Industrial dispensing technology for high-performance production processes

Increase efficiency and productivity with high-end dispensing technology.

Welcome to Walther Systemtechnik – your specialist for industrial dispensing technology. We develop components and systems for demanding applications in industrial manufacturing. Our solutions are used wherever liquid, pasty or highly viscous media must be conveyed reliably, dispensed in defined quantities and applied with precision.

Discover a comprehensive product range covering the entire dispensing process chain.

Dispense lubricants such as oil, grease and paste with us, as well as wax and cavity protection compounds, preservatives, silicone and adhesives, anti-squeak coatings, fluxes, release agents, paint, primer and many other media. Our product range is aligned with the functional requirements of modern dispensing processes: structured into four categories, it provides all dispensing components required for the design and implementation of high-performance fluid systems and dispensing installations.

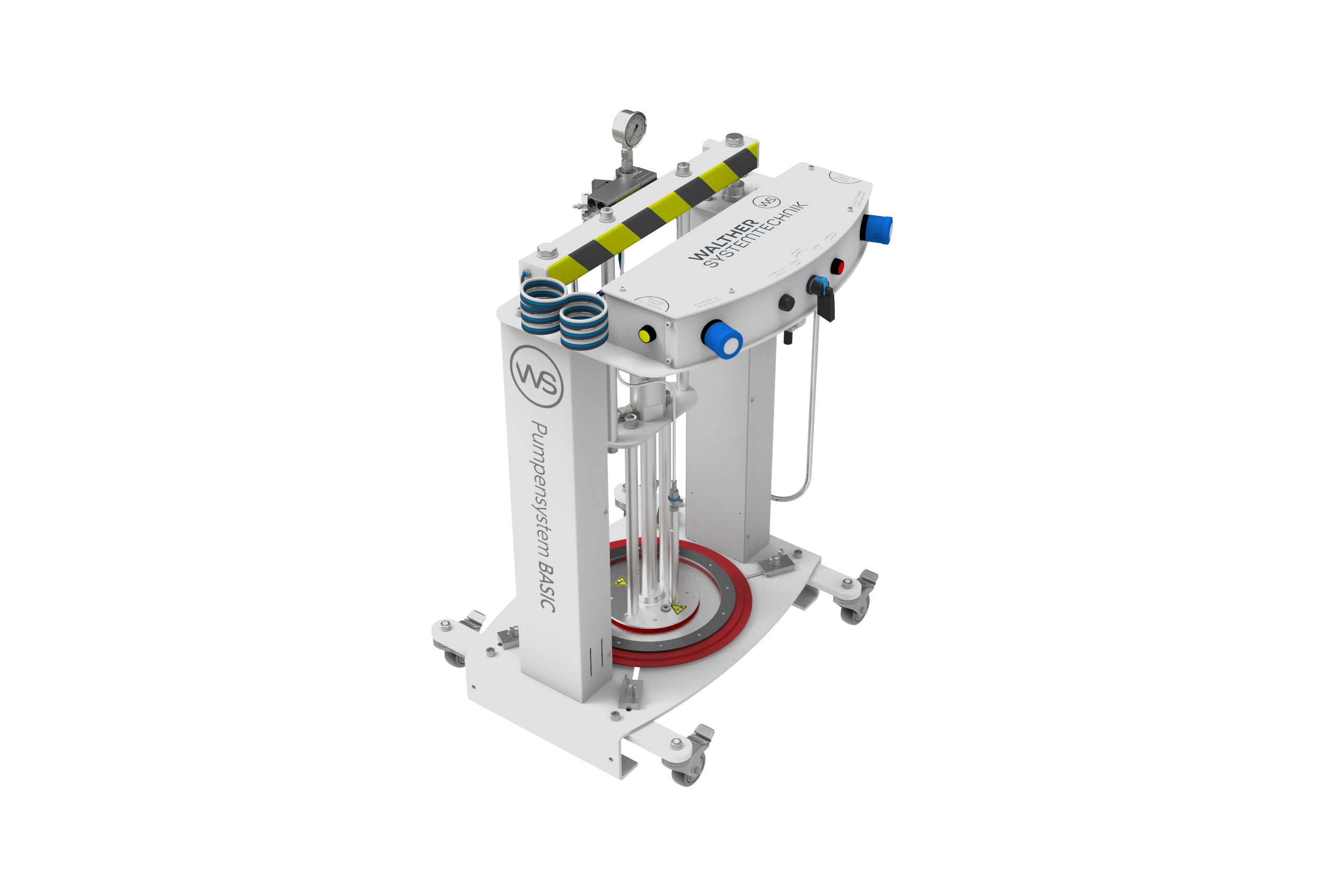

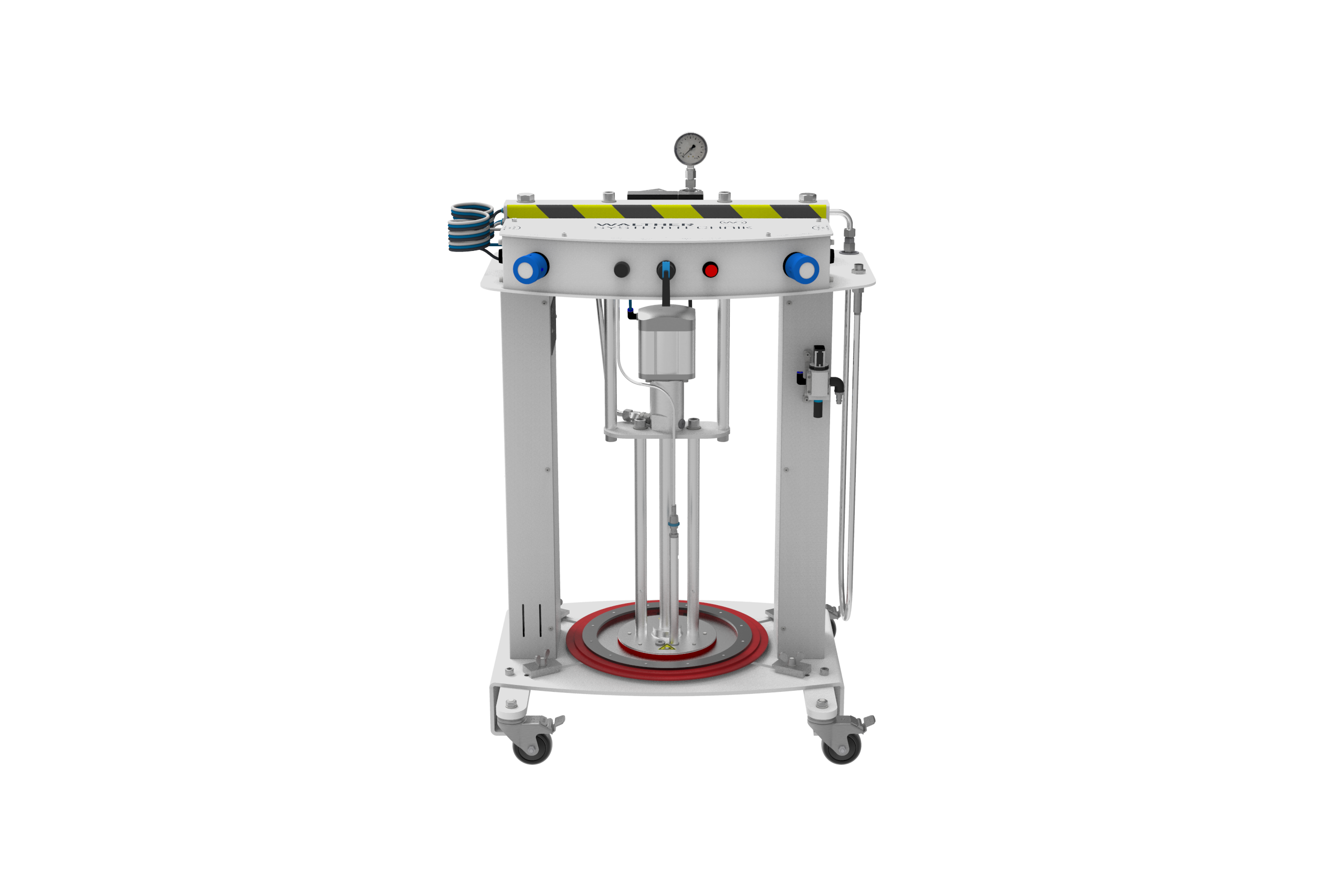

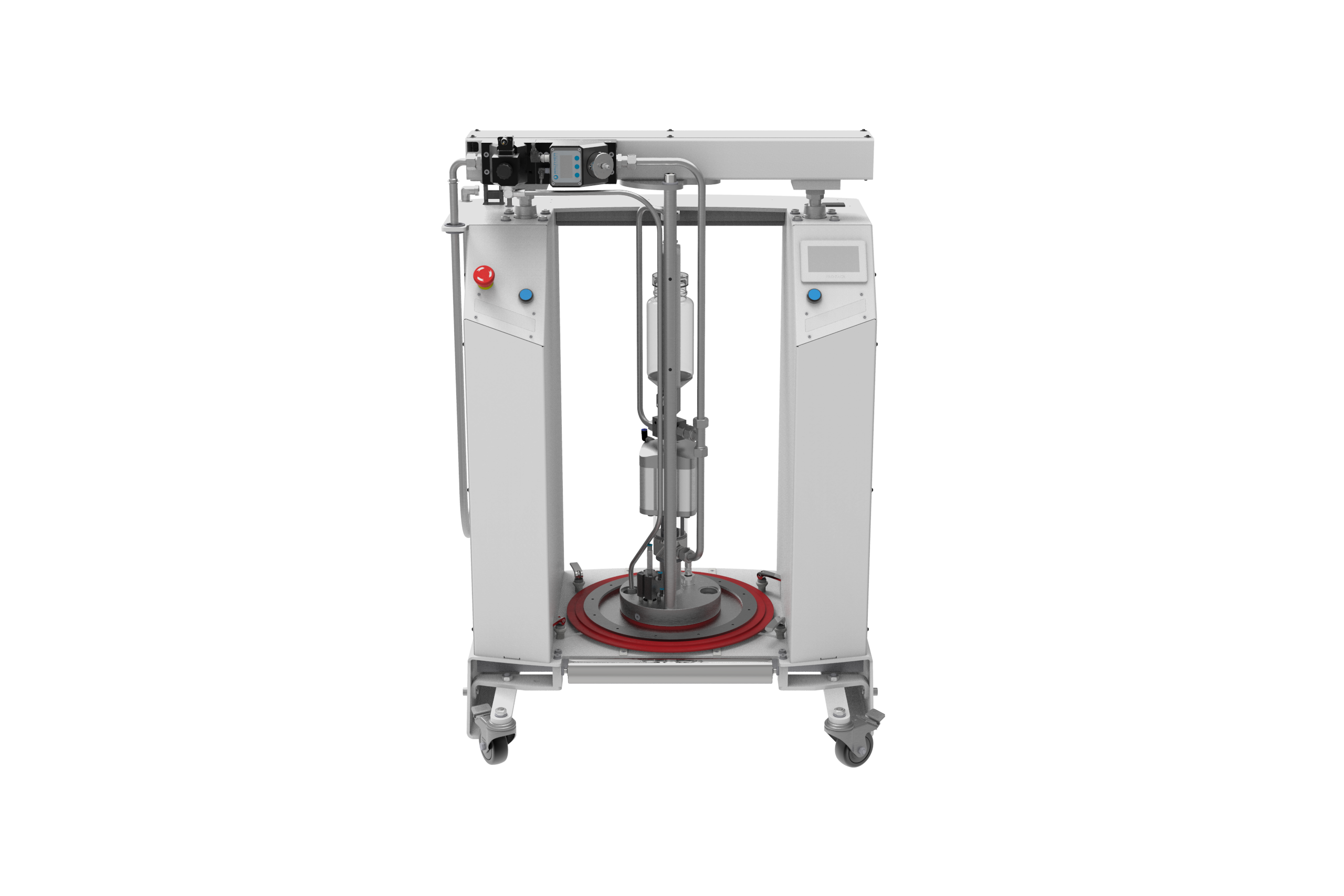

Feed systems and accessories for the reliable supply of viscous media in the dispensing process.

Modular units and accessories for the simple integration and expansion of fluid and dispensing systems.

