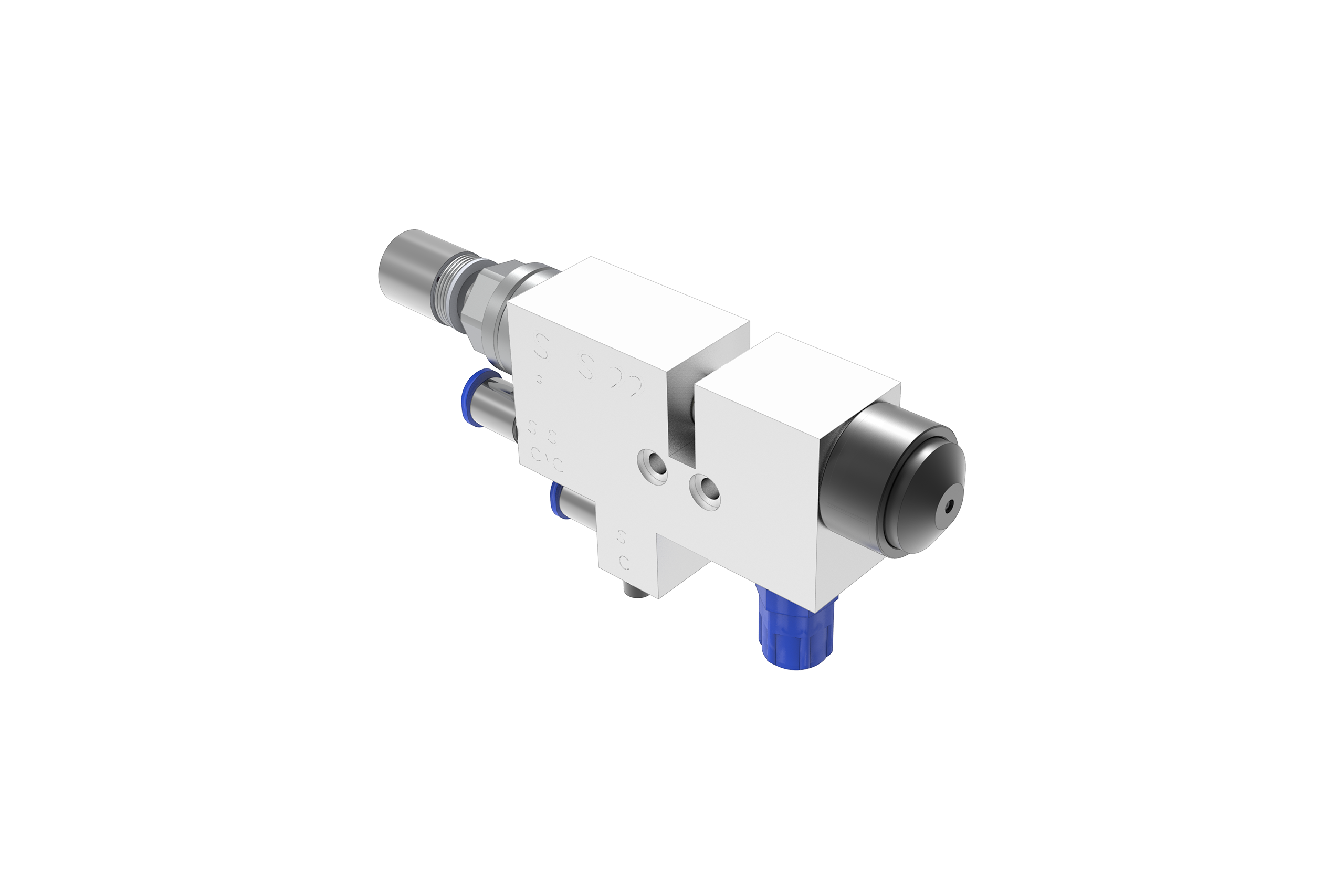

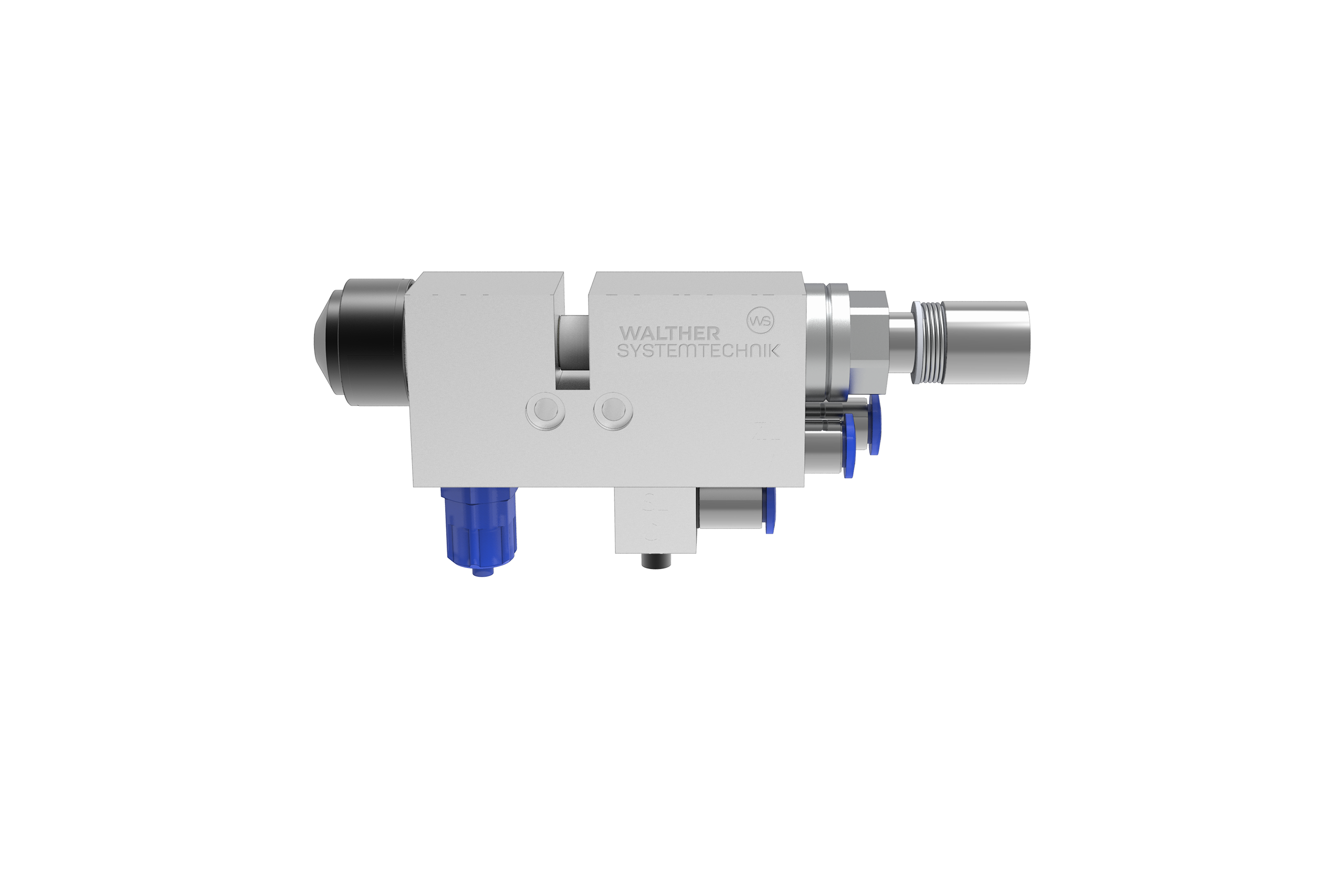

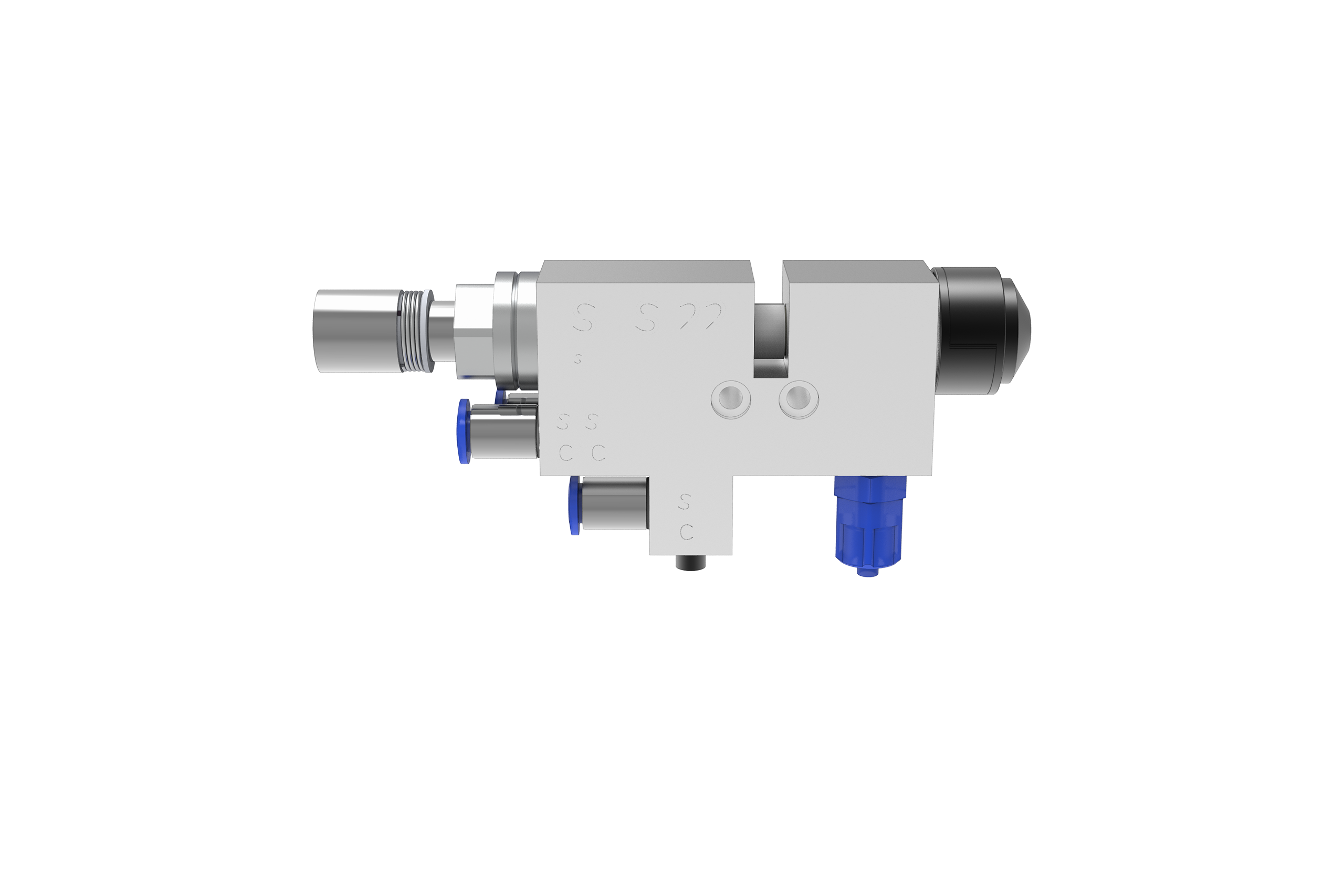

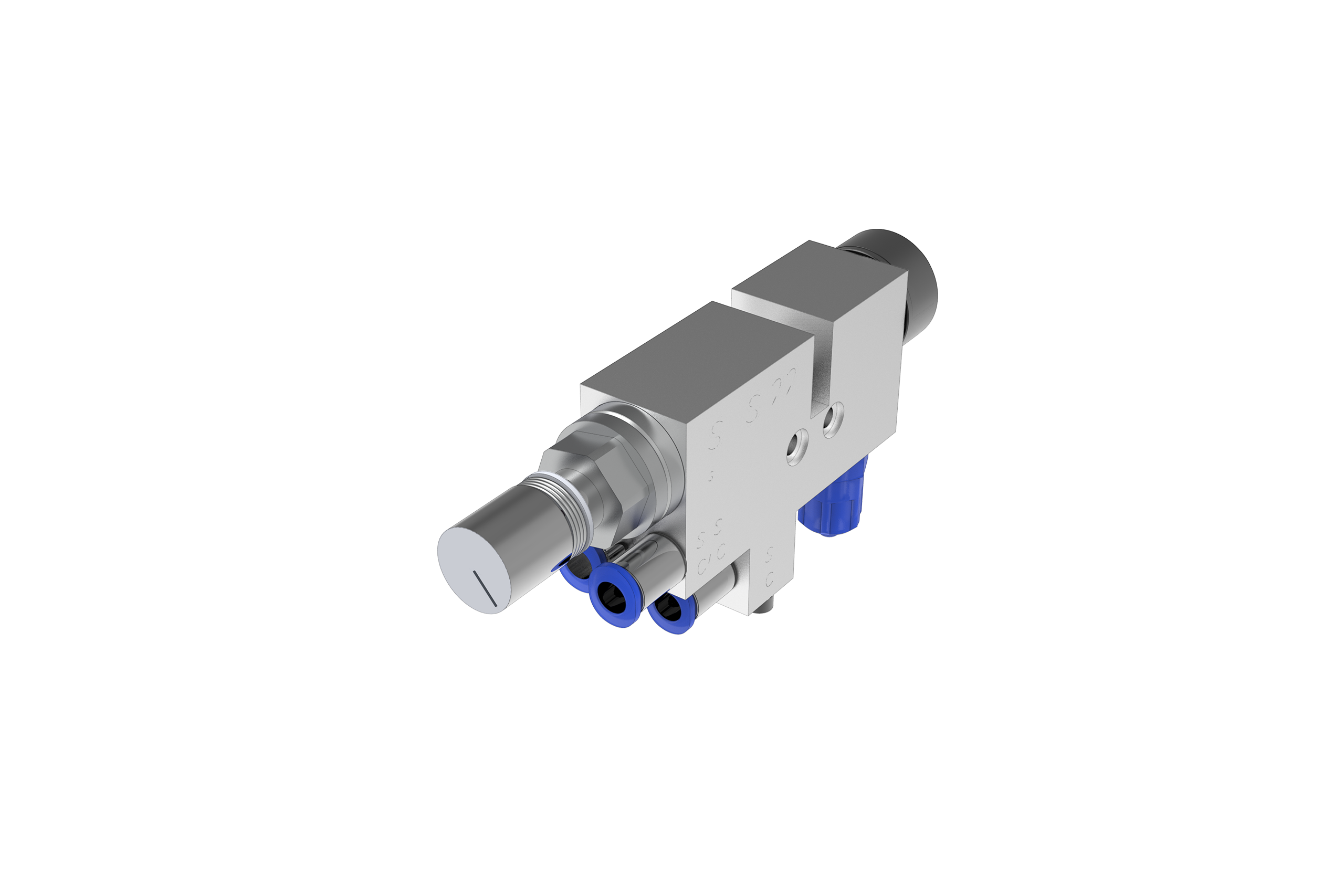

