Filter system diagnose-capable WFSD

Smart filtration for more reliable production: The diagnostic filter system WFSD by Walther Systemtechnik is designed for applications where consistently high media purity and stable application processes are essential. It reliably filters the media flow, protects downstream components in the fluid system from contamination, and makes a significant contribution to the repeatability of industrial production processes.

Unlike conventional filter systems, the WFSD features diagnostic electronics that continuously monitor key process parameters: inlet and outlet pressure, media temperature, degree of contamination, and the operating time of the filter cartridge. The current system status is displayed on the integrated screen. Operation and configuration are conveniently performed via tactile keys directly on the device – for example, to set alarm thresholds, select display units or enable password protection.

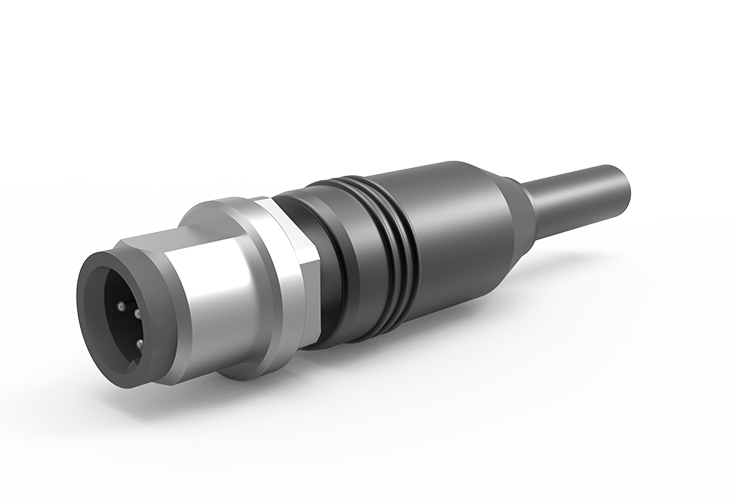

Full control instead of unplanned downtime: To support integration into automated environments, the system includes an RS485 interface with MODBUS RTU protocol. This enables external readout and configuration of all operating data and device settings. Four digital alarm outputs (24 VDC) can be assigned to specific process events – for instance, to signal limit value violations for pressure, temperature or contamination. The combination of local display, external communication, and customizable alarm signaling lays the foundation for predictive maintenance: the ideal time for cartridge replacement becomes plannable, and downtime can be minimized.

