Walther Spray valve WSV

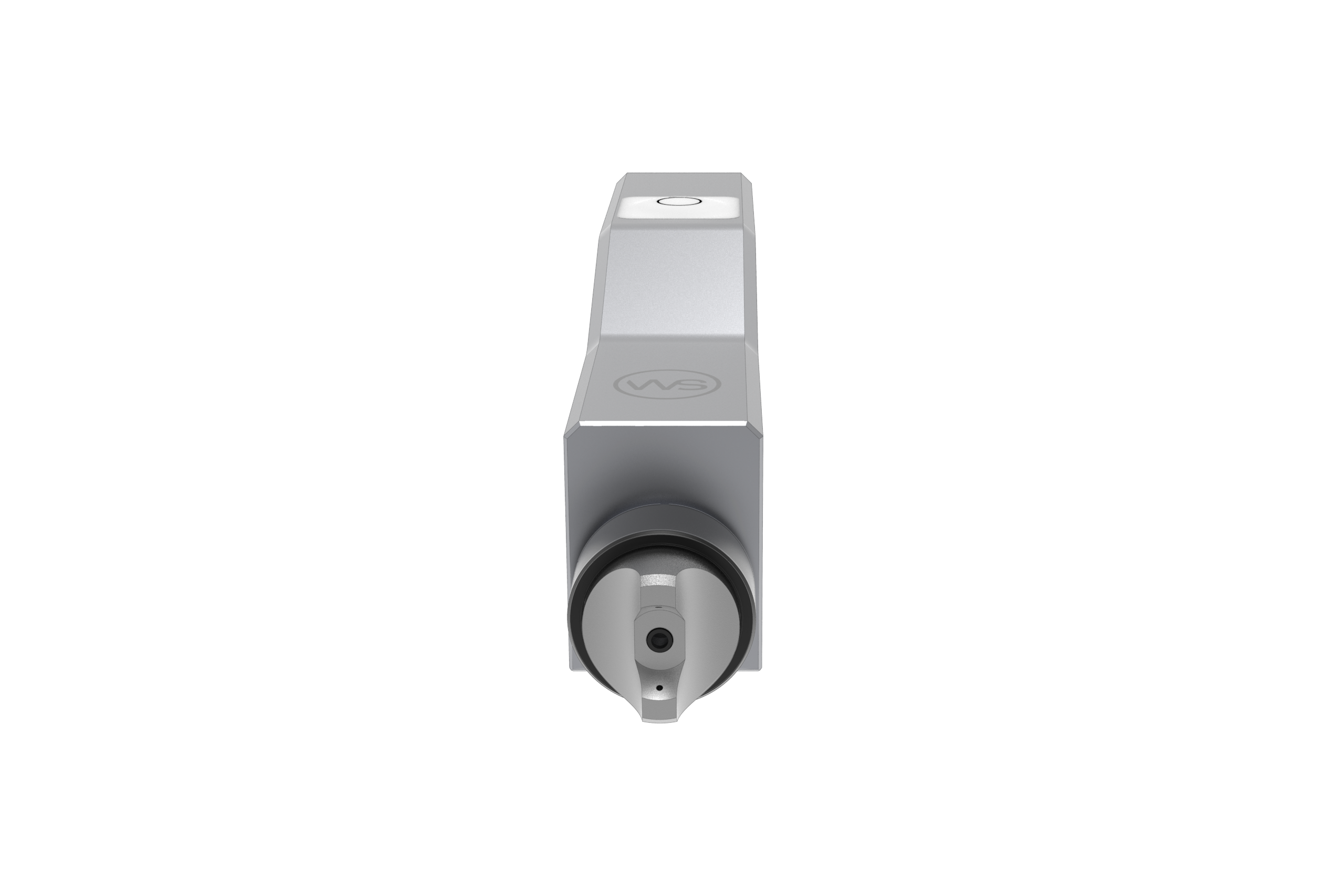

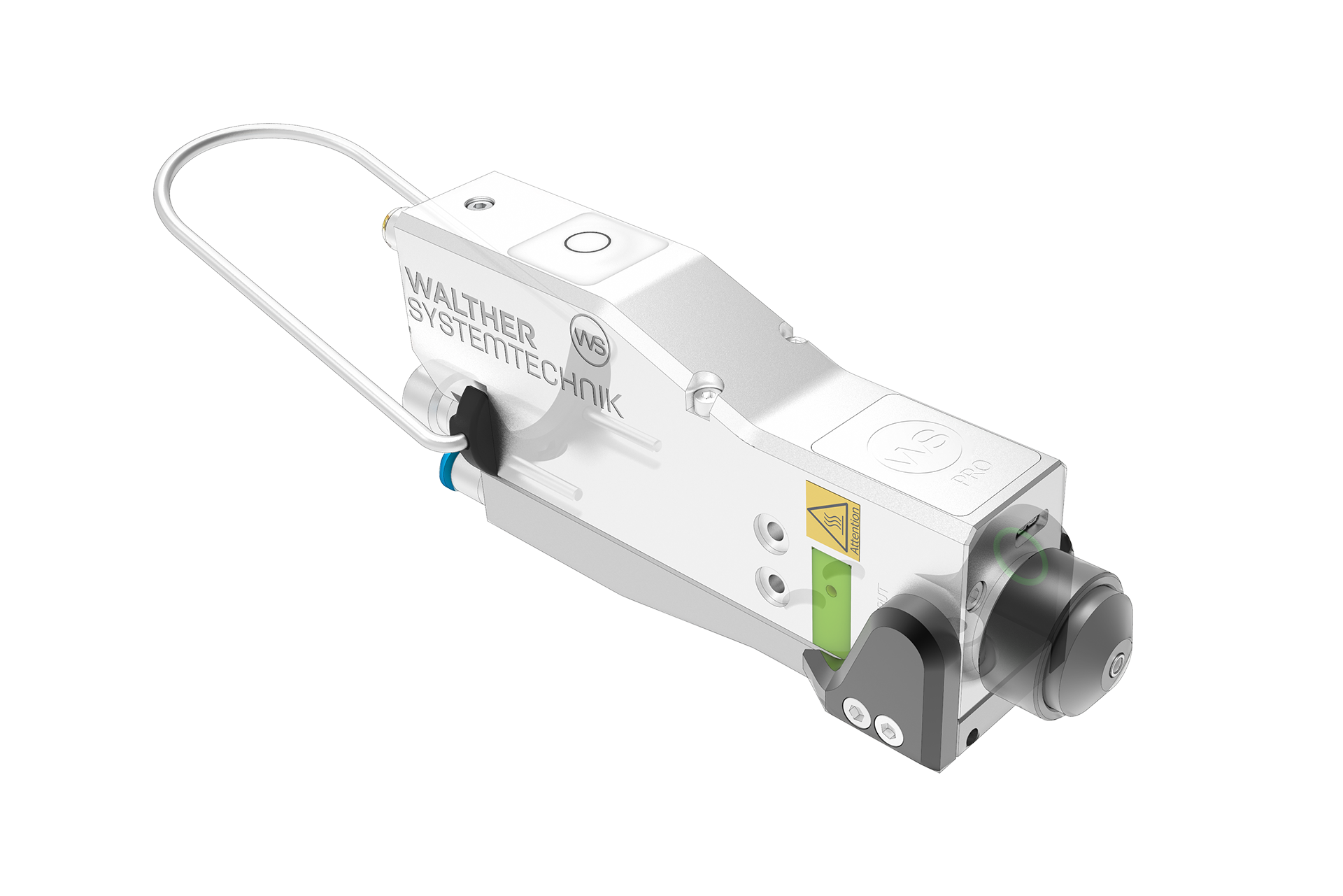

The WSV spray valve is a universally applicable electric spray valve for the reliable and uniform application of low- to high-viscosity media. With its compact design (134.5 x 25 x 45 mm) and integrated electronics, it is suitable for direct integration into existing and new production systems without the need for additional control hardware or software. An Ethernet-based bus connection enables full parameterization and visualization of all process parameters via a web-based dashboard.

The equipment of the WSV spray valve includes four digital input/output channels (DIOs) for controlling peripheral devices, a valve heater with temperature control for targeted tempering of the medium, and a pressure sensor for monitoring and analyzing the process pressure profile. These functions provide a high level of flexibility and process reliability. A built-in pushbutton allows manual activation of the spray valve for immediate inspection of the spray pattern, further simplifying commissioning and maintenance.

Flexible process control: With the option of real-time monitoring and documentation of process parameters, the WSV spray valve enables intelligent improvements in process capability, overall equipment effectiveness (OEE), and product quality. Remote parameterization and diagnostics via the web interface allow for efficient error detection and resolution. Alarms and notifications are freely configurable and can be linked to specific process variables.

