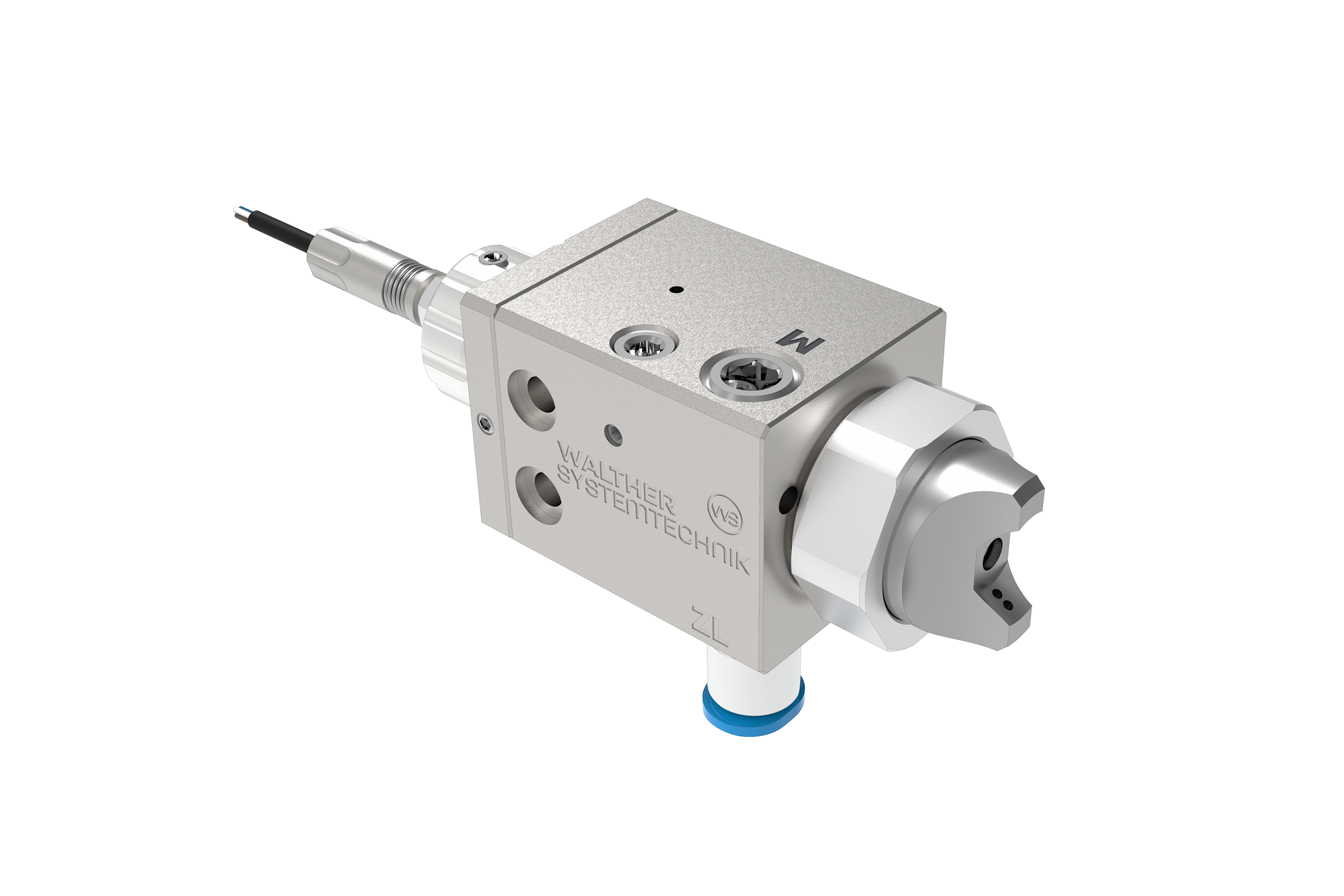

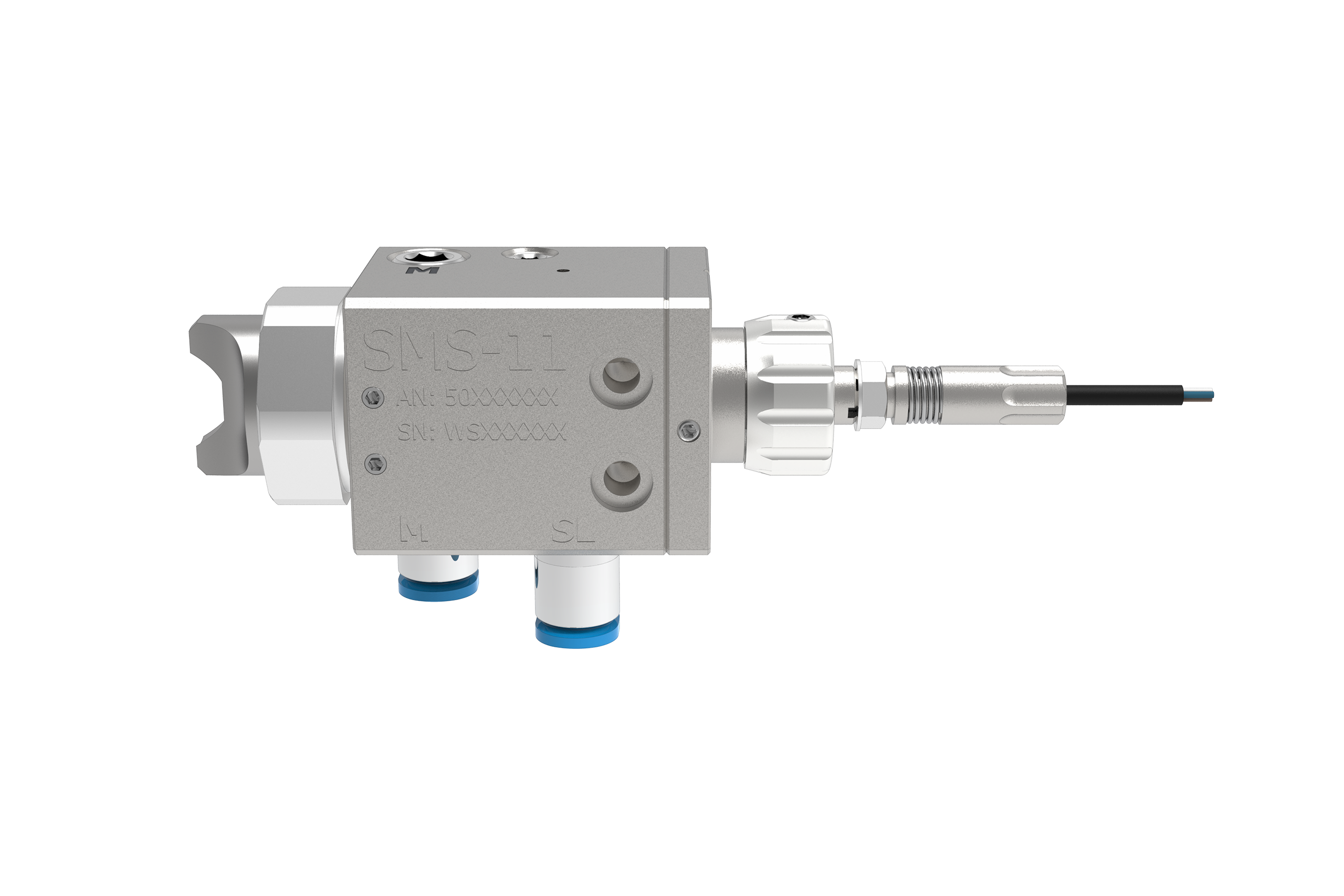

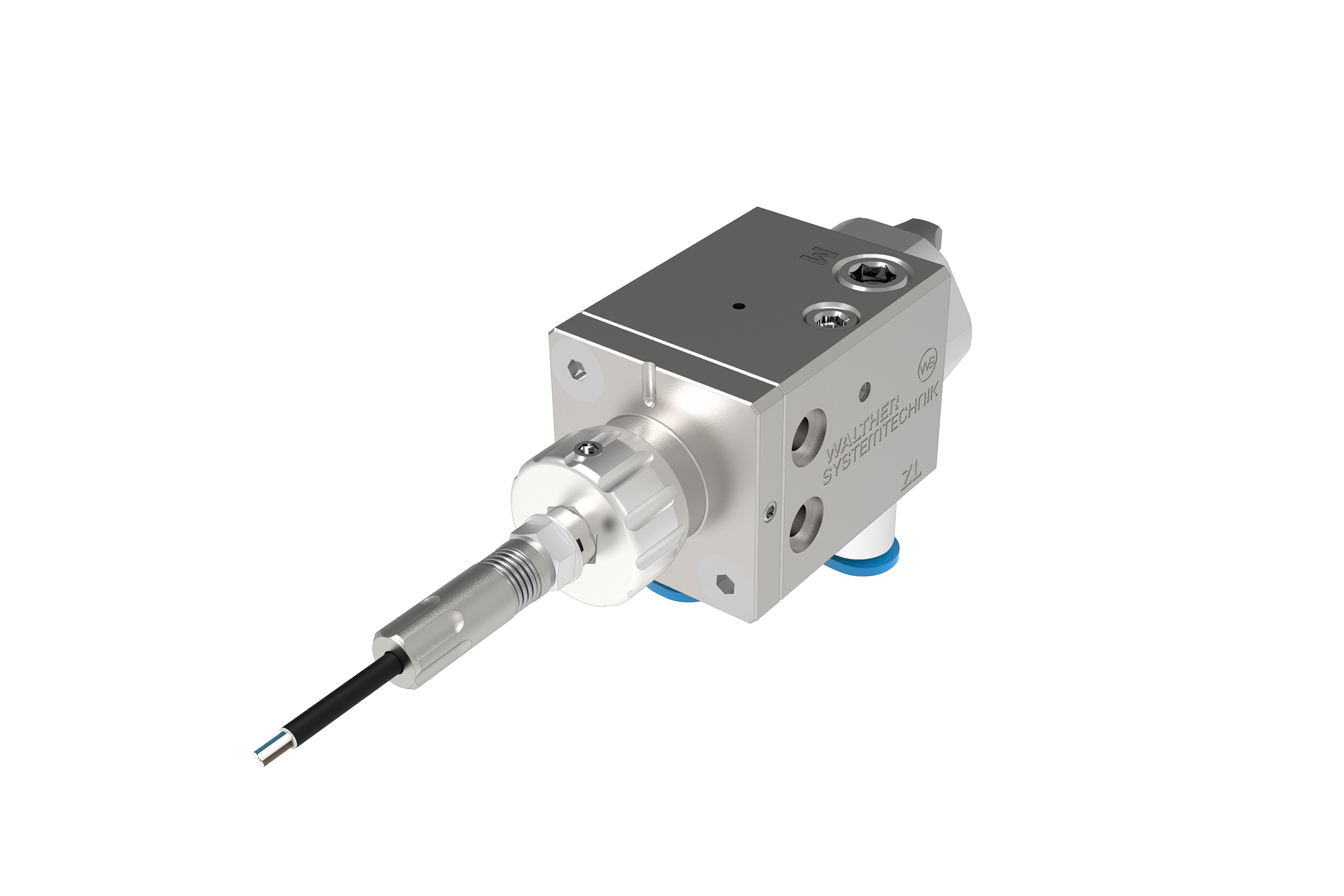

Spray Valve SMS-11

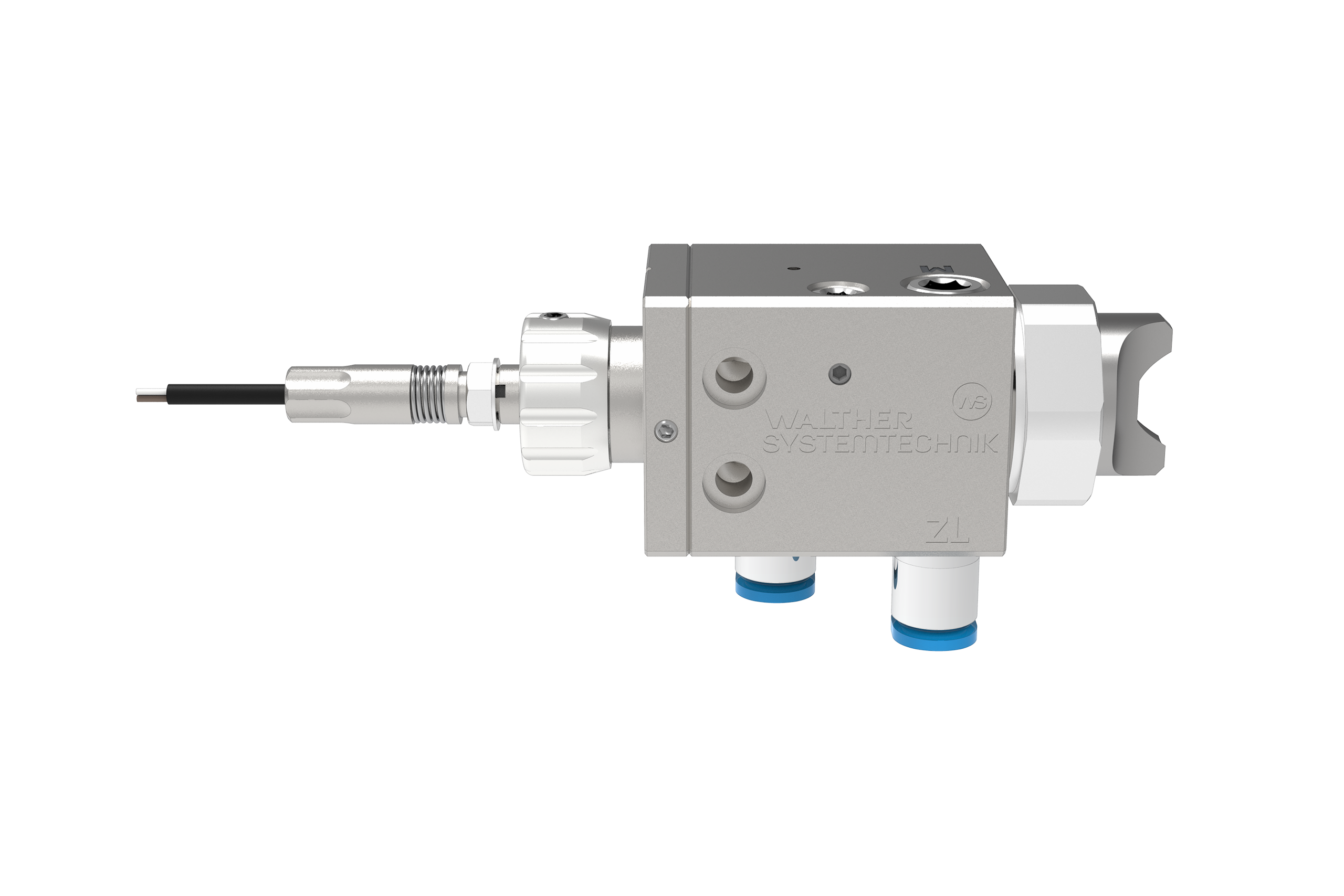

Pneumatically controlled spray valve for the precise application of viscous media: The SMS-11 is a compact precision spray valve designed for the reliable application of low- to medium-viscosity media. With dimensions of approximately 30 × 42 × 79 mm, it is ideally suited for integration into both new and existing production lines. The valve is operated entirely pneumatically, allowing direct integration into existing compressed air systems without the need for additional electronics or software.