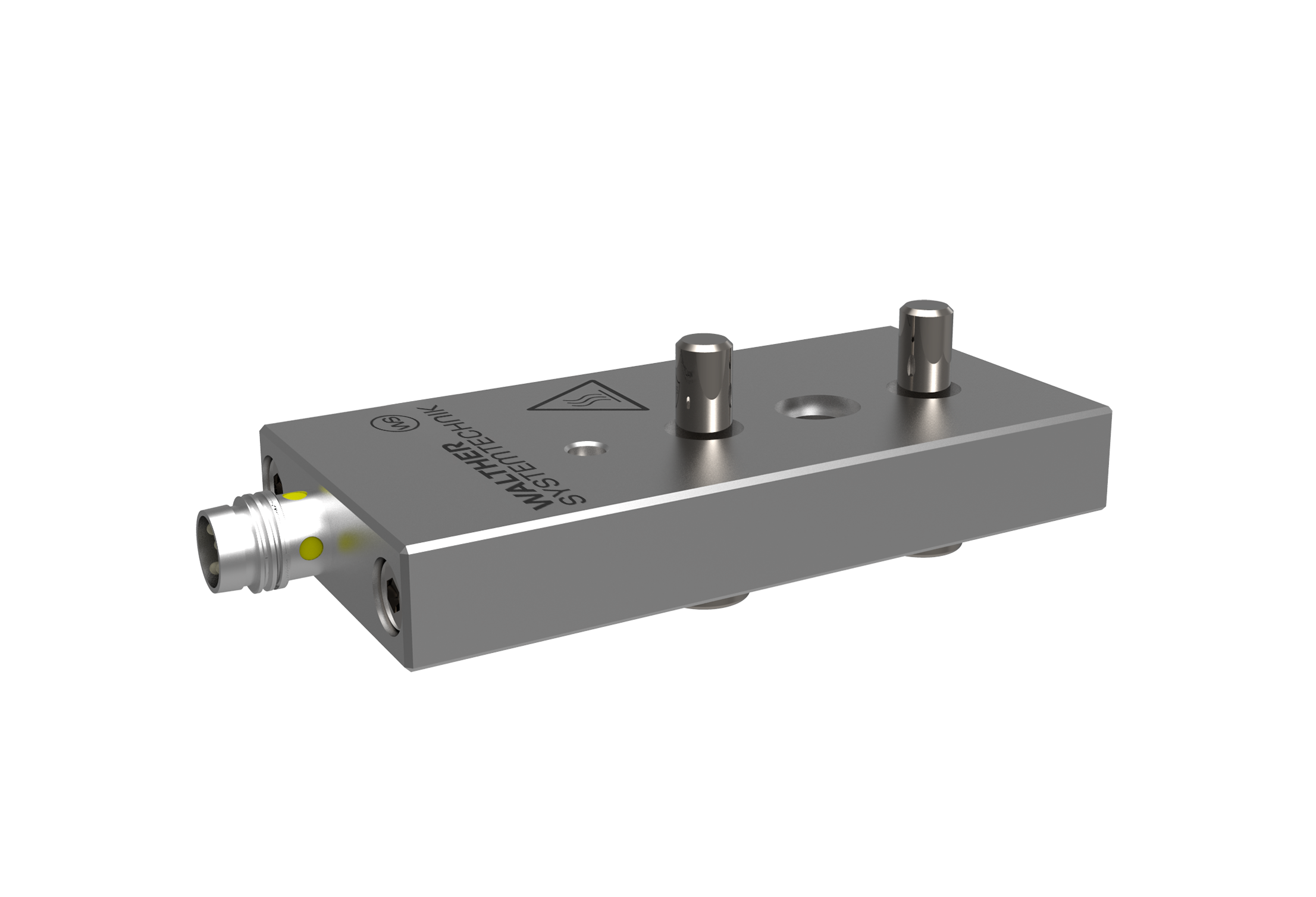

Spray Valve SMS-22

The pneumatically actuated spray valve SMS-22 is designed for the precise and uniform application of low- to medium-viscosity media. Typical applications include the spraying of oils, greases, release agents, corrosion protection fluids, paints, or low-viscosity adhesives – particularly in automated production processes with high demands on process reliability and dosing accuracy.

