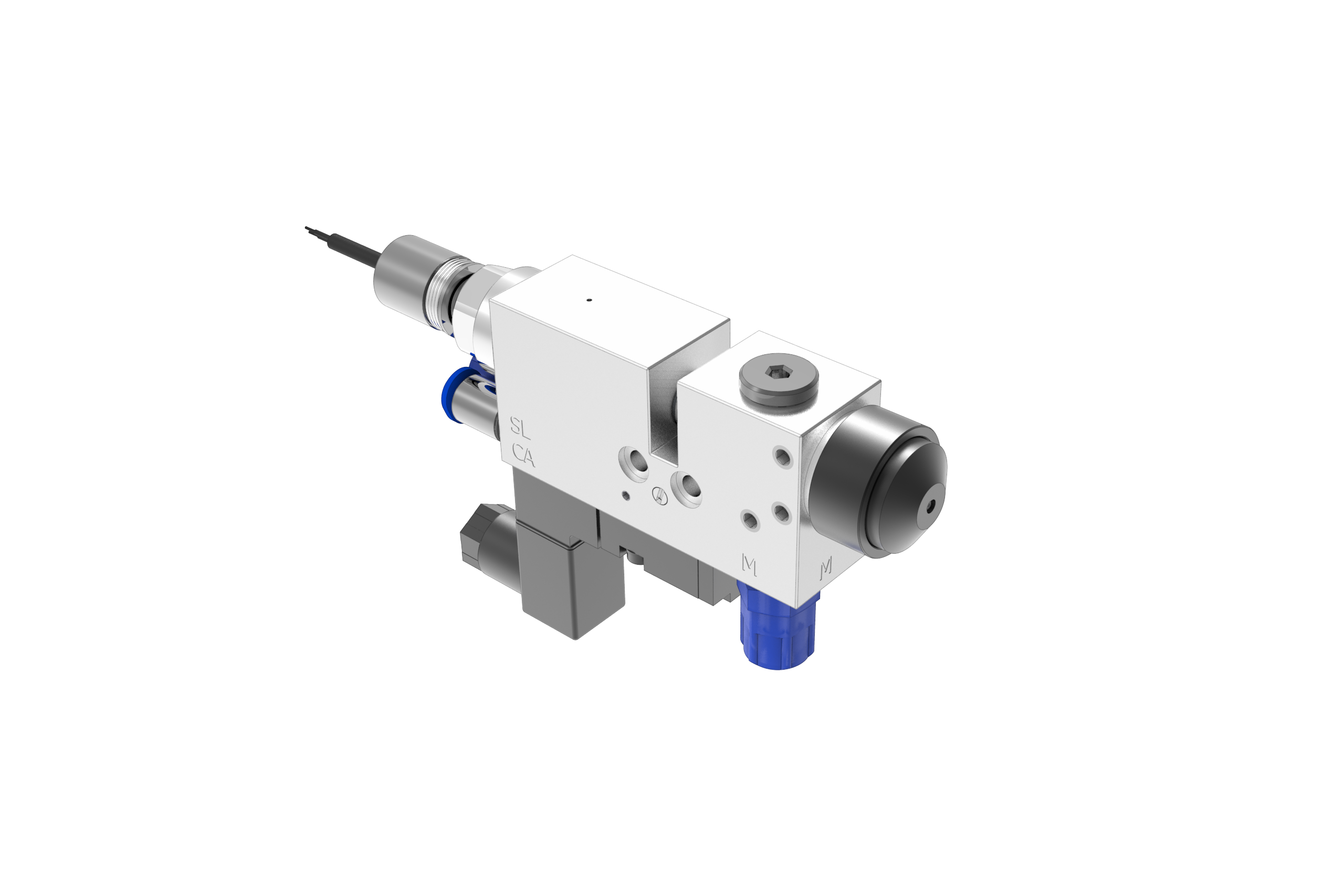

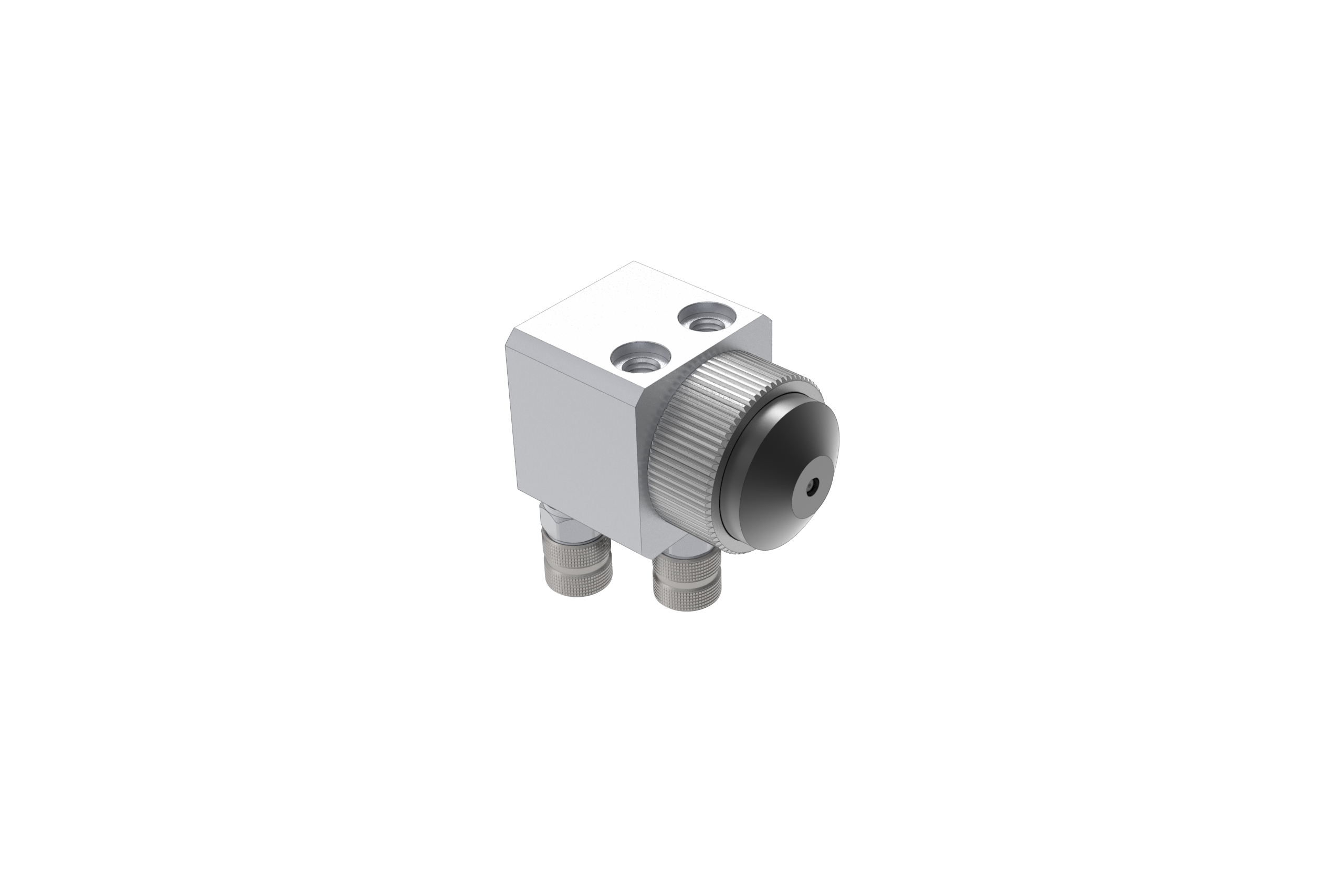

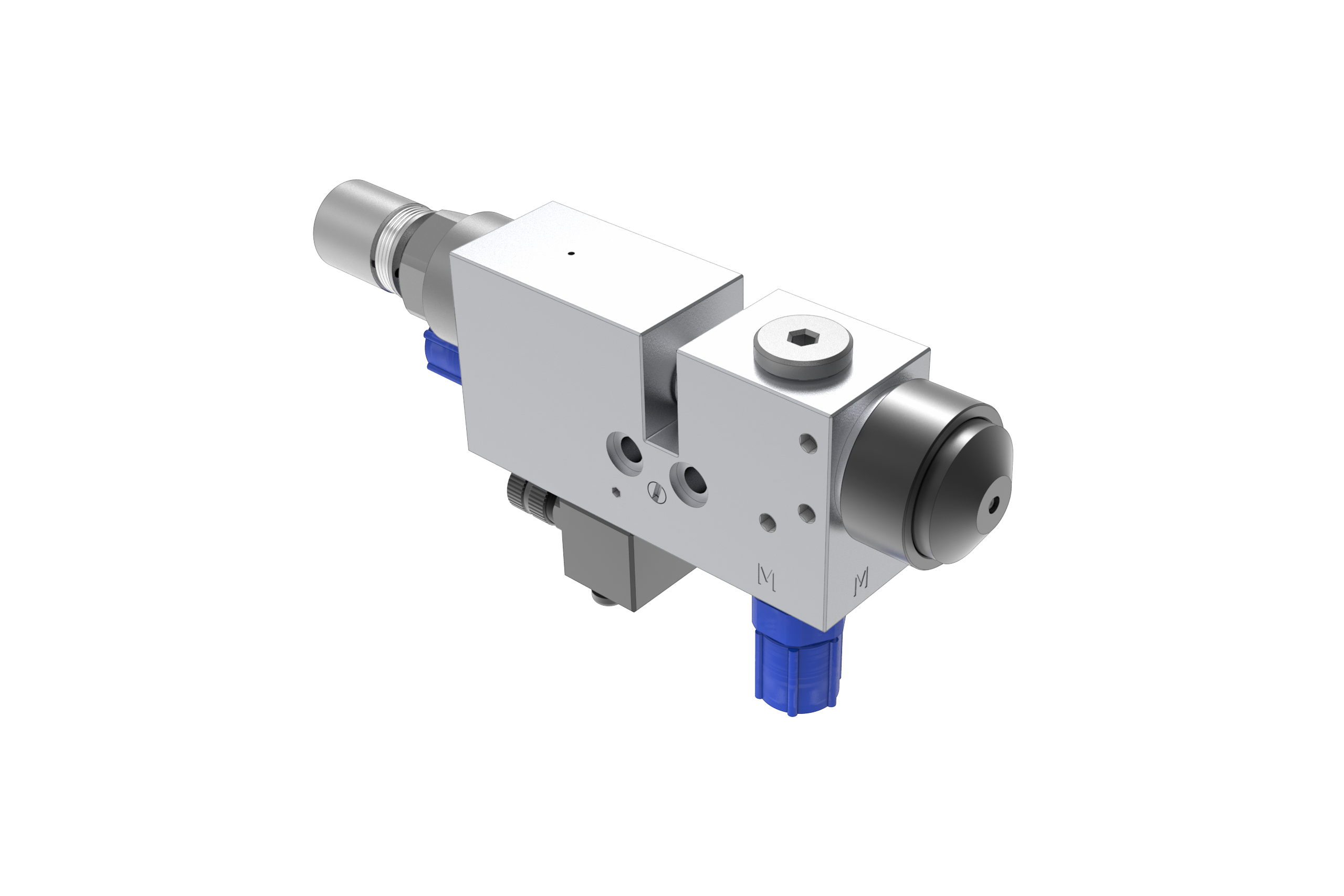

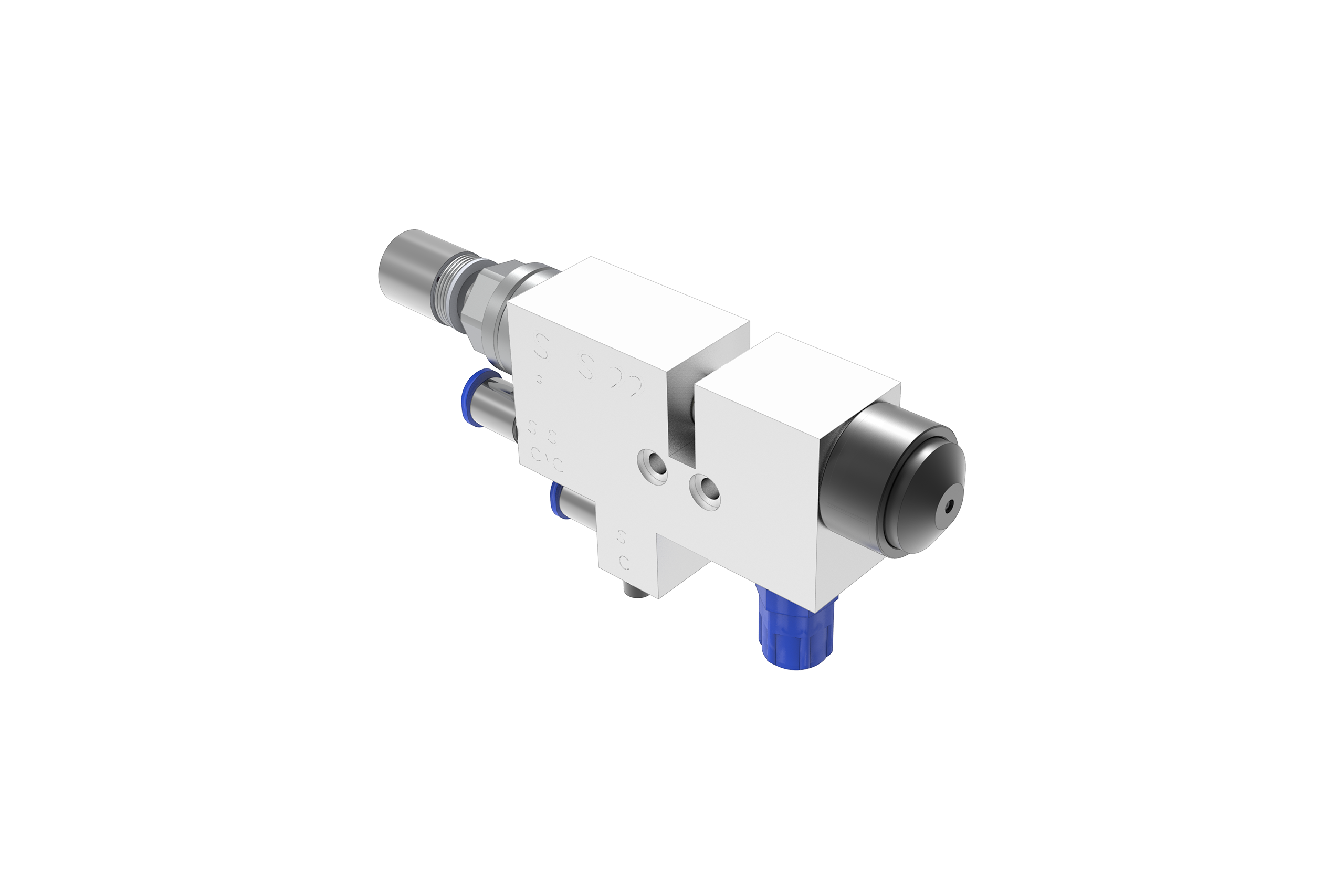

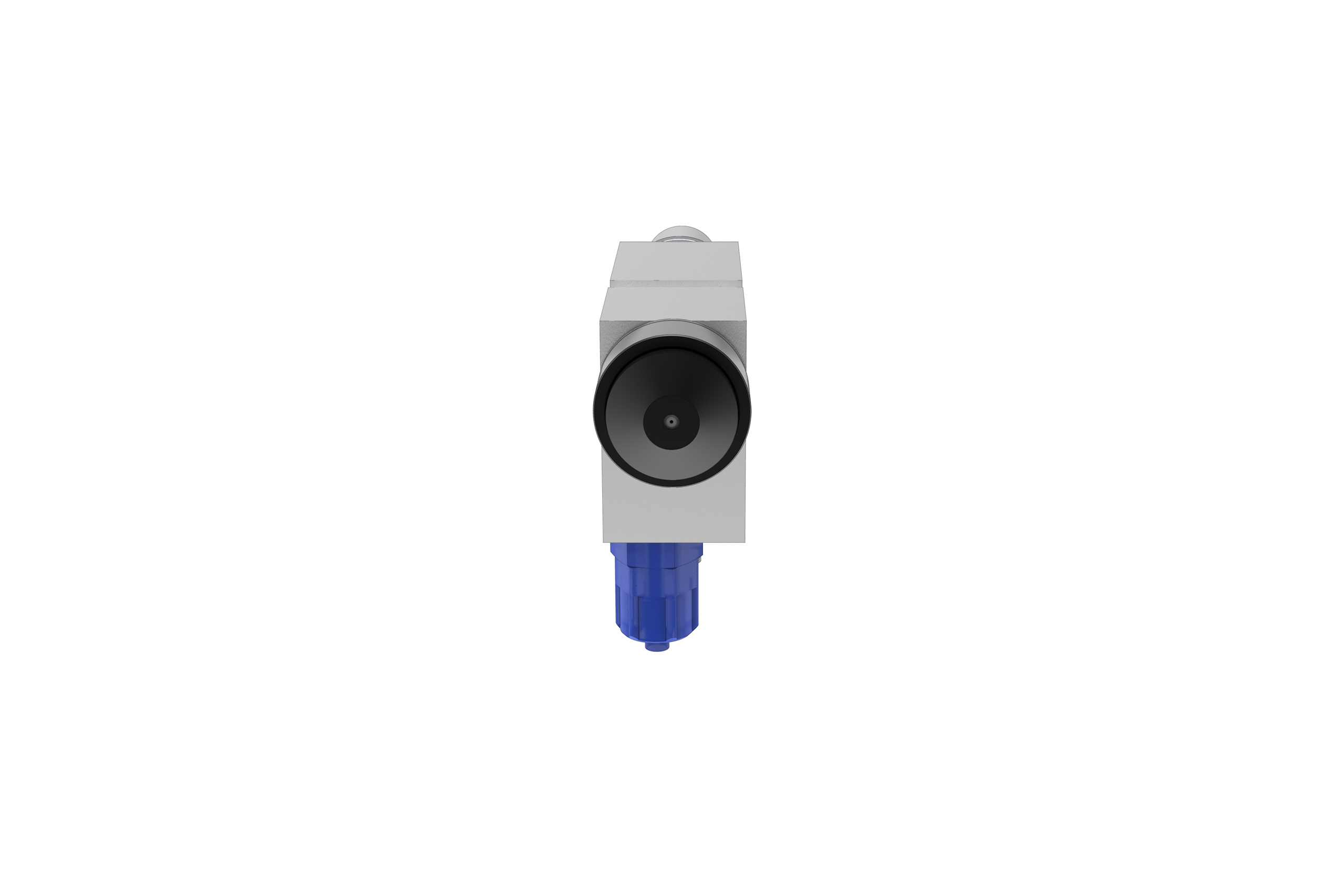