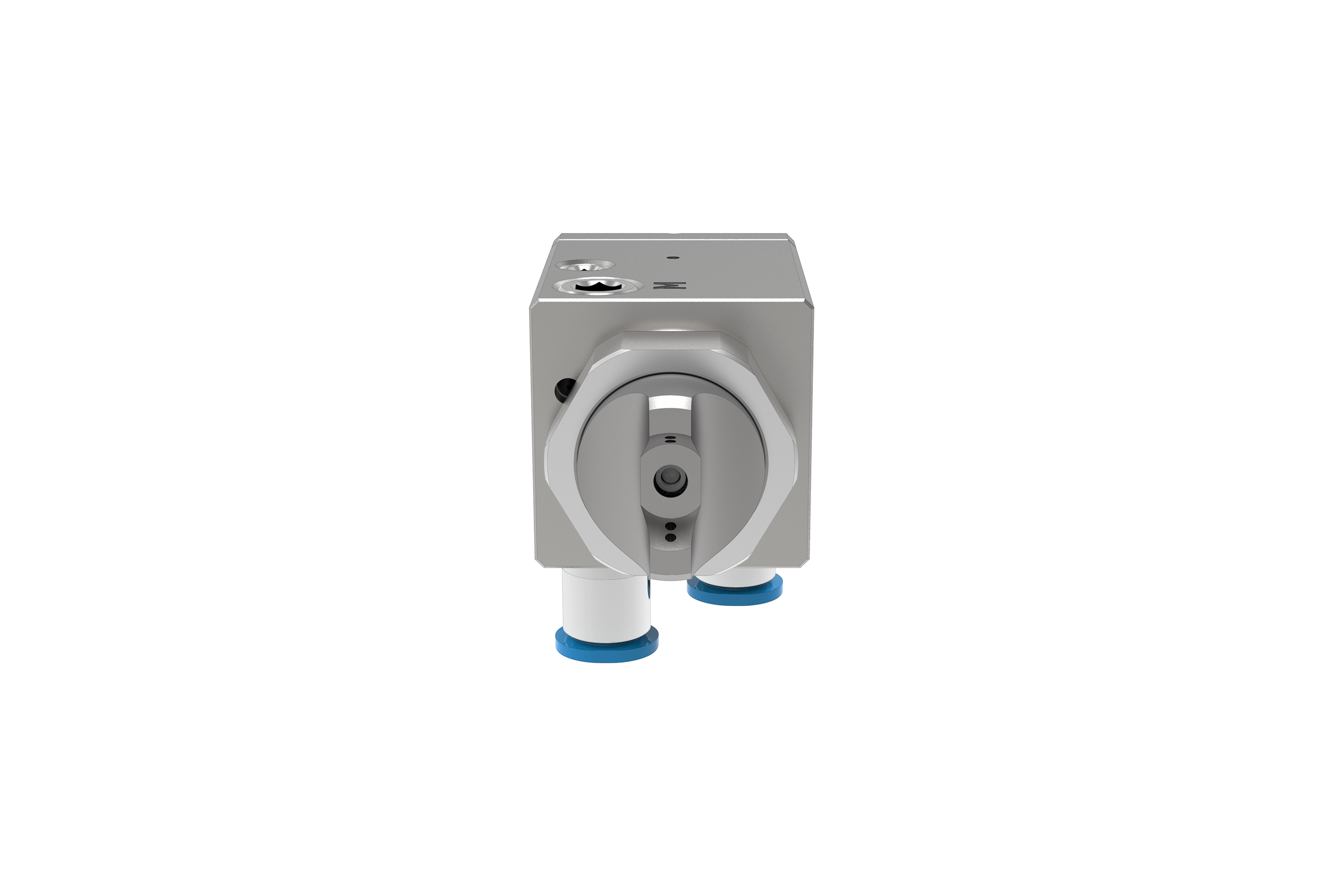

Targeted spray pattern adjustment: The atomising air can be actuated and regulated separately. It atomises the medium into fine droplets and, in combination with the selected air cap, produces flat or round spray patterns. The spray pattern can be flexibly influenced by atomising air pressure and nozzle geometry; for flat spray applications, the integrated spray width control additionally enables stepless adjustment of the application width. Width adjustment is carried out either internally via a throttling screw or externally via a separate pressure regulator. The advantage: A single valve covers a wide range of applications – from pinpoint dosing to homogeneous coatings – without conversion or valve change.

Controlled media cut-off: The valve needle is pneumatically opened and reliably closed by spring force. By adjusting the post-air duration, the medium strand is finely atomised and cleanly separated at the nozzle tip during closure. This prevents stringing and dripping – for a clean, defined cut-off. With up to 40 cycles per second (under suitable conditions), the SMS-11 is designed for dynamic short-cycle processes in automated production lines.

