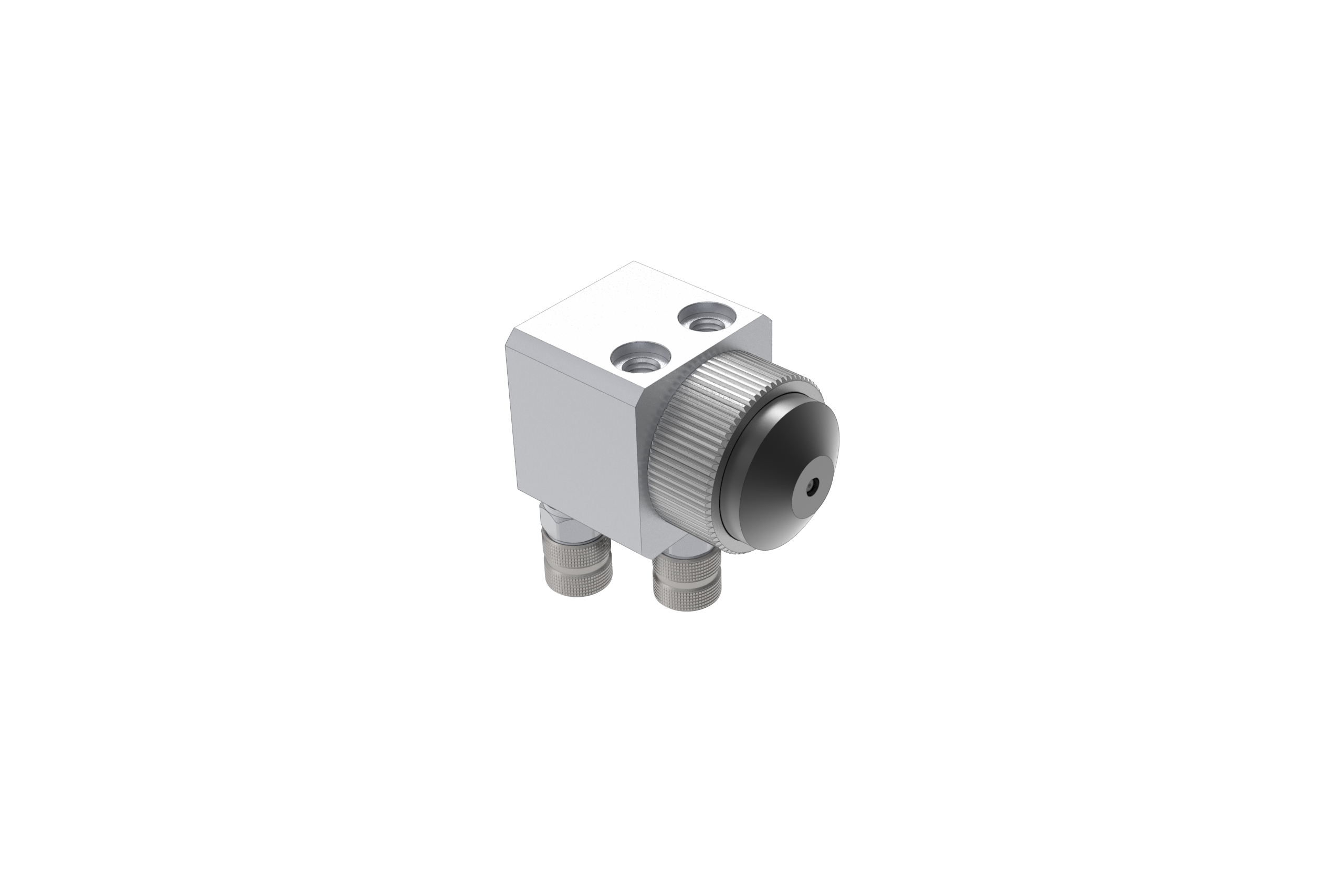

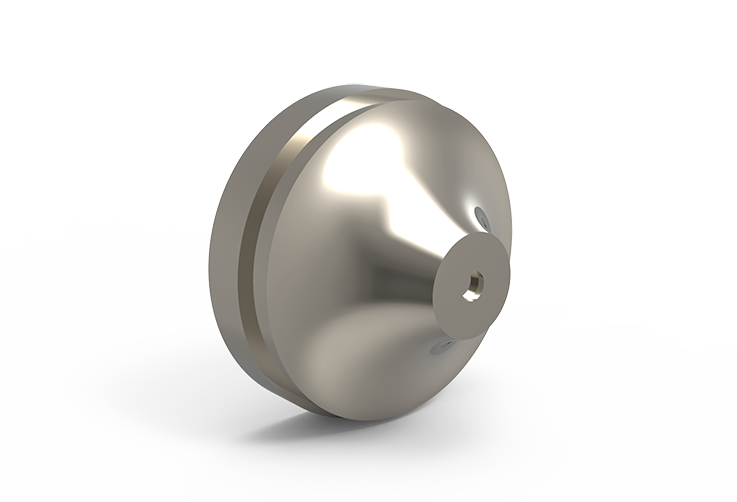

Spray Valve SMS-04

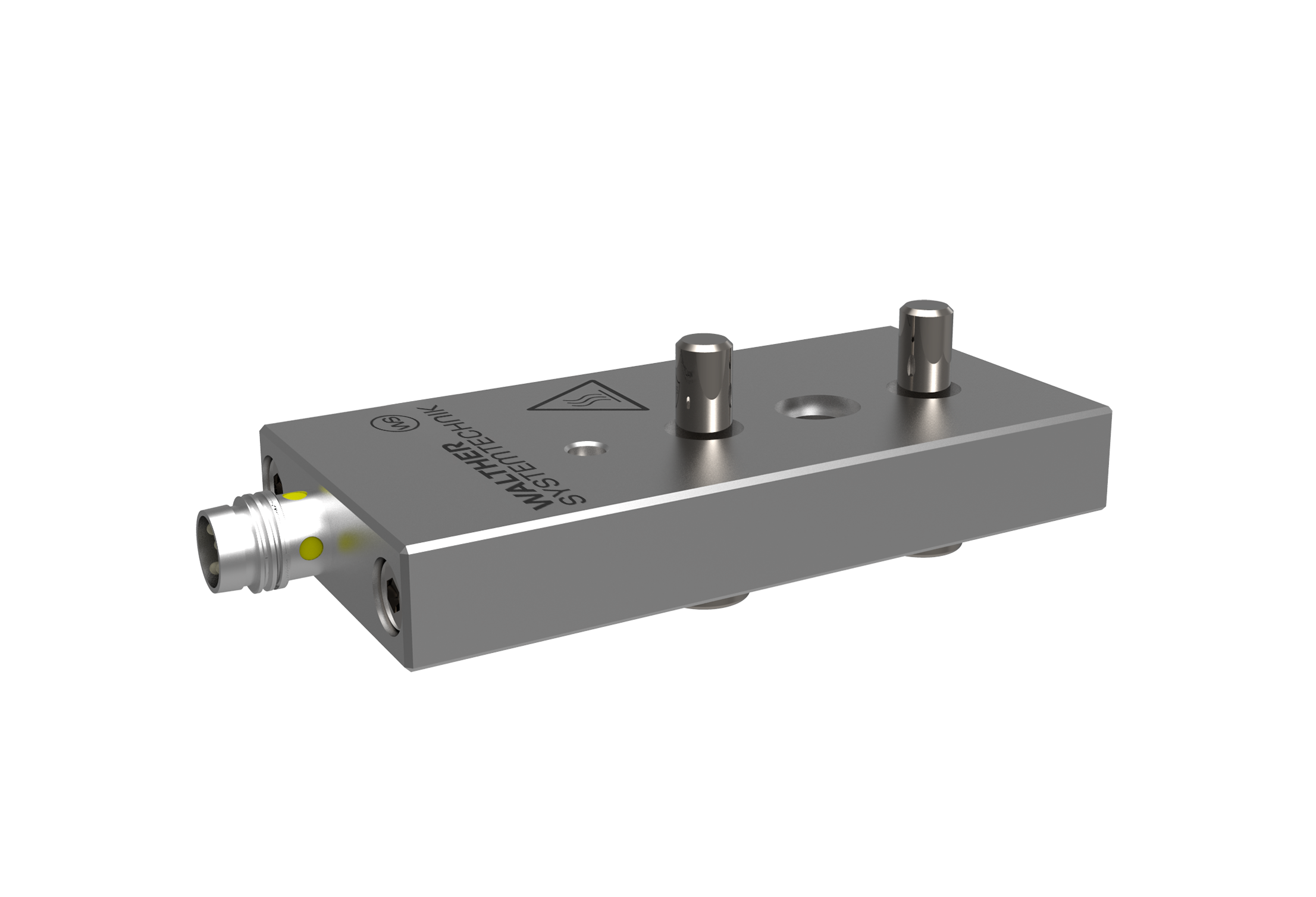

Compact, lightweight, and high-performance: The pneumatically actuated spray valve SMS-04 is specifically designed for the precise application of low- to medium-viscosity media – especially in installations with limited space or where minimal moving mass is required. Its low weight and small footprint make it ideal for use in robotic systems, axis modules, or machine-mounted applications with high dynamics.