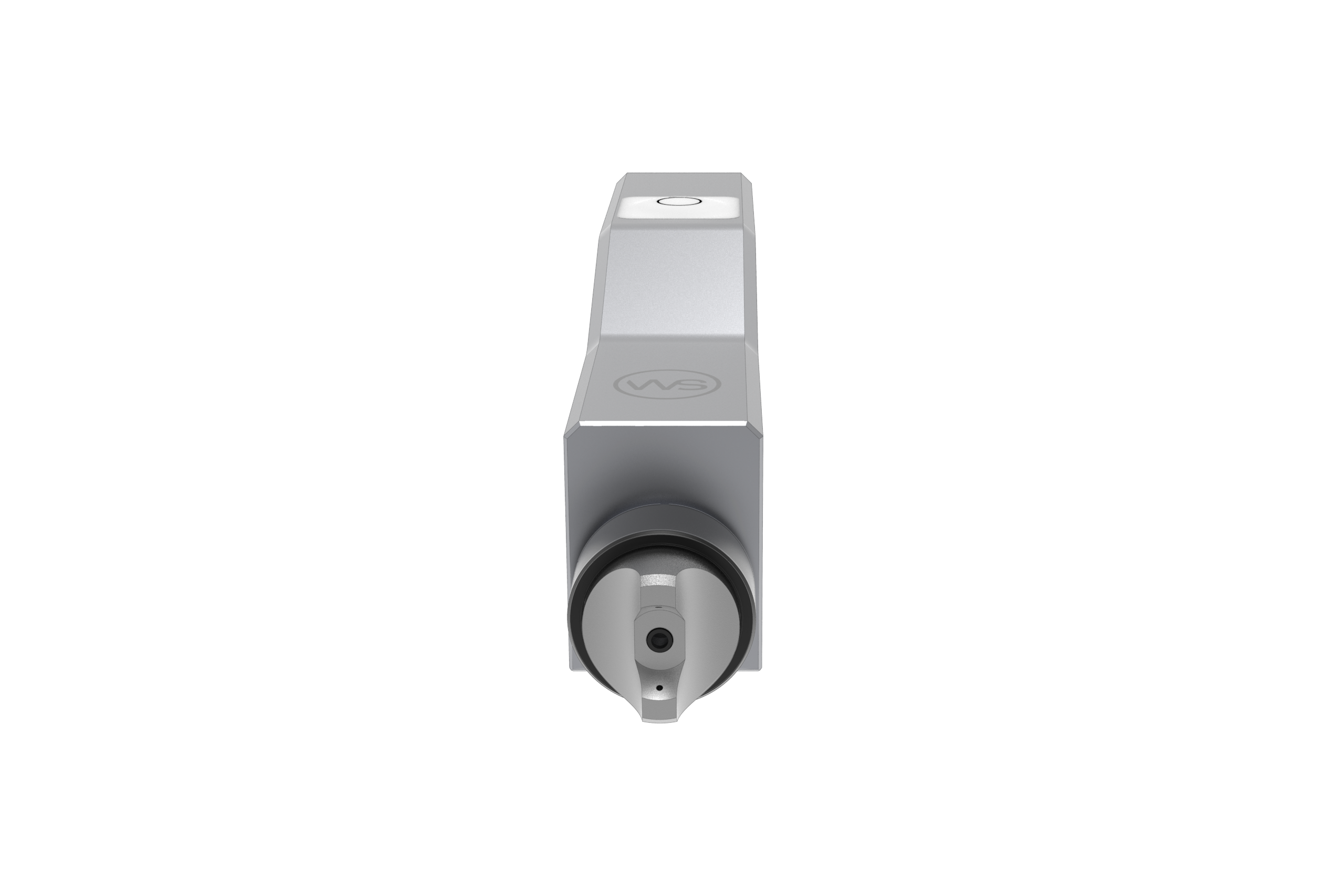

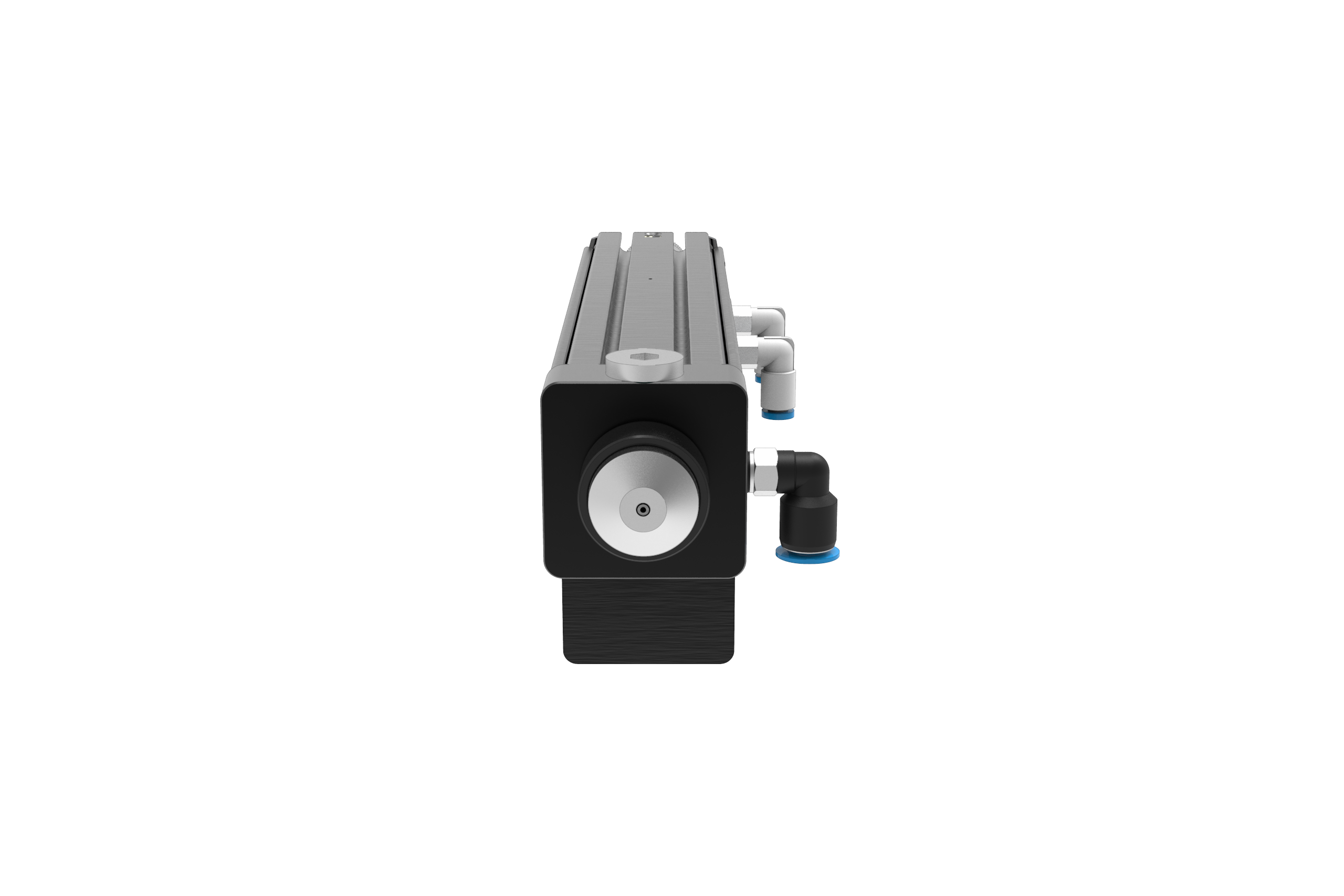

Spray valves for uniform surface coating

Spray valves from Walther are designed for both intermittent and continuous application of viscous media. They enable uniform, non-contact coating of component surfaces with a homogeneous, finely atomized film – reliable, material-efficient, and process-safe.

The spray pattern can be precisely adapted to the specific application task by adjusting the nozzle geometry, air cap, and optional nozzle extensions. Depending on the application and component geometry, it is possible to generate spot, flat, rotationally symmetric, or segmented spray patterns. This variety of spray configurations and mechanical adjustment options allows for targeted coating even in hard-to-reach areas – such as undercuts, sealing surfaces, internal housing contours, or circumferential component geometries – without material waste or contamination of adjacent zones.

Typical applications include the application of release agents, corrosion protection oils, cleaning and wetting agents, and functional coatings. The valves are suitable for use in manual workstations as well as for integration into automated production lines, robotic systems, or semi-automated setups.

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request