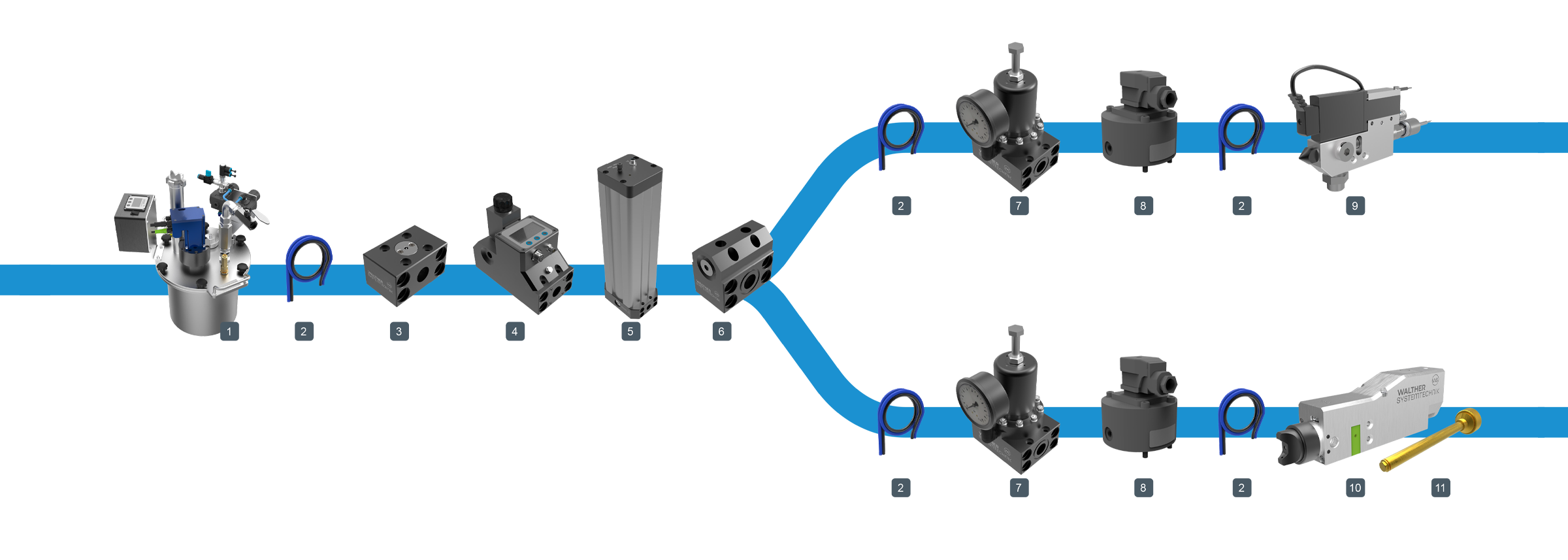

Fluid systems: Exemplary structure of an oil application system

Oil application systems are a fundamental component of industrial production, where they play a key role in quality assurance and efficiency improvement. These systems are designed to apply oil selectively and uniformly to different materials and components. Precise application of lubricating oil is essential to reduce friction between moving parts, minimise wear and optimise the operating performance of machinery. Integrating oil application systems into production lines allows manufacturers to precisely control the amount and placement of oil. This precision is essential for producing durable, high-quality products. In addition, the efficient use of lubricants results in lower maintenance costs and reduced material consumption. Through the targeted use of these technologies, companies can make their production processes more efficient and at the same time reduce their environmental impact through reduced lubricant consumption. Overall, oil application systems help to optimise production processes and reduce production costs.