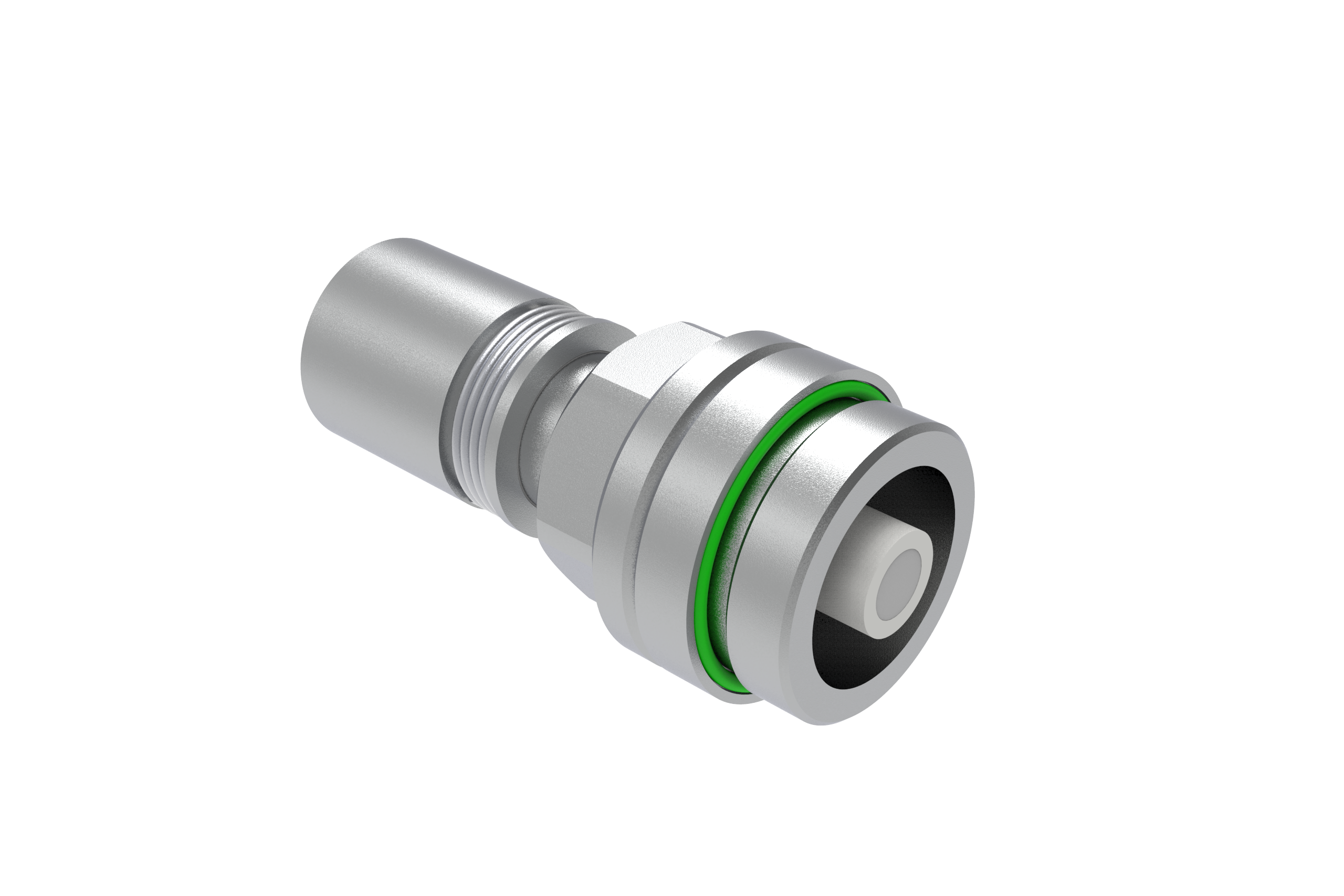

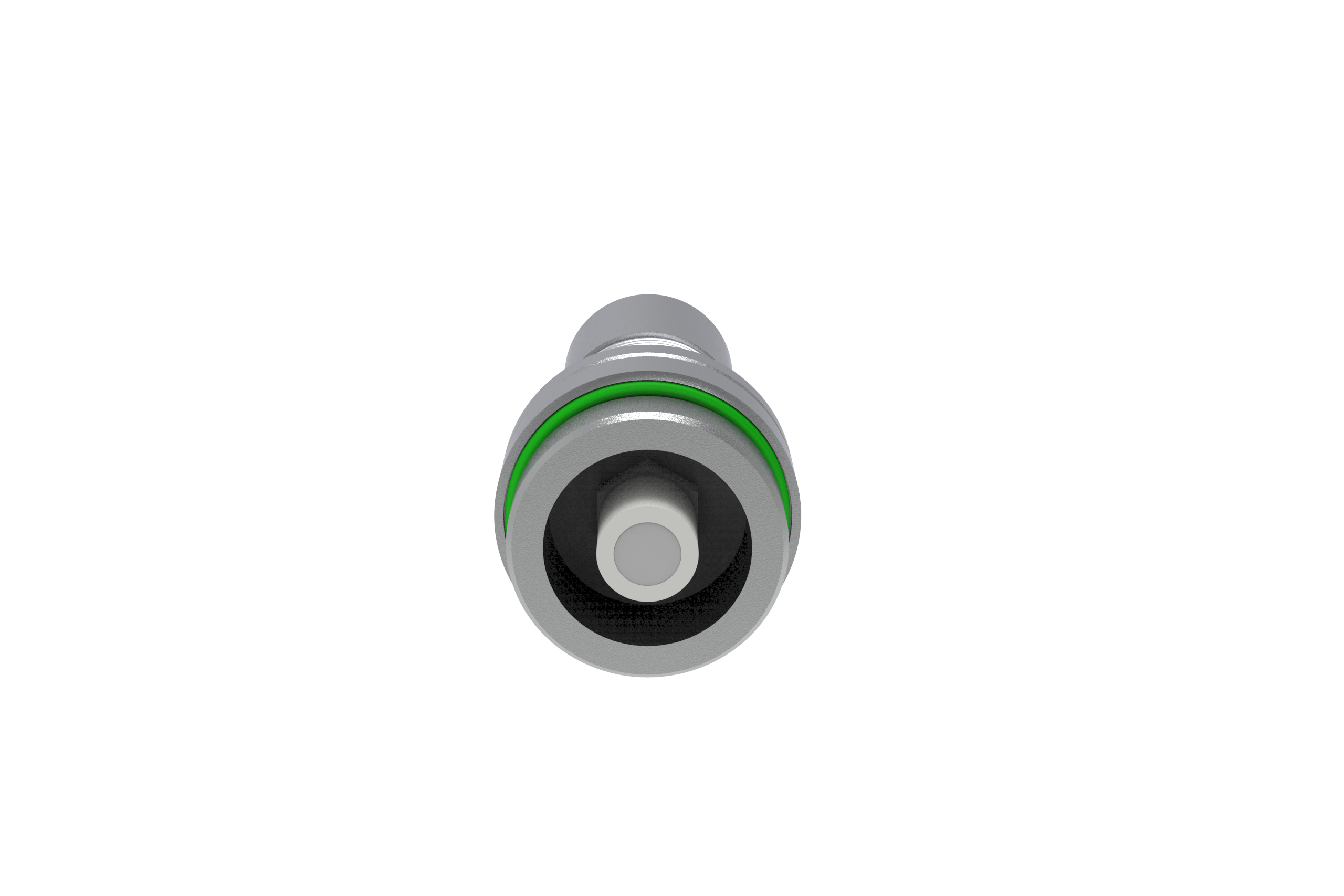

Flexible spray patterns with flat or round jet: Depending on the selected air cap, the SMS-04 produces either a flat spray for surface coverage or a round spray for targeted coating. It supports both continuous and intermittent spraying, making it suitable for a wide range of industrial use cases – from component coating to surface treatment.

Simple actuation and precise spray pattern control: The valve is actuated via an external 3/2-way valve. Additionally, the atomising air can be regulated independently via a second 3/2-way valve, enabling precise adjustment of the spray pattern according to part geometry, application requirements and material characteristics.

Broad media compatibility with high material pressure: The SMS-04 is suitable for processing oils, greases, release agents, paints, and corrosion protection media. It can handle material pressures of up to 30 bar, enabling clean material cutoff, short cycle times and consistent spray volumes, even at higher throughputs.

