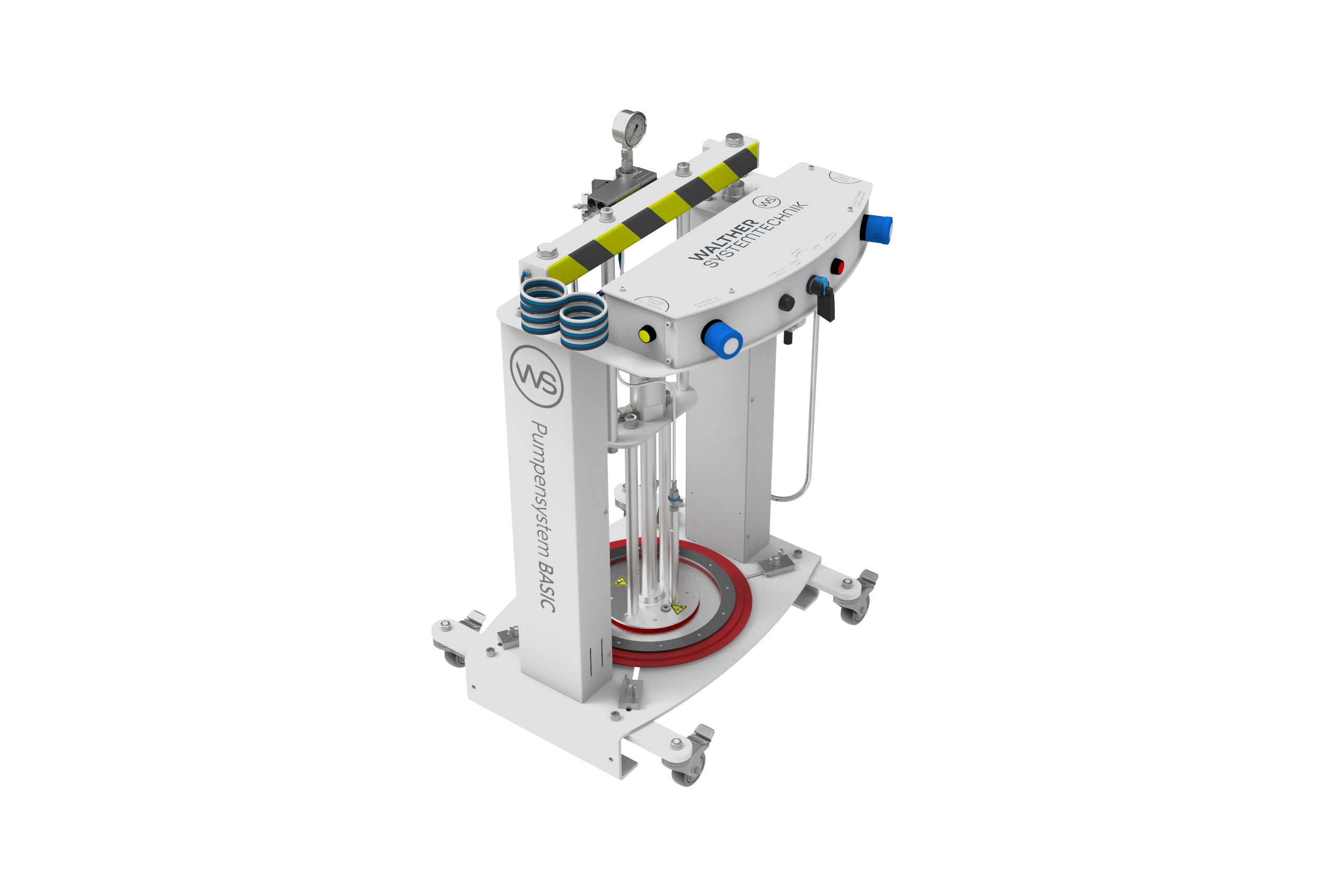

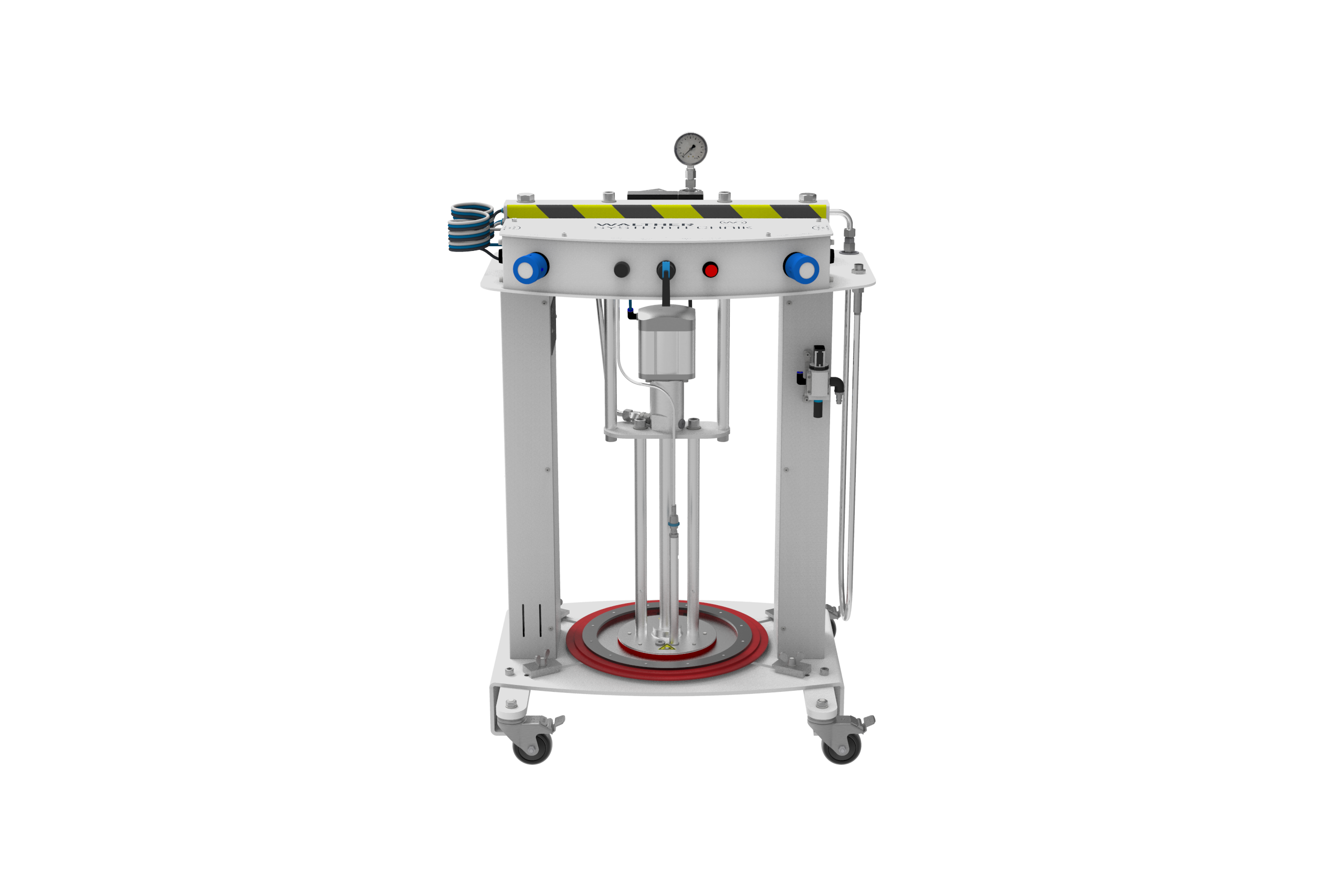

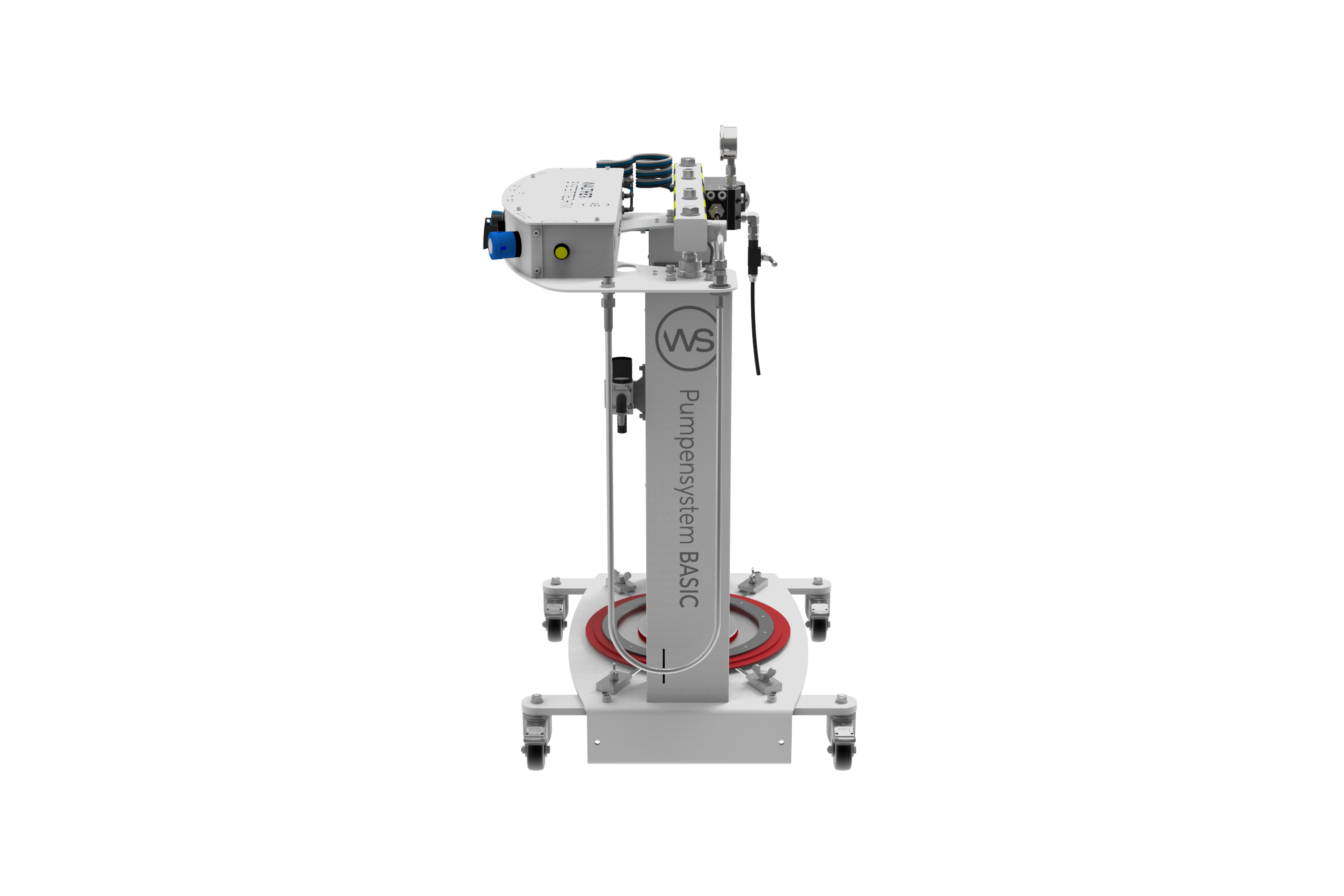

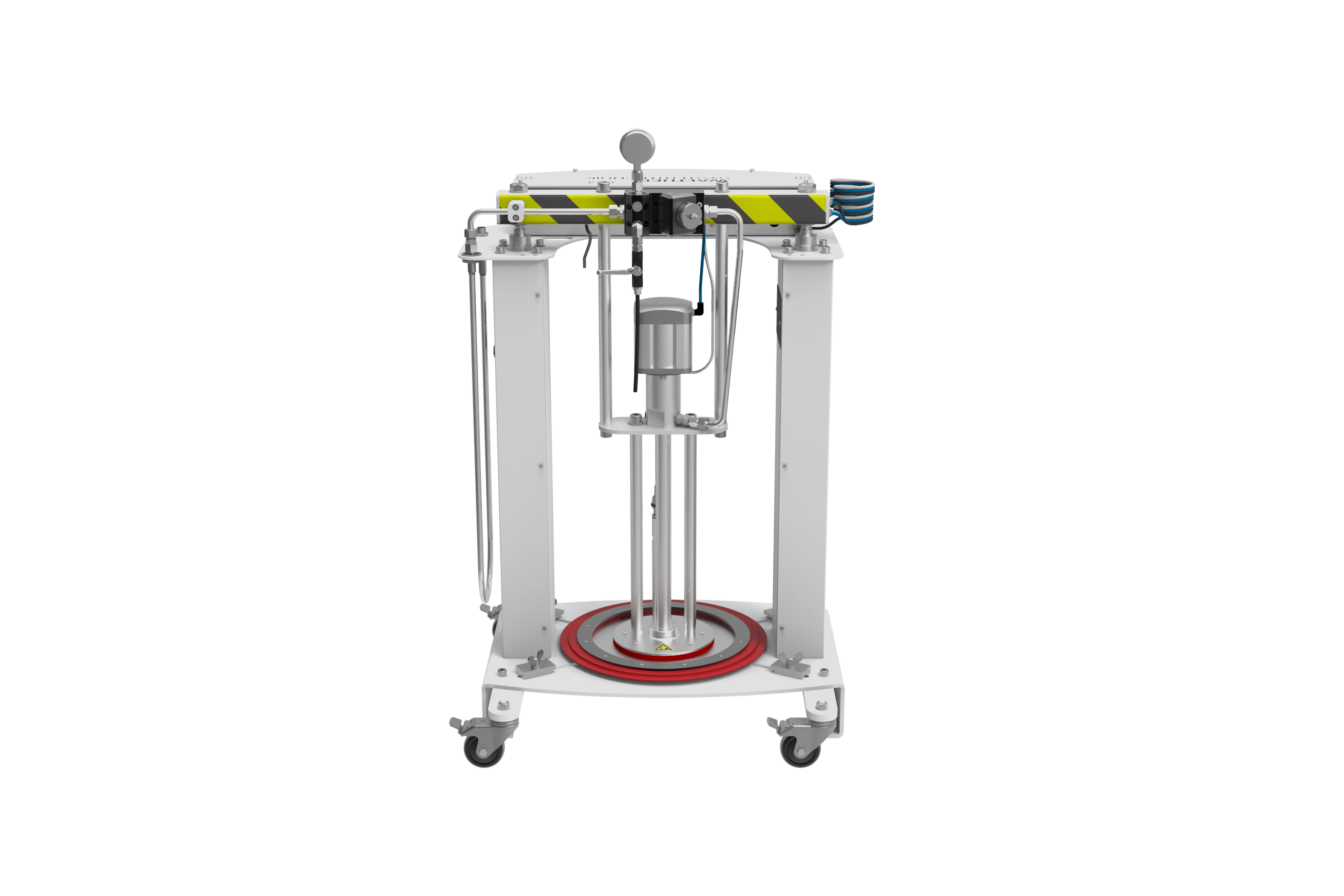

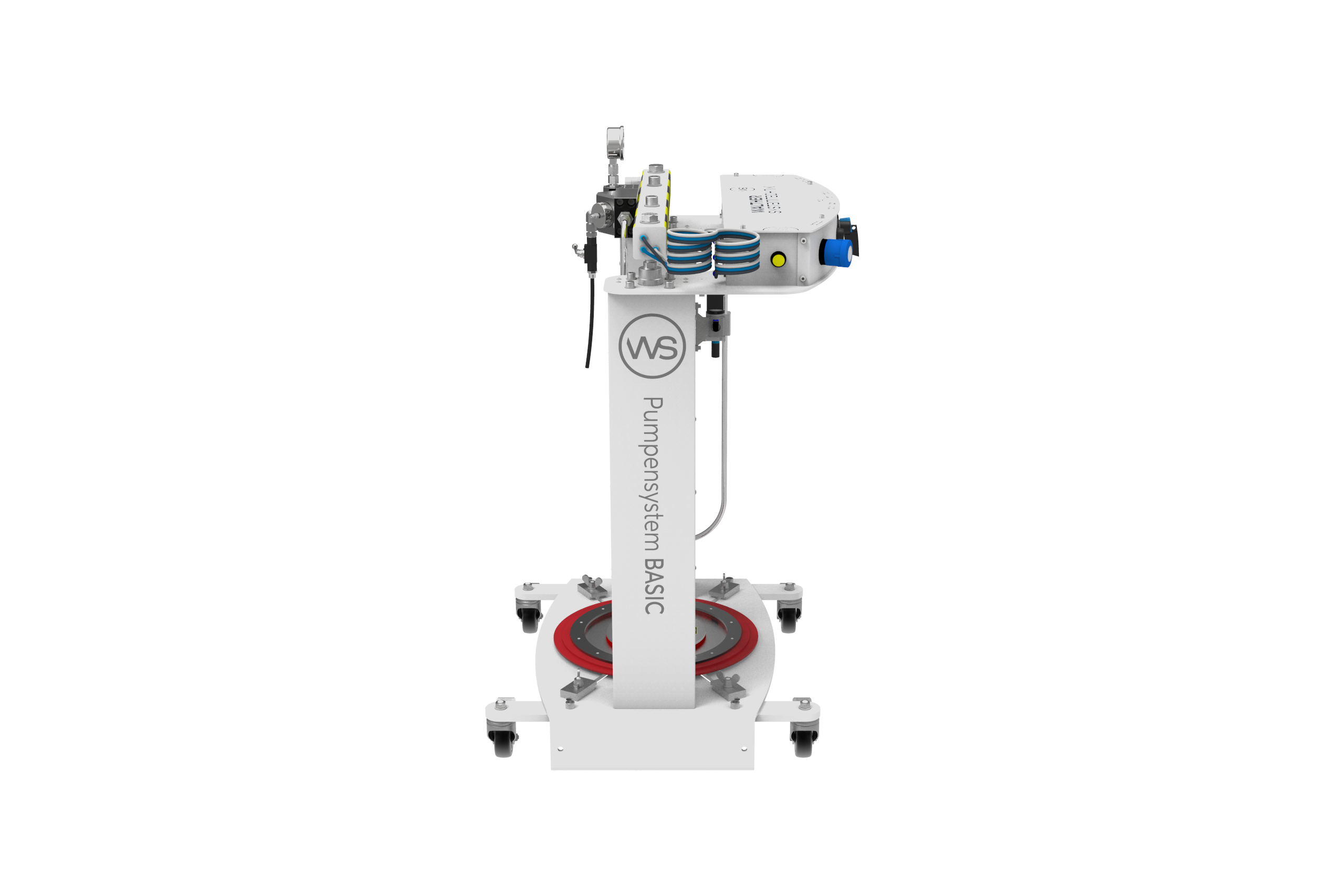

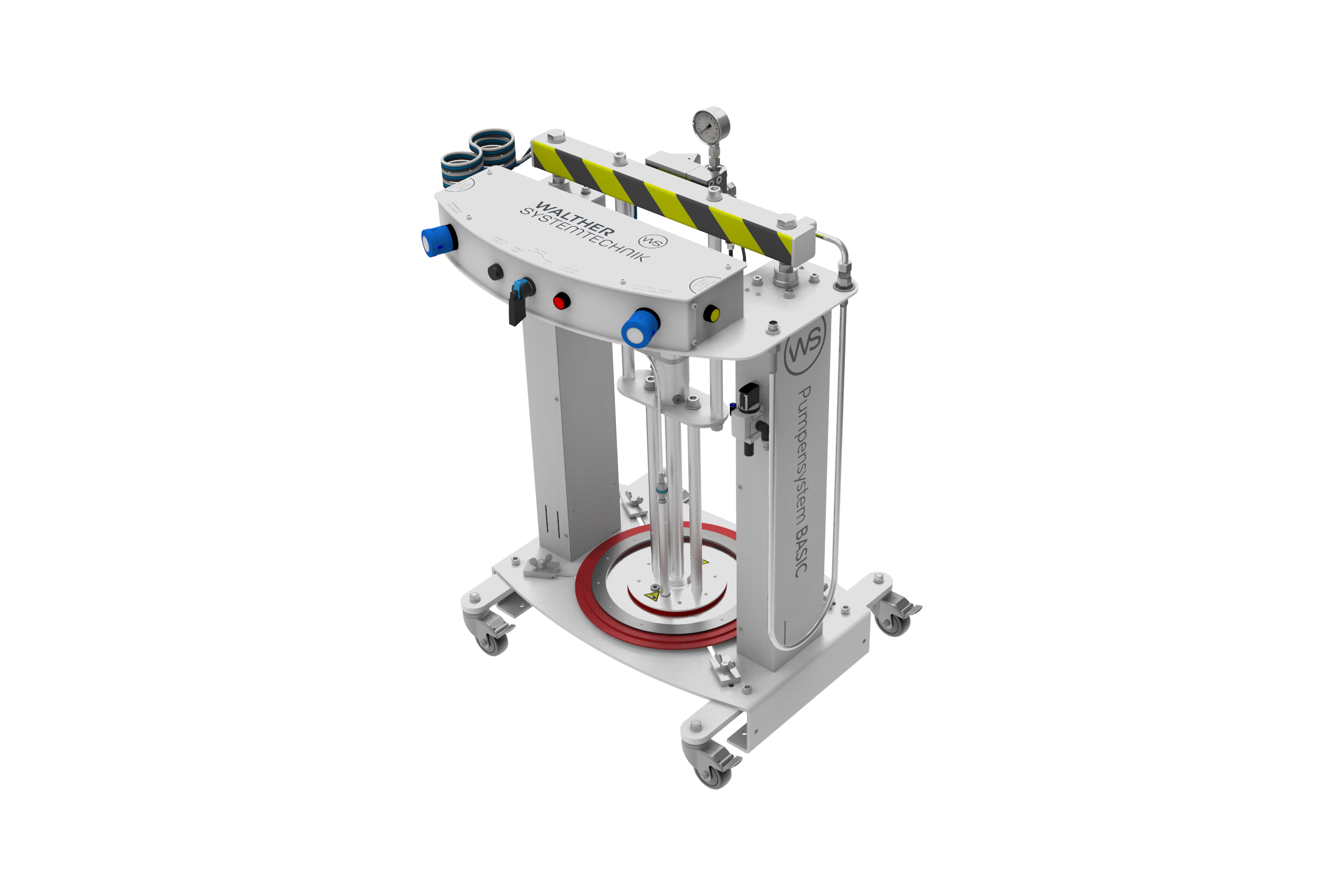

Pump System WPS BASIC

The WPS BASIC pump system is a pneumatically operated piston unit for conveying medium- to high-viscosity media directly from original containers (particularly lubricating greases up to NLGI class 3). It serves as a robust base unit for manual dispensing processes or for supplying material to downstream components. The system ensures a