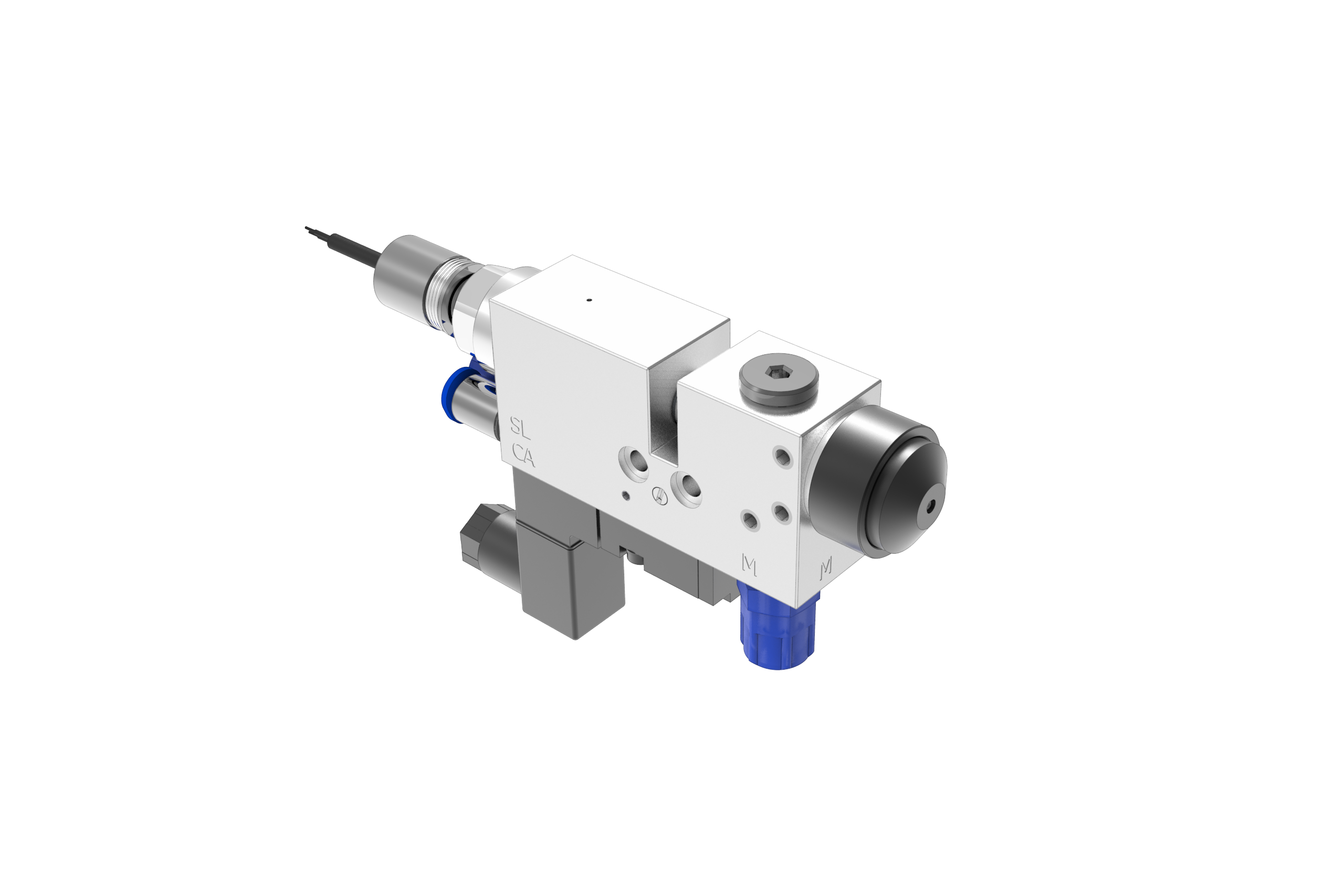

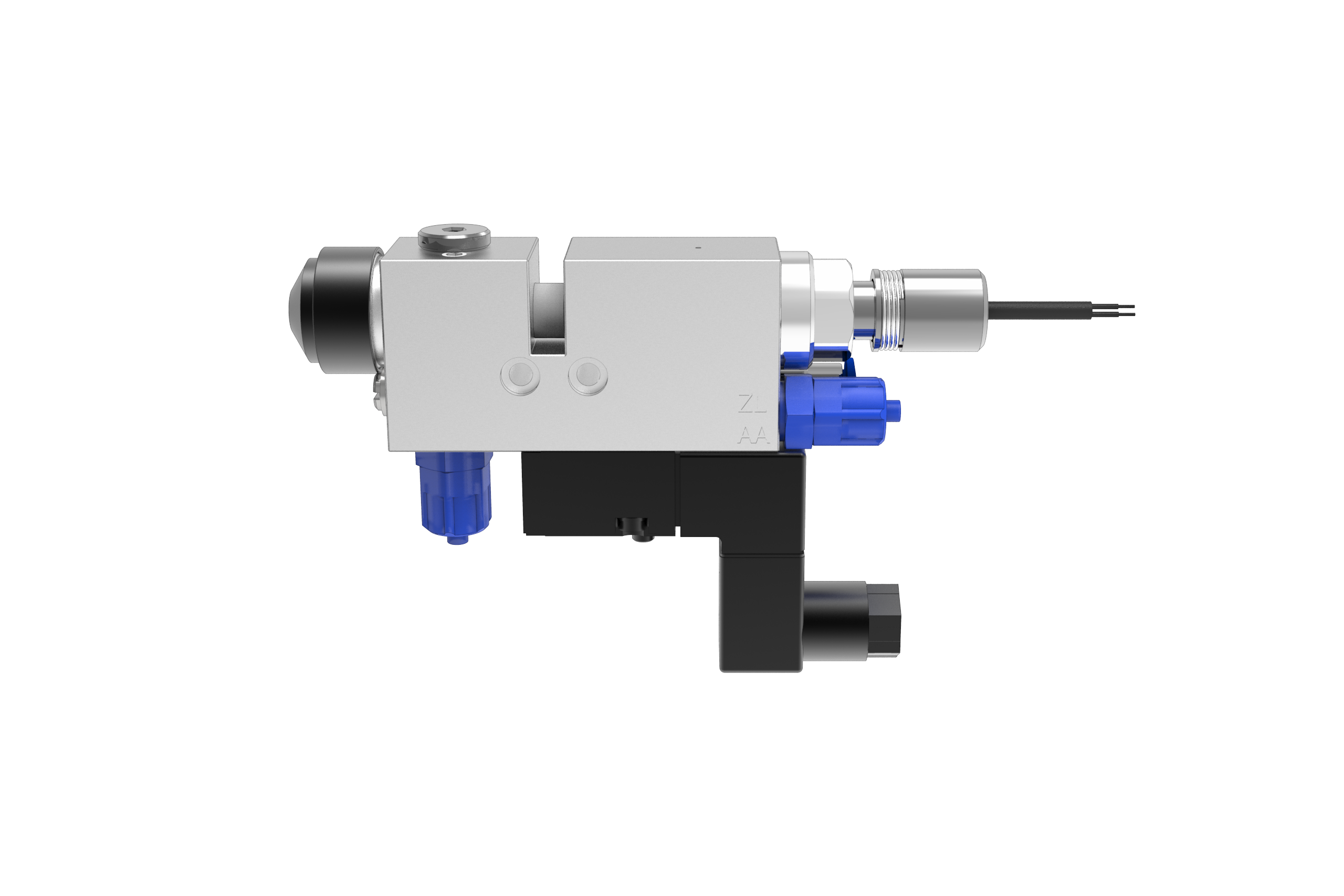

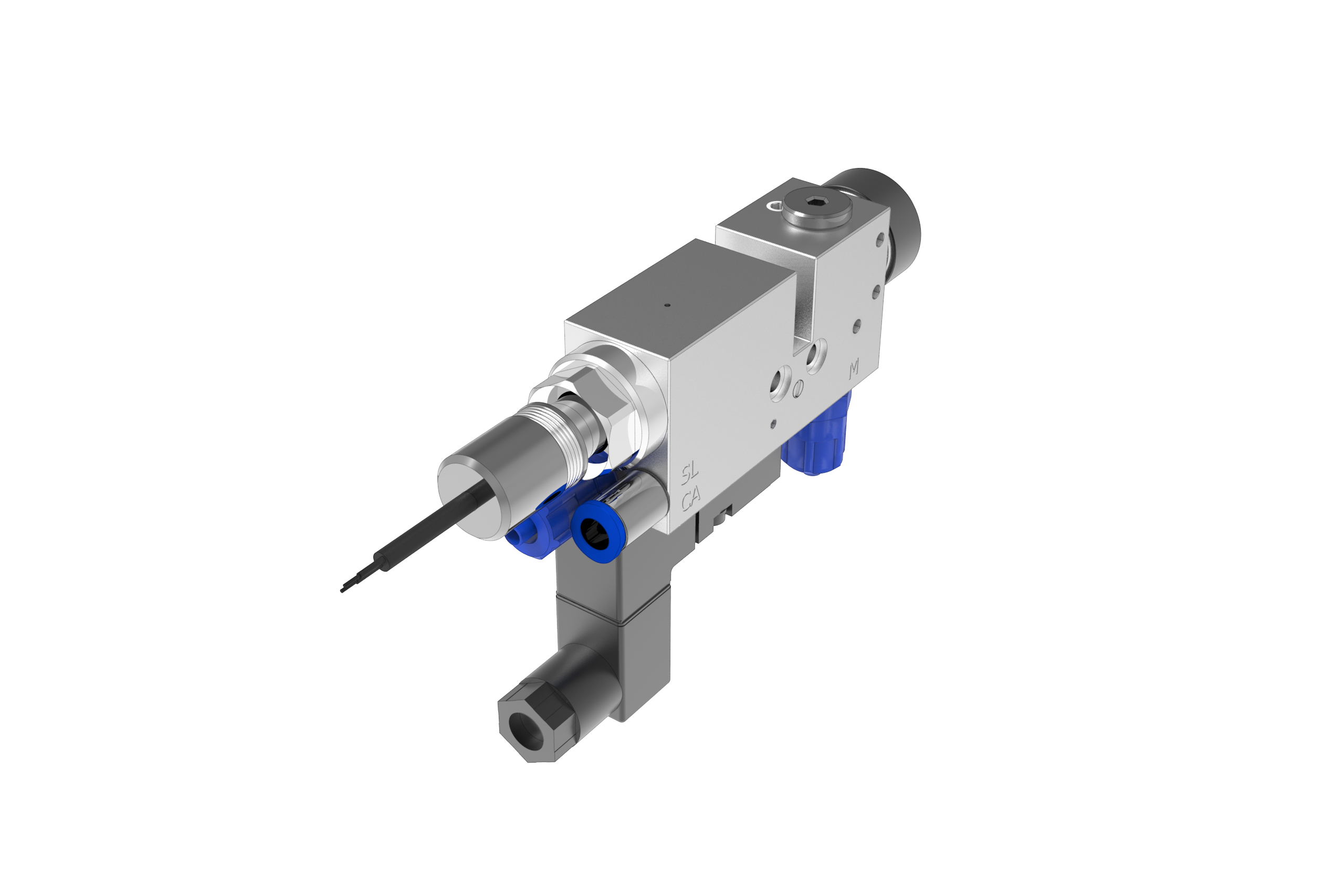

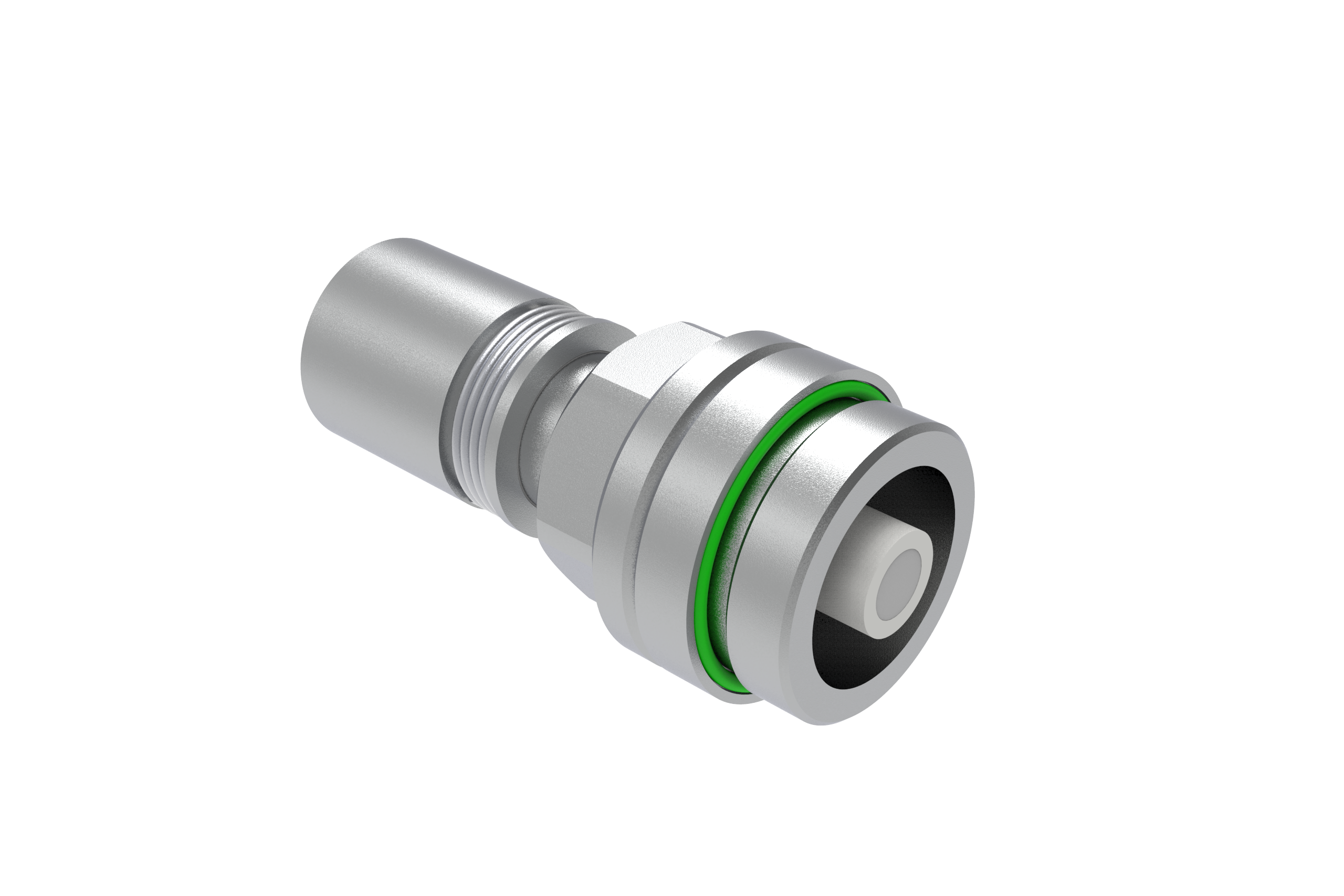