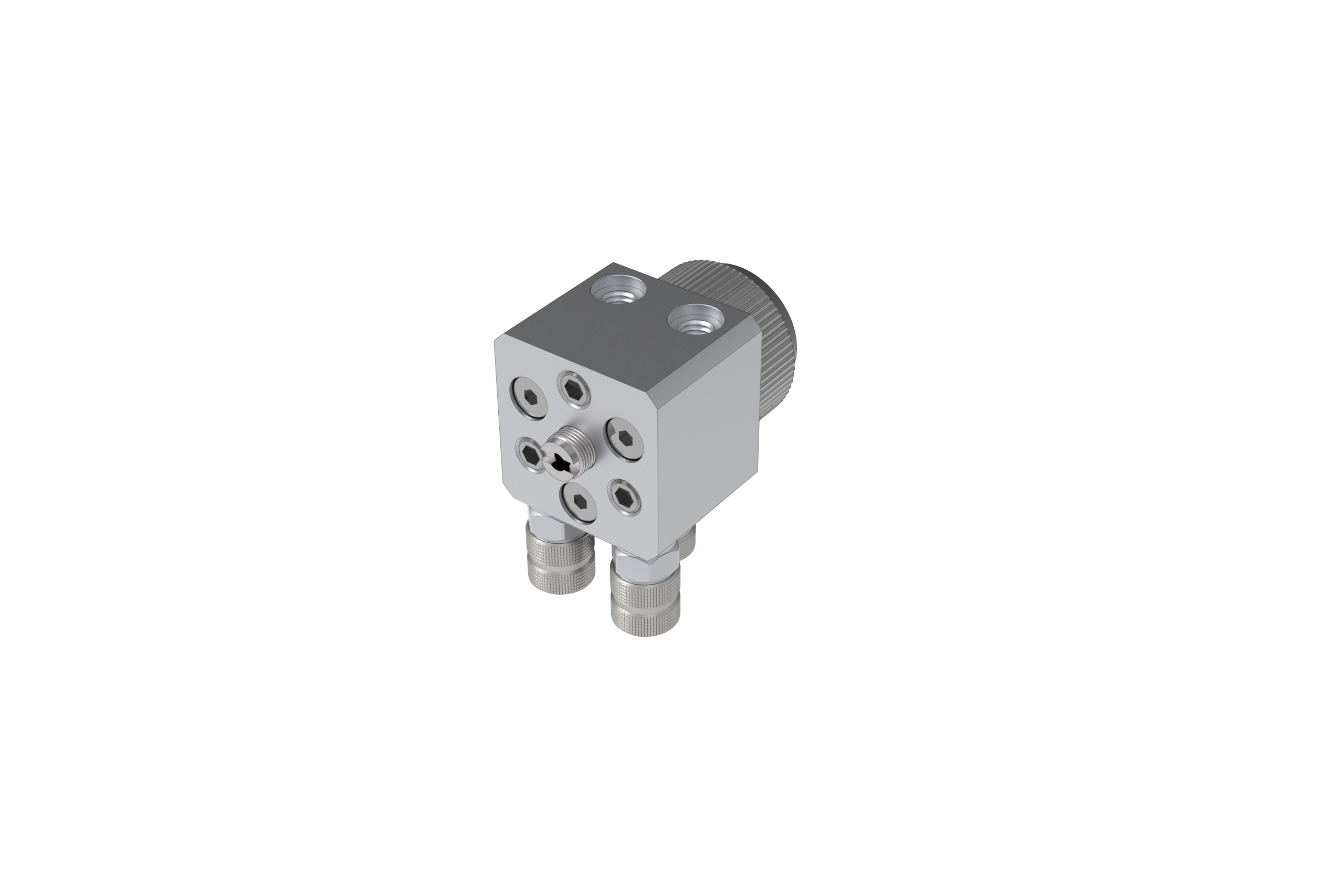

Efficient integration and multi-valve setups: The compact design allows for the installation of multiple valves in confined spaces, such as on multi-axis systems or mounting plates. Its robust construction and maintenance-friendly design make the SMS-04 a reliable choice for series production with high demands on precision, repeatability, and operational uptime.