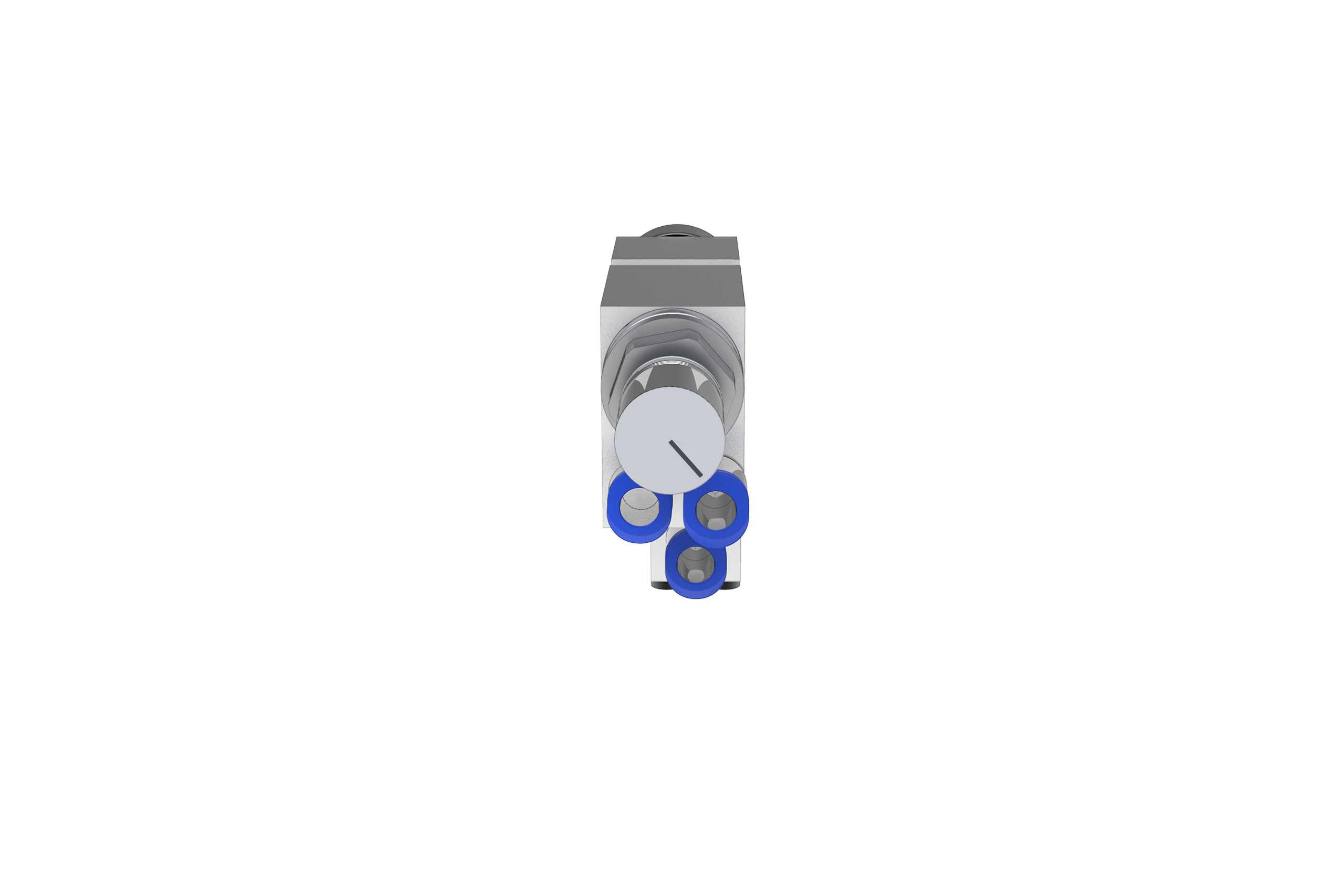

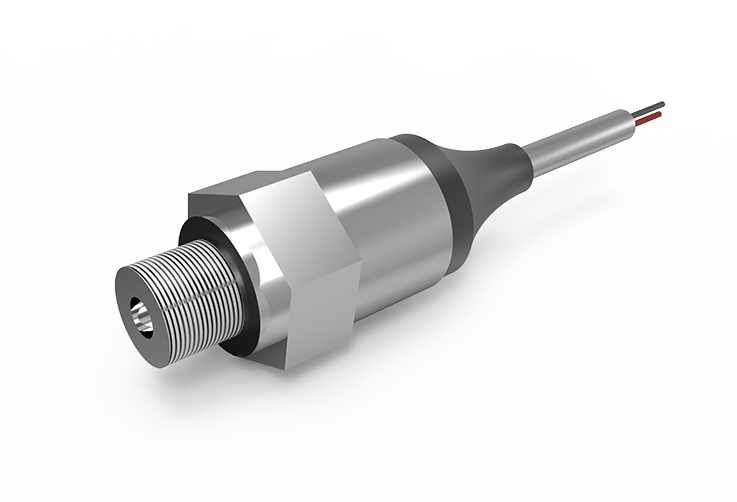

The valve needle is opened by control air and reliably retracted by a combination of separately supplied closing air and spring force. This force-assisted retraction ensures a clean, well-defined cut-off at the nozzle – even under elevated material pressure.