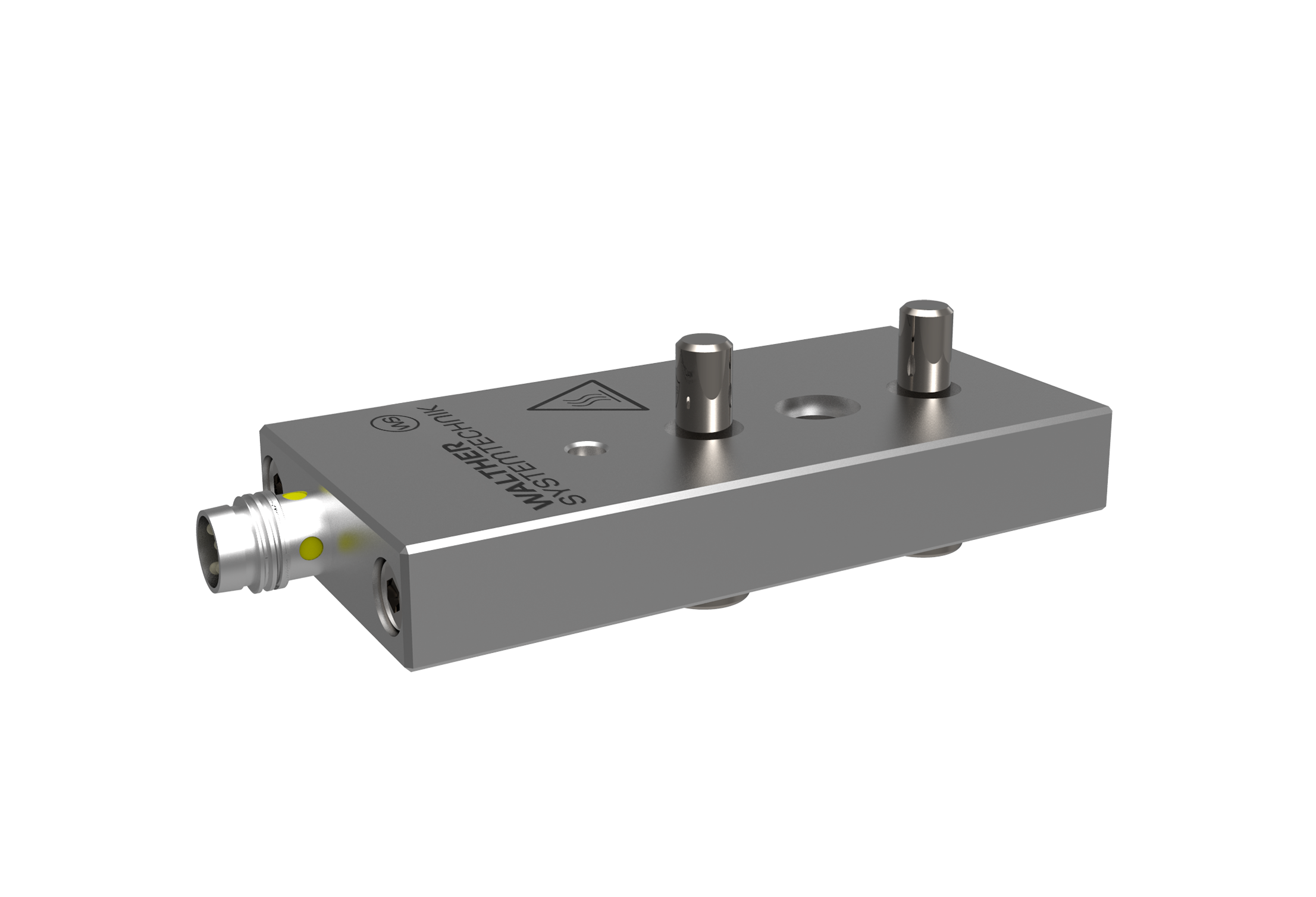

Spray Valve SMS-02

The SMS-02 is an electropneumatically actuated spray valve designed for the precise and repeatable application of low- to medium-viscosity media. It is suitable for both intermittent and continuous use across a wide range of industrial applications – for example, for the pinpoint or surface application of oils, greases, release agents, paints, and other sprayable substances. Even special formulations with appropriate viscosity can be applied reliably with the right parameter settings.

