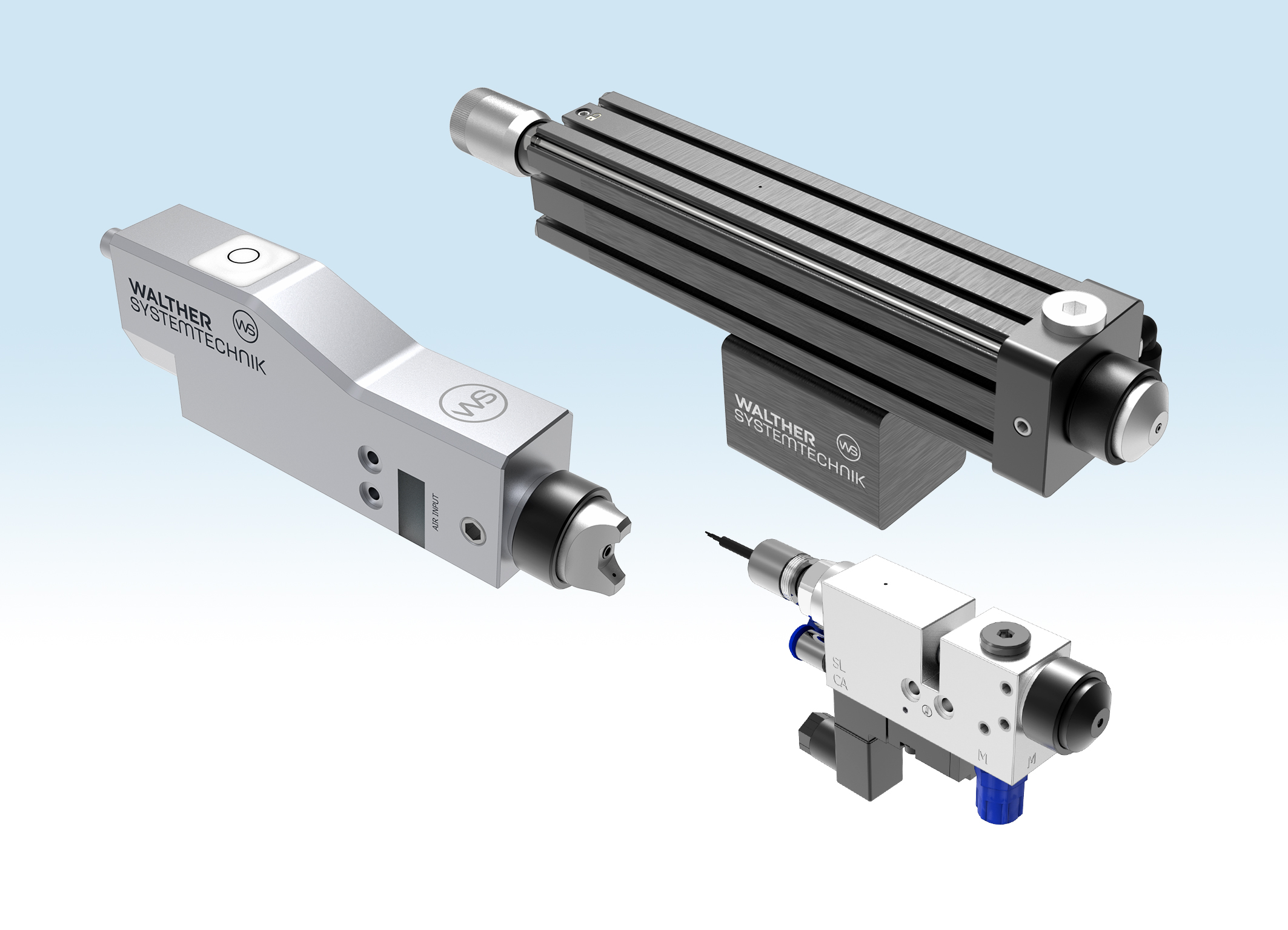

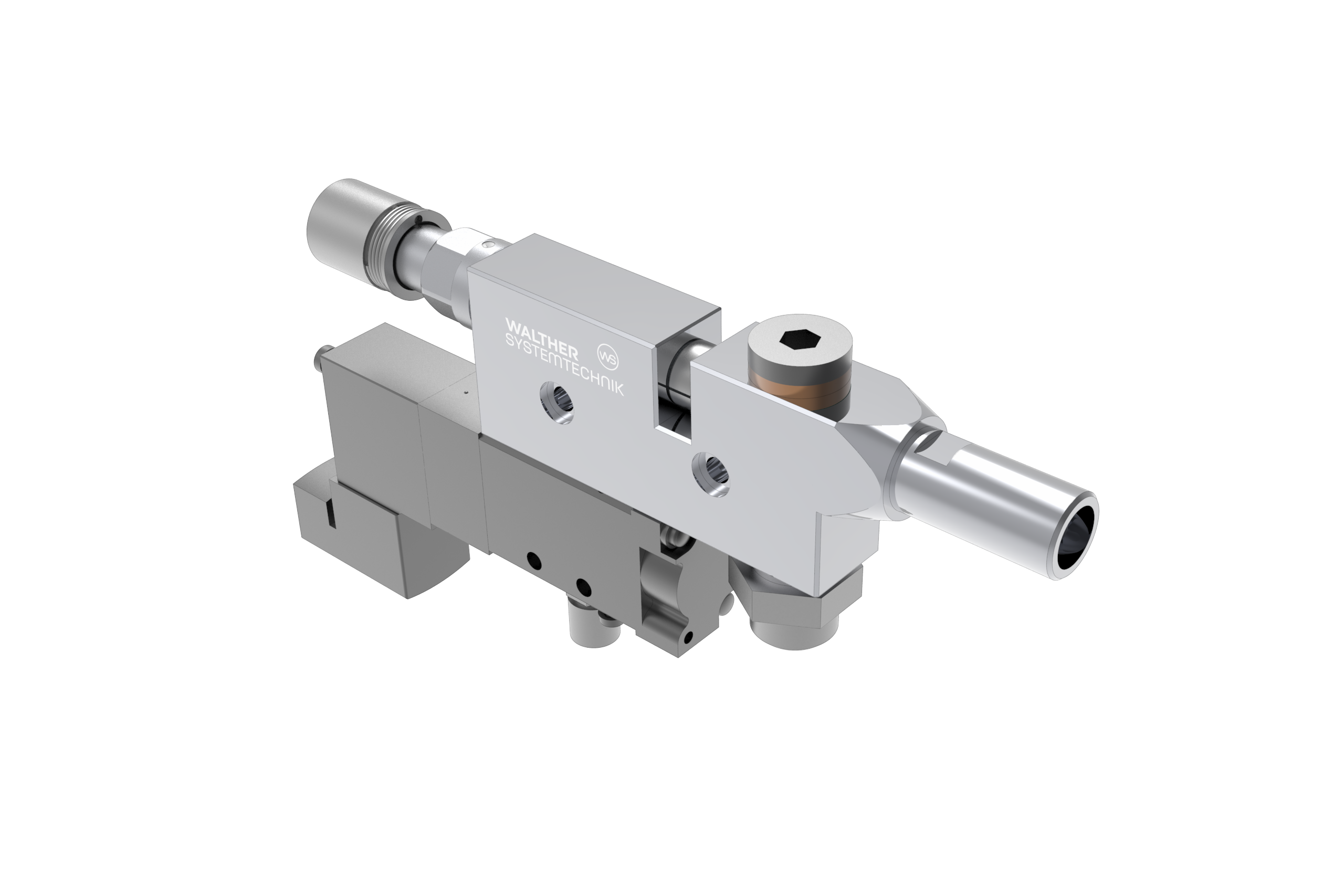

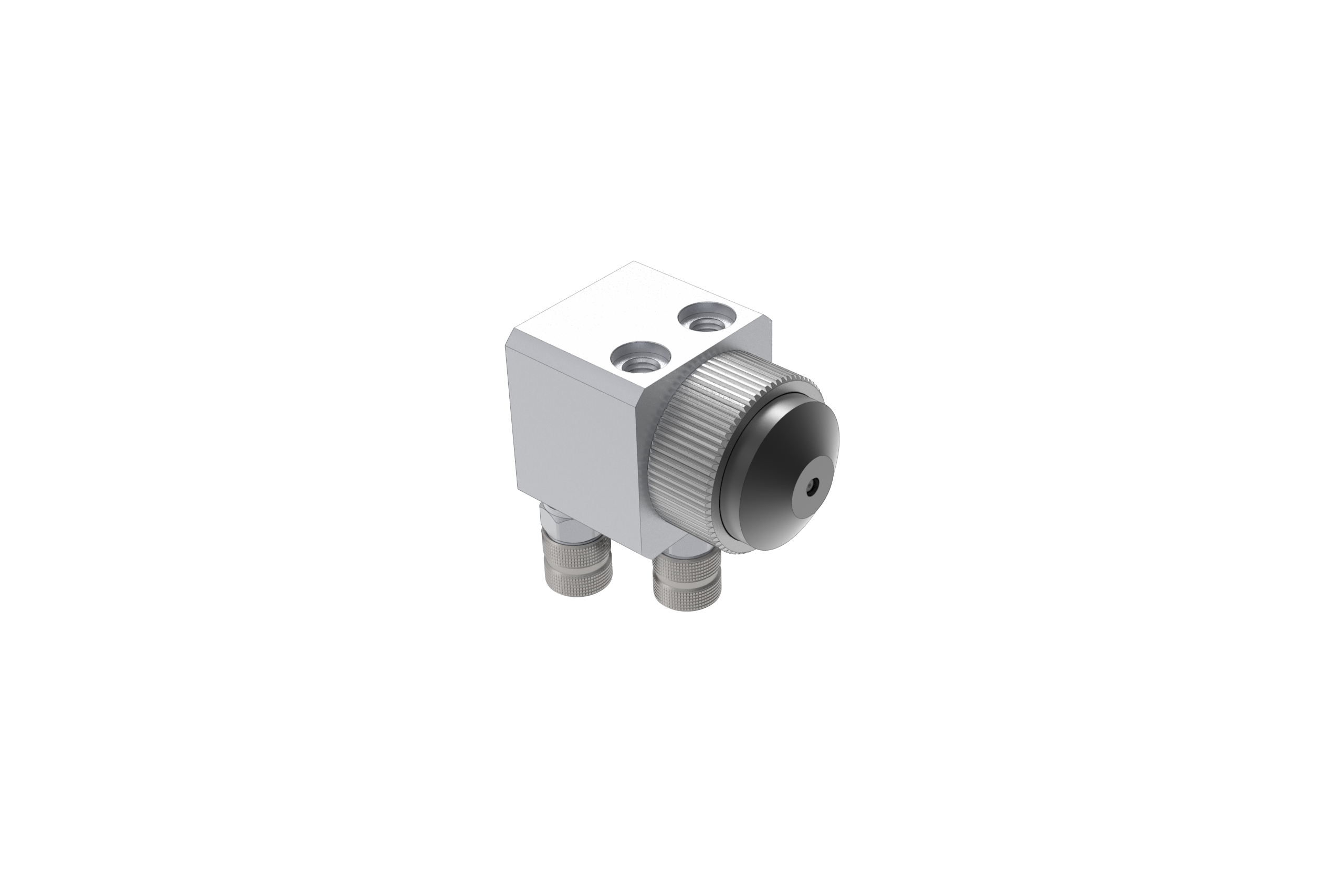

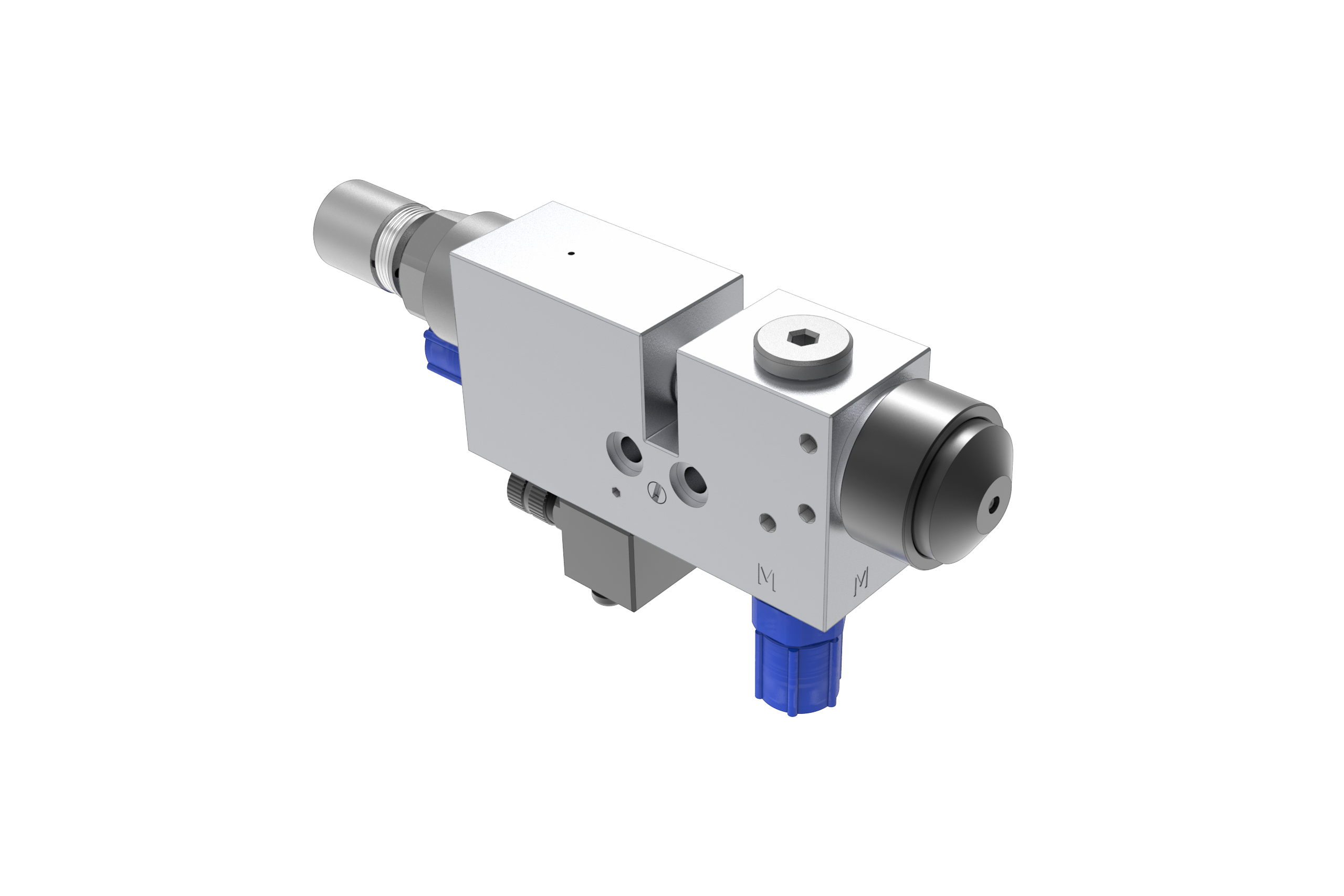

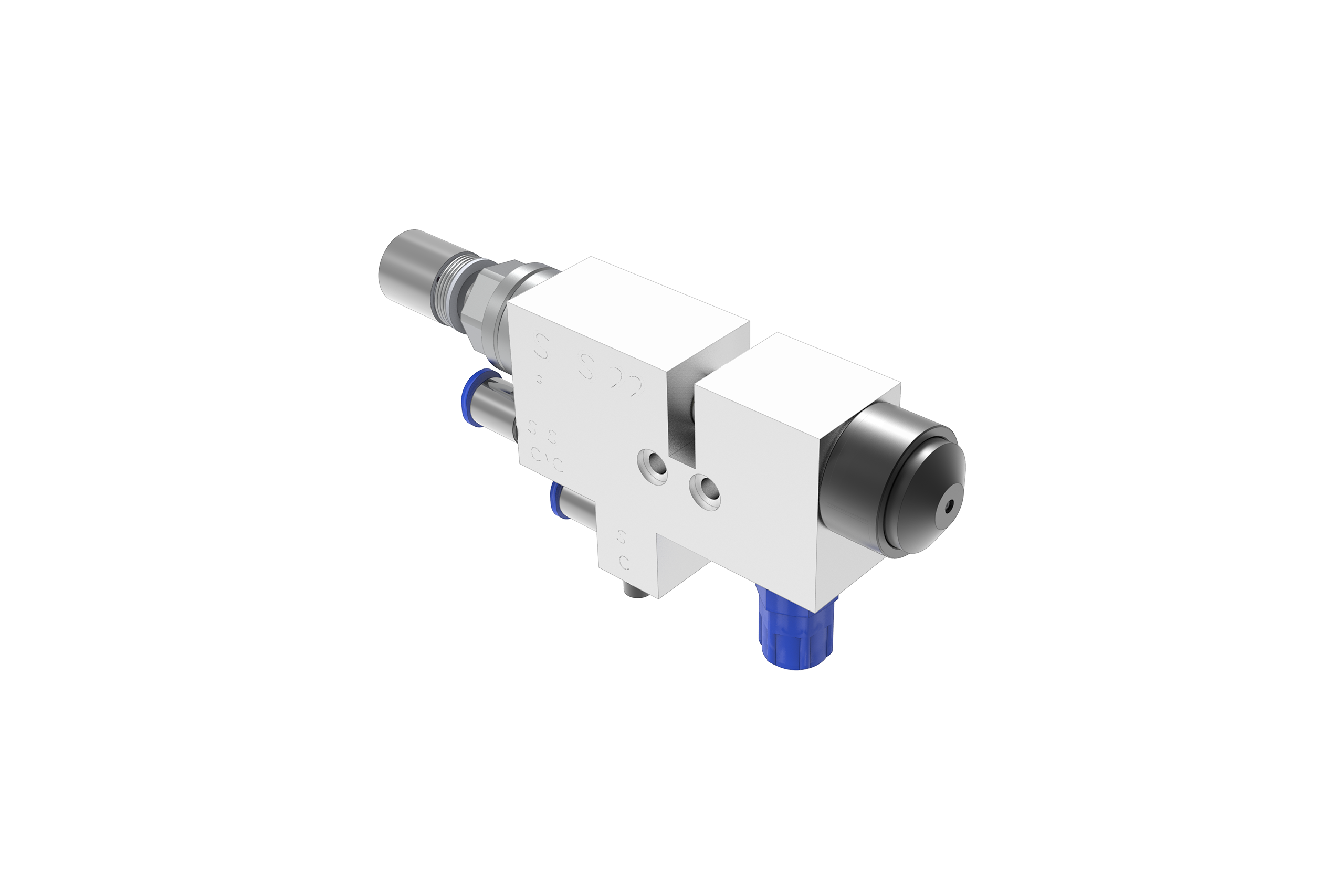

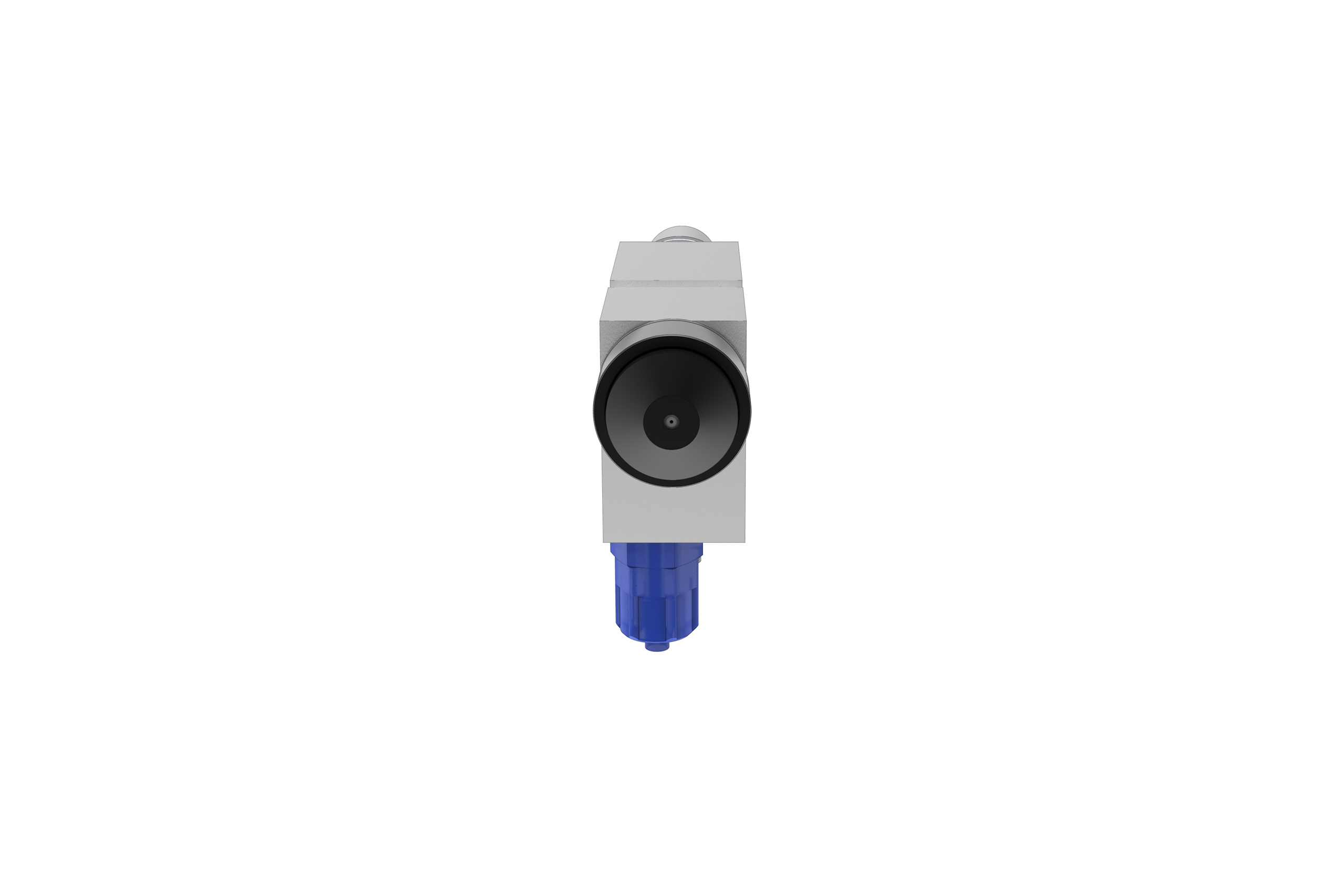

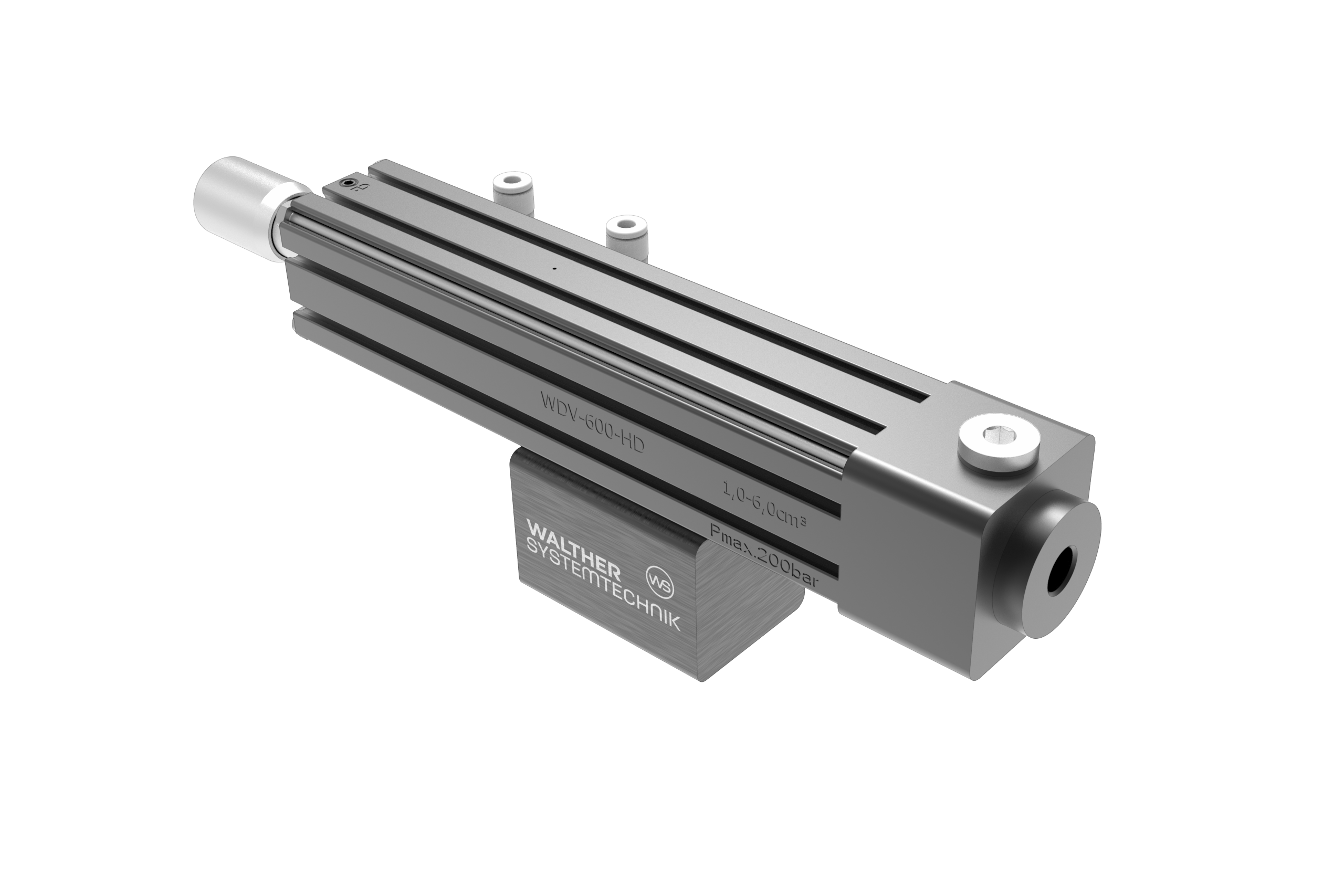

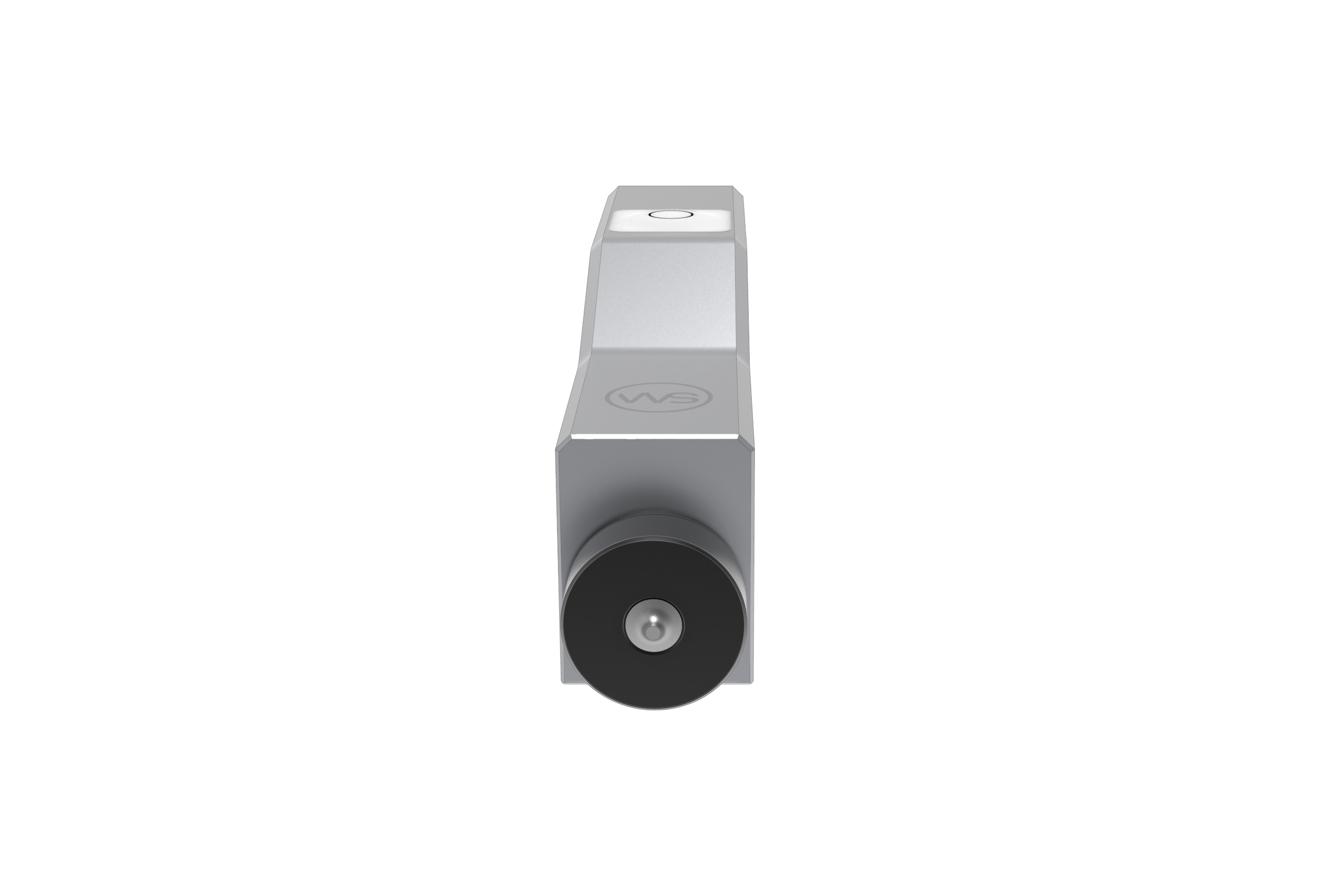