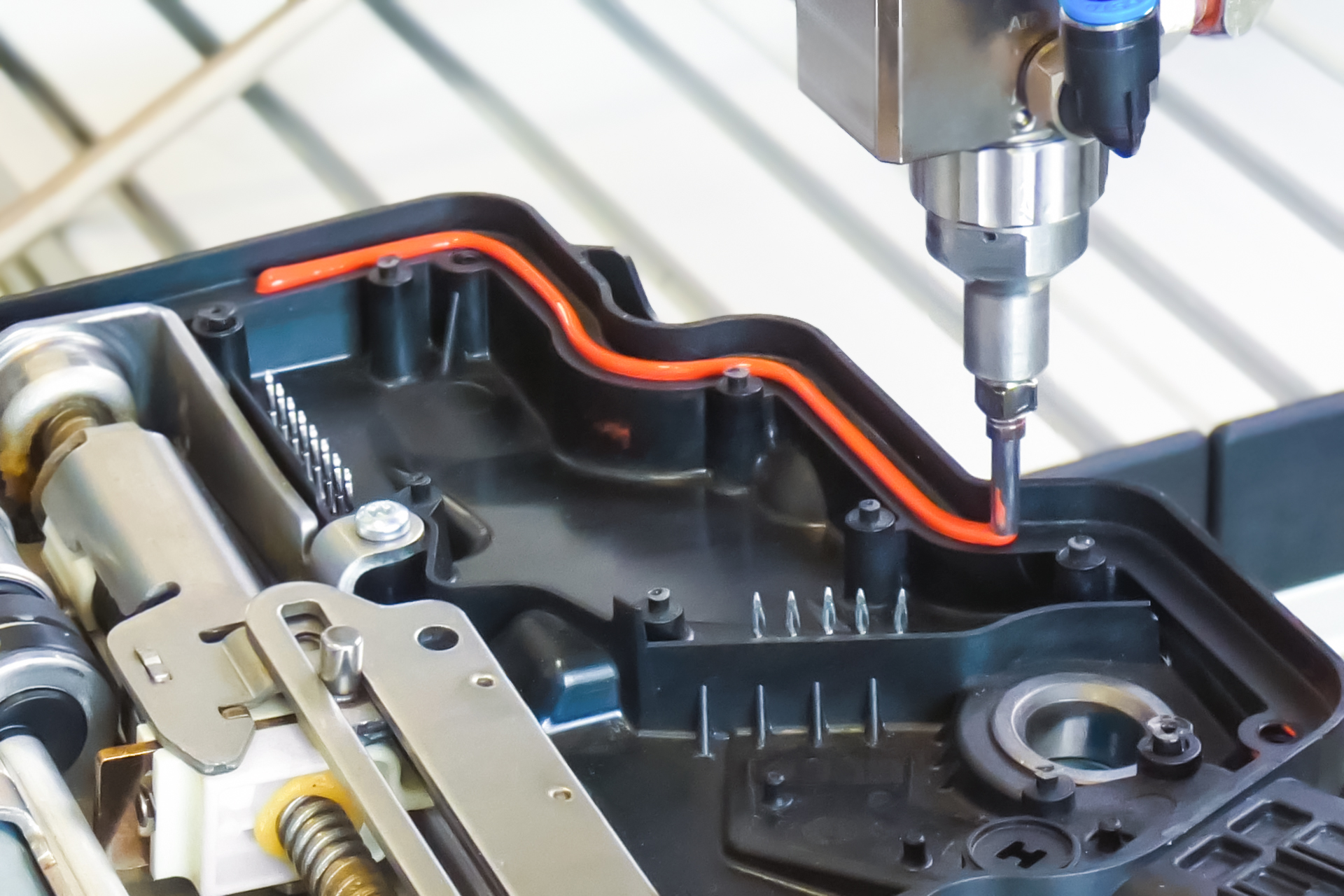

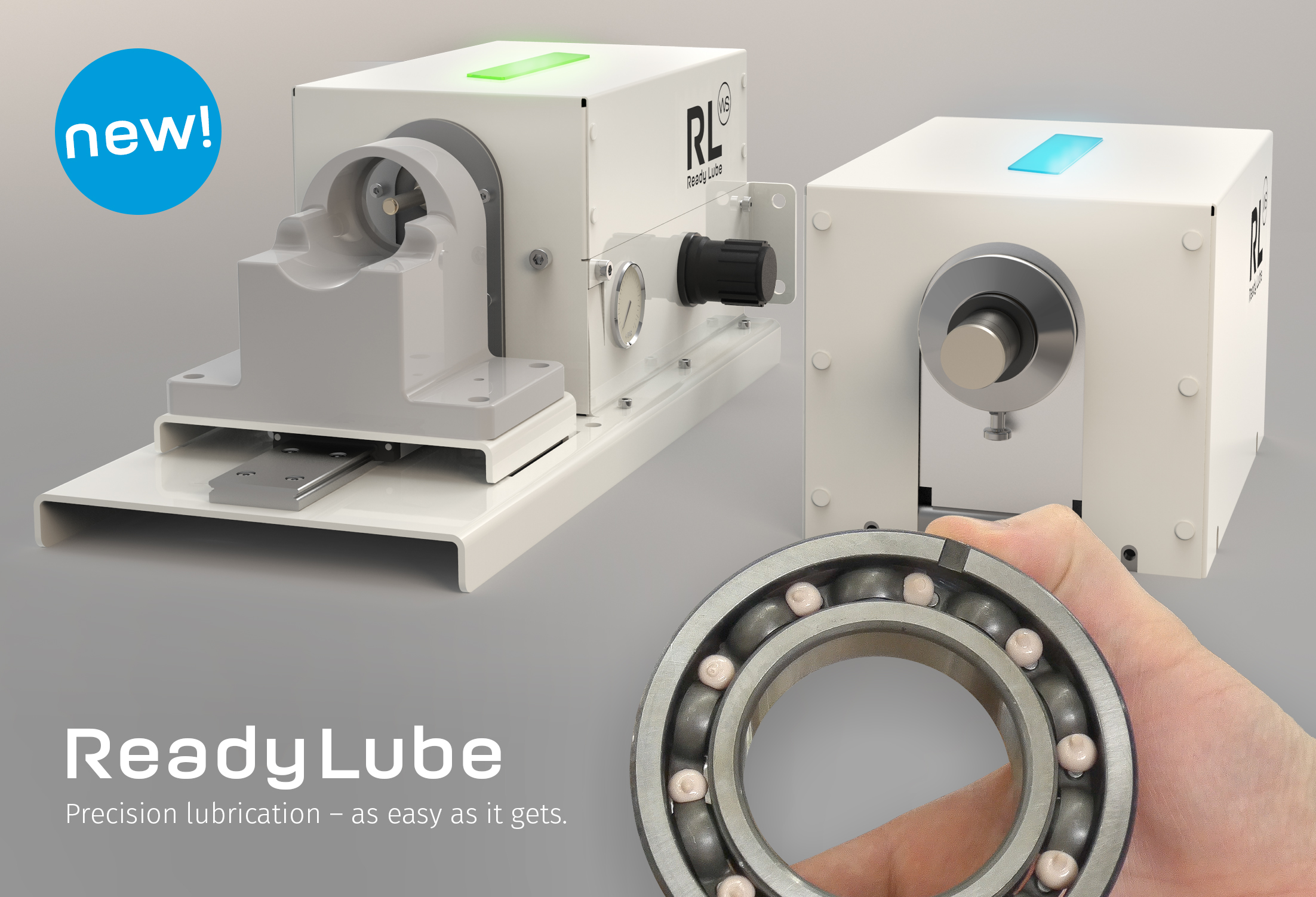

Technologies, components and accessories for the precise application of liquid and viscous media.

Systems and components for the continuous monitoring and control of dispensing processes.

Dispensing with Walther Systemtechnik – your dispensing project in safe hands

As a one-stop shop, we provide everything from a single source across the entire dispensing process chain, including media characterisation, machine engineering and automation. Whether sealing, bonding, marking, greasing or oiling: Walther Systemtechnik supports your project from initial concept through to implementation. Your benefit: a single point of contact and a team of specialists managing your project with technical expertise.

Services

We support you comprehensively in the implementation of your dispensing project – well beyond successful commissioning.

• Initial trials • Feasibility studies • Sampling • Training • Installation • Commissioning • Maintenance • Repair • System optimisation

Proven dispensing technology components for system integrators

Drum and Container Pumps

for conveying viscous media directly from the original container.

Pressure Container Systems

for the constant and pulsation-free supply of liquid media.

Filter Units

For the removal of impurities and agglomerates from the medium.