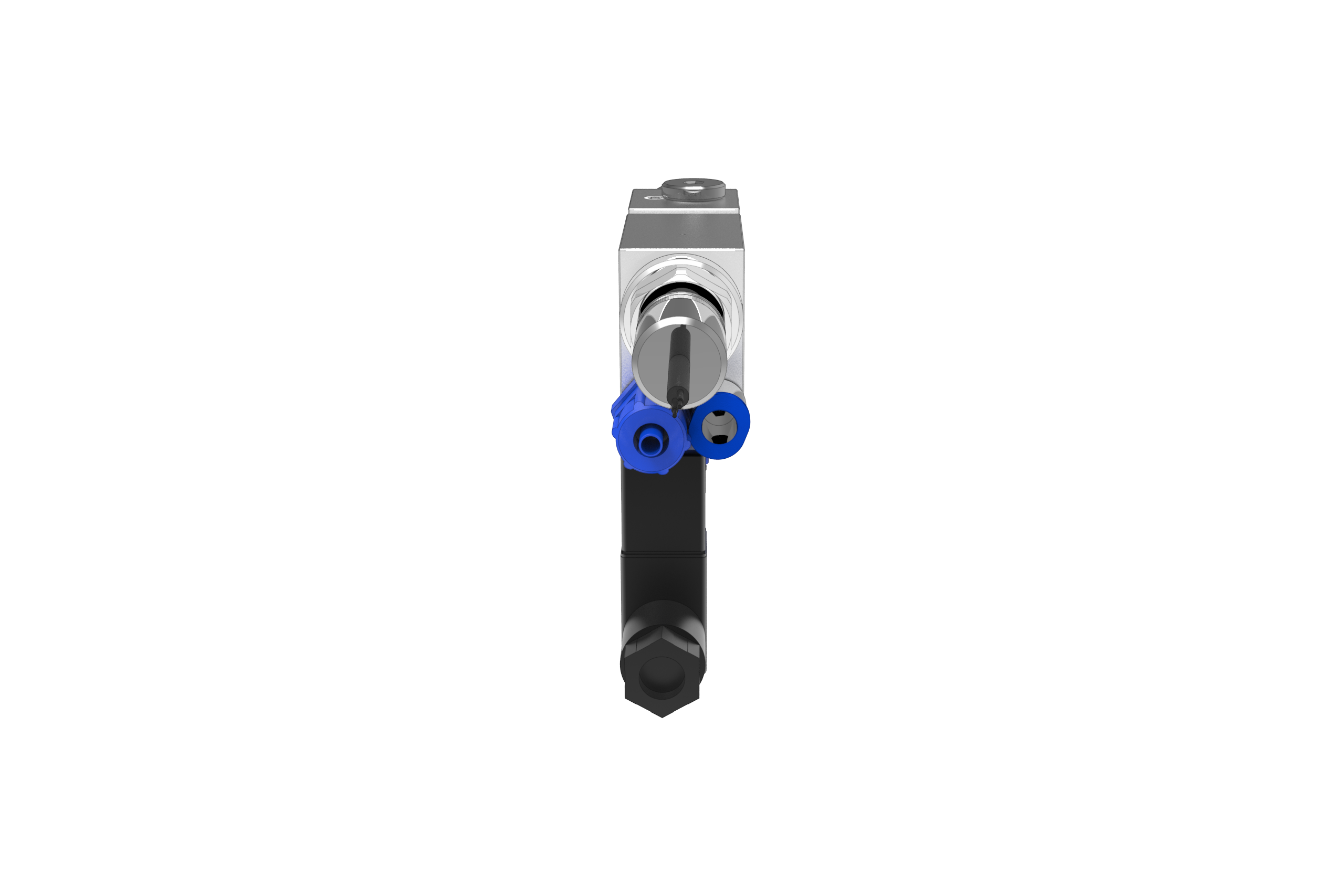

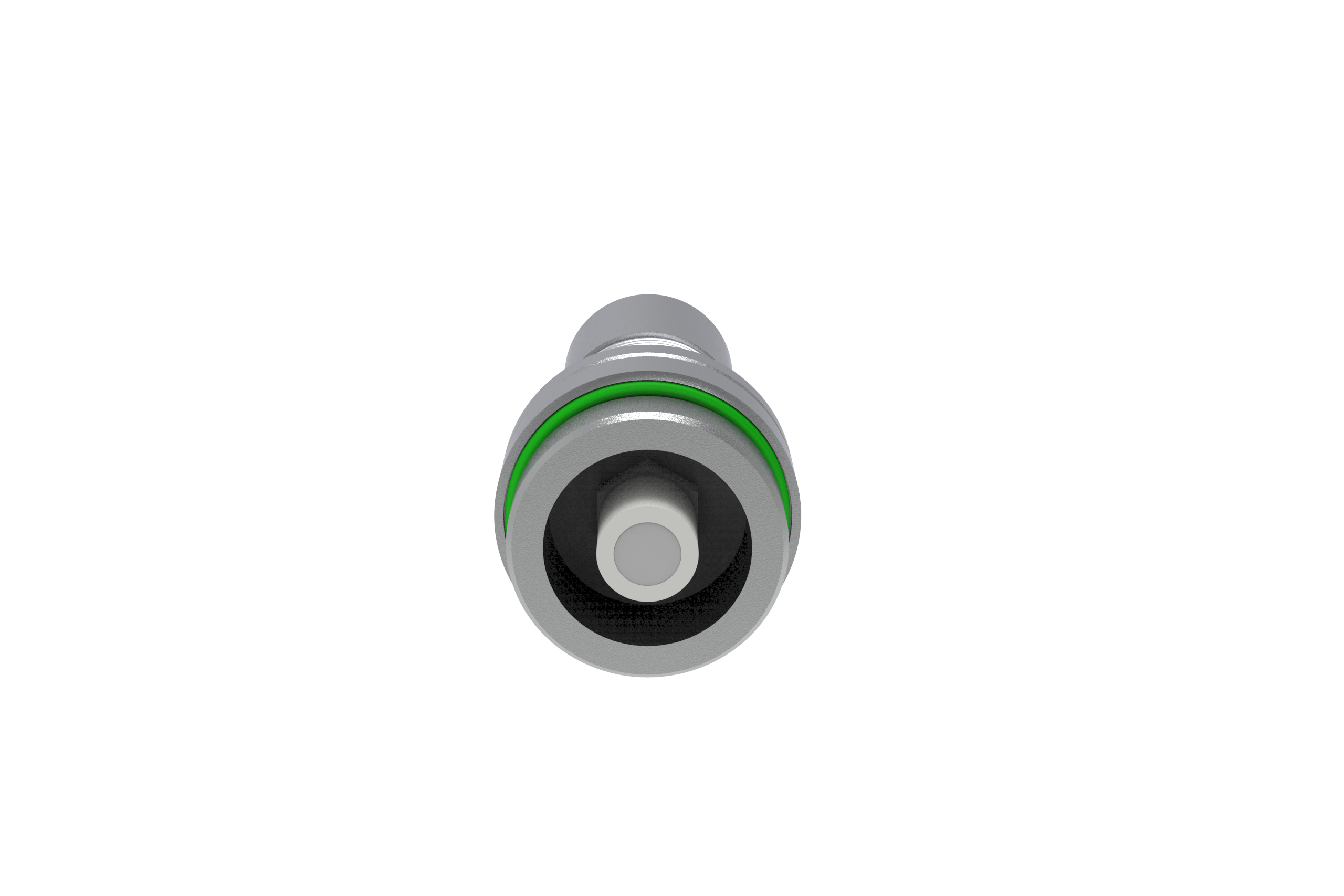

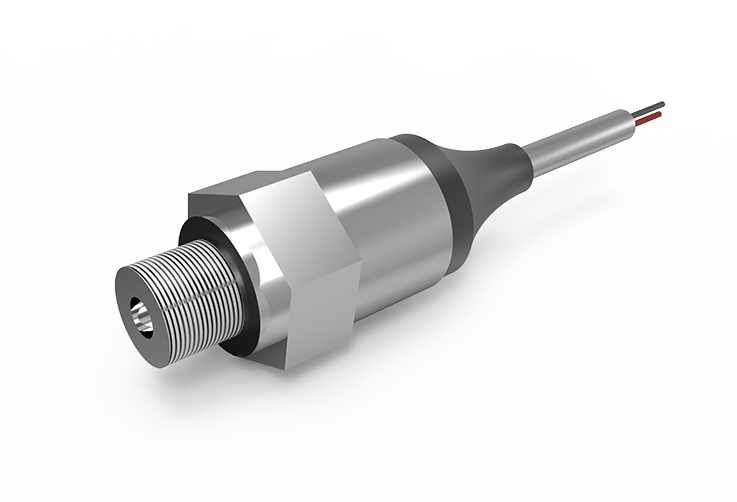

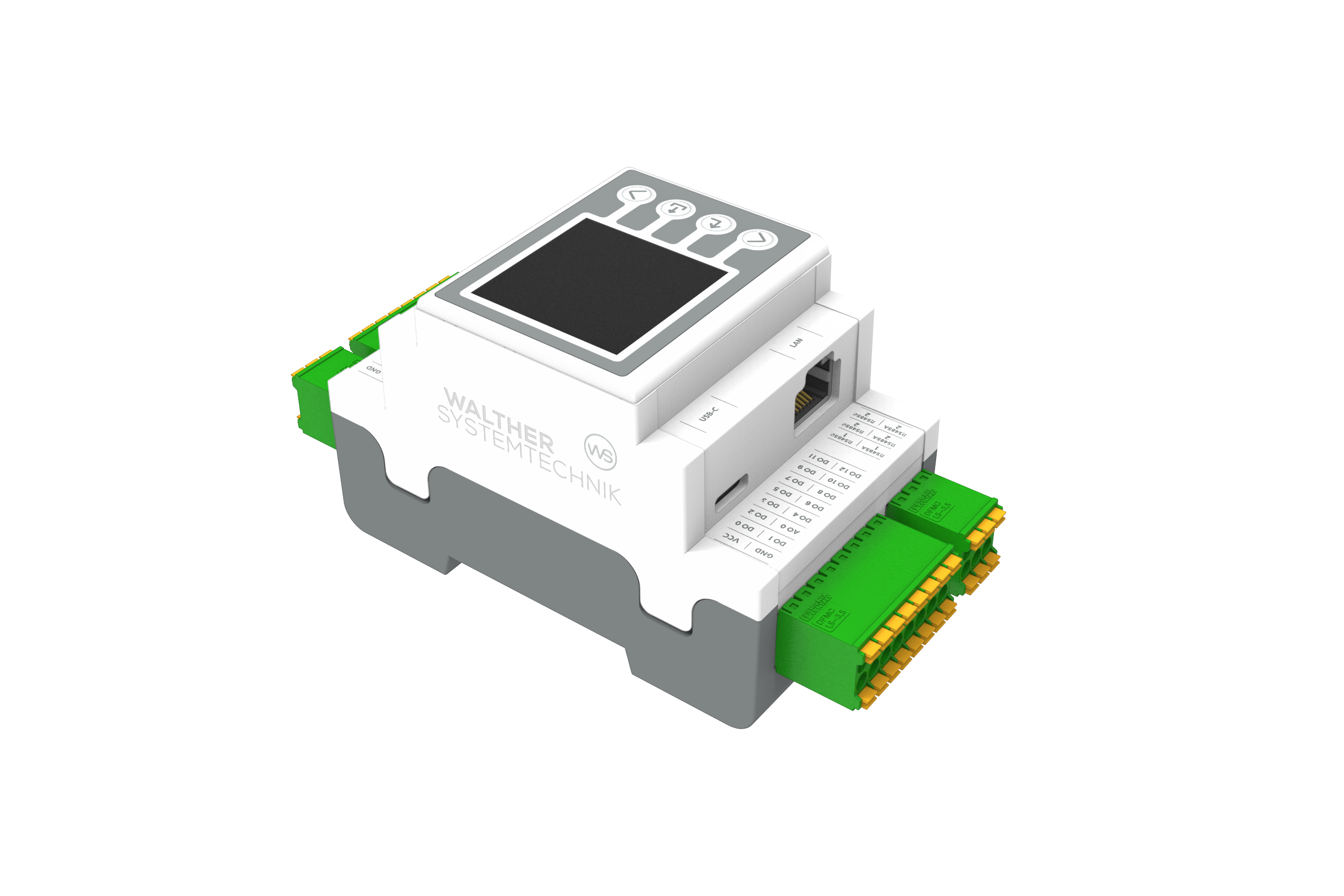

Spray process control: The needle movement of the SMS-02 is triggered by a directly mounted electric 5/2-way solenoid valve. Extremely short control air paths enable fast and precisely repeatable opening and closing movements of the needle. The material flow can be adjusted to the application using individually selectable nozzle sizes and by regulating the atomizing air pressure. The post-spray air duration is controlled