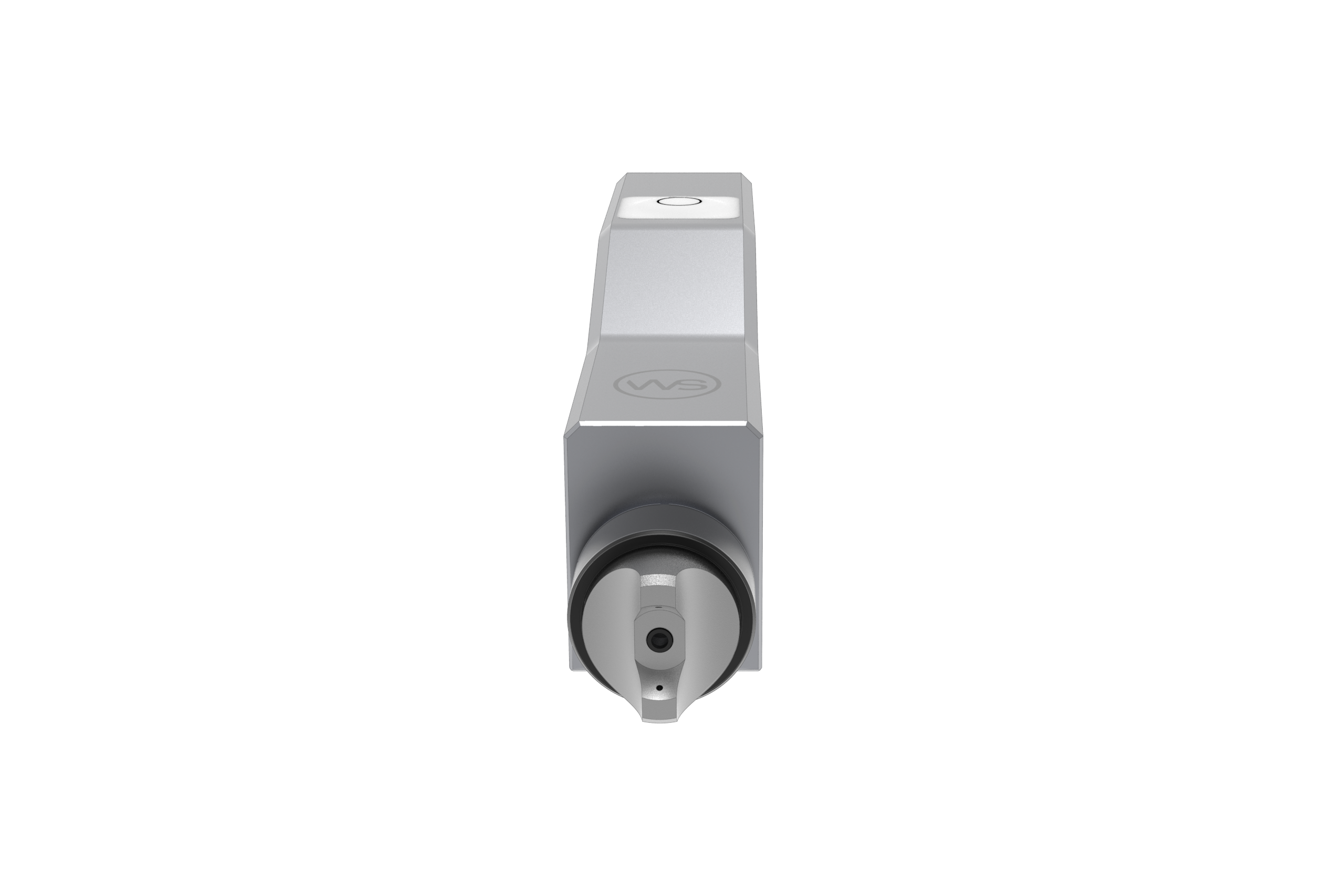

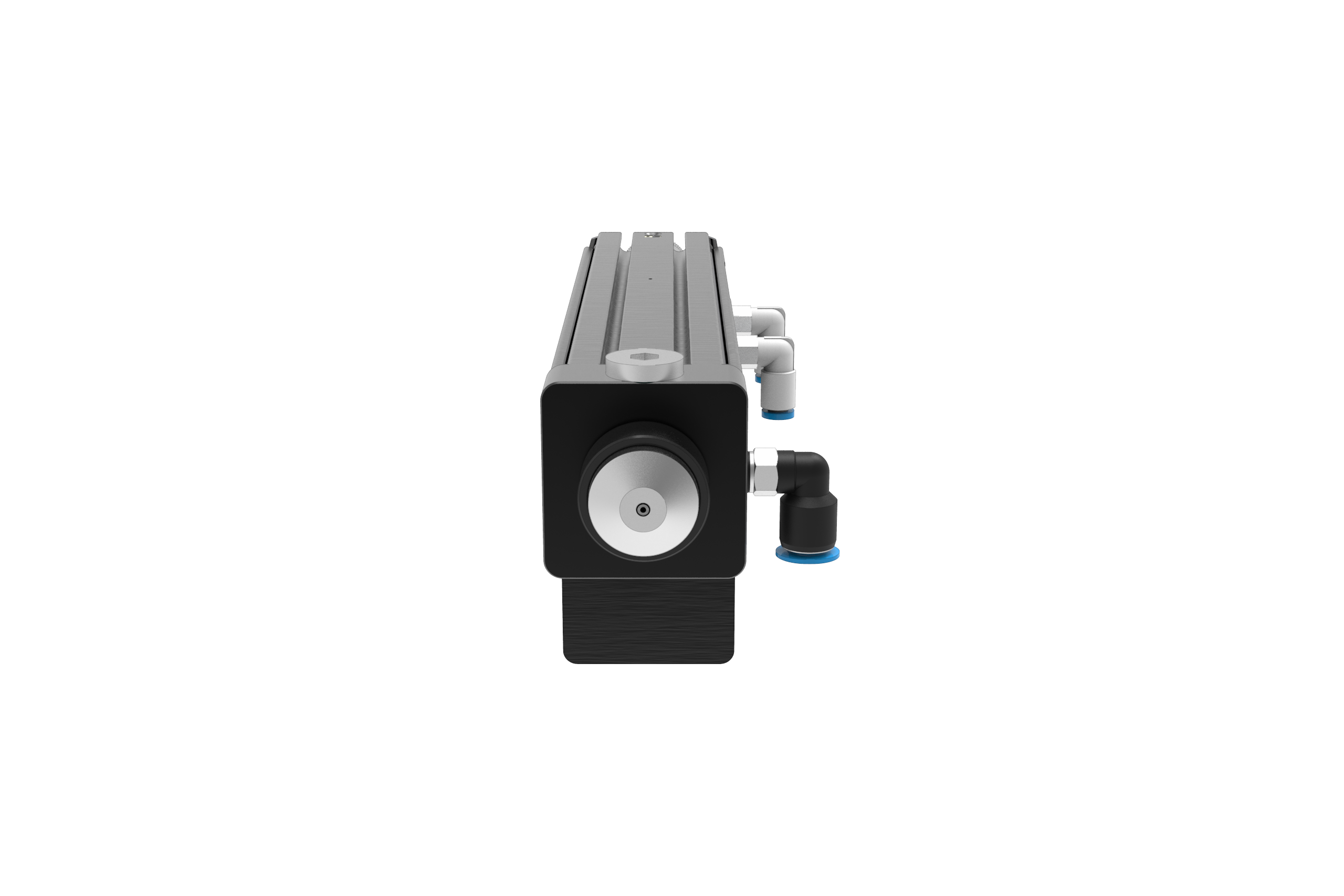

Dosing valves for precision media application

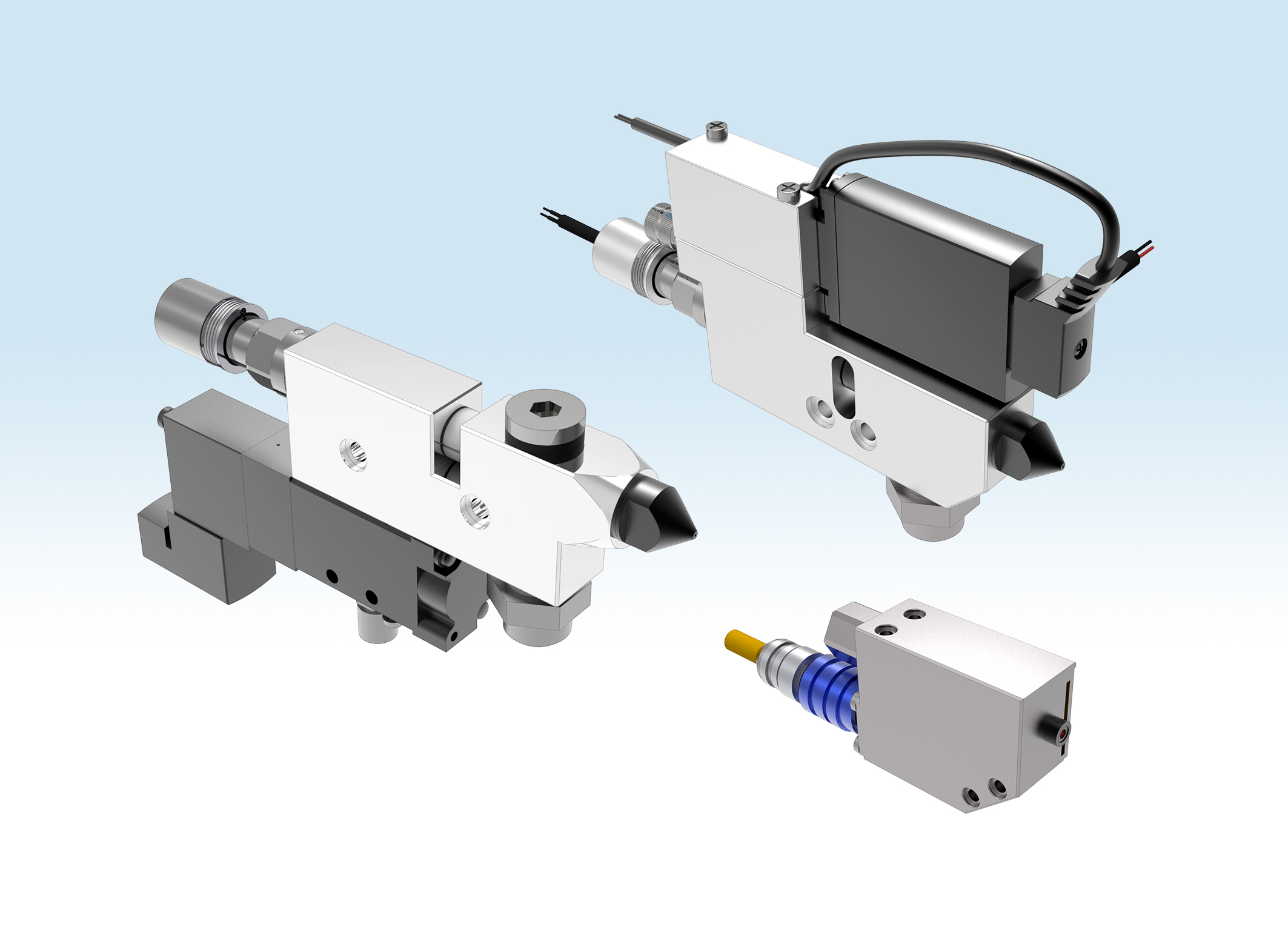

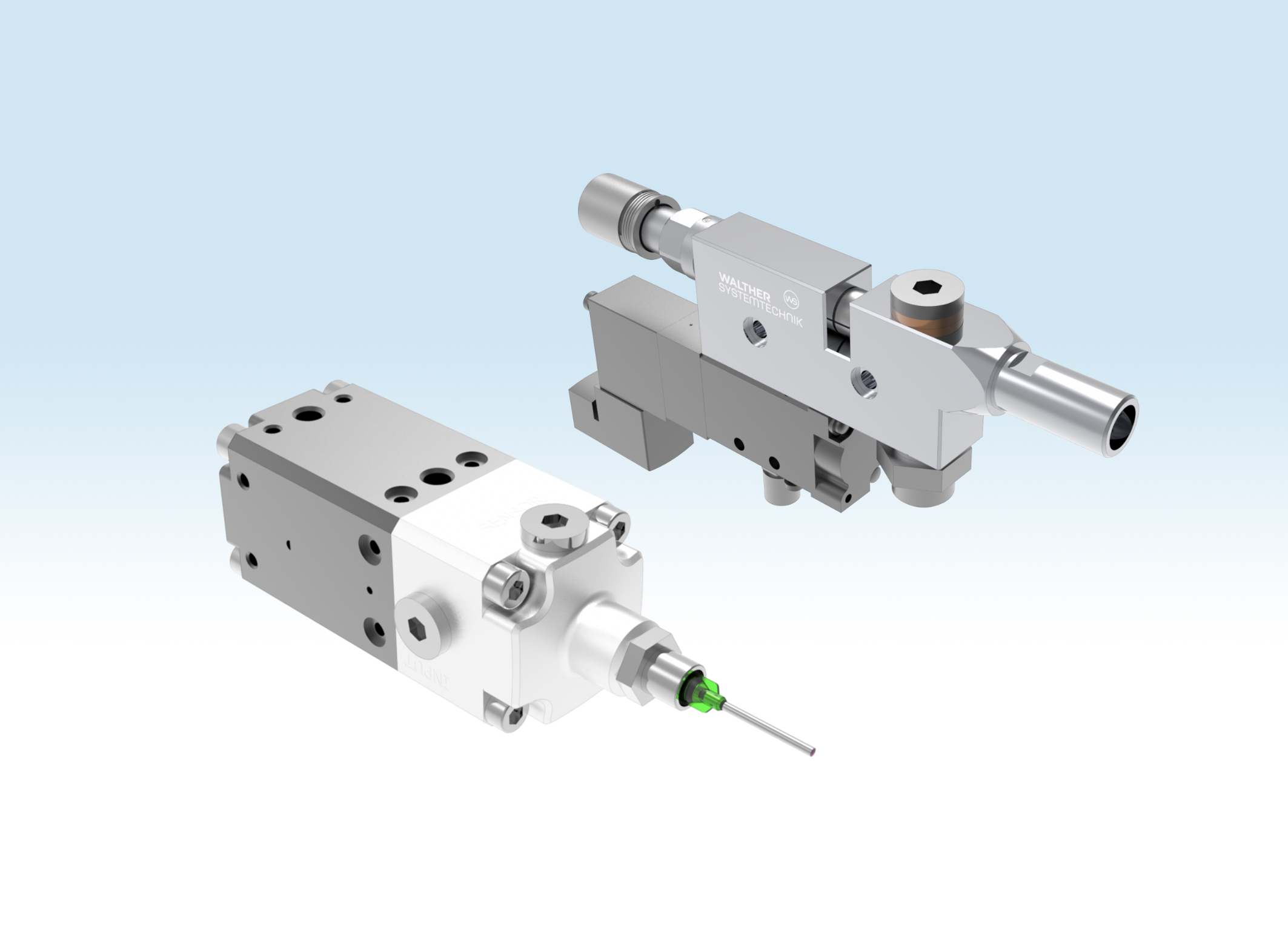

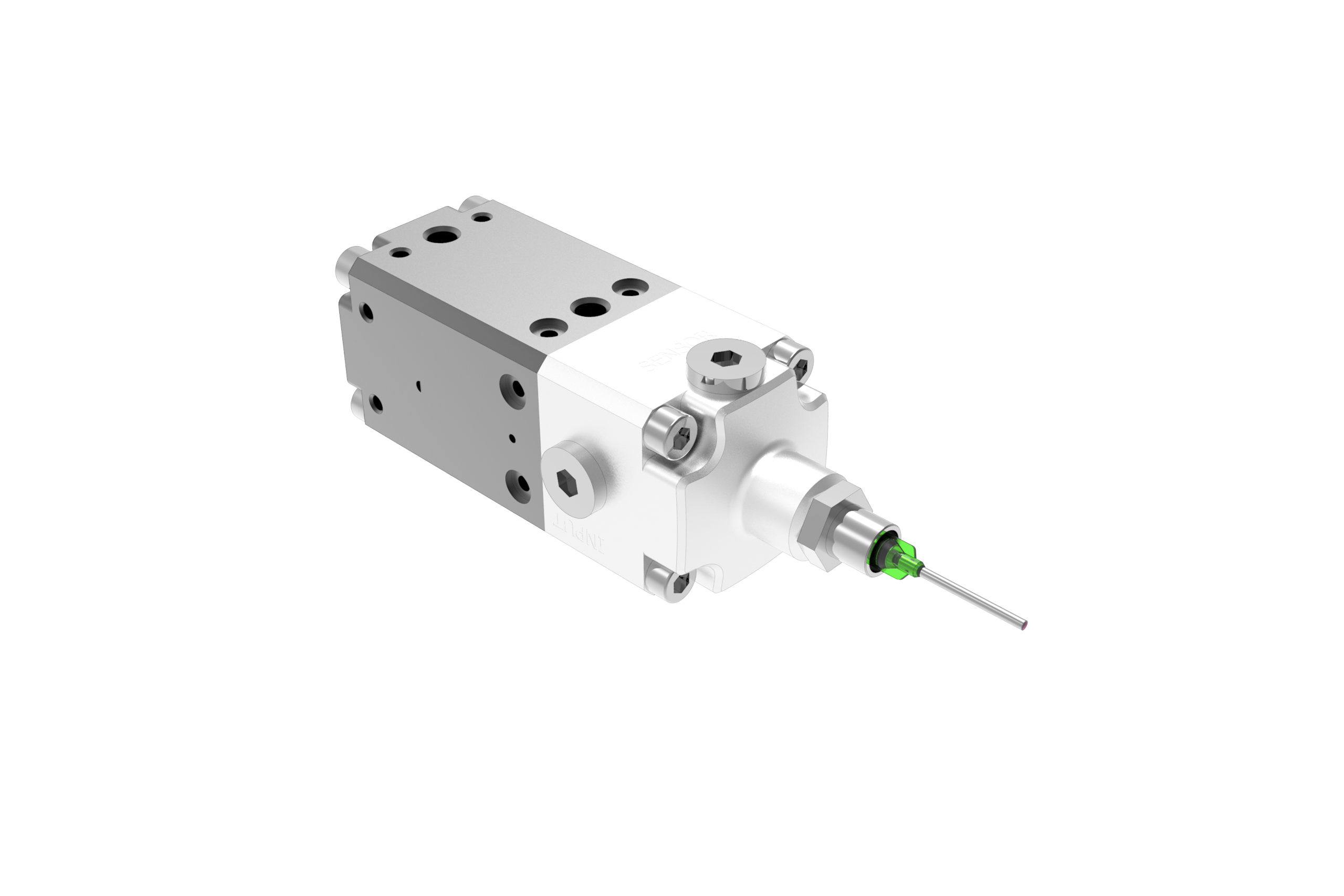

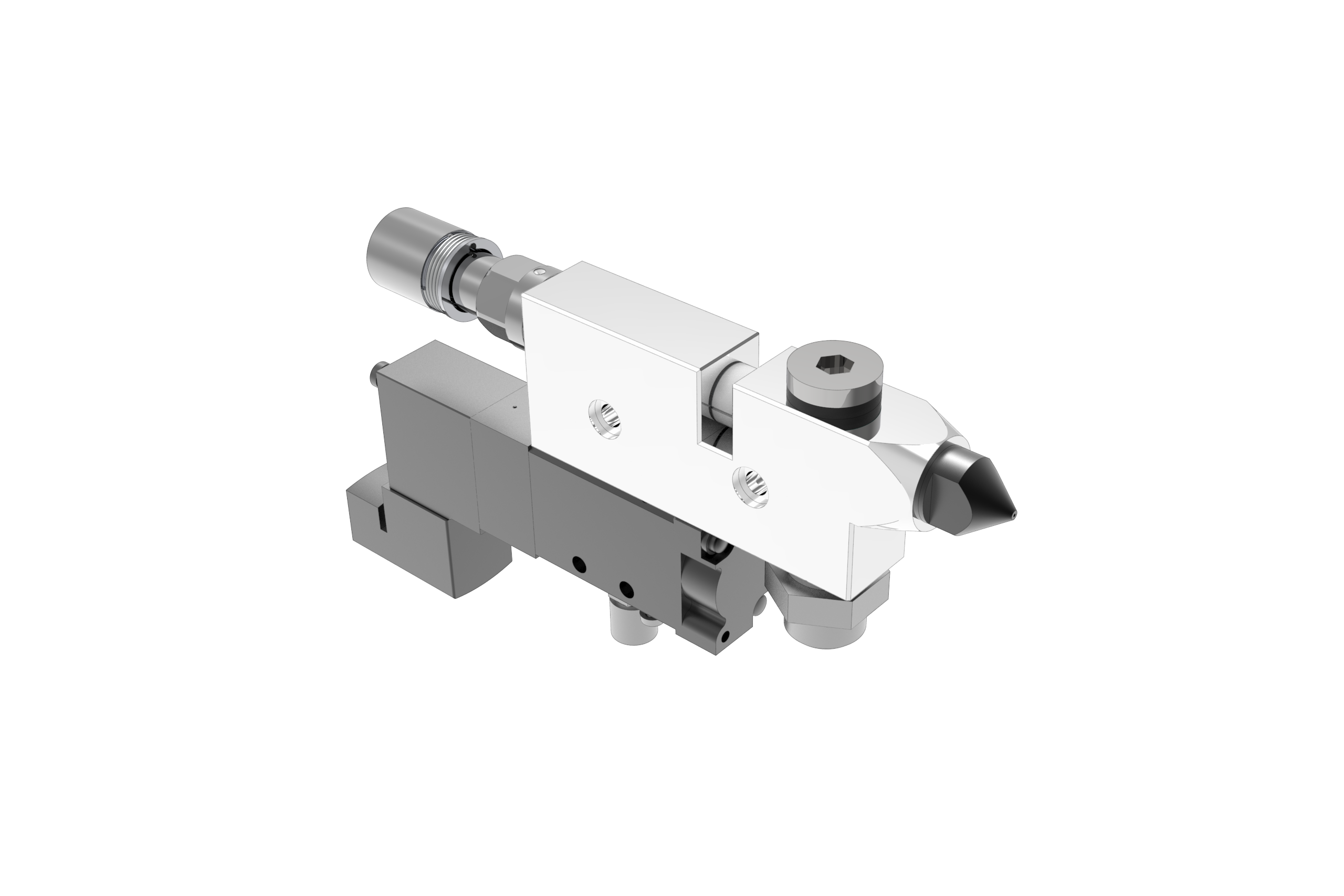

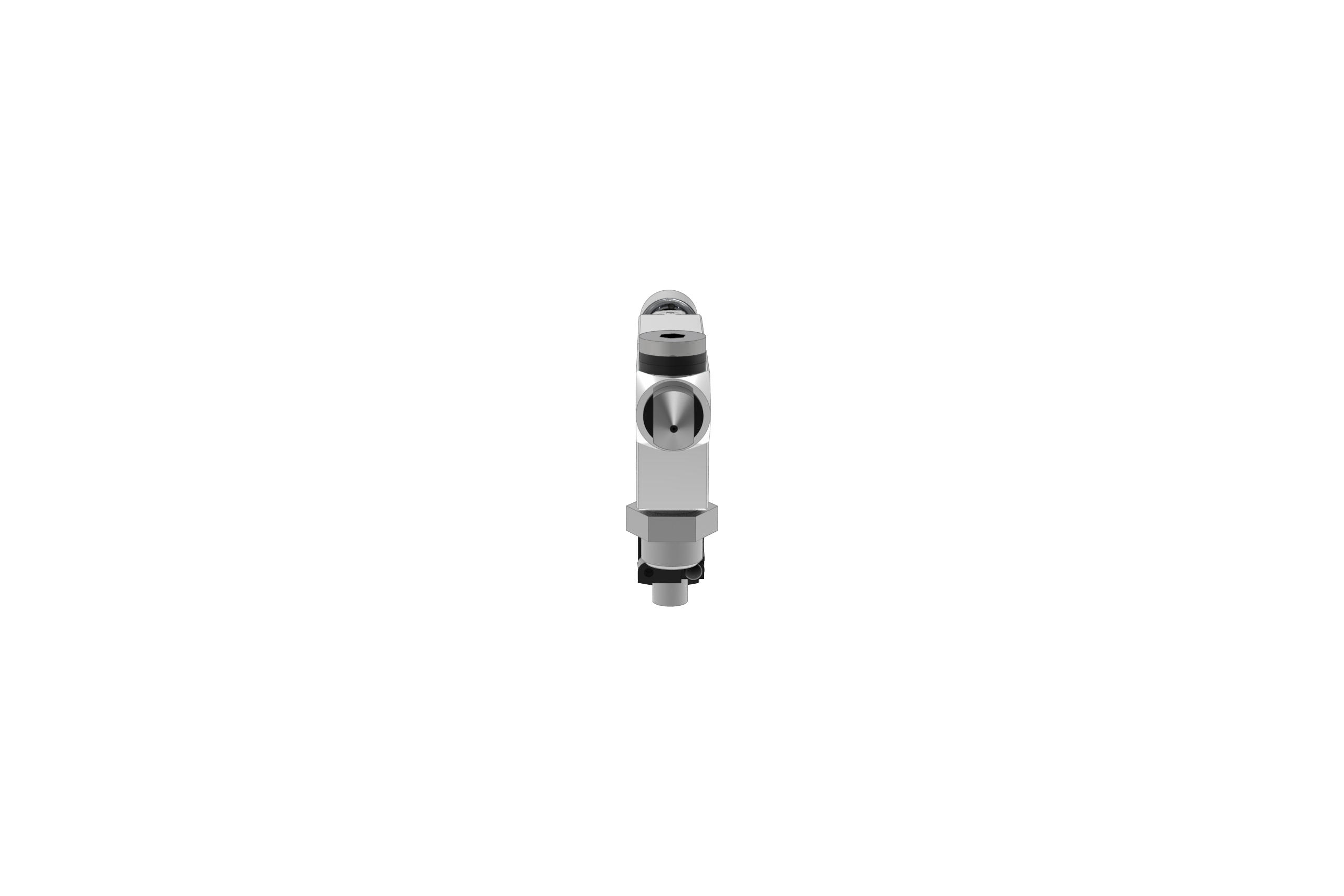

