a manually adjustable component for pressure control in pipeline systems used in feed and circulation applications. It reliably reduces the material pressure to a defined target value within a range of 2 to 50 bar, maintaining it consistently, even under highly fluctuating inlet pressures of up to 150 bar. In this way, the WMDR-50 effectively protects downstream, pressure-sensitive components such as dispensing valves in fluid and dosing systems from overpressure and ensures a controlled media supply.

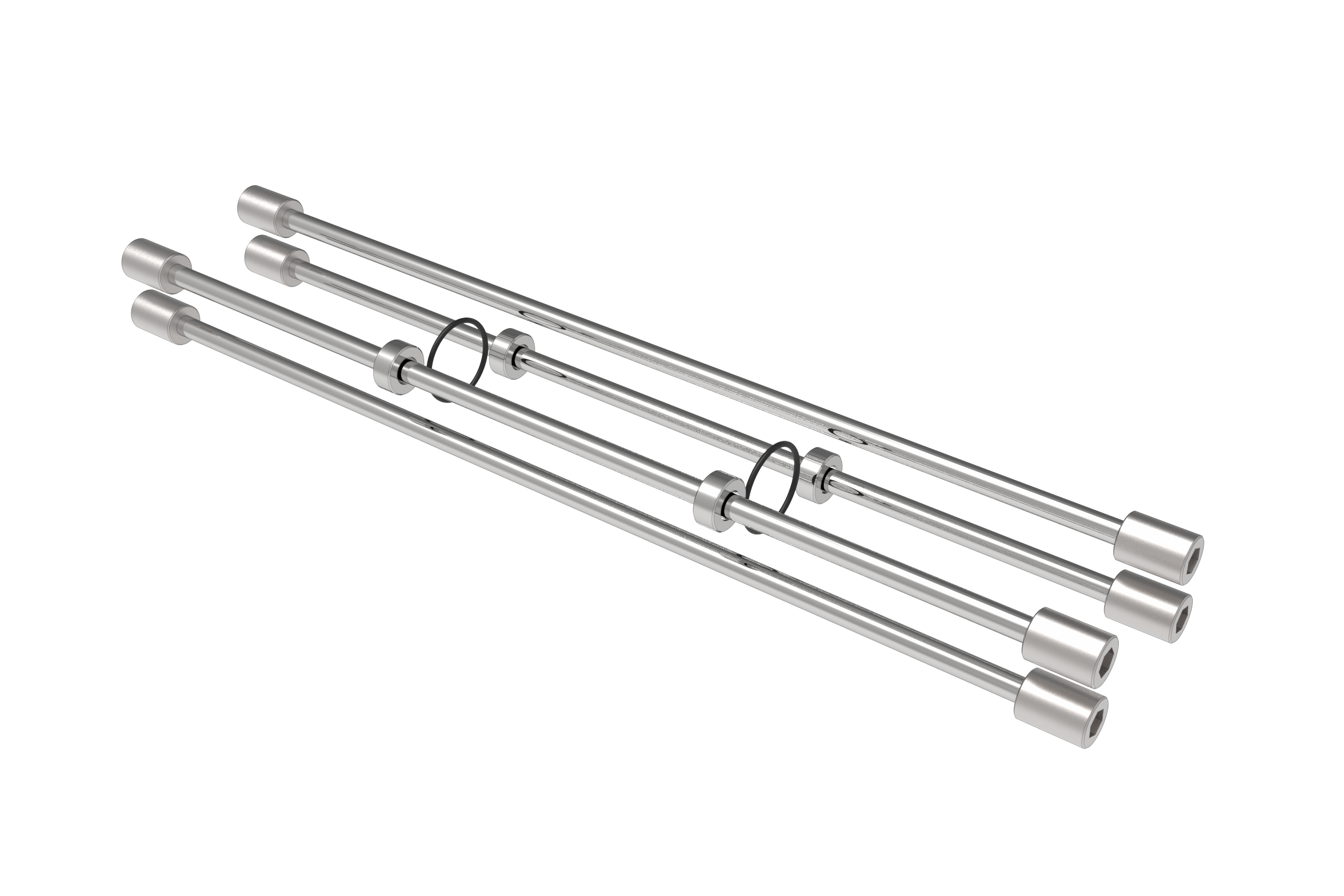

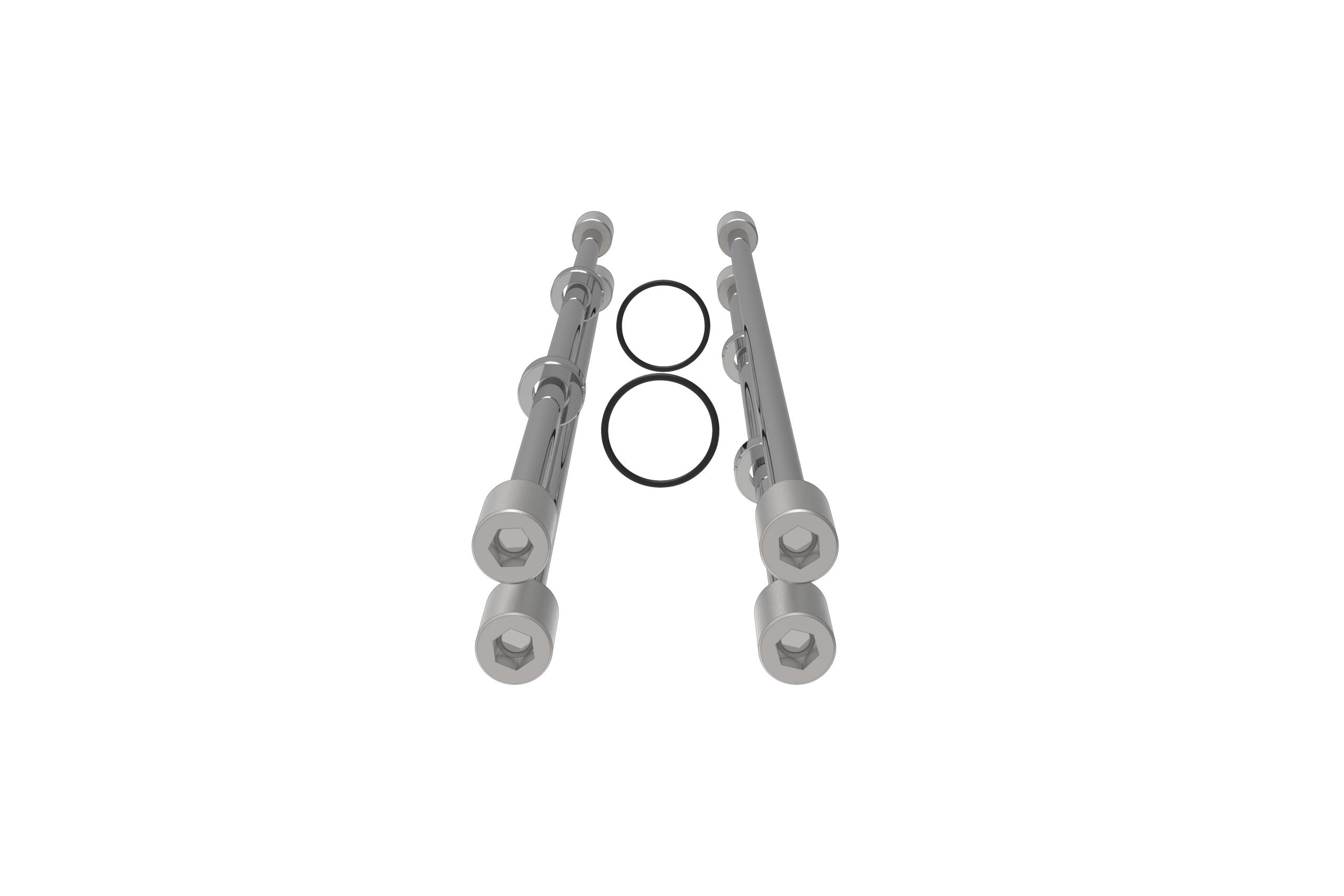

Pressure regulation is achieved mechanically via an adjustment screw that preloads a spring, which acts on a diaphragm to move a guided plunger. This plunger regulates the valve cross-section in response to the force balance between spring tension and outlet pressure. The combination of diaphragm control and guided plunger enables highly precise, stable and tightly sealed pressure regulation, even under pulsating inlet conditions.

An integrated stainless steel filter screen (630 µm) reliably protects the system against coarse contamination. A digital pressure sensor for pressure monitoring is optionally available. The unit is particularly suited for use with self-lubricating media such as greases and oils, and is designed for operation in non-hazardous environments.

An additional option is the SAVE kit – a tamper-proof safety mechanism with combination lock, preventing unauthorised adjustment of the configured pressure setting.

Thanks to its well-engineered design, high operational reliability and low maintenance requirements, the WMDR-50 offers an efficient and durable solution for demanding industrial pressure regulation tasks.