via an integrated air control piston inside the valve, which is an effective measure to prevent droplet formation, overspray or unwanted edge zones in the spray pattern.

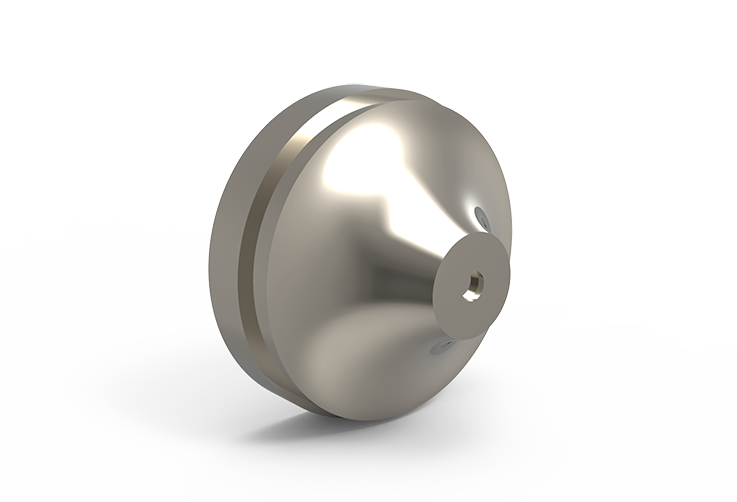

Customizable spray geometries: round or flat jet: Depending on the air cap used, the SMS-02 can produce either a round or a flat spray pattern. This allows for the targeted and uniform coating of various surfaces, edges or geometries, with reduced material consumption and consistent layer quality.

Robust design for industrial requirements: The SMS-02 is designed for continuous operation under demanding production conditions. The valve housing is compact and robust, while all media-contacting components are made from durable materials and are optionally available in hardened versions. The maintenance-friendly design allows for quick cleaning and easy replacement of wear parts. Control air, atomizing air, and material are supplied via three clearly separated hose connections. Combined with the compact design of the valve, this enables space-efficient and organised integration, even in multiple configurations on traverses, axis systems or mounting plates.