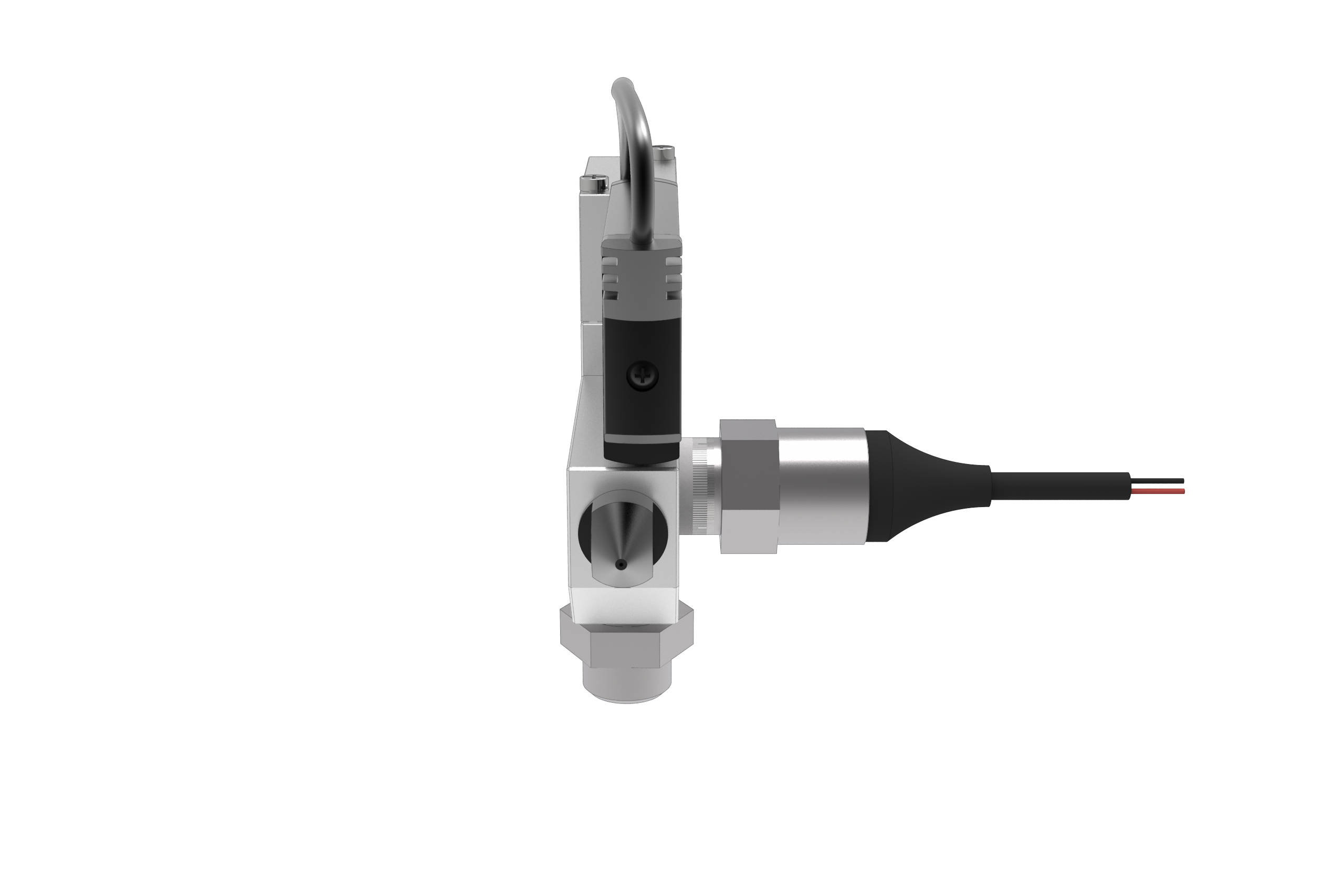

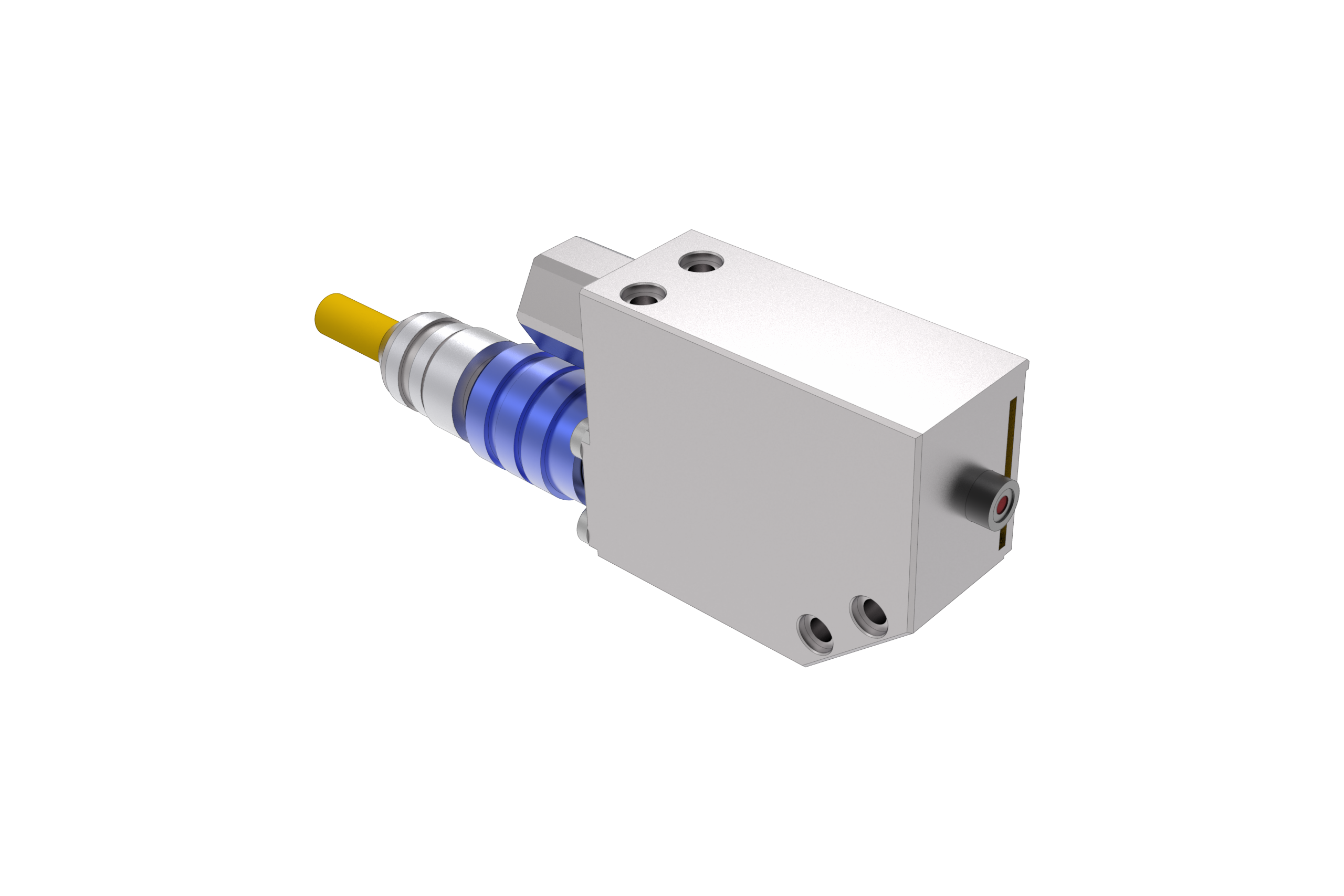

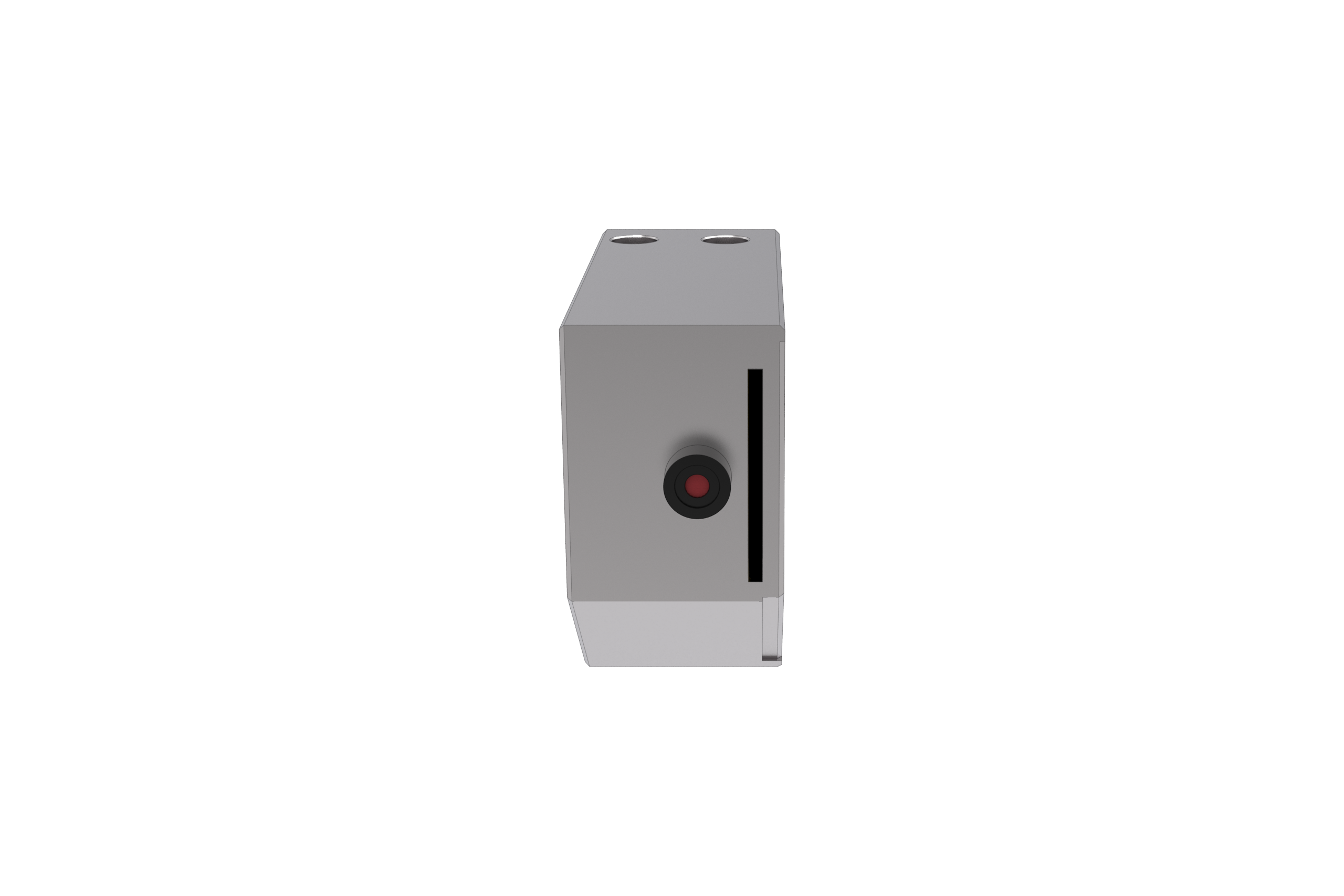

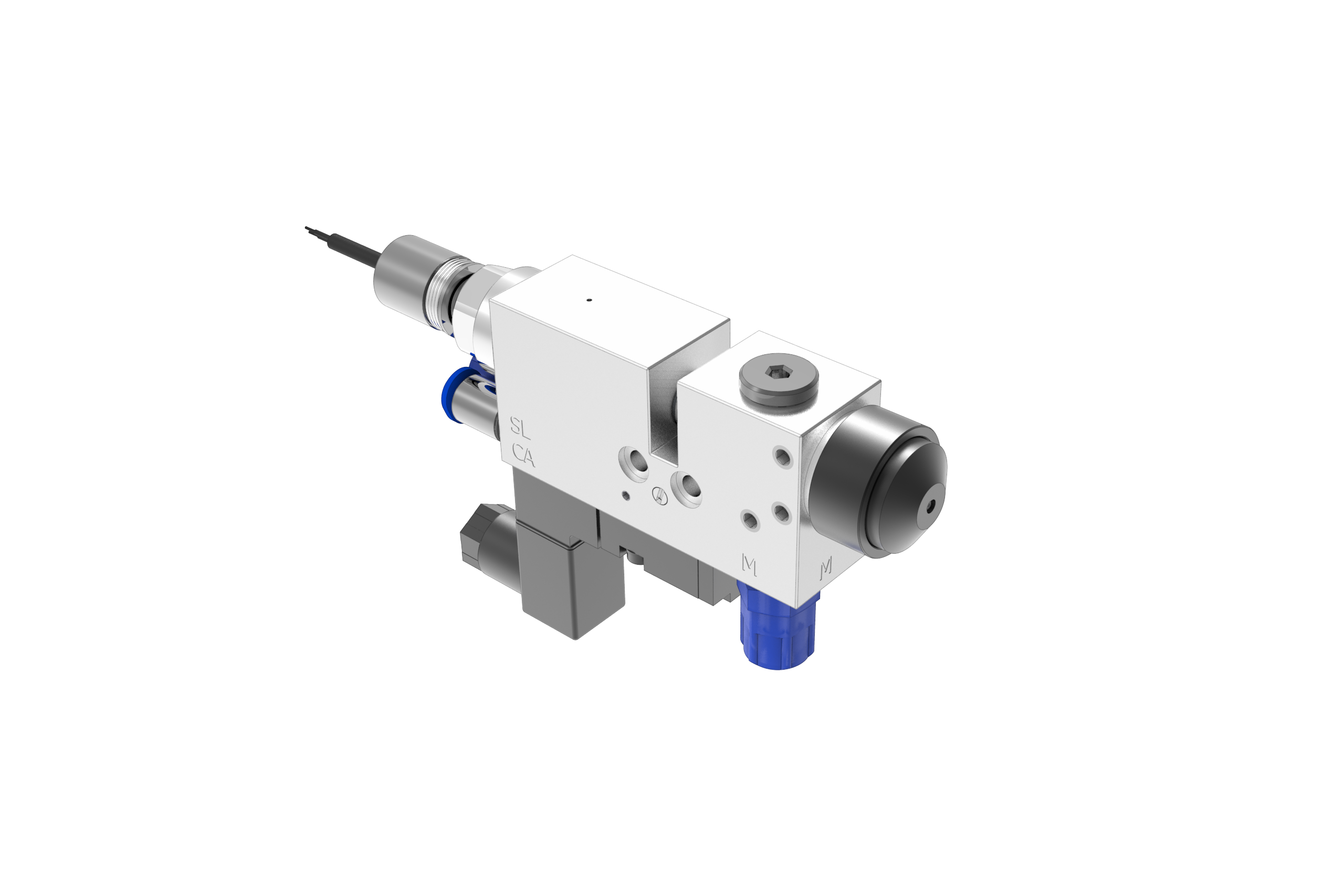

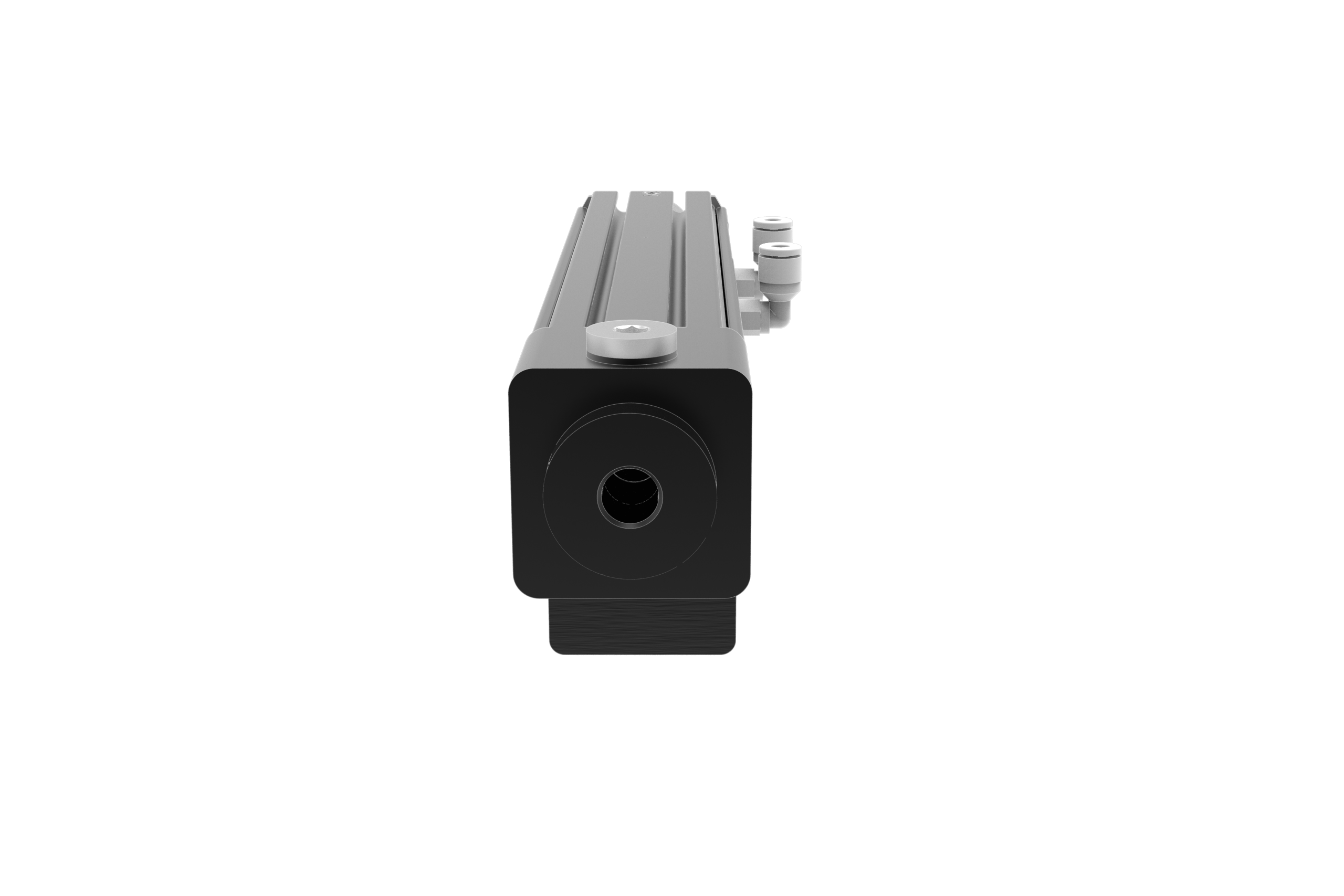

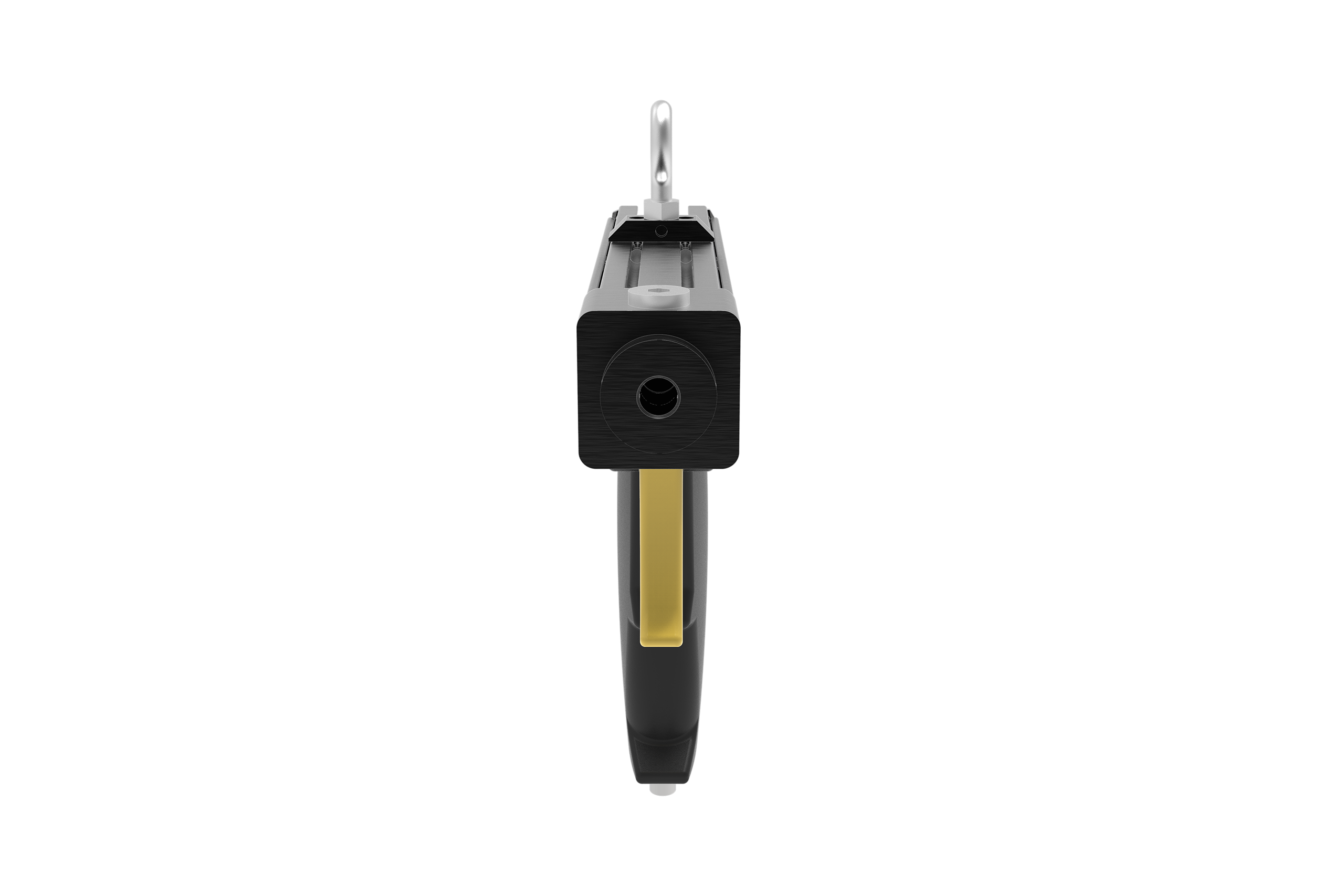

Dosing valves enable the controlled application of low- to high-viscosity media – in continuous, cyclic, or