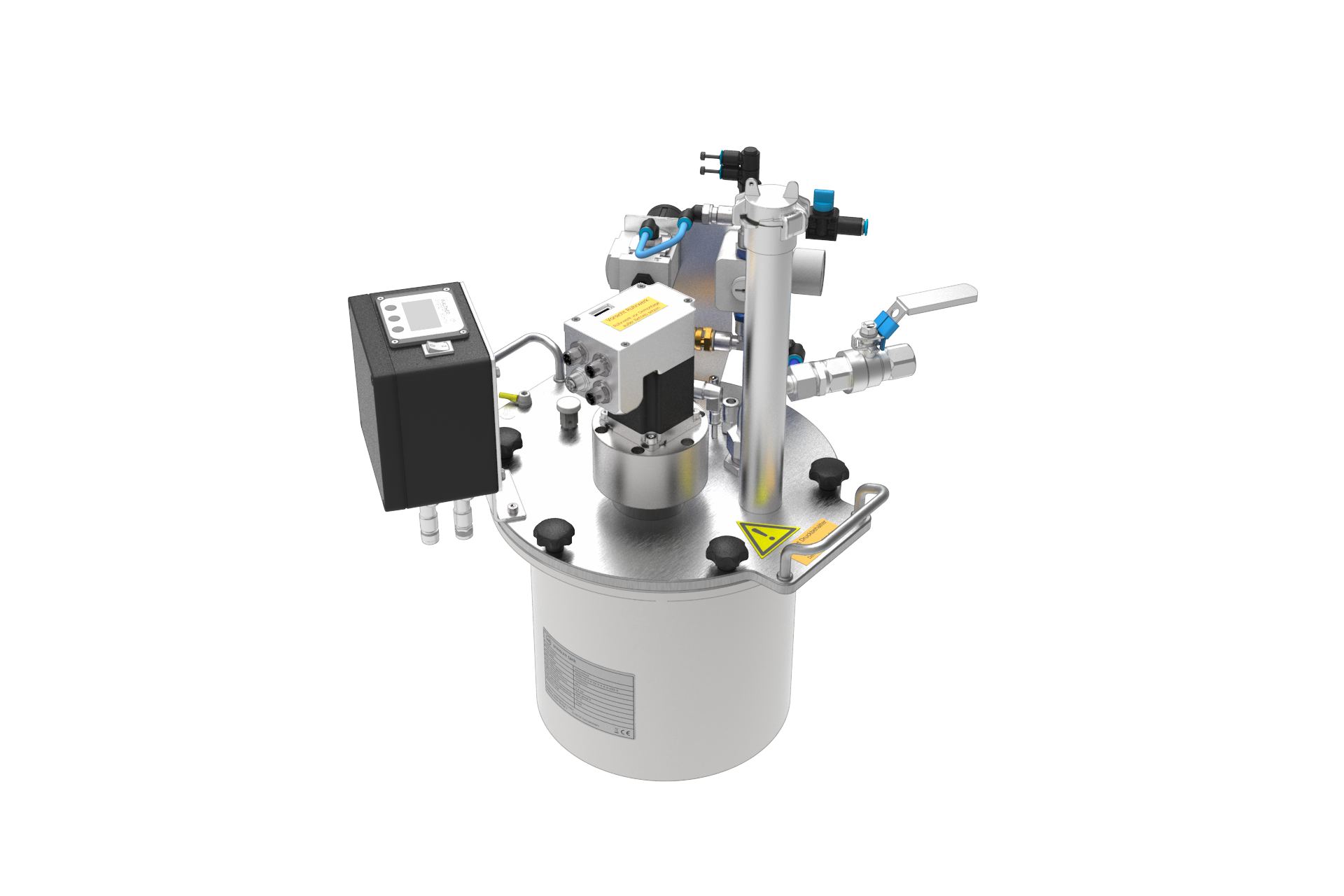

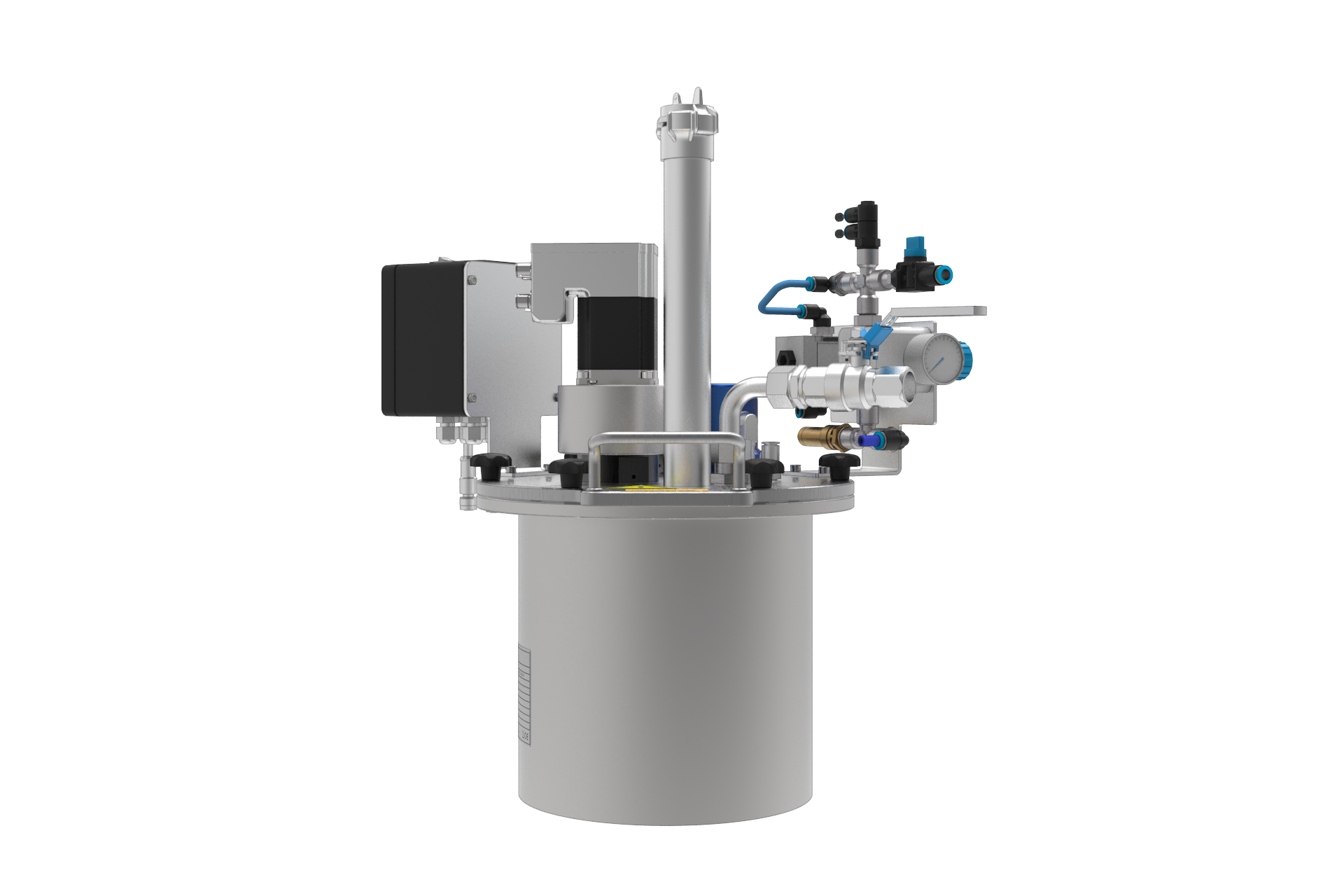