- regulation of valve needle stroke allows an esay setting of the medium quantity

- large selection of different valve nozzles and air caps (flat and round) for an individual adaptation of the spraying image

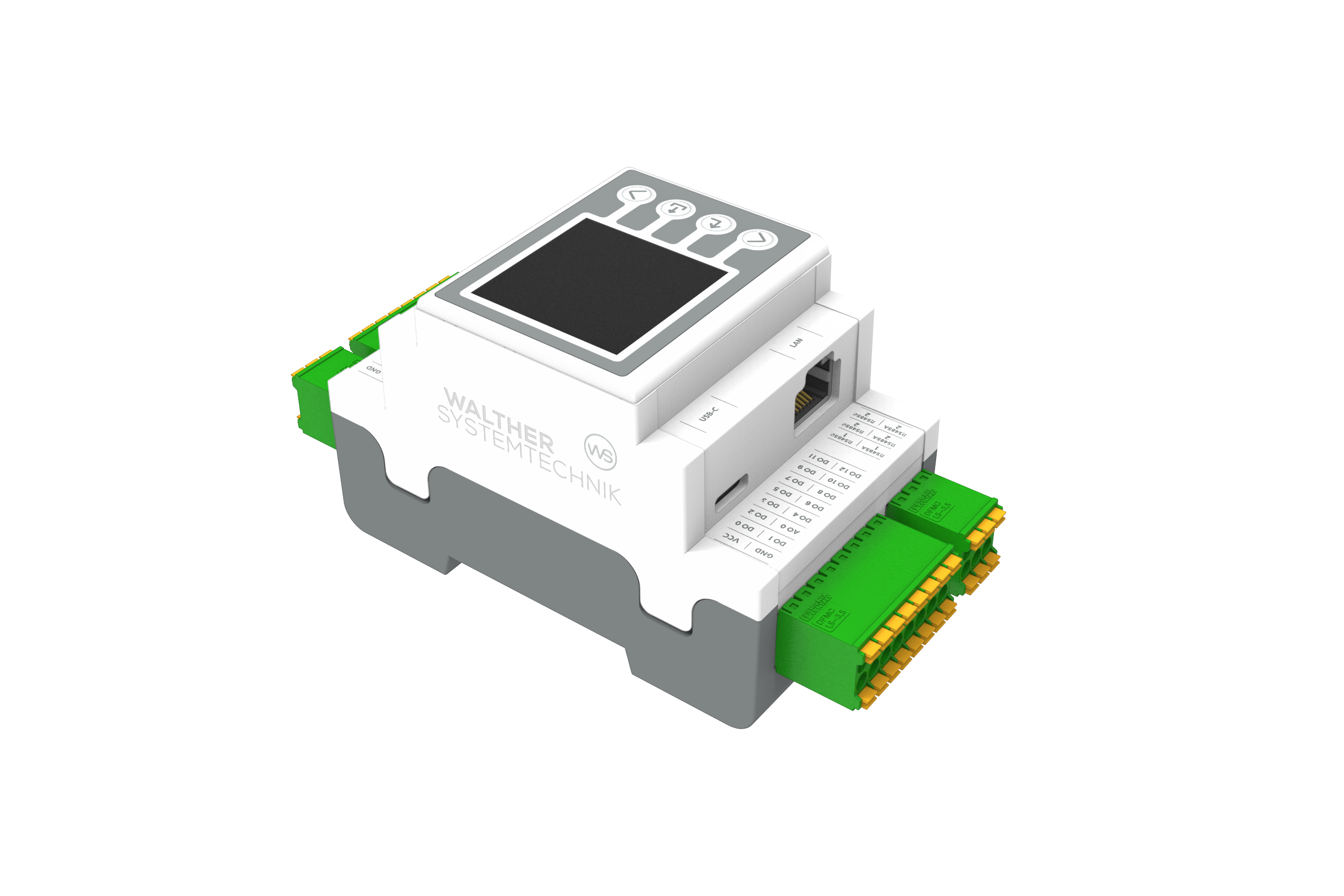

- optional sensor available for monitoring the valve needle stroke

- for complex spraying tasks, we offer a variety of adapted nozzle extensions optionally

- optional heating plate available for tempering the valve body

- process pressure: max.30 [bar]

- control air pressure: 3 to 6 [bar]

- atomizer air pressure: 0,5 to 6 [bar]

- process connection (medium): G1/4" incl. hose screw joint 6/4

- process connection (air): hose scre joint 6/4

- dimensions (l x w x h): 39 (42) x 25 x 25 [mm]

- weight: 0,14 [kg]

- nozzle & needle: optionally hardened (kolsterised)