pulsed operation, typically in the milligram or microliter range. Common designs include spray valves for area-wide coating, jet and pulse valves for non-contact spot application, chamber dosing valves for volumetric microdosing, and straight jet valves for linear material application.

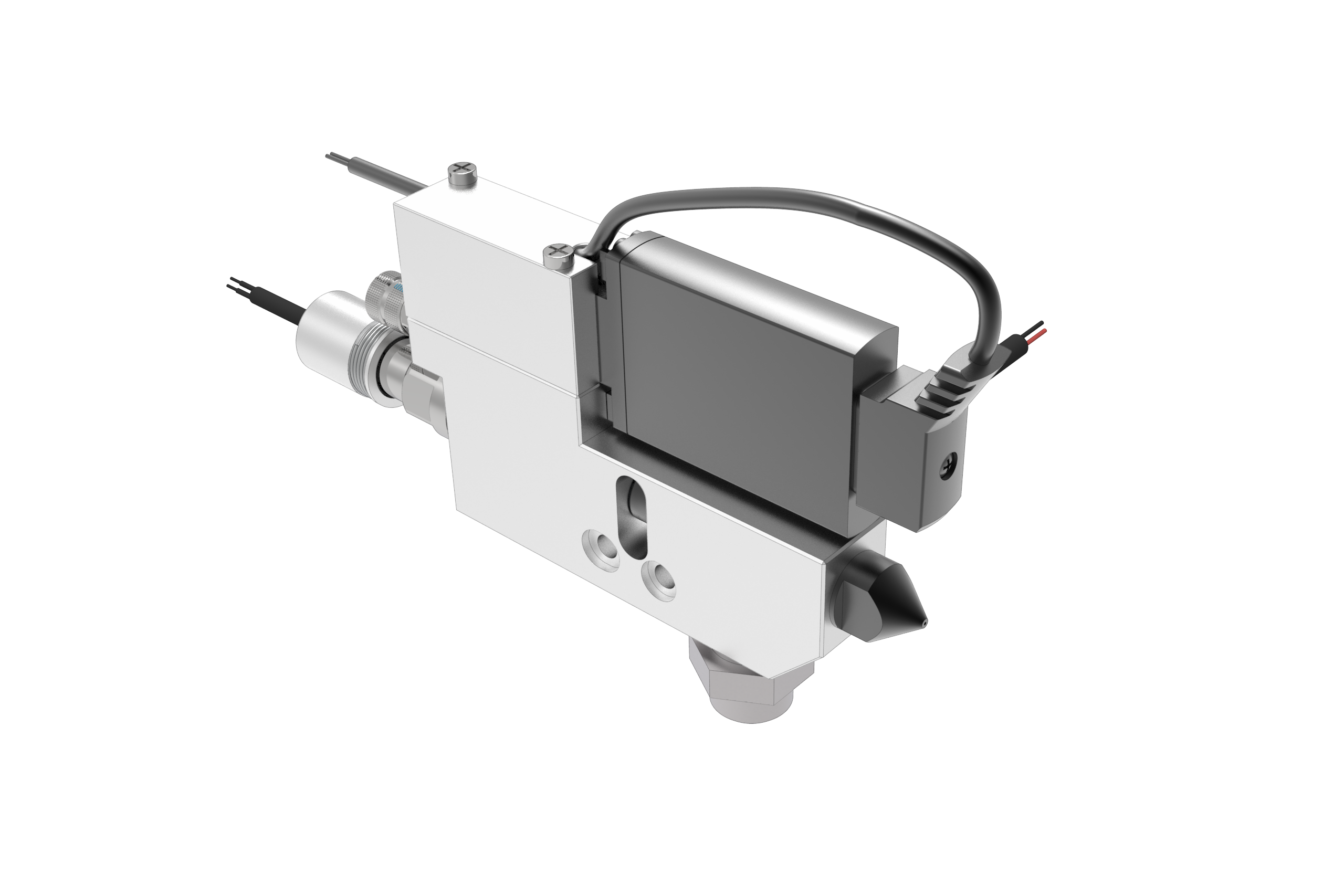

In industrial production, the focus lies not only on dosing accuracy per cycle but especially on reproducibility across large batch volumes. Modern dosing valves support this through adjustable actuation parameters, integrated sensors for process monitoring, and – depending on the configuration – media heating or pressure monitoring. This ensures stable integration of dosing processes into automated production lines with traceable and consistent quality control.

Depending on the application, dosing valves are suitable for spot or bead application of materials such as sealants, adhesives, thermal interface materials, solder pastes, lubricants, greases, release agents, or encapsulants. Selection is based on the medium’s viscosity, the required application pattern, and the necessary cycle rate.

In addition to pneumatically and electrically actuated versions, systems with integrated electronics and Ethernet connectivity are increasingly gaining ground. These enable centralized parameter configuration, integration into higher-level automation systems, and real-time monitoring of key process variables such as temperature, pressure, or needle stroke. Such valves ensure precise and flexible media application – even under stringent requirements for traceability and process reliability.

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request

Price on request