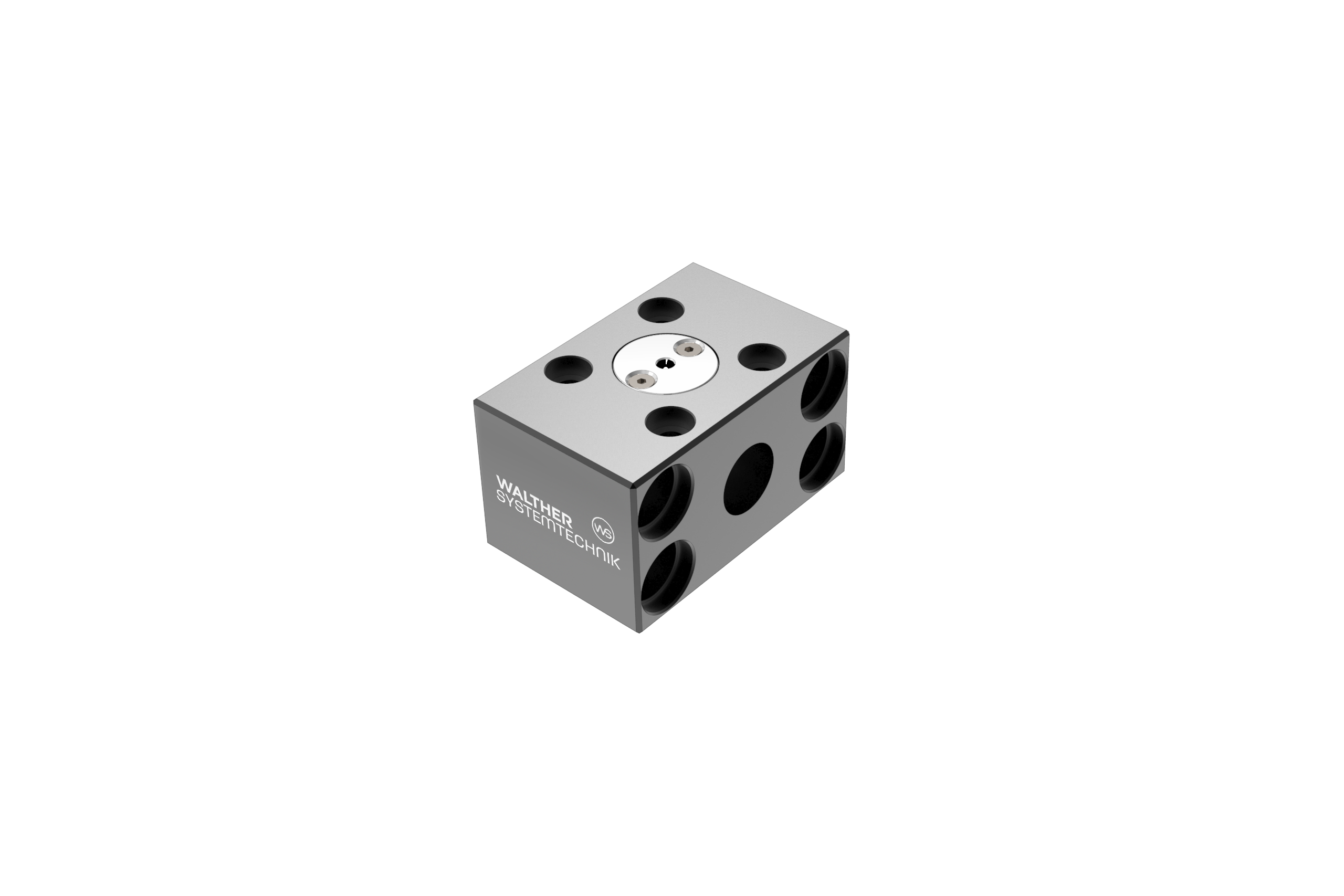

