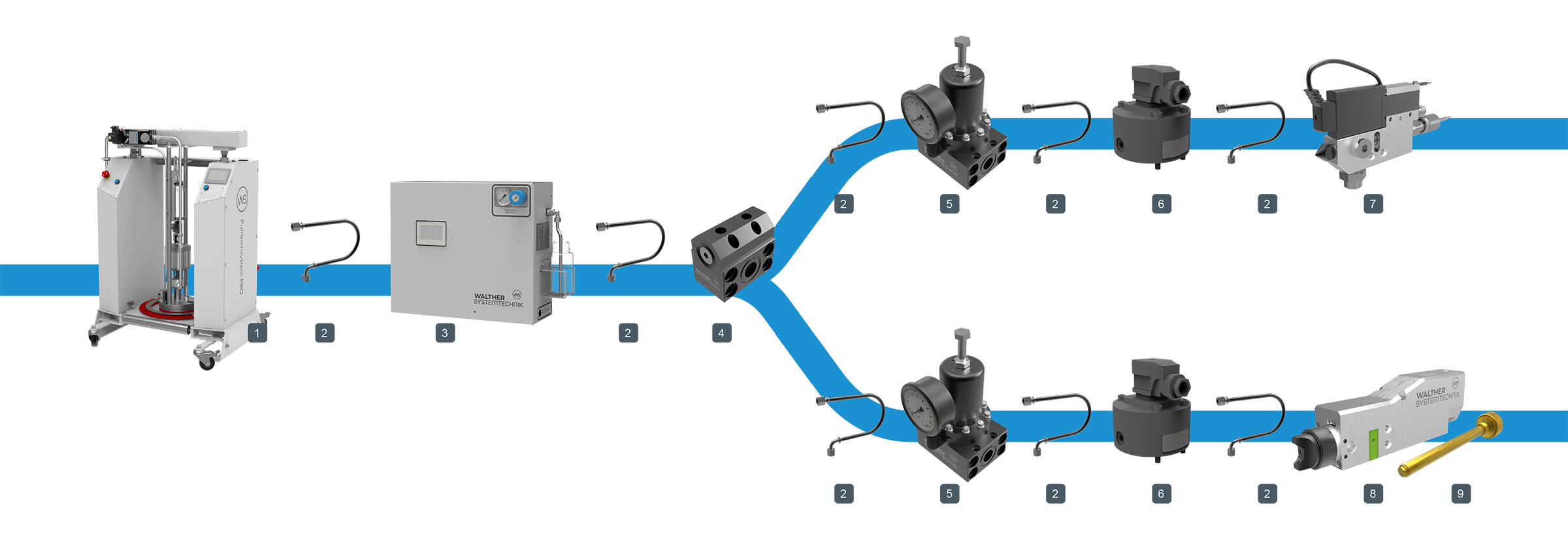

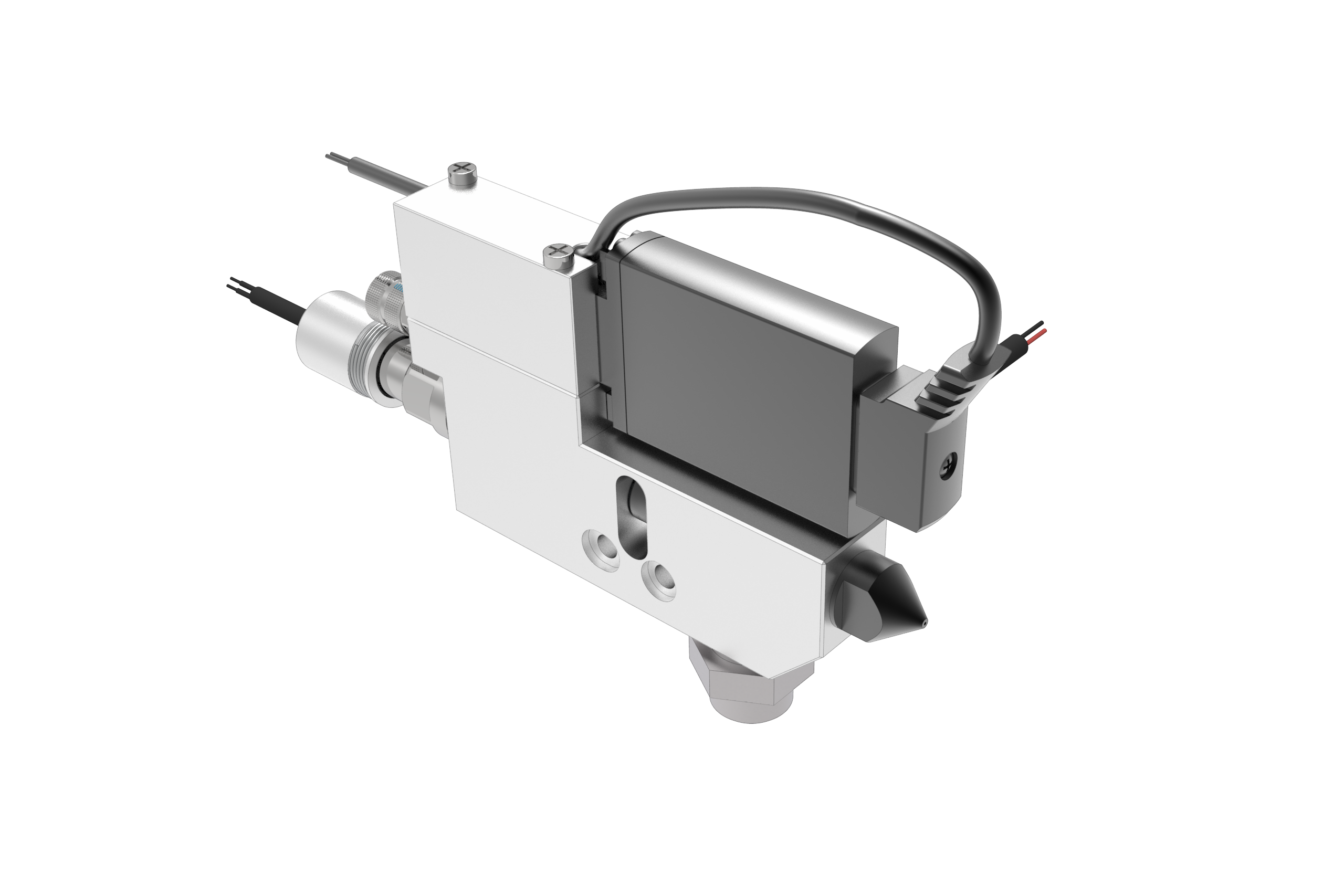

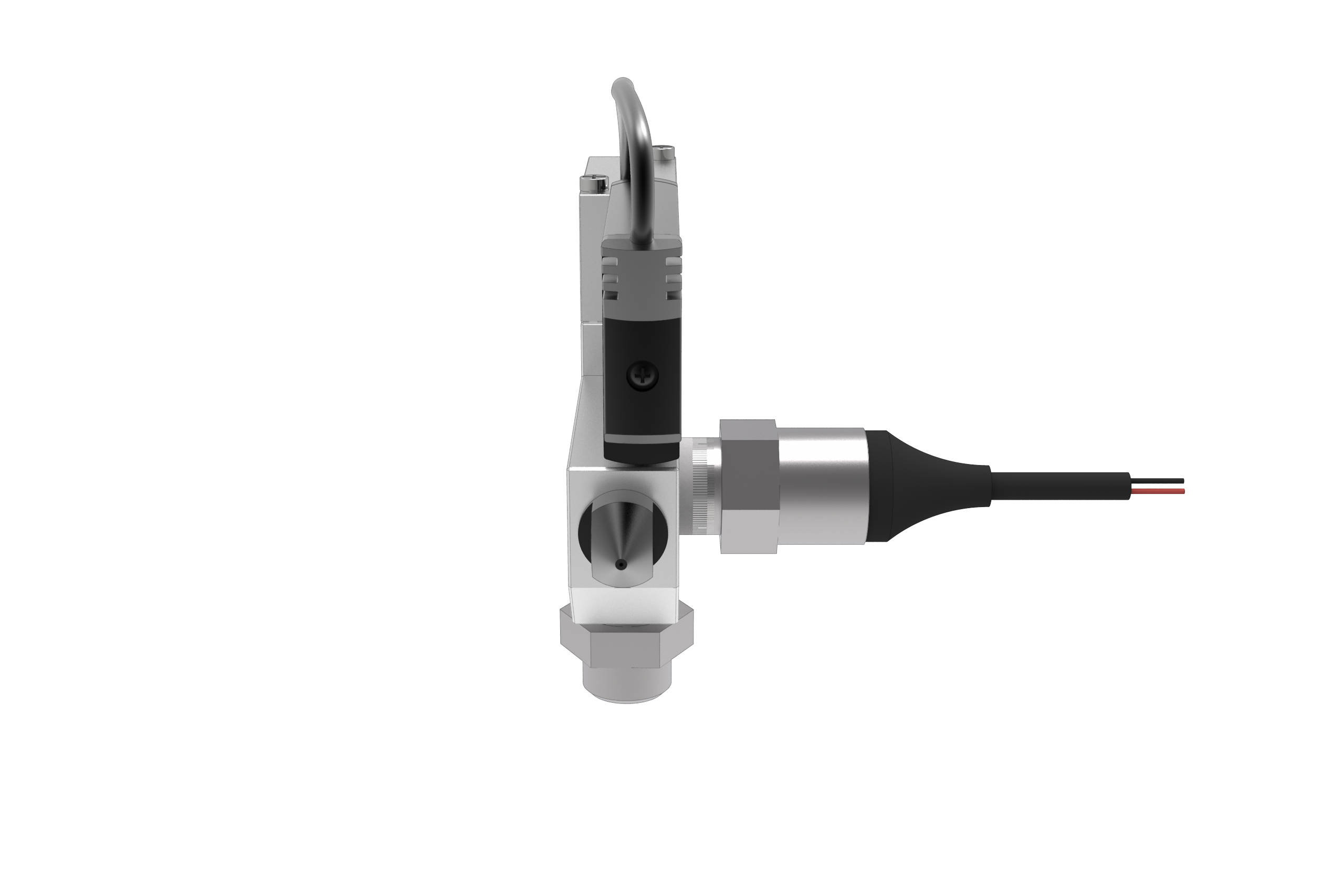

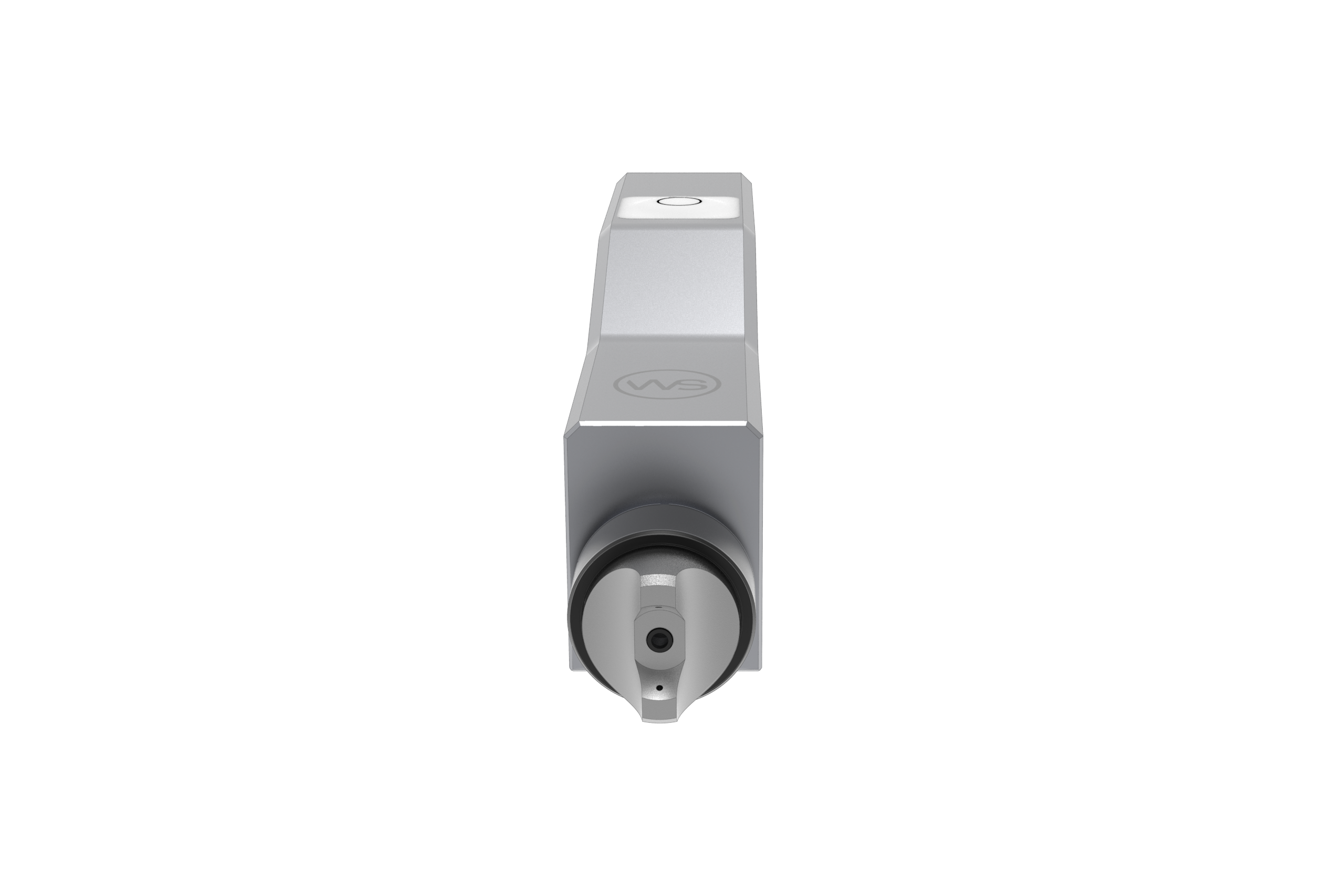

Fluid systems: Exemplary structure of a grease application system

Fluid systems, particularly grease application systems, are essential in modern industrial manufacturing to improve the efficiency and quality of manufactured equipment, products and goods. These systems are specifically designed to apply grease accurately and efficiently to a wide range of materials and components. Precise control over the amount and placement of grease improves the manoeuvrability of mechanical parts, reduces wear and extends product life. By using grease application systems, companies can not only improve product quality, but also minimise maintenance requirements and optimise material consumption. These technologies therefore help to make production processes more sustainable and cost-effective.