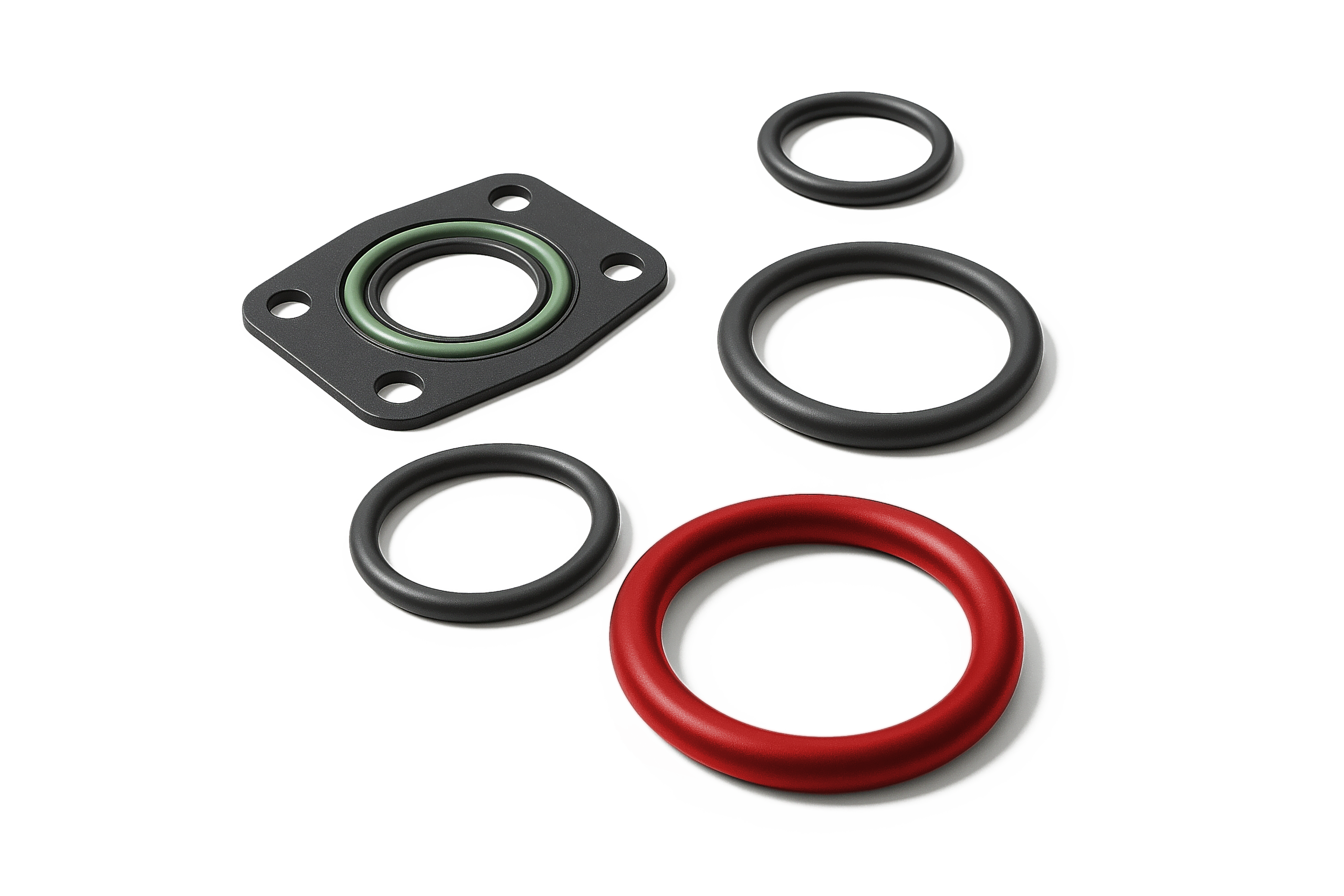

Reliable media handling: The SMS-11 processes a wide range of industrial media such as oils, greases and single-component adhesives. The stainless steel construction and chemically resistant seals ensure reliability and durability, even under continuous operation.