Atomizing air is supplied via a separate inlet, independently of the control air. It can be activated before material delivery begins and maintained after needle closure. This enables immediate atomization at the start of spraying and supports the automatic cleaning of the nozzle tip. Pre- and post-air durations can be freely adjusted on the system side to optimize the spray behavior according to the medium and process requirements.

Two external pilot valves are required for actuation; for atomizing air control, the use of an externally actuated 3/2-way valve is recommended, especially for applications involving low operating pressures. Pneumatic control components are not included in the scope of delivery.

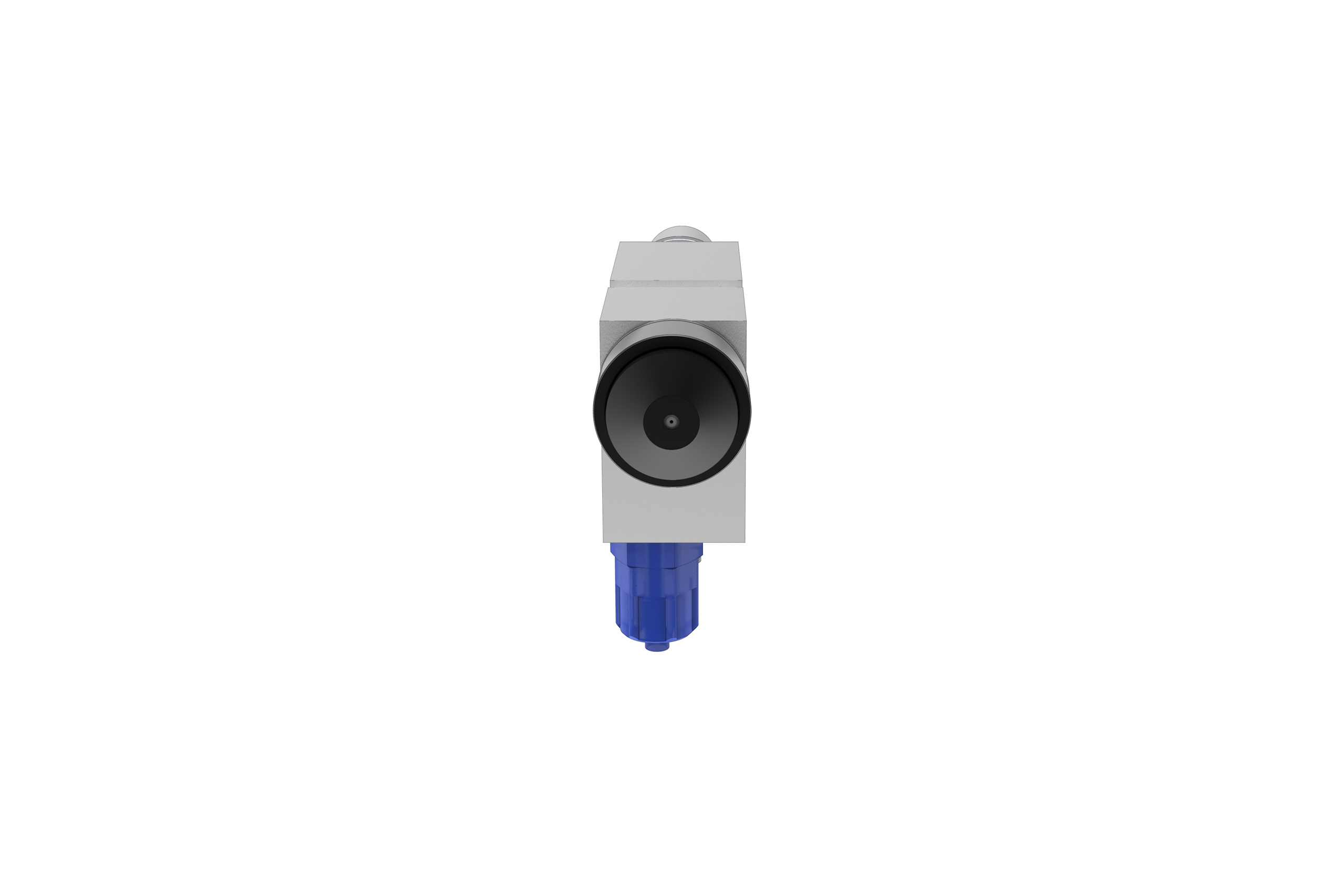

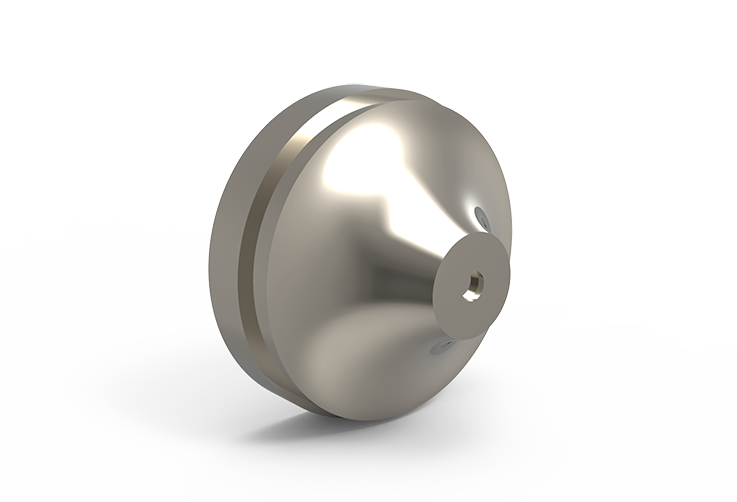

The dosing quantity is adjusted via a finely indexed stroke adjustment mechanism. An optional version with integrated sensor is available to digitally monitor the needle’s open state. A variety of nozzles and air caps, for round or flat spray patterns, are available and can be tailored to suit specific component geometries.

With its compact design, process-reliable functionality and high degree of flexibility, the SMS-22 is the ideal solution for demanding spray applications across a wide range of industrial sectors.

- pneumatically controlled, active closing of valve needle

- different nozzles and air cap combinations for a perfect adaptation to the desired spraying image

- for complex spraying tasks, we offer a variety of adapted nozzle extensions optionally

- optional heating plate available for tempering the valve body

- atomizer air and control air controlled independently

- process pressure: max. 35 [bar]

- control air pressure: min. 5 to 6 [bar]

- atomizer air pressure: 0,5 to 5 [bar]

