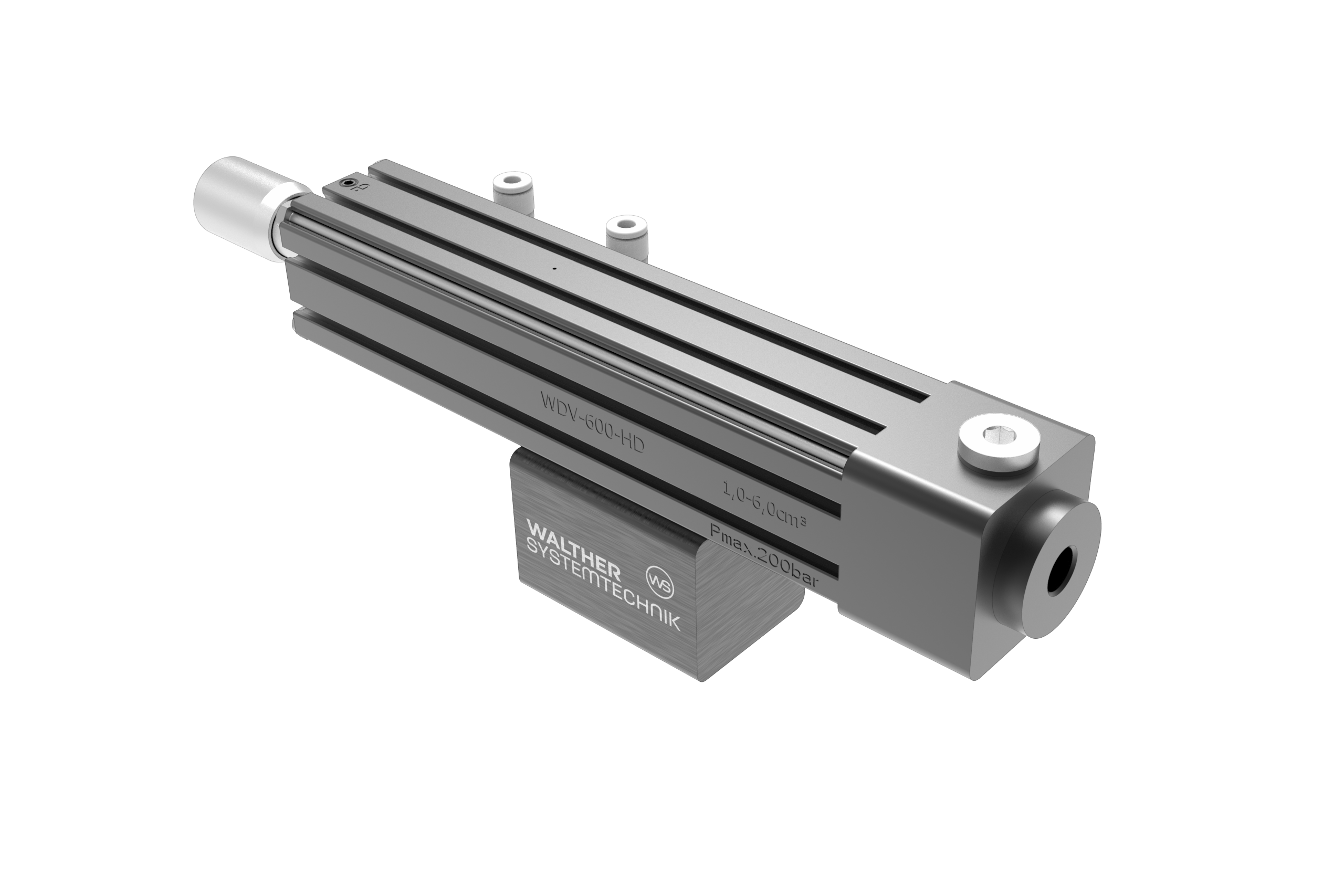

Chamber dosing valves for volumetric dispensing

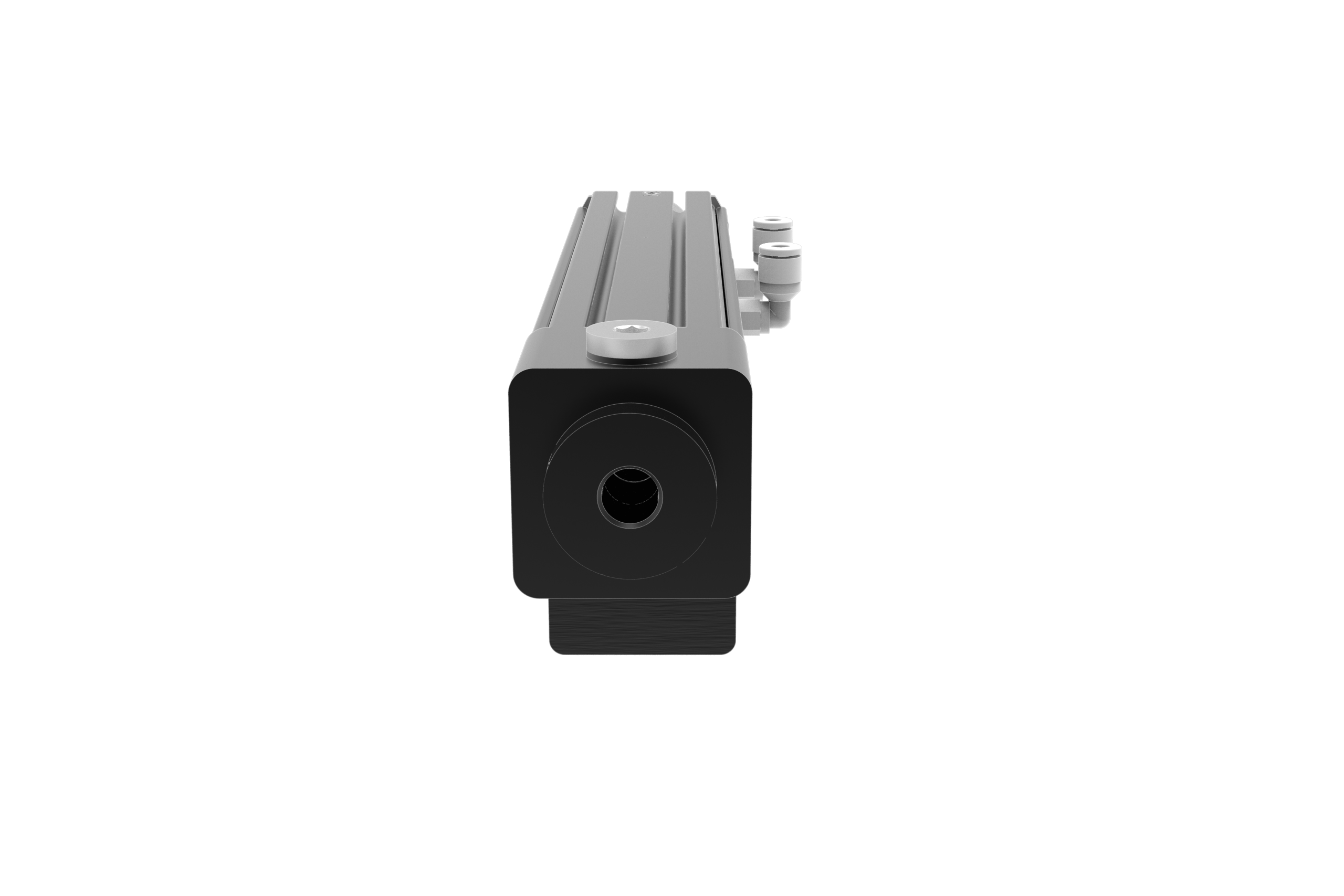

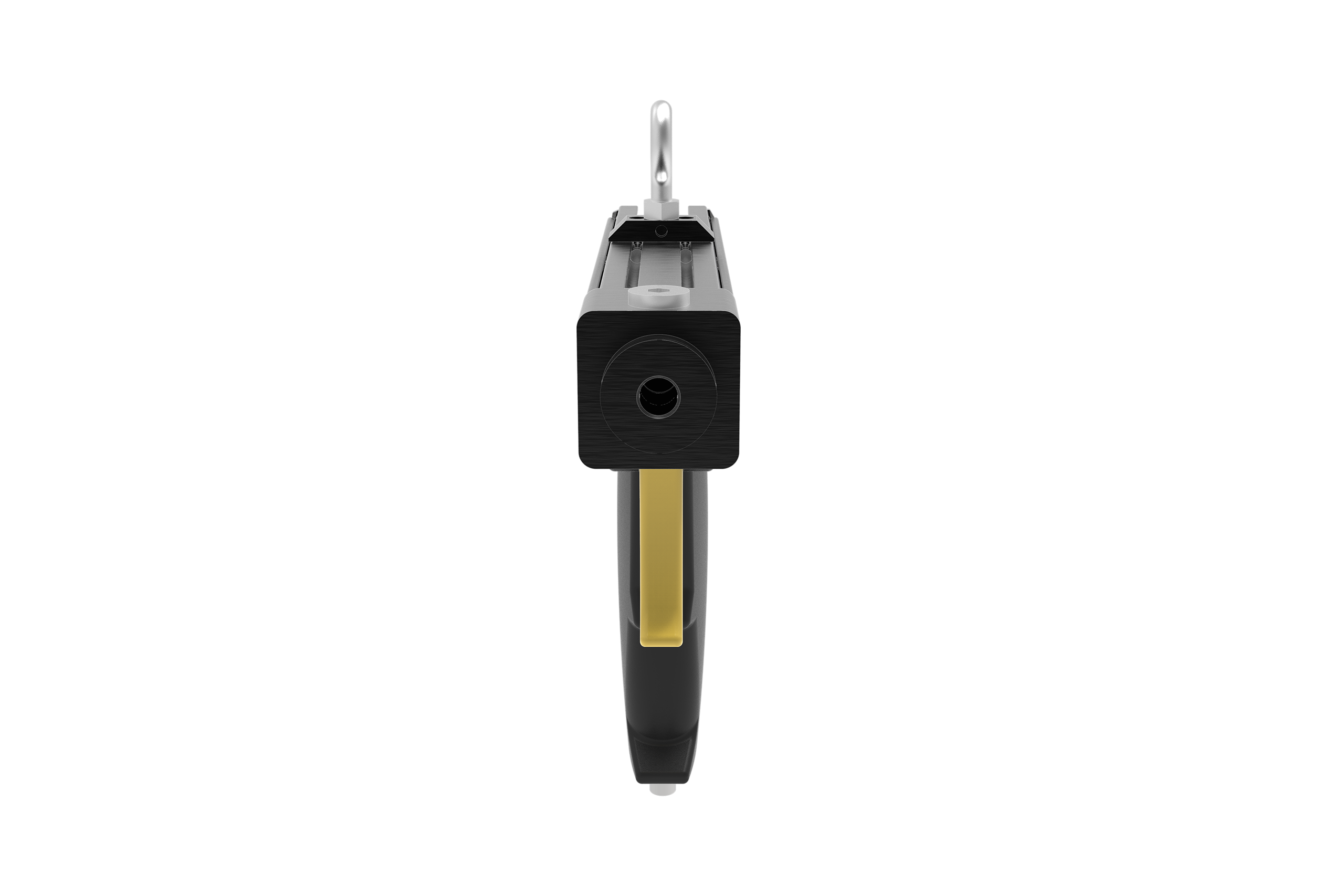

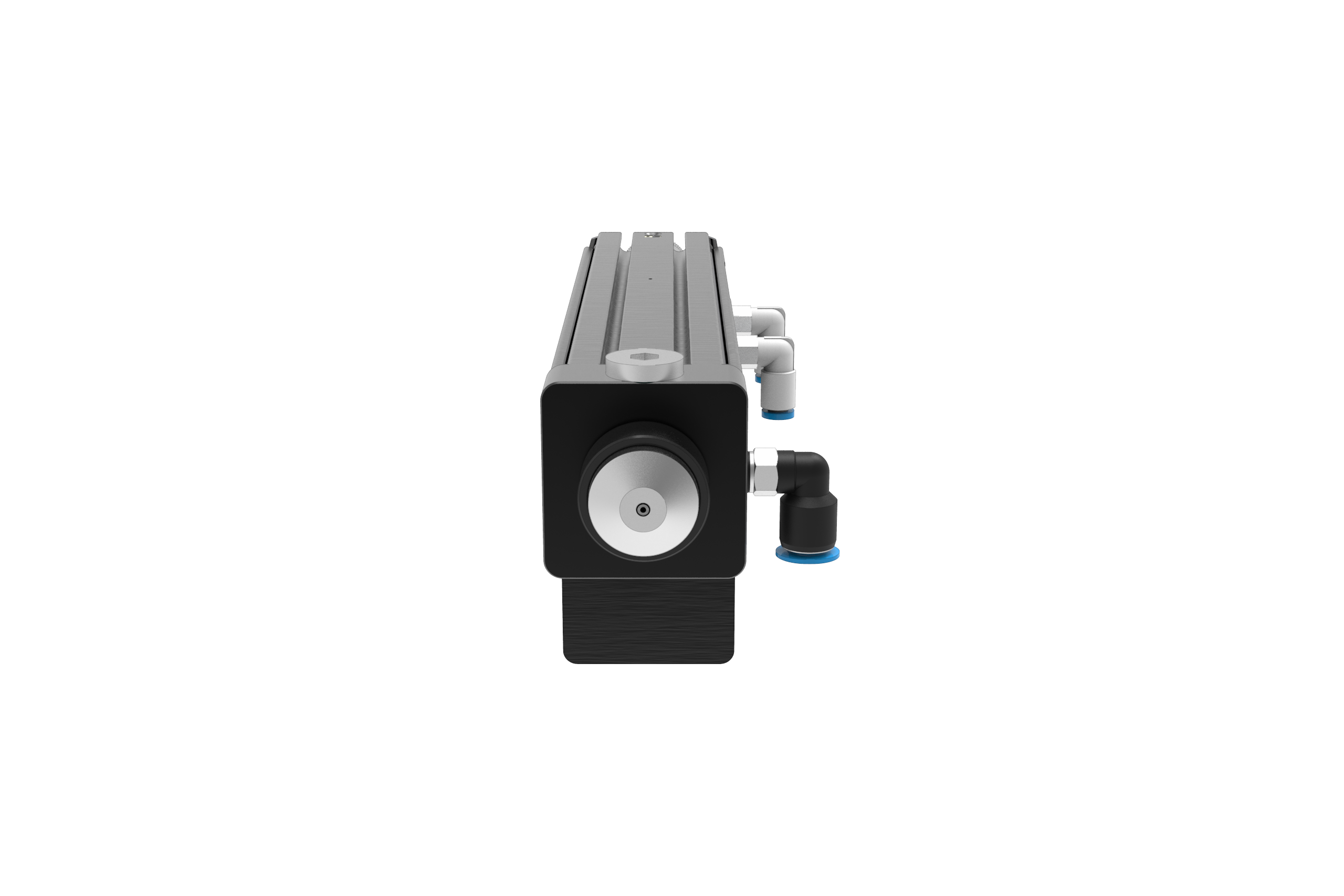

Chamber dosing valves enable the precise dispensing of defined volumes of viscous media – regardless of fluctuations in viscosity or temperature. The volumetric filling and emptying of a dosing chamber ensures high repeatability and process-reliable application.**

**For dot or bead applications, the valve and the component are typically positioned relative to each other along the Z-axis. The medium is cleanly detached from the valve nozzle by adhesion to the component surface. The result is a controlled application pattern without splashing or stringing – ideal for highly viscous, pasty, or stringy media such as lubricants, sealants, or single-component adhesives.

For surface coating applications, spray valves with chamber dosing are used. Here too, the discharge is based on a precisely defined chamber volume, combined with targeted atomization at the nozzle outlet. This allows uniform and reproducible layer thicknesses to be achieved on larger surfaces or complex geometries – for example, when applying corrosion protection agents, release agents, or functional coatings.

The valves can be permanently integrated into manufacturing fixtures and configured for contour-following dispensing processes or multi-point applications – including use in automated or semi-automated production environments.

Price on request

Price on request

Price on request