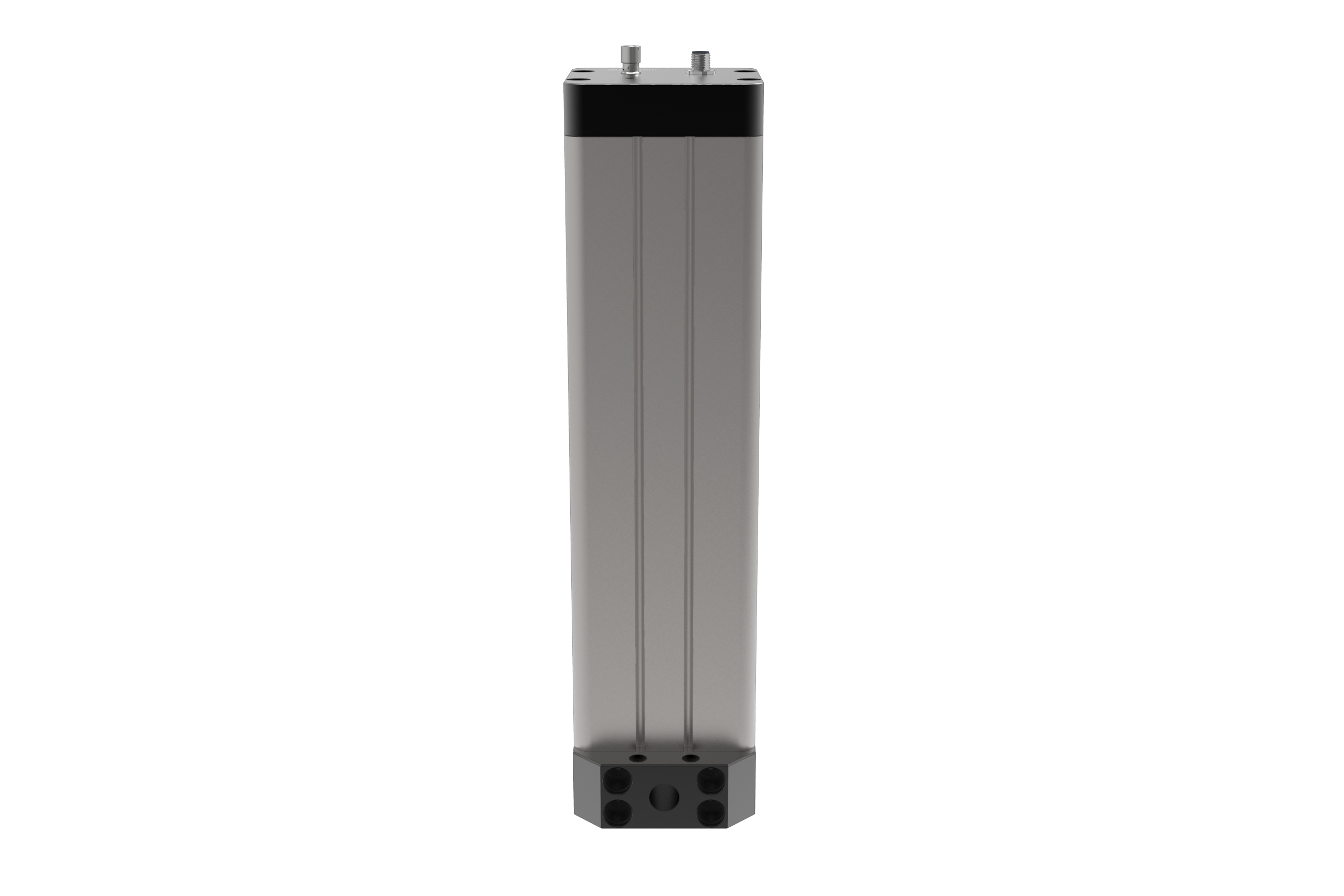

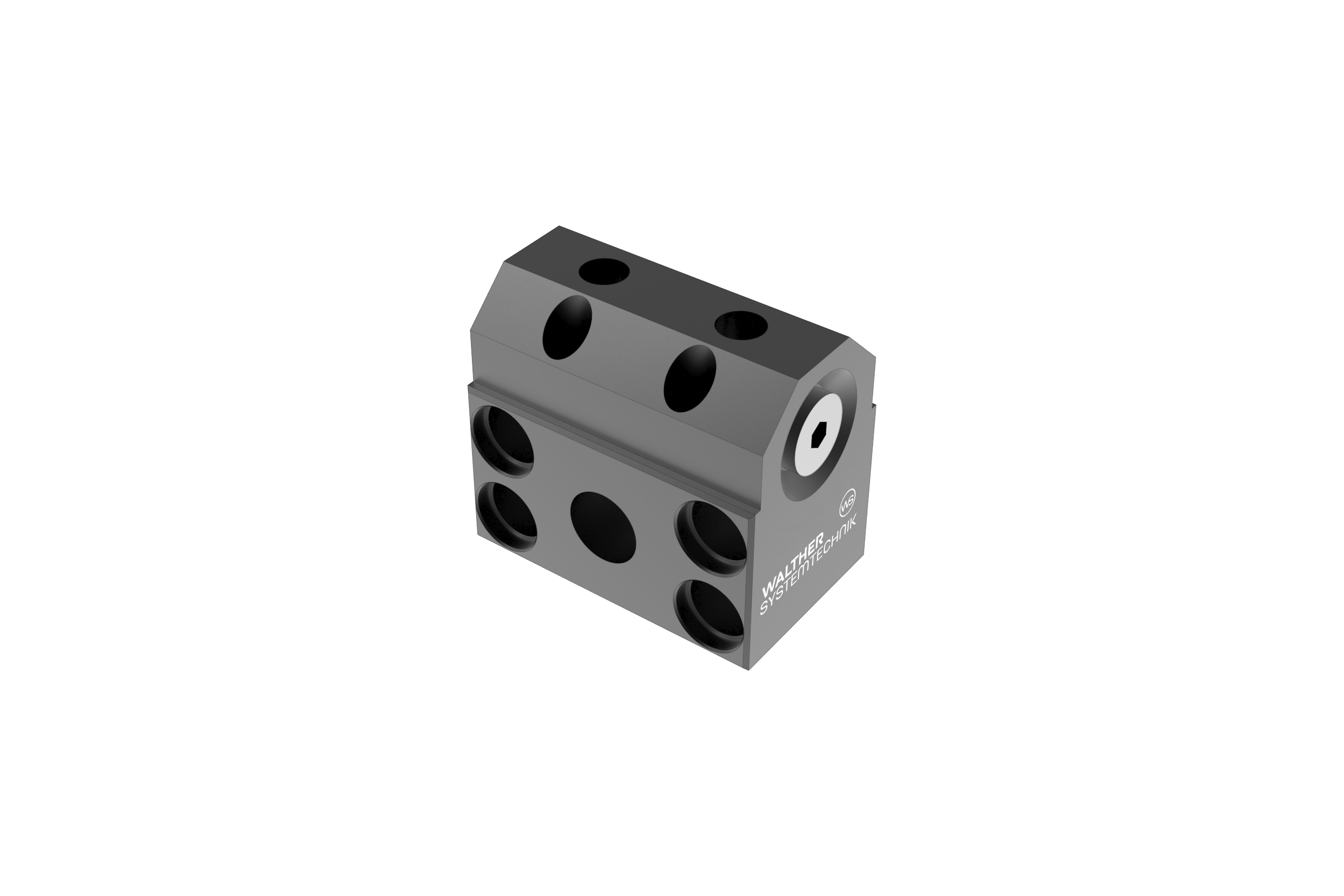