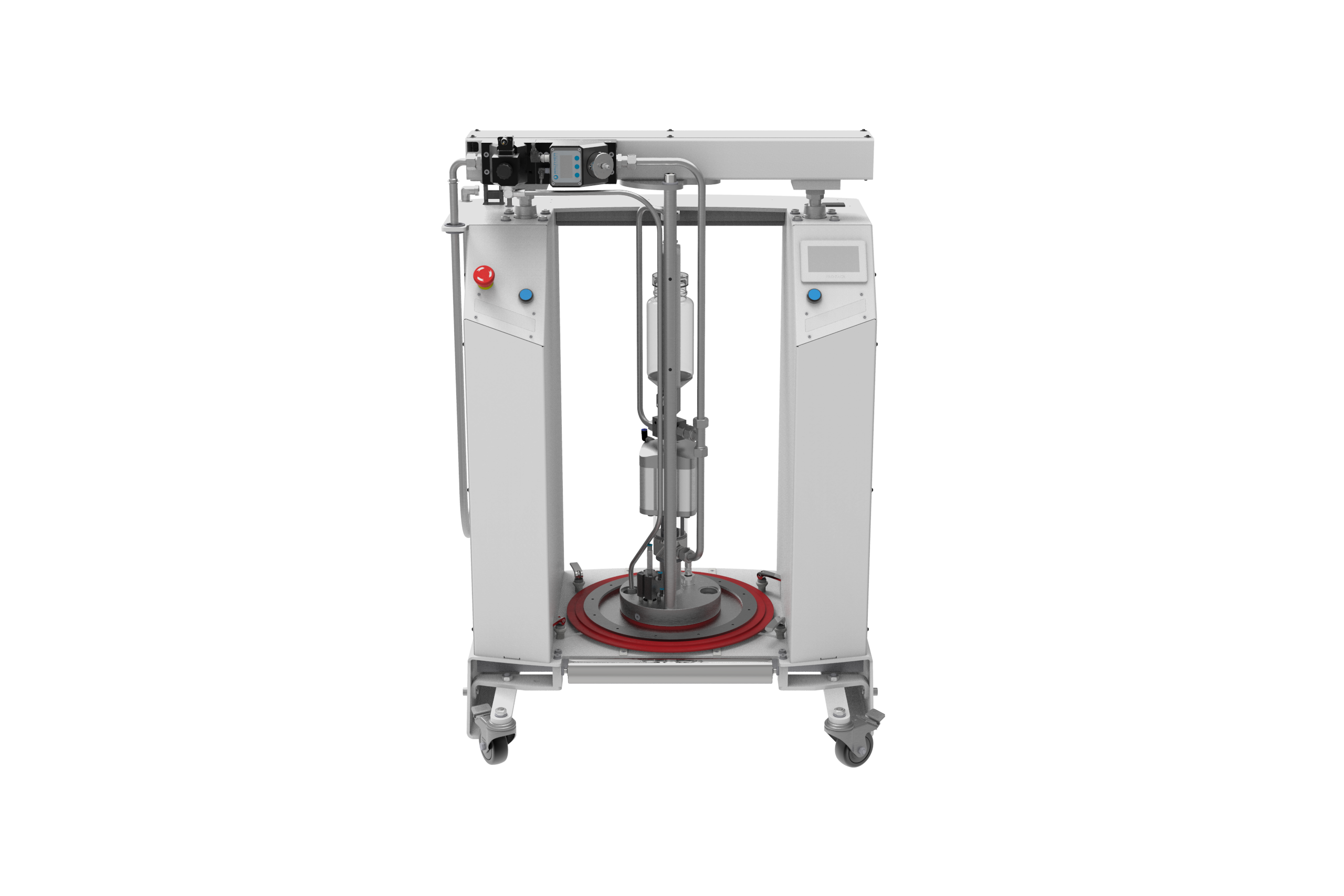

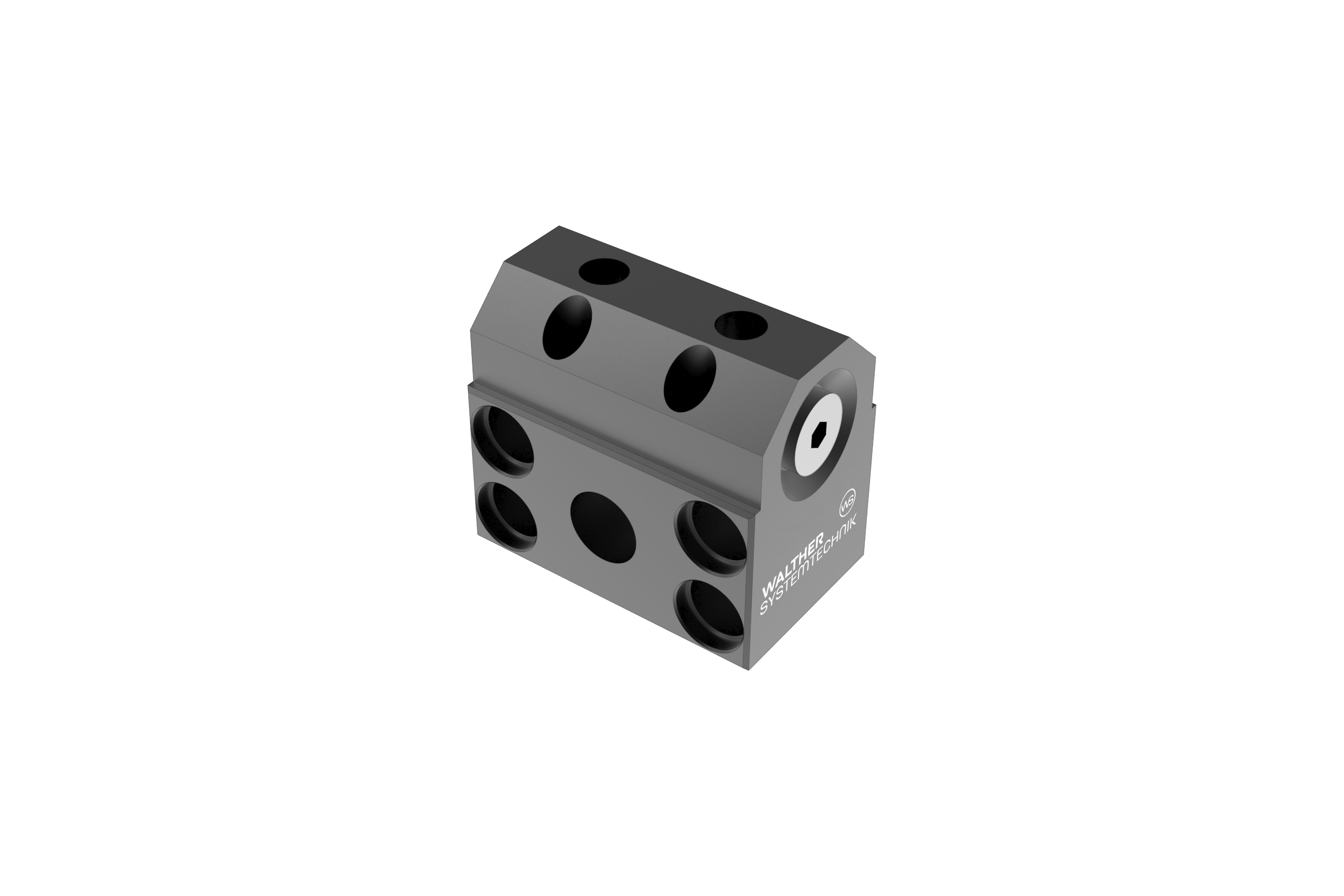

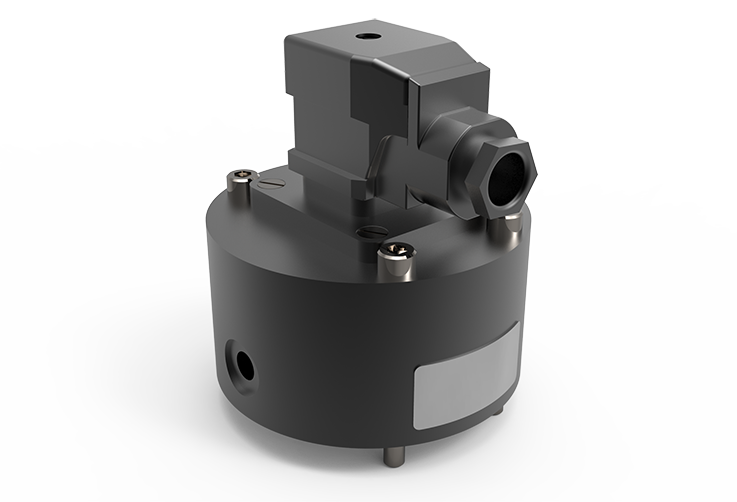

Our exemplary grease application system consists of several key components that work together seamlessly.