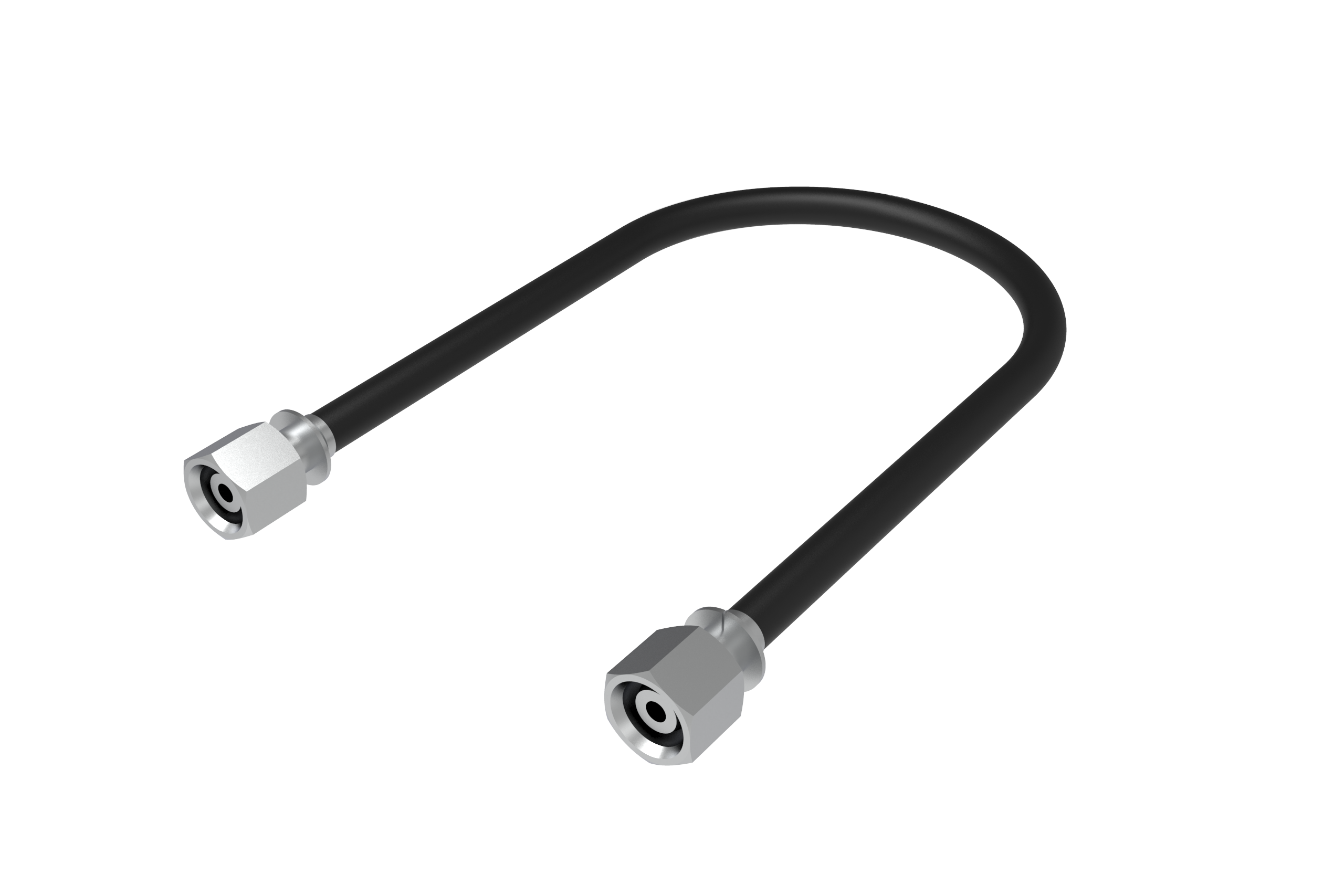

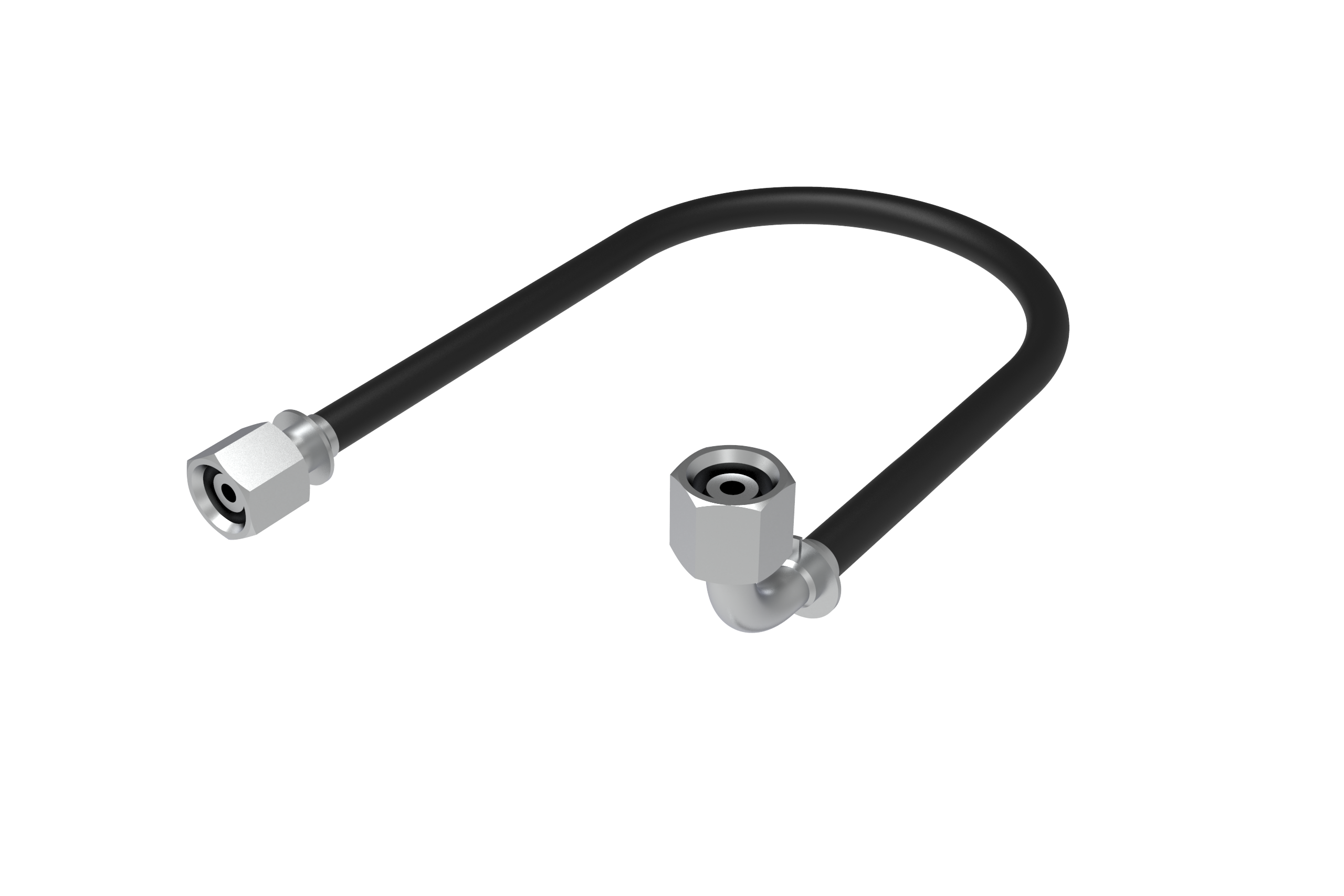

High-Pressure Hose WMS-HDS

-

Price on request

Please send your enquiry for this item, including quantity and order code, via form or email.

The rigid material hose WMS-HDS is the ideal solution for dosing processes with demanding requirements in terms of temperature resistance, pressure strength and chemical compatibility. Featuring a PTFE inner hose with stainless steel braid, it is designed for industrial applications under extreme conditions and delivers reliable performance across a temperature range from –60 °C to +250 °C.

Designed for extreme operating conditions: The WMS-HDS is specifically engineered for applications involving frequent temperature fluctuations, aggressive media or high operating pressures. Permissible pressure limits are graded according to the inner diameter, enabling safe use in a wide range of high-pressure applications.

PTFE inner layer for optimised media flow:

- Excellent chemical resistance to a wide variety of aggressive media

- Smooth inner surface to minimise pressure loss and deposits

- Long service life under continuous thermal load

Flexible configuration and connection options: The WMS-HDS is delivered ready for installation and can be seamlessly integrated into existing systems. With customisable connection types, freely selectable hose lengths and inner diameters, it offers maximum flexibility for your specific application.

- Design: rigid, with stainless steel braid for increased pressure resistance

- Bending radius: limited, not suitable for confined installation spaces

- Connections: flexibly configurable depending on the application

- Configuration: delivered ready to install in defined length and nominal diameter

- Application: high-pressure use with diameter-specific pressure ratings

- Temperature range: –60 °C to +250 °C

- Operating pressure (at 20 °C) and bending radius:

- DN 06: 224 bar | bending radius 80 mm

- DN 08: 207 bar | bending radius 102 mm

- DN 10: 195 bar | bending radius 135 mm

- DN 12: 161 bar | bending radius 180 mm

- DN 16: 126 bar | bending radius 210 mm

- Media-contacting material: PTFE (Teflon)