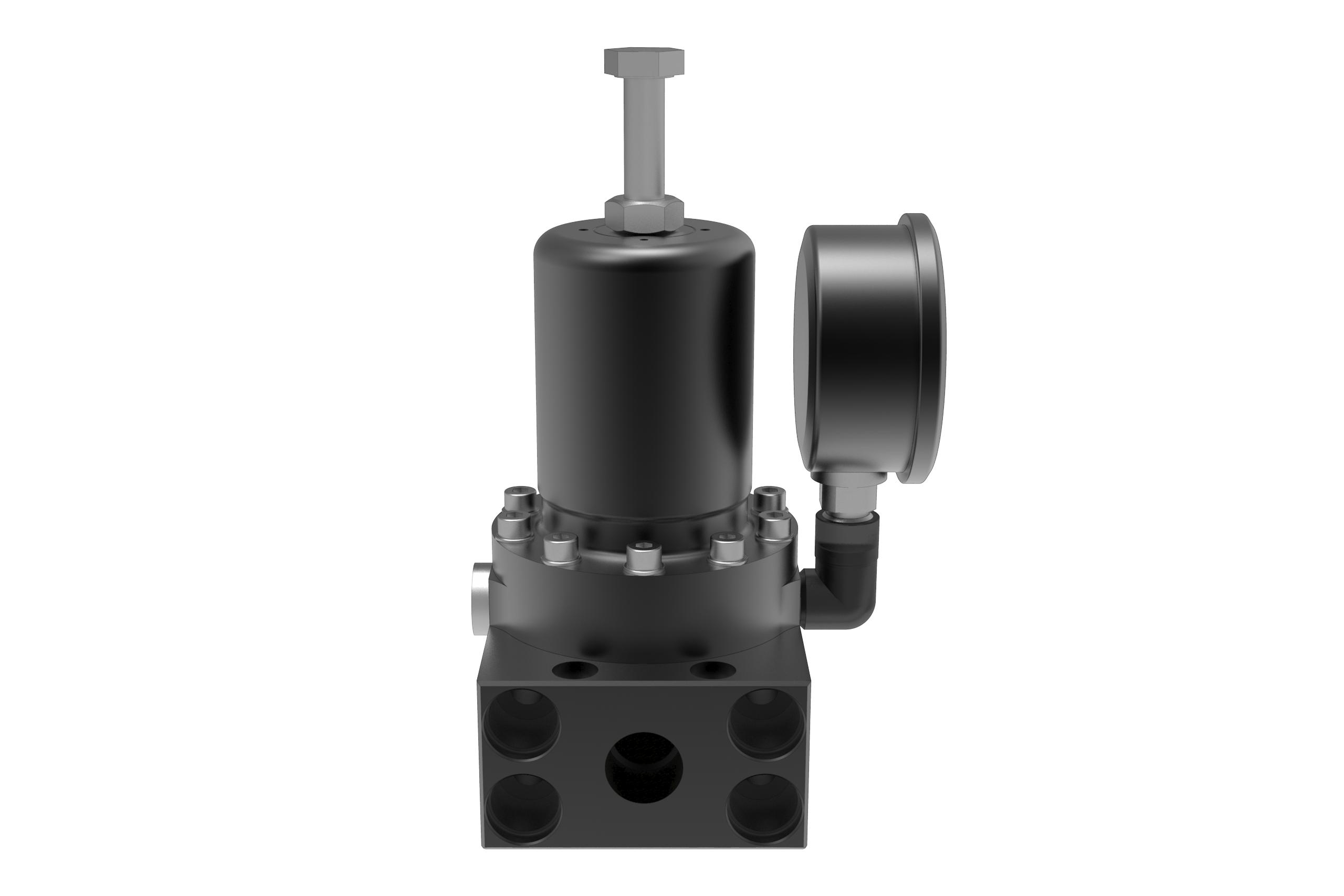

As part of the Walther MODULAR system, the WMDR-50 can be quickly and securely combined with other functional units using a standardised module connector. Its compact design and flexible mounting options allow for easy integration into both new and existing dosing and application systems.

- highly dynamic controlling without stick-slip-effect

- low weight of components

- integrated filter sieve catches larger contaminations

- compensation of pulsations in supply line

- device from WALTHER MODULAR series, therefore smaller installation area, easy mounting and simplified maintenance

- operating pressure: max. 150 [bar]

- control range: 2 to 50 [bar]

- dimensions (l x w x h): 102 x 79 x 187 [mm]

- weight: 1,8 [kg]

- Walther-Module length: 2 [TE]

- connection: G1/2"i and flange Walther-Modular