- no additional pneumatic valve required for controlling the atomizer air

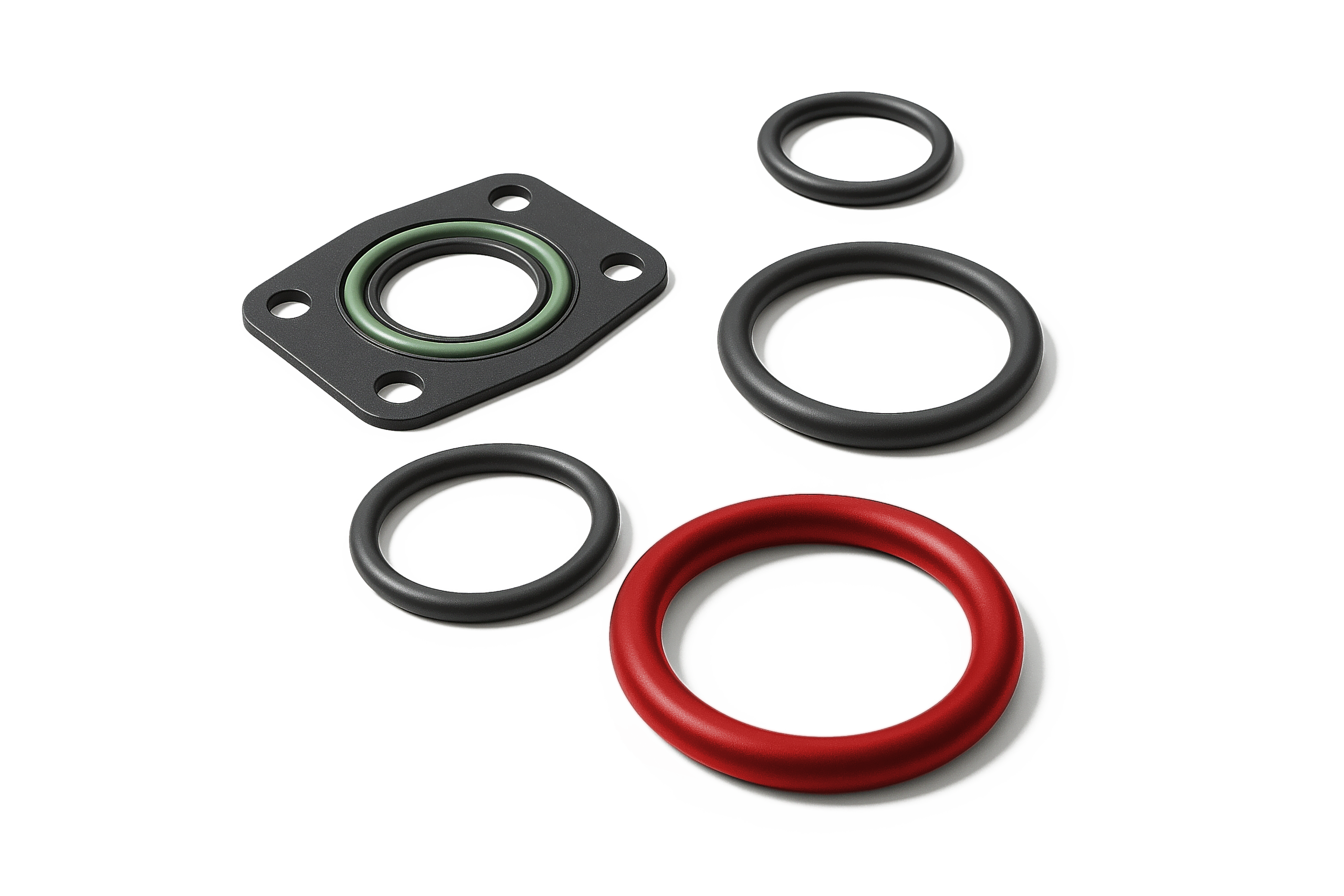

- different nozzles and air cap combinations for a perfect adaptation to the desired spraying image

- optional sensor available for monitoring the valve needle stroke

- for complex spraying tasks, we offer a variety of adapted nozzle extensions optionally

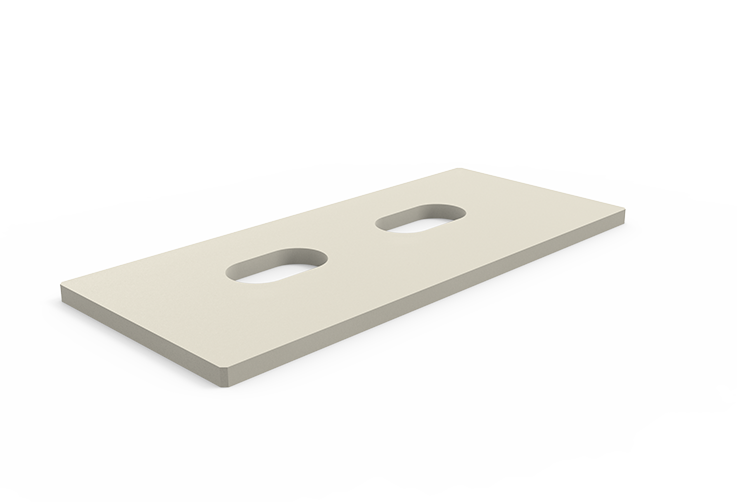

- optional heating plate available for tempering the valve body

- process pressure: max. 35 [bar]

- control air pressure: min. 5 to 6 [bar]

- atomizer air pressure: 0,5 to 6 [bar]

- process connection (medium): G1/4" incl. hose screw joint 6/4

- process connection (air): hose screw joint 6/4

- dimensions (l x w x h): 132 x 81 x 22 [mm] (incl. magnetic valve)

- weight: 0,525 [kg]

- nozzle & needle: optionally hardened (kolsterised)