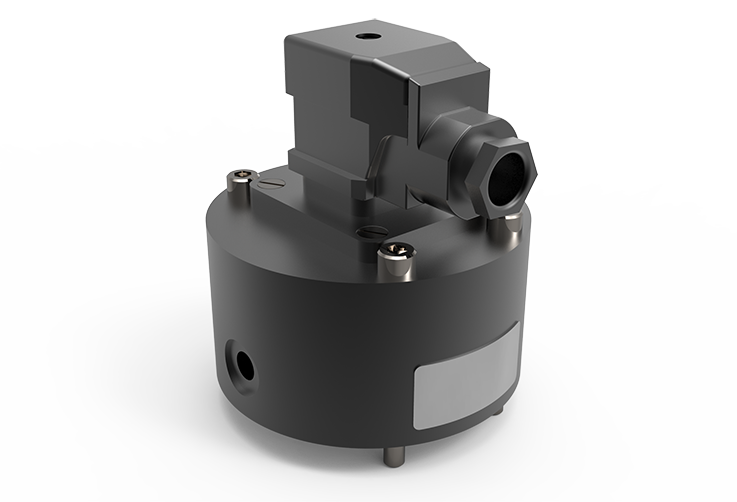

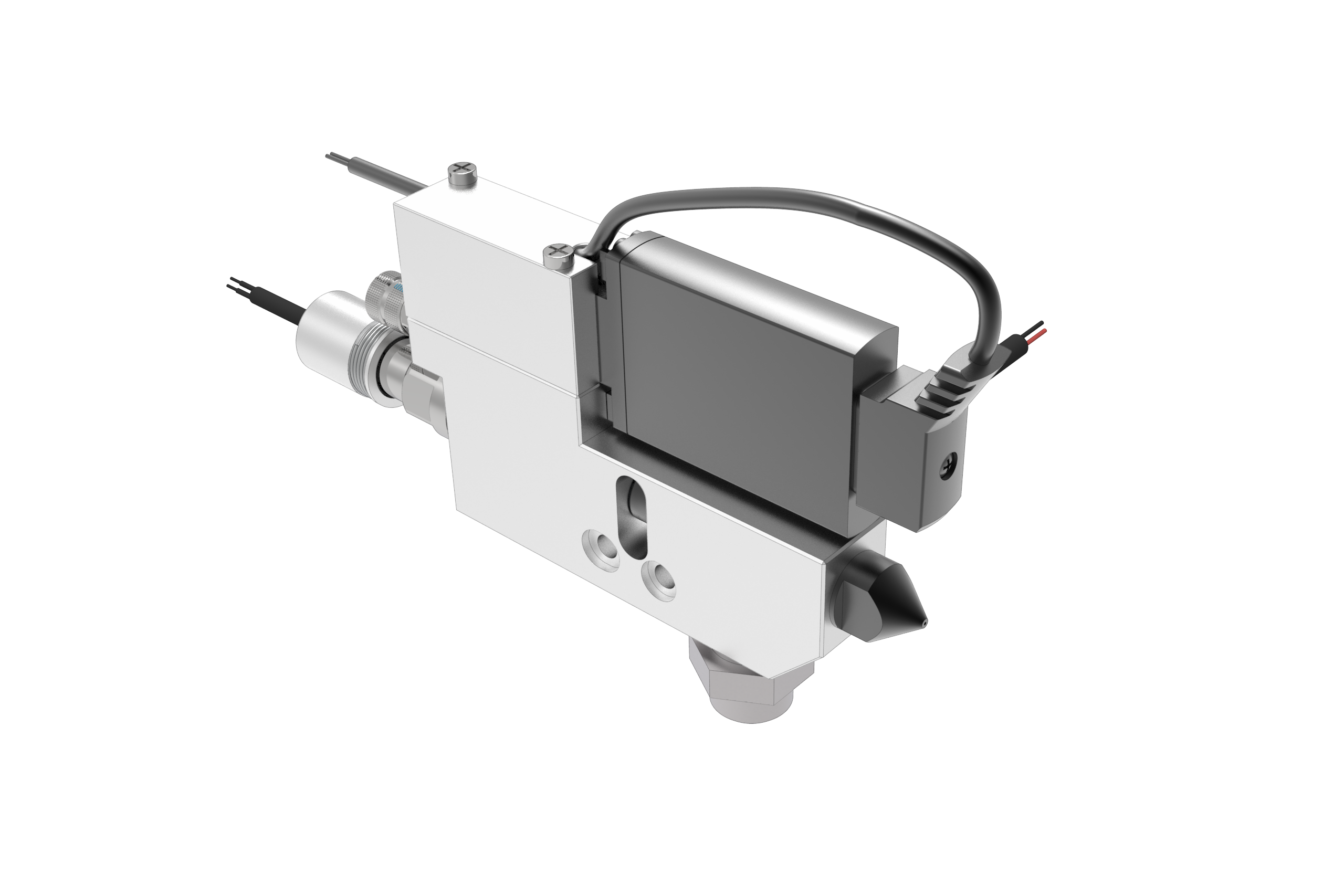