consistent media feed and supports stable dosing performance while maximizing material utilization.

The system is designed for 20-, 30-, or 60-liter containers and features a follower plate that rests on the medium and follows it downward during the conveying process. The follower plate pressure can be precisely adjusted to match the viscosity of the material. This ensures continuous suction performance even with shear-thinning (structure-viscous) media. Centered guidance reliably prevents the plate from tilting – for example, in containers with ribs or manufacturing tolerances.

Stable conveying and efficient material utilization: To reduce pulsating feed movements, the WPS BASIC pump system is equipped with a mechanically adjustable piston return stroke limiter. This minimizes pressure surges in the medium and protects downstream dispensing components. It also contributes to extending the system’s service life.

A pneumatic end-position switch automatically stops the conveying operation as soon as the follower plate reaches its bottom position. This prevents the pump from running dry and eliminates the need for time-consuming venting of the entire fluid system. Optionally, the empty state can be indicated via an acoustic or visual warning signal. The residual amount in the container is less than one percent, which increases material efficiency and reduces disposal costs.

Fully pneumatic operation – no external control system required: The WPS BASIC pump system is controlled entirely pneumatically and designed for manual on-site operation. Its straightforward handling facilitates integration into existing production lines without the need for additional control systems or software. The robust design ensures reliable operation under continuous industrial use.

Typical applications: The WPS BASIC pump system is used for conveying lubricating greases in assembly processes, particularly for supplying material to dispensing and application valves at manually operated workstations. Typical areas of application include the automotive industry, household appliance production, and general manufacturing.

- filter system already integrated

- pump system turns off automatically after complete emptying of container

- almost completely empty containers due to adapted follower plates

- two-hand control for a safe lowering of the pump lifter

- follower plate pressure can be steplessly adjusted

- expandible by various options

- process pressure: max 150 [bar]

- supplied volume: max. 1500 [cm³/min]

- pneumatic inlet pressure: max.6 [bar]

- follower plate pressure: max. 6 [bar]

- container sizes: 14 to 180 [l]

- container outside diameter:

>> size 2: max. 435 [mm]

>> size 3: max. 617 [mm]

- container height:

>> size 2: max. 680 [mm]

>> size 3: max. 930 [mm]

- dimensions (w x d) - mobile version:

>> size 2: max. 757 x 734 [mm]

>> size 3: max. 927 x 788 [mm]

- height - mobile version:

>> size 2: min. 1,208 - max. 1,908 [mm]

>> size 3: min. 1,458 - max. 2,408 [mm]

- empty weight:

>> size 2: 93 [kg]

>> size 3: 122 [kg]