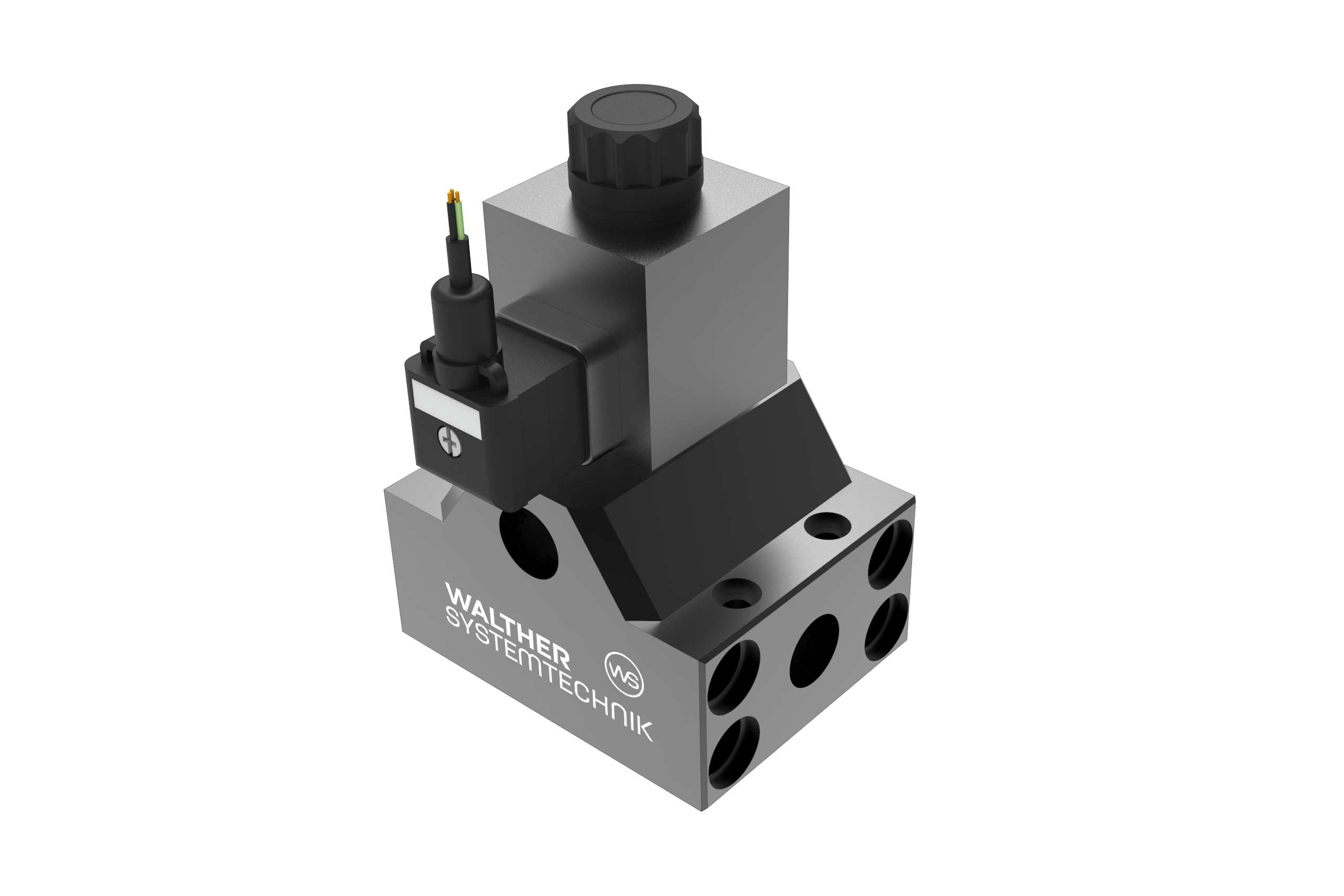

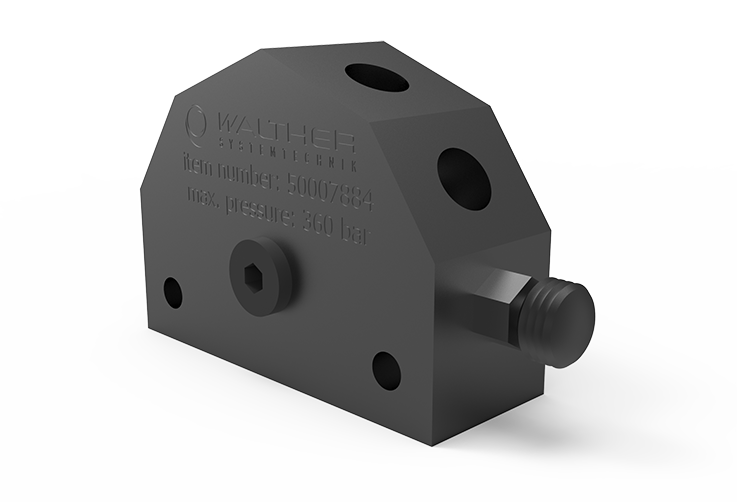

Dispensing Valves

Precision applicator and process valves for a wide range of media.

Nozzle Extensions

for targeted wetting of hard-to-reach application areas.

Valve Control

for precise control and regulation of dispensing valves.