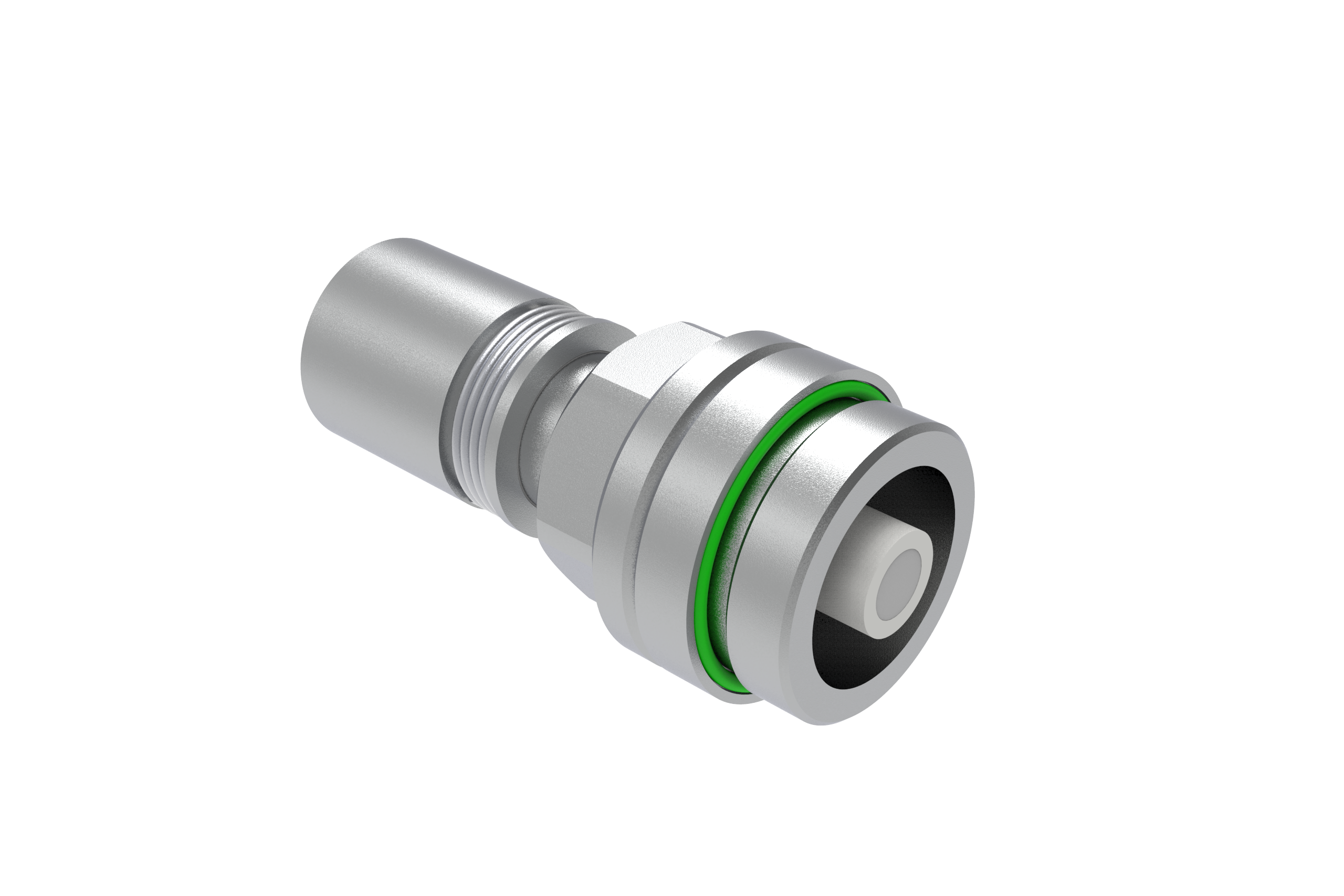

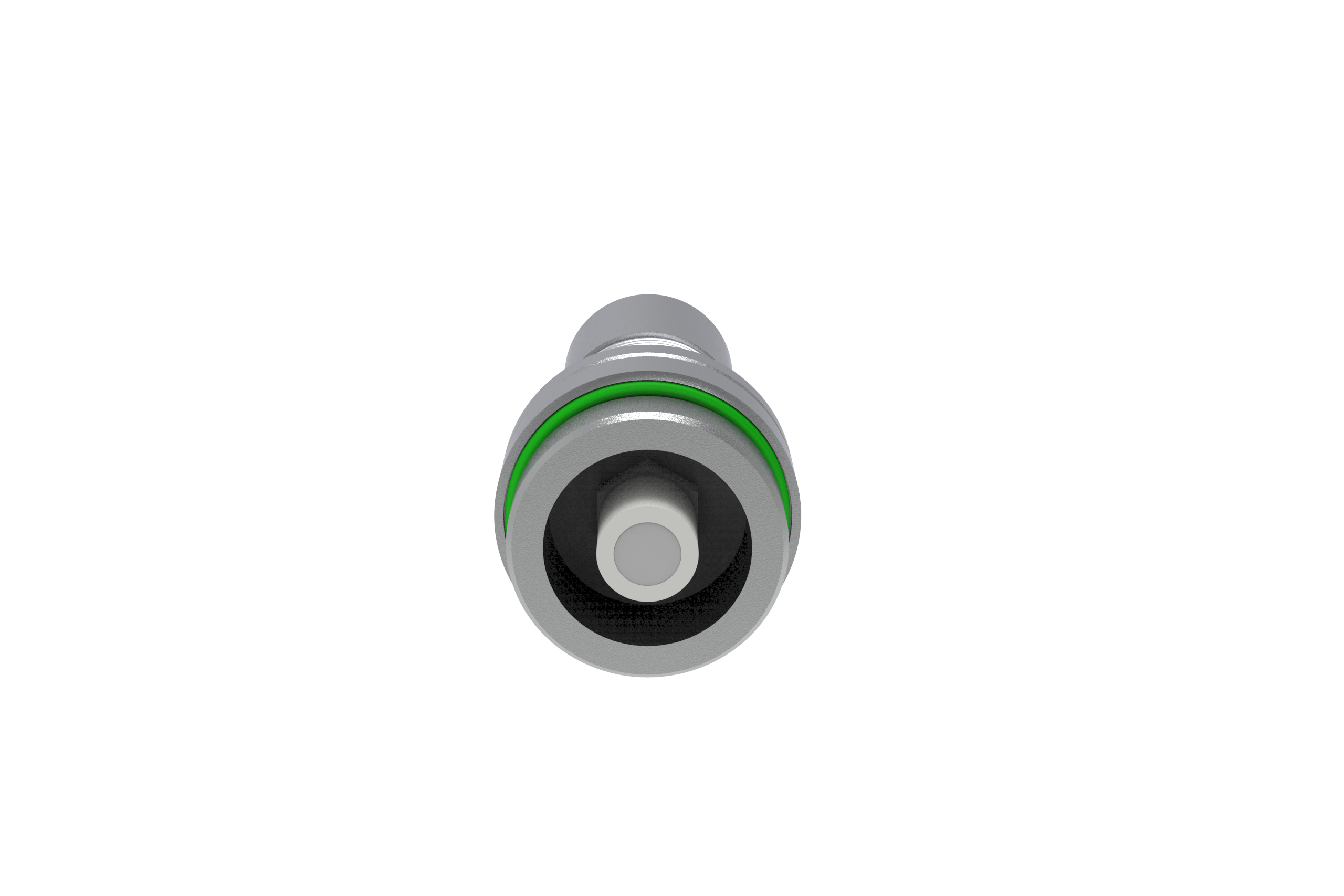

- process connection (medium): G1/4" incl. hose screw joint 6/4

- process connection (air): hose screw joint 6/4

- dimensions (l x w x h): 131 x 23,5 x 57,5 [mm]

- weight: 0,5 [kg]

- nozzle & needle: optionally hardened (kolsterised)