Air Bubble Outward Transfer ABPS

Air and gas inclusions in liquid and pasty media frequently lead to unstable dosing results when exiting dispensing valves: the bubbles expand abruptly, which can result in underdosing, defective application patterns, and in some cases even mechanical damage to the valves.

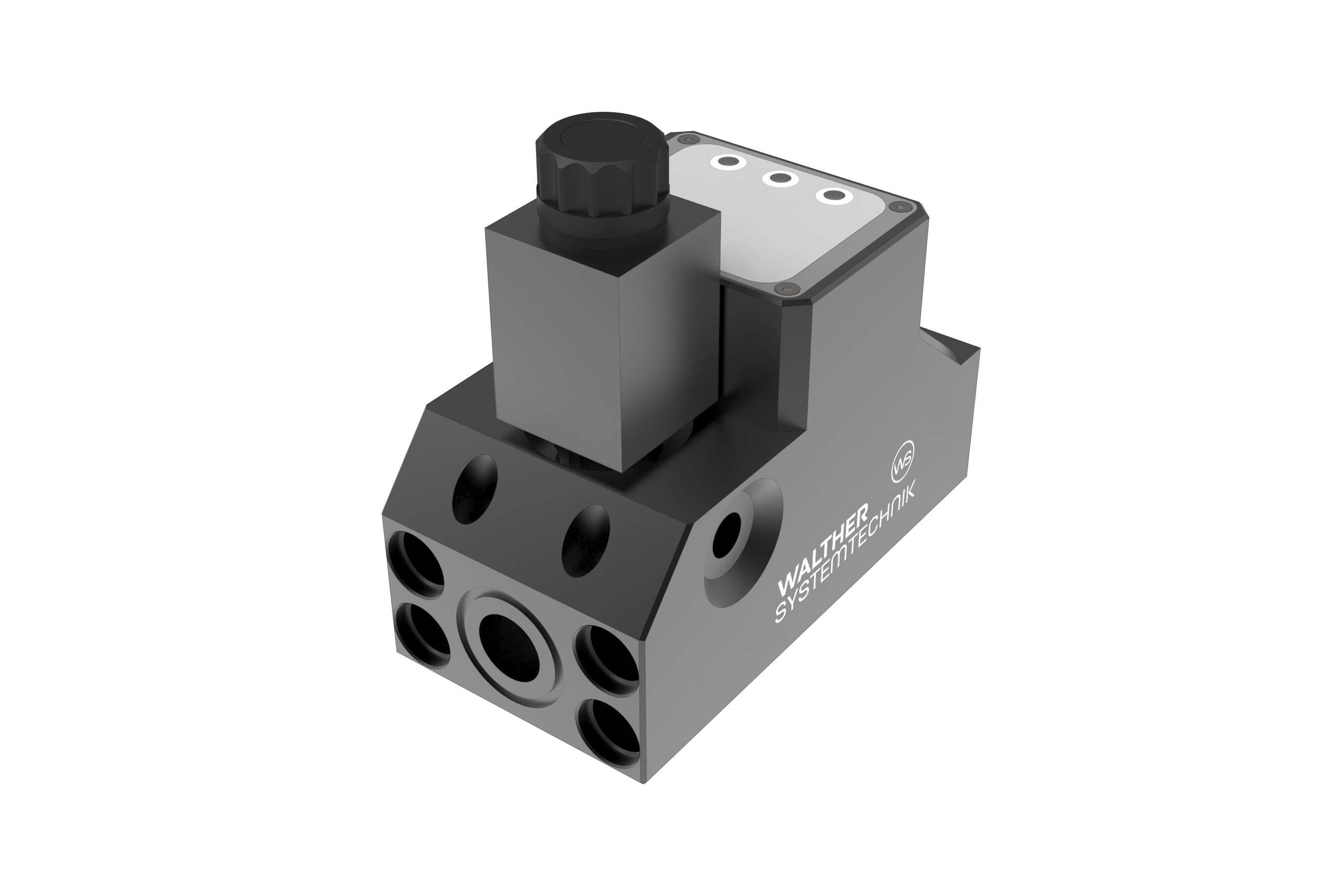

The Air Bubble Protection System (ABPS) was developed to minimise these process-related risks. As a compact functional unit, it continuously monitors the media flow and automatically removes air and gas inclusions before they reach the critical part of the process.

An integrated sensor detects bubbles with a diameter of 1.3 mm or larger. Once a bubble is identified, a solenoid valve automatically opens a lateral venting outlet and the air-contaminated medium is selectively discharged. This ensures that the regular media flow remains free of air inclusions while material loss is reduced to an absolute minimum due to the high detection and separation accuracy.

Bubble removal is fully automated based on freely definable threshold values. In addition, the ABPS monitors further key figures such as the number of detected bubbles, the duration of the last discharge cycle, the cumulative venting time, and the air inclusion ratio over the last 10 or 60 minutes. All measured values are shown on the integrated display. Device configuration – including sensitivity level, threshold settings, language selection, and password protection – is carried out directly via three on-device buttons.