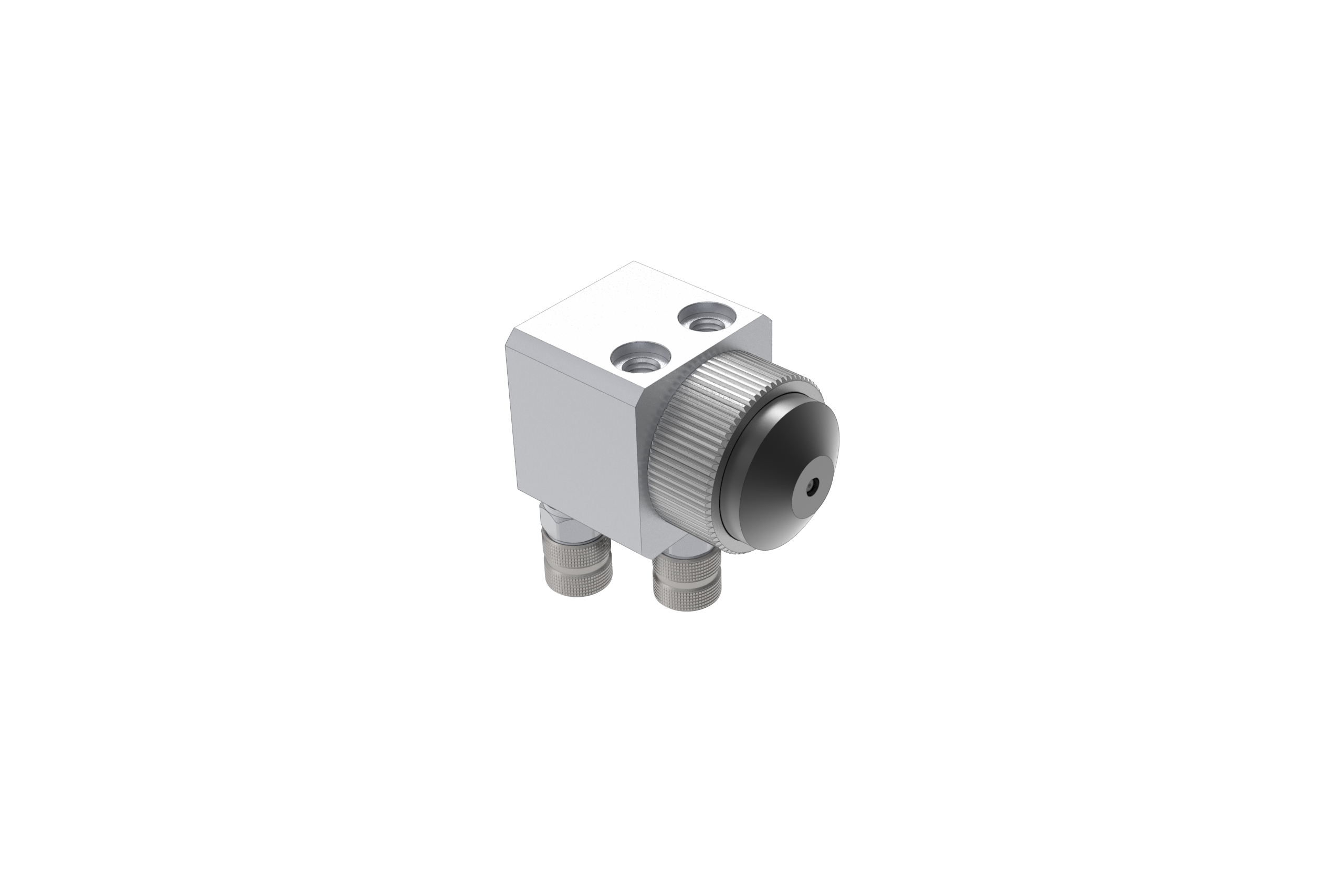

Sensors

for pressure detection and volumetric flow measurement.

Accessories

such as fittings and hoses for secure connections.

Selected highlights of dispensing technology

Top sellers. Popular and frequently ordered:

Experience dispensing technology live: trade fairs and events

Can't get enough of our dispensing technology? Stay up to date – become a follower.

You can find articles under Dispensing Technology News or simply follow us on Facebook , Instagram , LinkedIn and more.