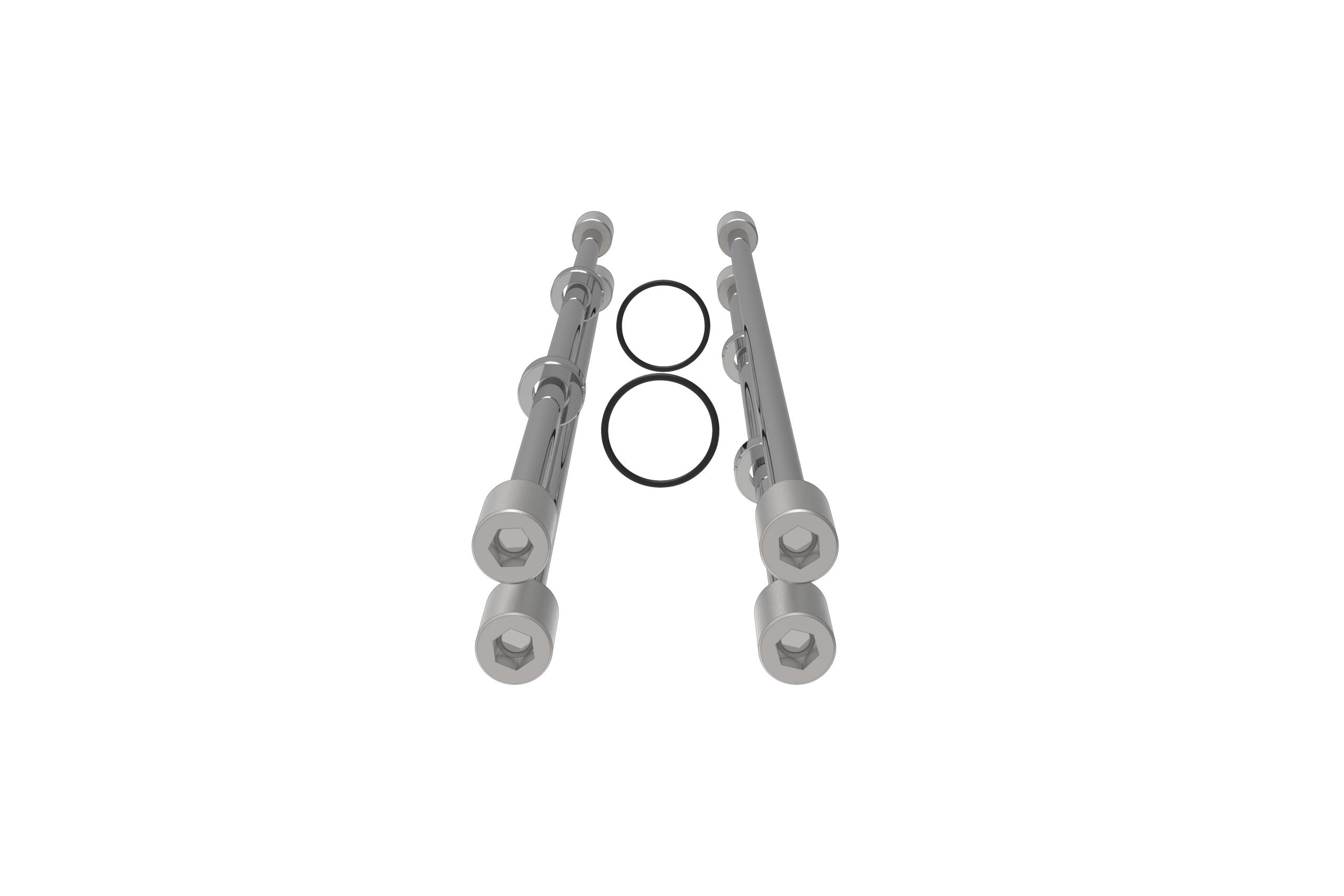

Tool-free maintenance: The WFSD is available with filter cartridges in three filtration grades (150 µm, 300 µm, 500 µm). The cartridges can be replaced without tools: open the cap, insert the cartridge, close – done. Venting after cartridge replacement is quick and secure via the integrated vent screw. Thanks to its robust design, the filter unit is also suitable for applications with high differential pressures and can be used flexibly with various non-aggressive liquids such as lubricants or process oils.

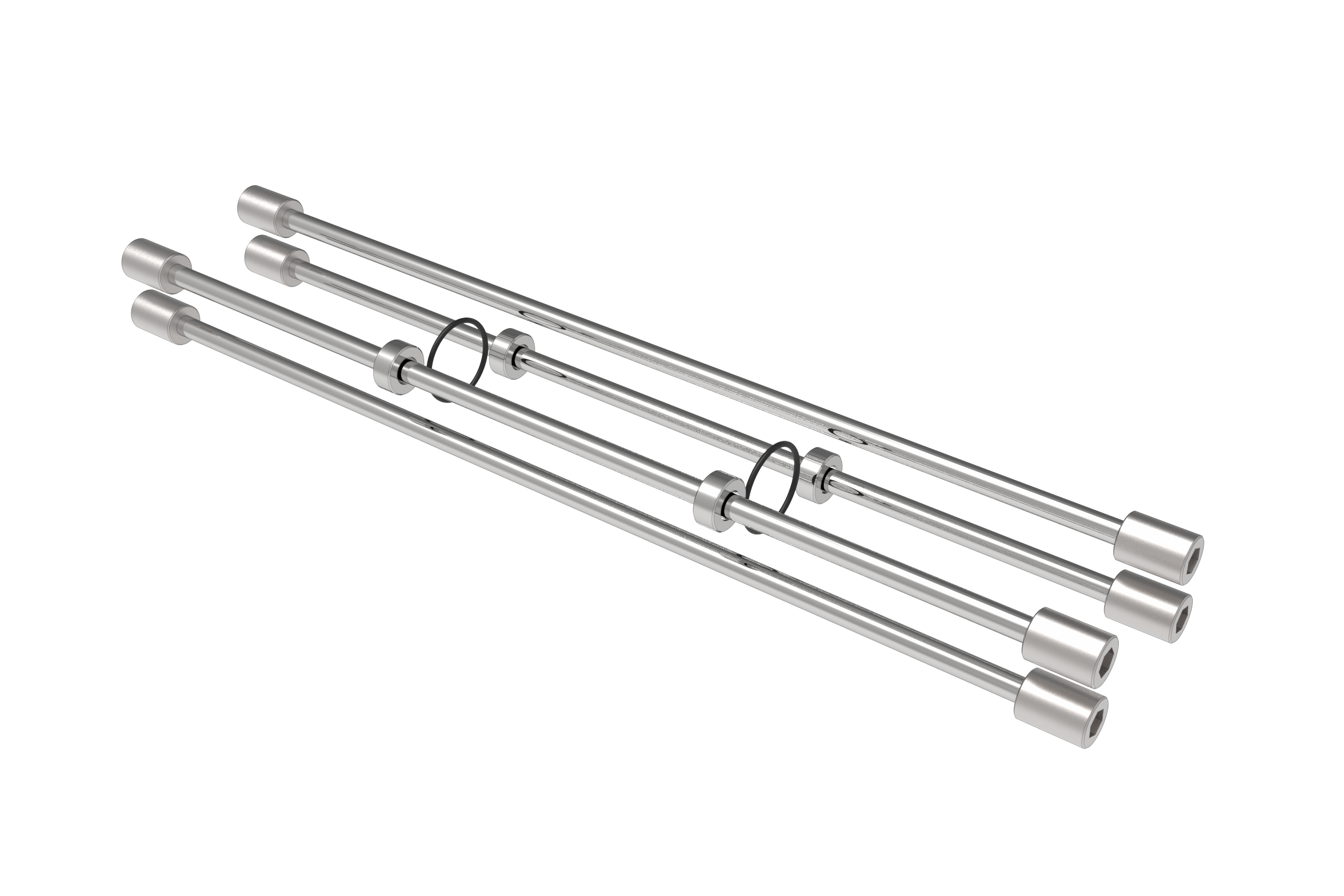

Compact and compatible: As part of the Walther MODULAR system, the WFSD filter can be quickly and securely connected to other functional modules using a standardized module connector set. Its compact dimensions (153 × 79 × 91 mm) and G½" ports ensure seamless integration into new or existing dispensing and application systems.

- continuous monitoring of filter contamination and of process values inlet/outlet pressure, runtime filter cartridge, pump frequency and medium temperature

- freely configurable alarm outlets for displaying limit value breaches of selected process values

- integrated display for parametering and status display

- field-bus connection for access to all available process and status values

- device from WALTHER MODULAR series, therefore smaller installation area, easy mounting and simplified maintenance

- operating pressure: max. 200 [bar]

- dimensions (l x w x h): 153 x 79 x 91 [mm]

- weight: 1,2 [kg] # Walther-Module length: 3 [TE]

- connection: G1/2" and flange Walther-Modular

- supply voltage: 24 [VDC]