For integration into automated systems, the ABPS features an RS485 interface (Modbus RTU) and four freely configurable digital inputs/outputs (24 V DC). These can be used for both external control (e.g. RUN, Discharge) and for threshold monitoring and alarm signalling.

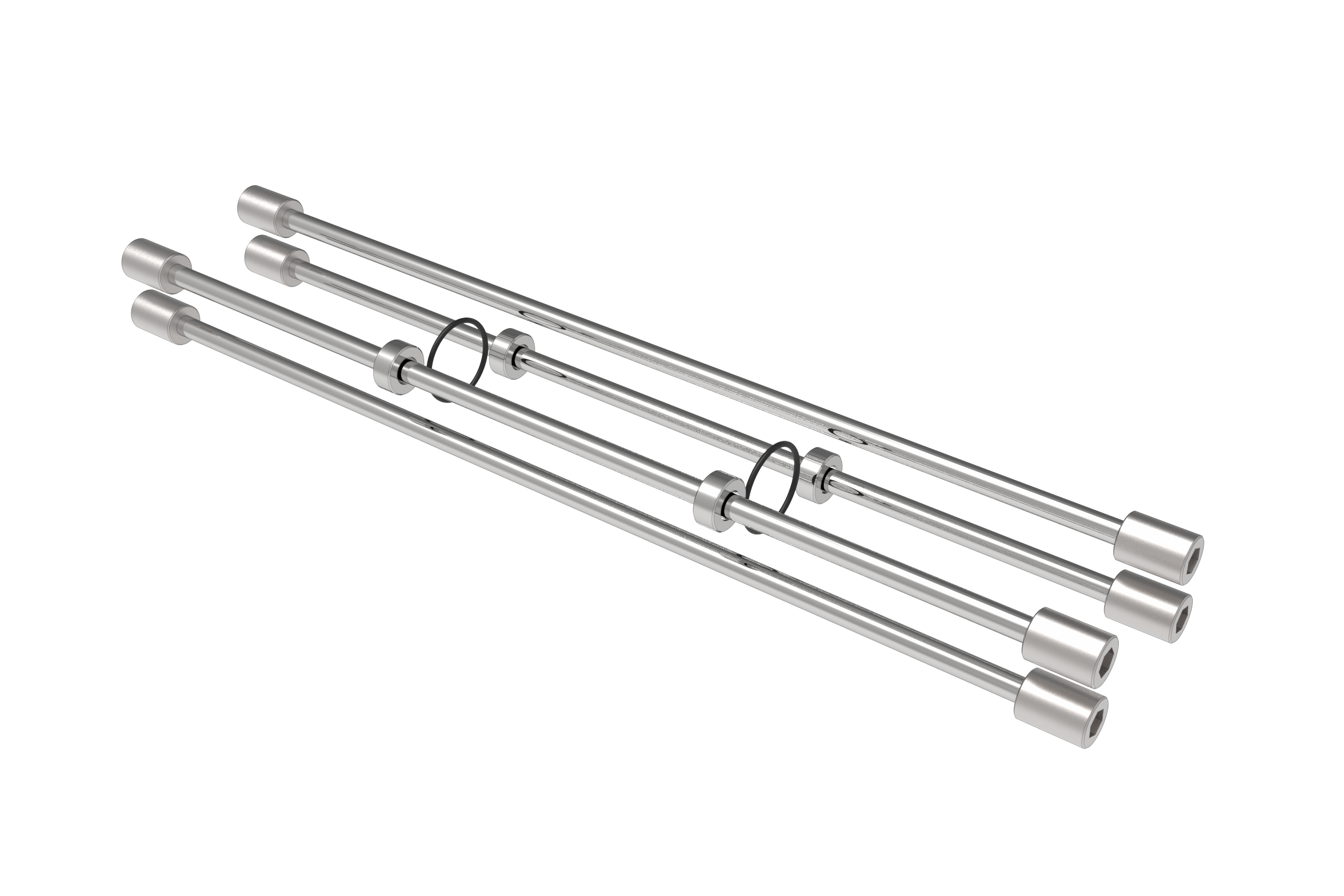

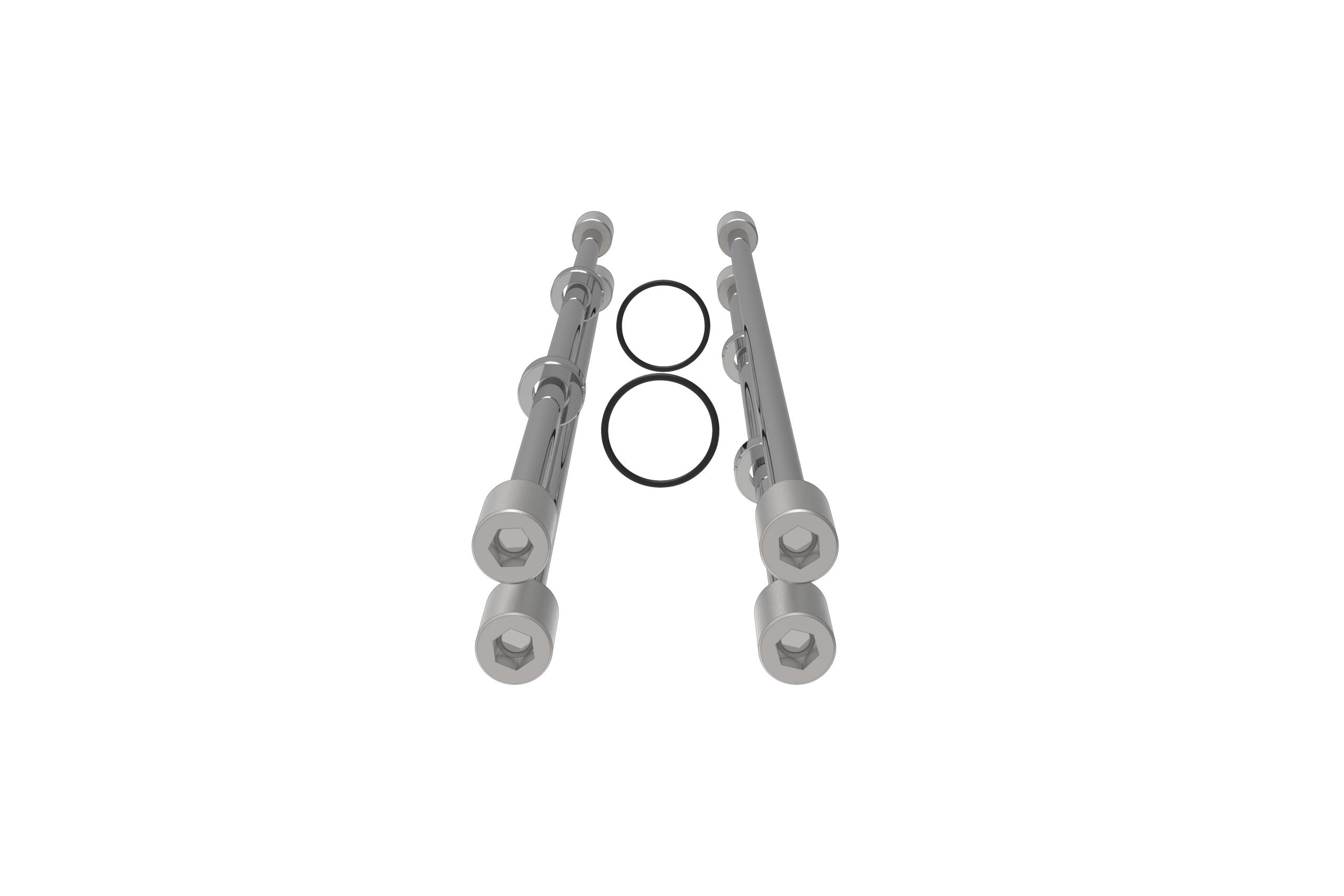

As part of the Walther MODULAR system, the Air Bubble Protection System can be quickly and reliably combined with other function modules via a standardised module connector set. With its compact design of 153 × 79 × 139 mm and G½" connections, it is ideally suited for integration into new or existing fluid and dispensing systems.

The system is suitable for non-aggressive, liquid to pasty media – such as oils and greases – which are processed at operating pressures of up to 10 bar and at process temperatures between +5 °C and +50 °C. The recommended flow rate is up to 100 cm³/min, depending on the medium and the desired venting behaviour. To optimally adapt bubble detection to the specific medium, a one-time teach-in process is required during initial commissioning or after a media change.

Combining precise bubble detection, automated separation, and flexible control integration, the ABPS ensures stable processes, minimises material waste, and reduces downtime caused by air-related disruptions. Thanks to its system-independent functionality, the ABPS is not only suitable for dispensing applications, but also for protecting pressure- and volume-sensitive components such as pumps, filters, mixers, or sensors. It safeguards the entire fluid system, regardless of whether disruptions occur in material handling, process control, or at the point of application.

- air inclusions in lubricants will be automatically detected and outward transferred

- size and number of air bubbles are monitored

- for each process value, limit values can be defined; freely configurable alarm outlets will indicate any breaches

- device from WALTHER MODULAR series, therefore smaller installation area, easy mounting and simplified maintenance

- operating pressure: max. 10 [bar]

- dimensions l x w x h: 153 x 79 x 139 [mm]

- weight: 2,8 [kg]

- Walther-Module length: 3

- connection: G1/2" and flange Walther-Modular

- operating voltage: 24 [VDC]