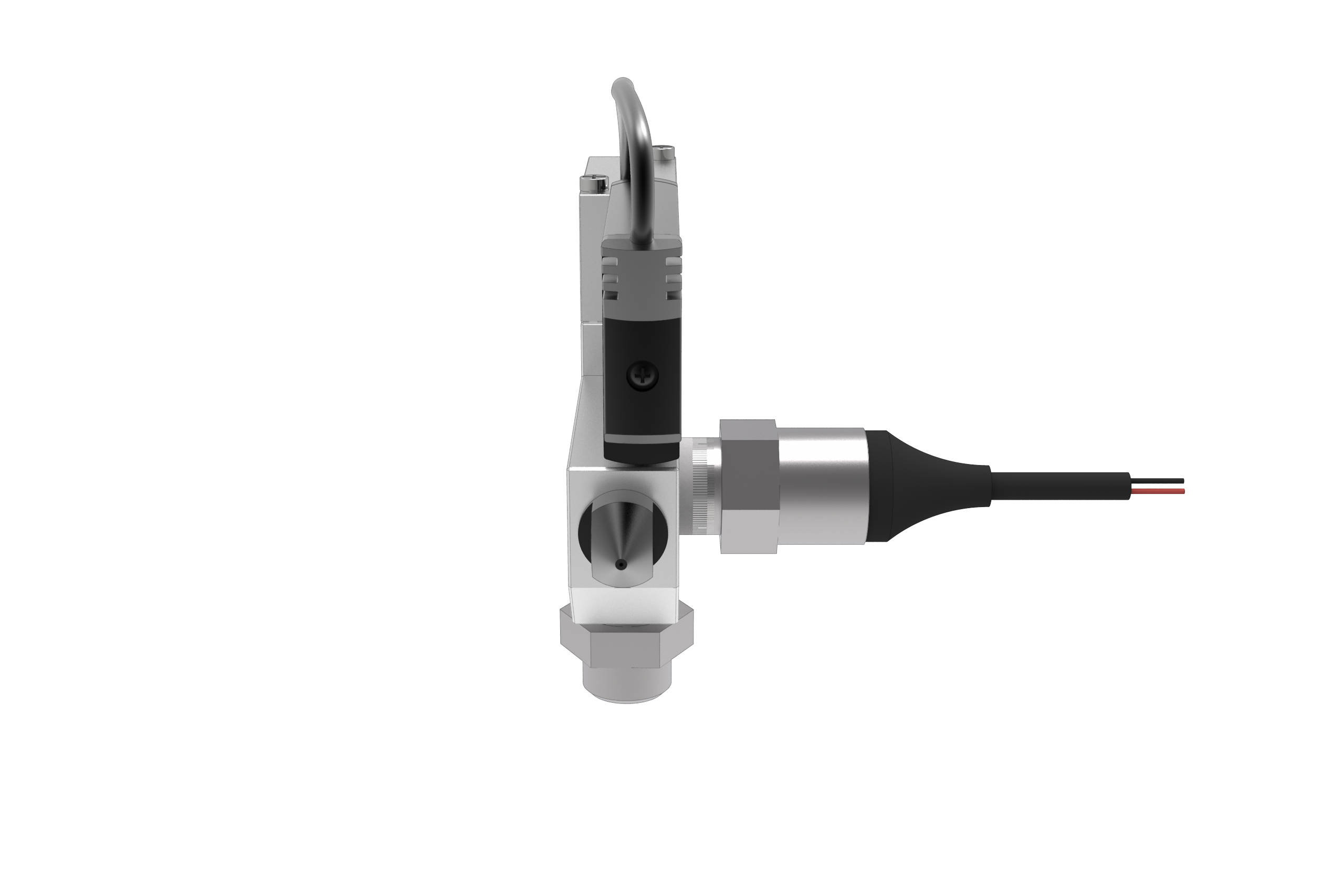

