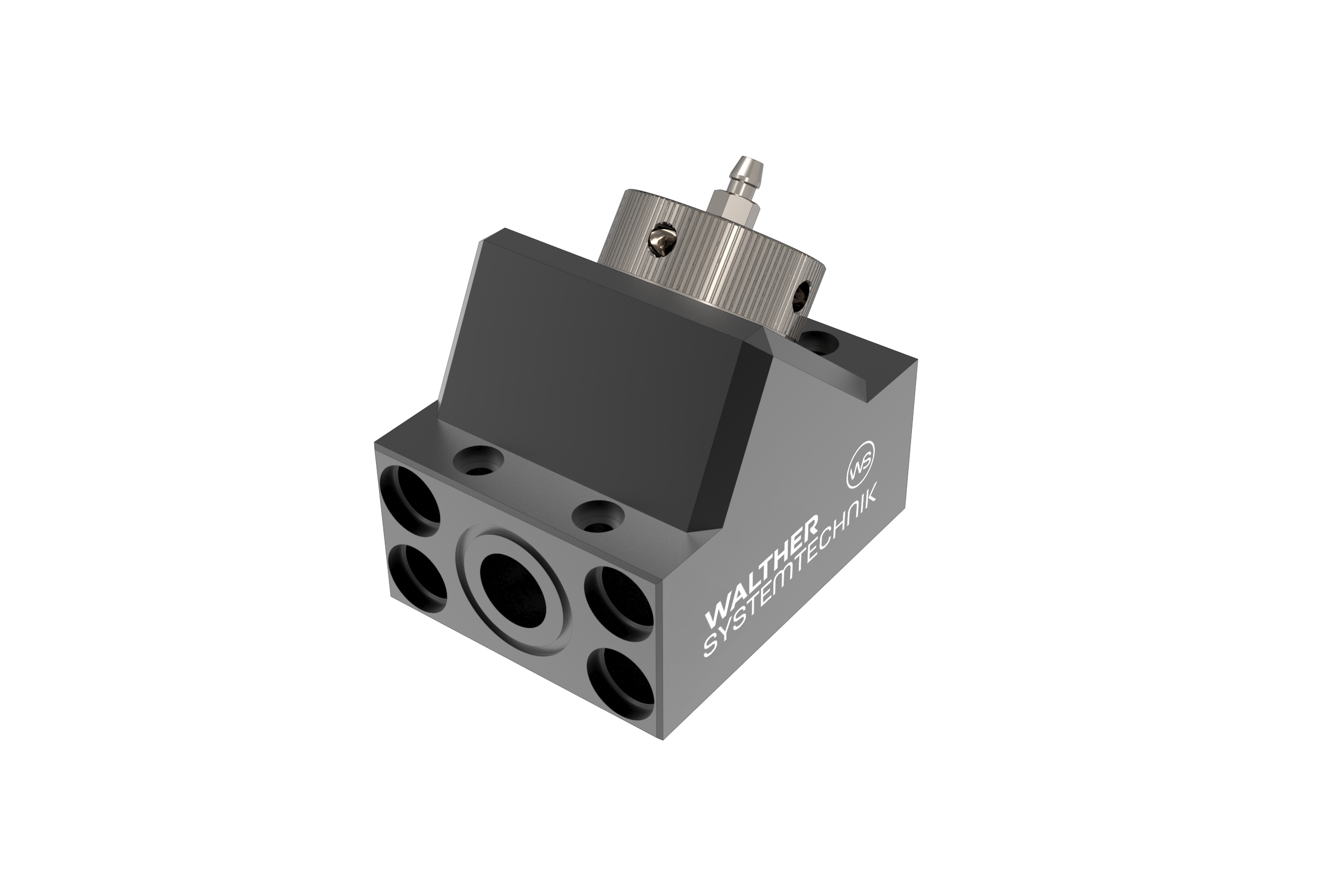

Filter system WFS

Compact, robust, and maintenance-friendly: The Walther WFS Filter System is designed for the reliable filtration of greases, oils and other non-aggressive media in demanding industrial production environments. With a maximum operating pressure of 200 bar, a temperature range of +4 °C to +50 °C, and a housing made of anodized aluminum, the system is ideal for use under high mechanical and process loads.

The WFS retains contaminants such as particles, deposits, and cured medium residues. This protects downstream components in fluid systems, such as dosing valves, from damage and helps ensure stable application conditions, which are essential for reliable and defect-minimized production processes.