Due to its high level of functional integration, the smart WSV provides a cost-efficient alternative to conventional valve solutions. Compared to pneumatic or hydraulic systems, the WSV’s electric valve actuation allows for precise control and energy savings. This leads to reduced operating costs, particularly in energy-intensive applications.

Configuration levels: The WSV spray valve is available in three configuration levels to meet different application requirements.

- BASIC: Integrated control and parameterization via dashboard, 4 digital inputs/outputs for messages and status display, analog output for control air regulation, integrated pushbutton.

- ADVANCED: Includes all BASIC features plus integrated heater for medium temperature control.

- PROFESSIONAL: Highest configuration level with additional pressure sensor for monitoring and evaluation of the process pressure profile.

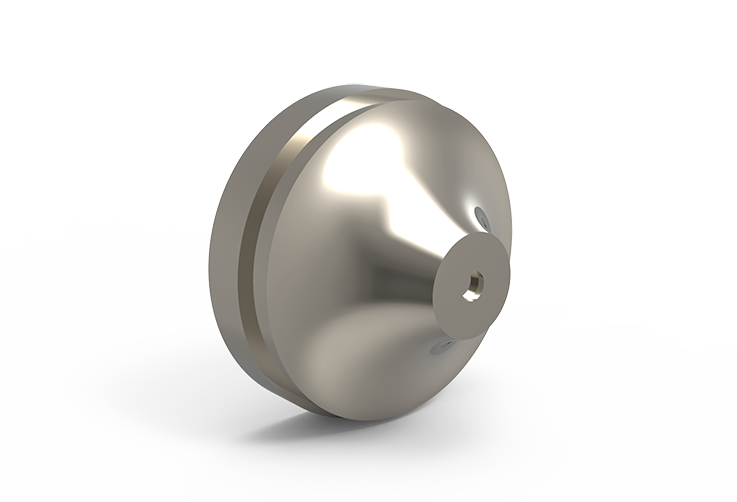

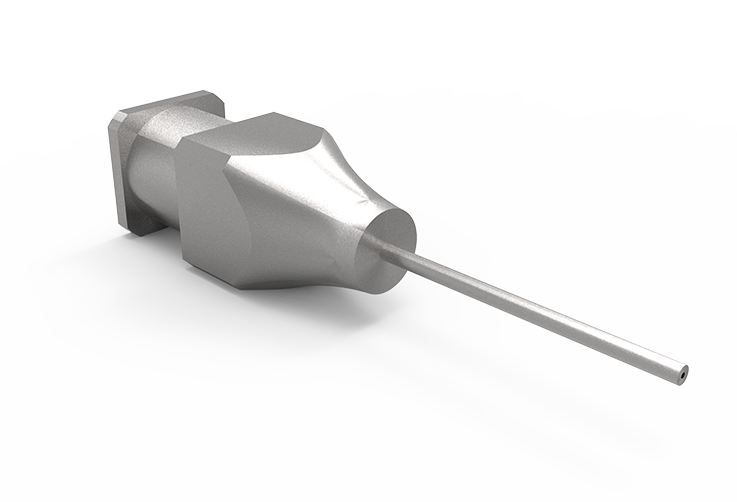

Compact and cost-efficient: All three versions of the WSV share identical dimensions. This simplifies installation and integration of the WSV variants into different systems. The modular design of the spray valve also allows for quick replacement of individual components, which reduces maintenance costs and minimizes downtime.

Add-ons and updates: To expand the functionality of the WSV spray valve, software add-ons such as “Ethernet Bus System,” “Needle Stroke Monitoring,” and “Multi Parameter Sets” are available. Firmware updates can be installed independently and allow continuous optimization of the valve functions.

- swift and easy commissioning with direct control via web interface

- cost- and time-saving integration without additional control technology, software, or programming

- reduce rejects and enhance process quality through continuous process monitoring

- quick commissioning facilitated by easy and comfortable adjustment

- additional features like atomizing air control via proportional pressure valve, built-in push-button for manual operation, and post-installation expandability through upgrades complement the extensive capabilities of this new valve type

- inlet pressure (medium): max. 50 [bar]

- inlet pressure (atomizer air): max. 6 [bar]

- supply voltage: 24 [VDC]

- valve heating: 0 to 80 [°C]

- ambient temperature: -5 to +45 [°C]

- needle stroke adjustment: min. 0.01 [mm]

- analog outlet: 4 to 20 [mA]

- digital I/O: 4 each 24 [VDC]