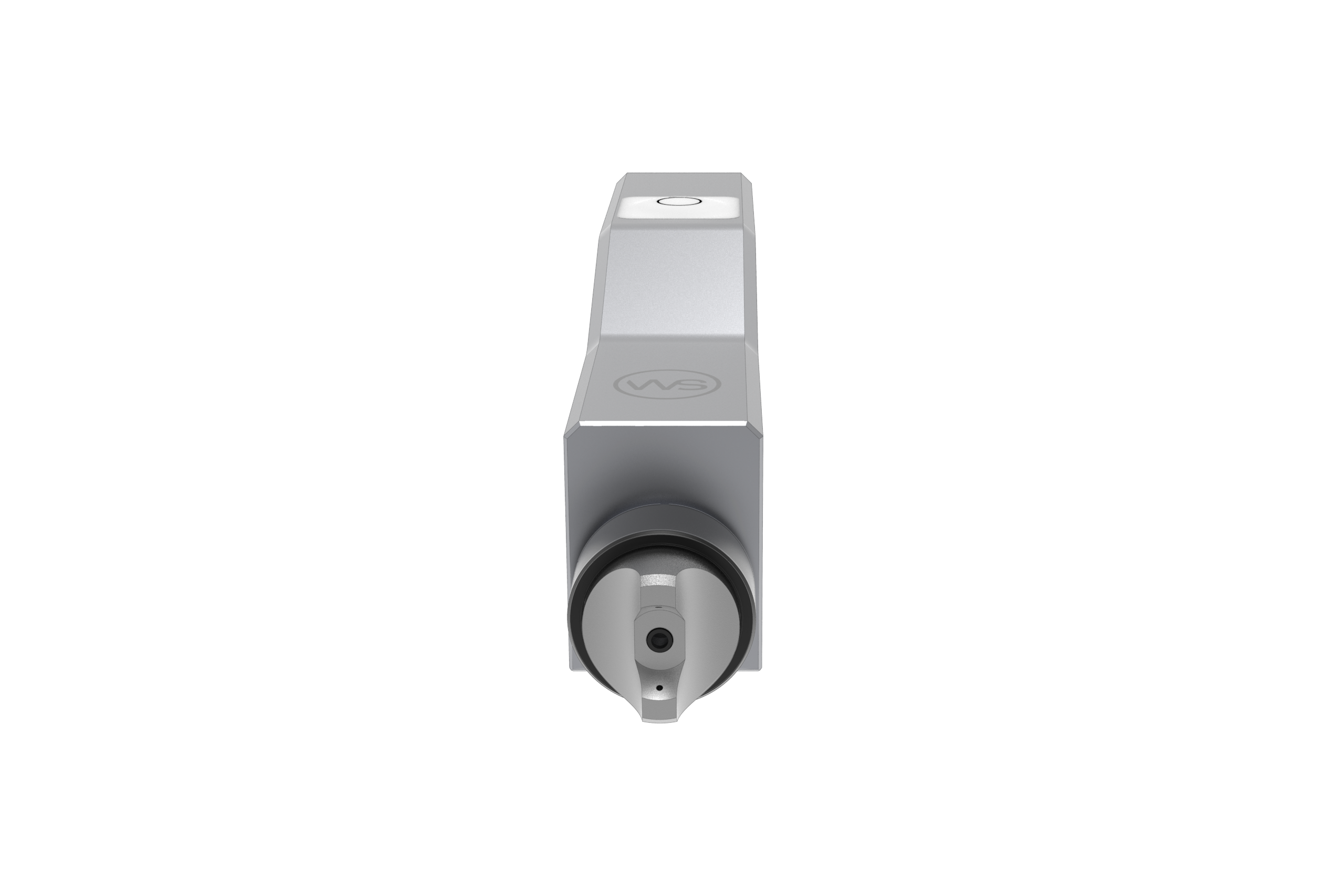

Our exemplary oil application system structure consists of several key components that work together seamlessly.