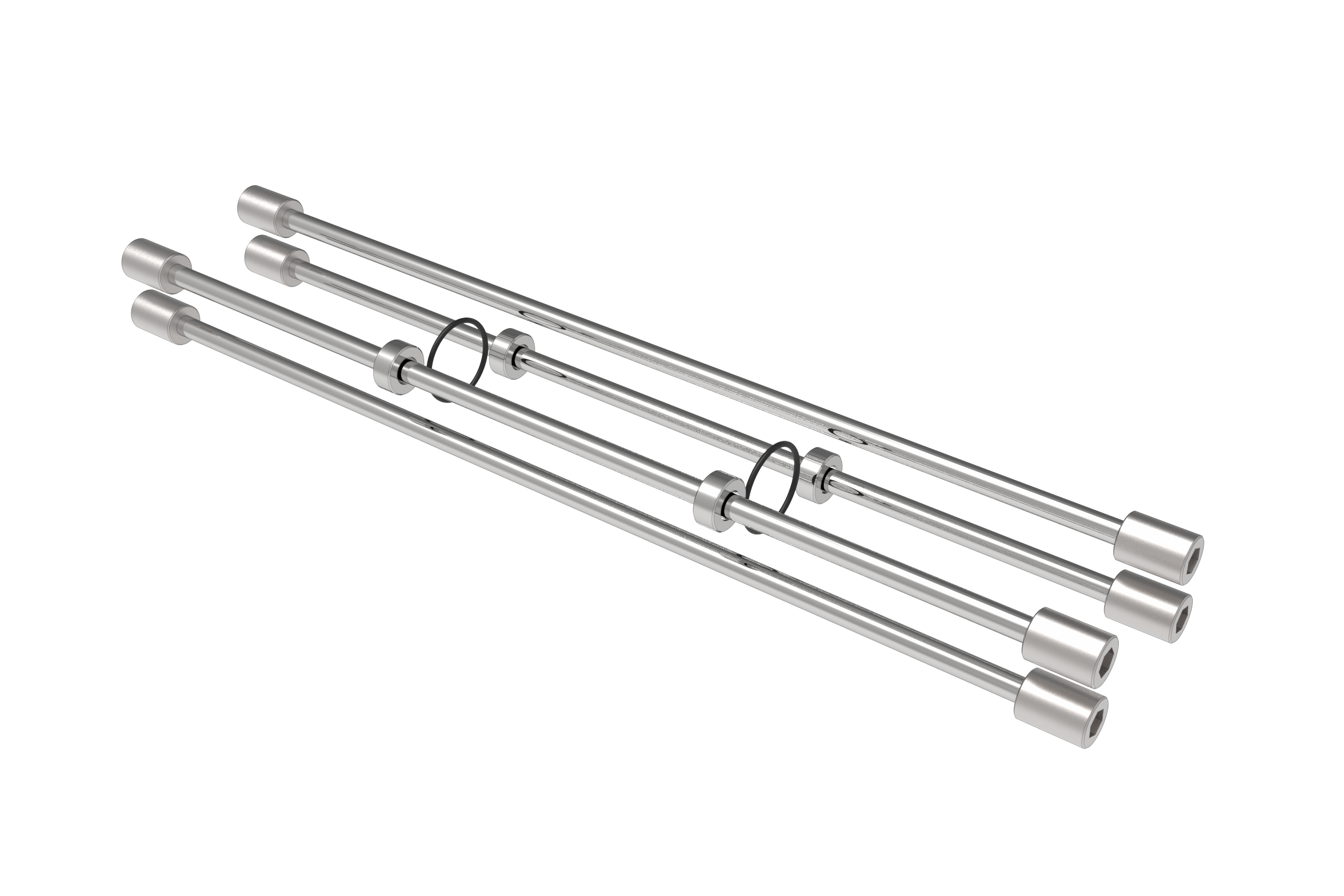

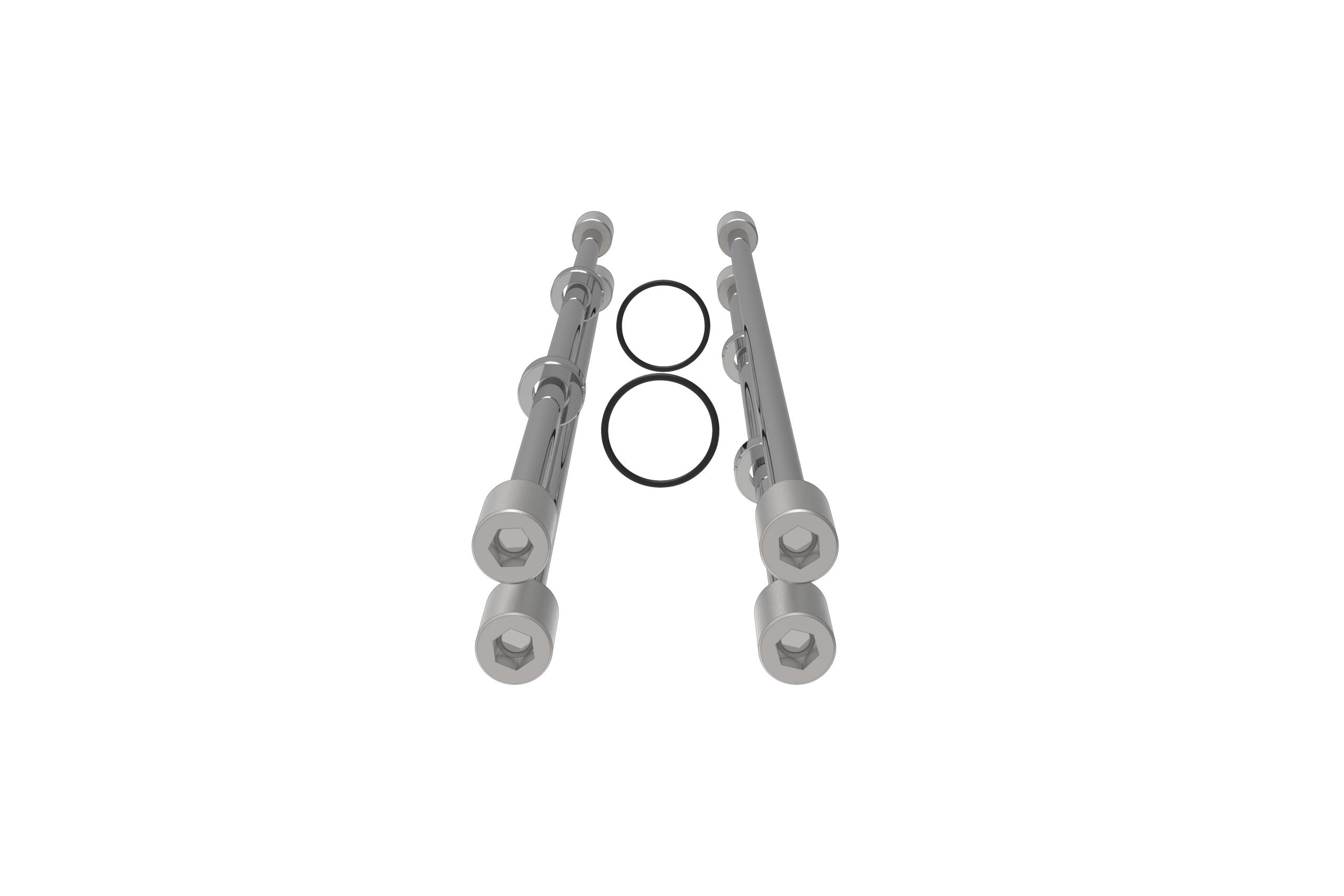

The filter cartridge is available in three filtration grades (150 µm, 300 µm, 500 µm) and can be replaced without tools: open the locking screw, insert the new cartridge, close – done. An integrated venting screw allows for safe and simple venting after cartridge replacement. Its robust cartridge design enables operation under high differential pressures, making the WFS suitable for a wide range of applications, even with various lubricant types.

The WFS Filter System is part of the Walther MODULAR System. Using a standardized module connector set, it can be quickly and securely combined with other functional modules. Its compact design (102 × 79 × 90 mm) and G½" ports enable flexible integration into both new and existing dosing and application systems.

- robust design of filter cartridge for large differential pressures

- integrated venting screw for venting the device after replacement of filter cartridge

- different mesh widths available for filter cartridges

- device from WALTHER MODULAR series, therefore smaller installation area, easy mounting and simplified maintenance

- operating pressure: max. 200 [bar]

- dimensions (l x w x h): 102 x 79 x 187 [mm]

- weight: 1,2 [kg]

- Walther-Module length: 2 [TE]

- connection: G1/2" and flange Walther-Modular