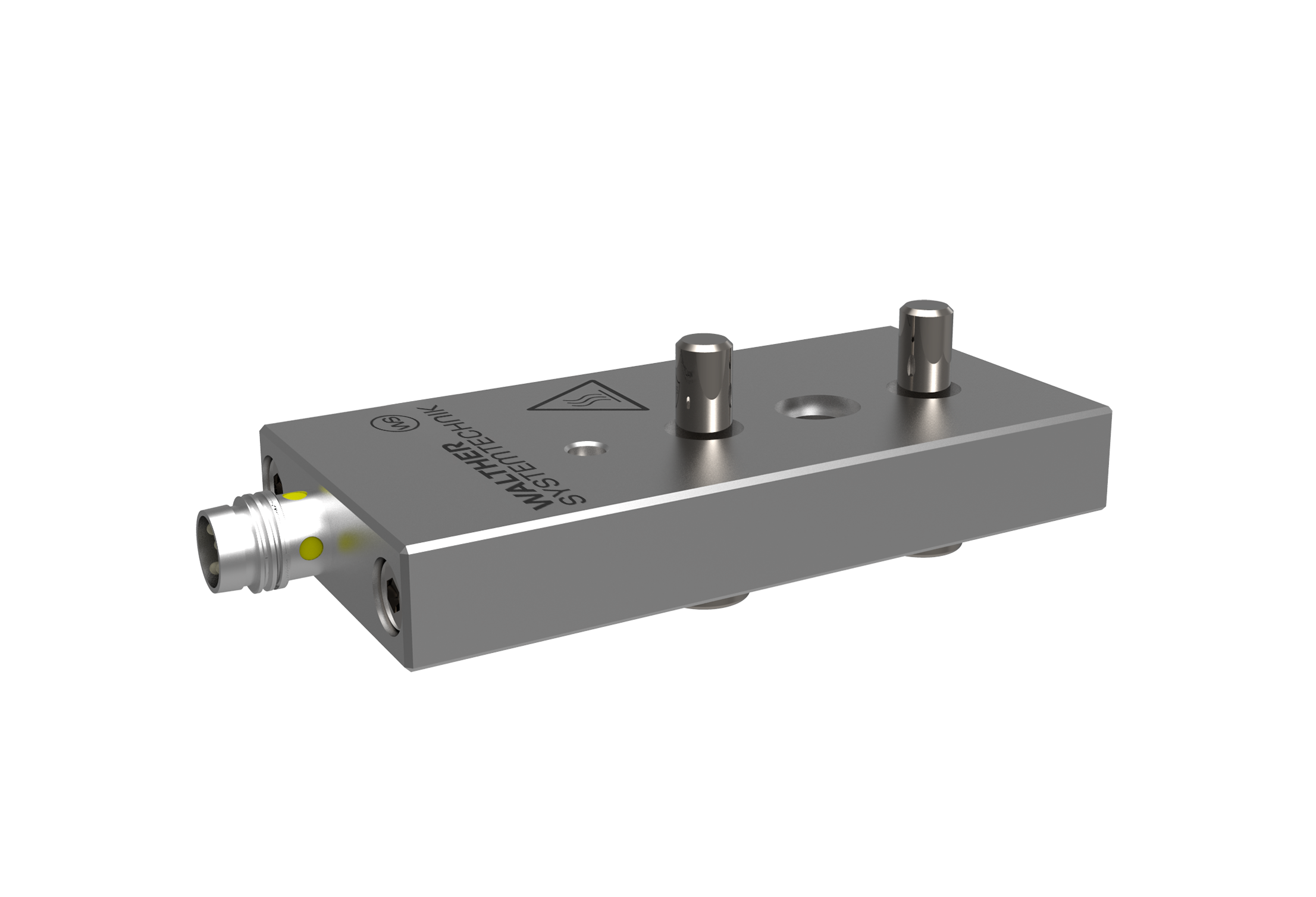

Flexible expansion: Additional options such as a heating unit for media temperature control, a media circulation system that keeps the medium flowing continuously through the valve to prevent sedimentation or curing and to ensure a consistent material flow, various nozzle extensions, and a needle stroke sensor enable the SMS-11 to be precisely adapted to the specific application.

Conclusion: With precisely adjustable operating parameters, high cycle frequency and reproducible spray patterns, the SMS-11 is a powerful spray valve for demanding production environments – robust in construction, efficient in application, and flexible in use.

- Compact design for flexible integration into production systems

- Independently adjustable atomising air for finest droplet formation and consistent spray quality

- Integrated spray width control for continuously adjustable spray patterns from lines to surfaces

- Clean media cut-off without dripping thanks to adjustable post-air function

- High process dynamics: up to 40 cycles per second (depending on medium, pressure and needle stroke)

- Media circulation prevents deposits, ensures consistent material flow and reduces downtime

- Optional needle stroke sensor for digital process monitoring

- Expandable with heating unit and nozzle extensions for demanding applications

- Maintenance-friendly design with quickly replaceable wear parts

- Dimensions: approx. 30 × 42 × 79 mm (without sensor) / 102 mm (with sensor)

- Weight: approx. 330 g

- Material pressure: max. 15 bar

- Control air pressure: 3.5 to 6 bar

- Atomising air pressure: up to 6 bar

- Air consumption: approx. 111 to 133 l/min (at 3 bar, 0.3 mm nozzle)

- Materials in contact with media: stainless steel 1.4301 / 1.4305 / 1.4404 / 1.4571, seals FKM

- Ambient temperature: 0 to +40 °C