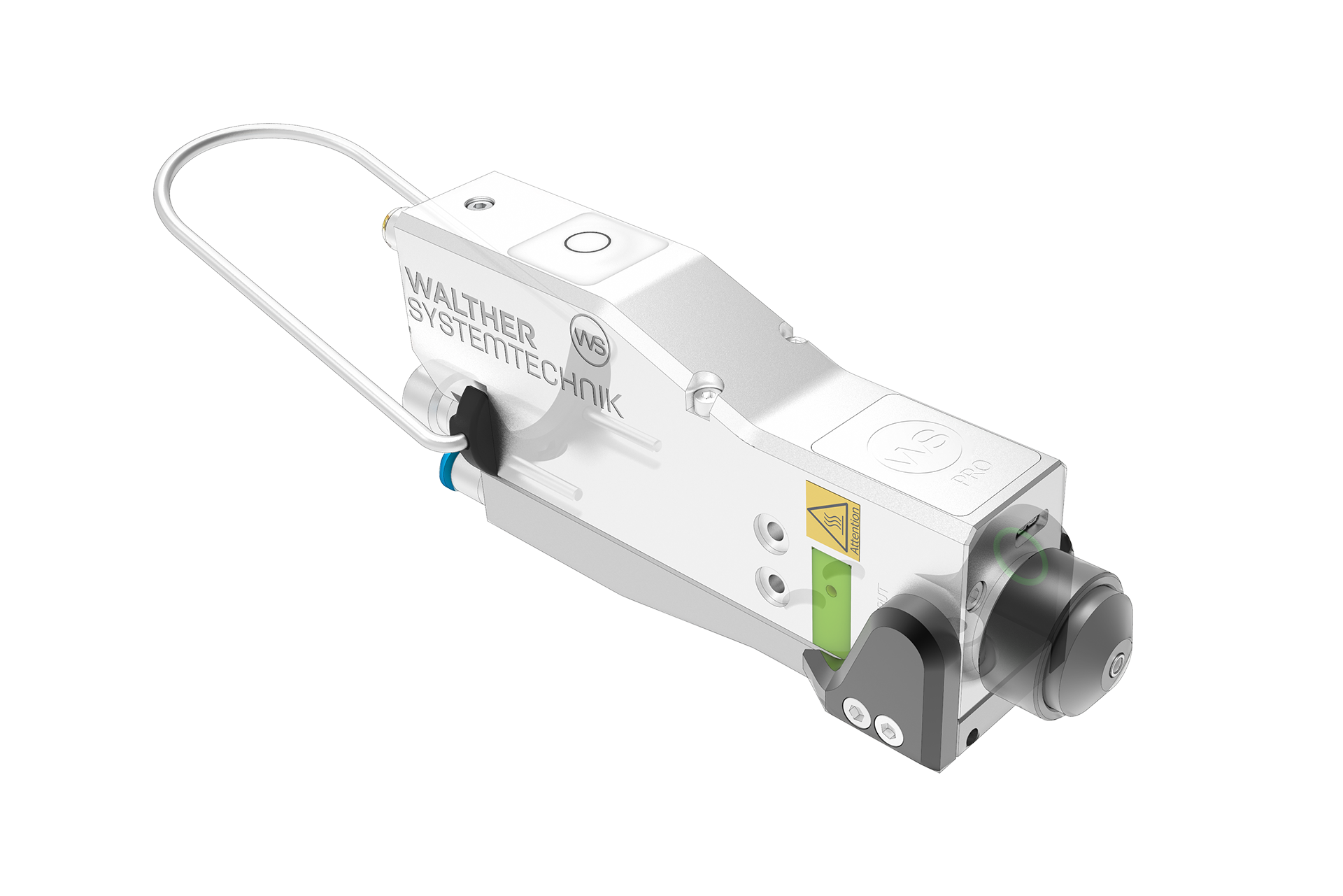

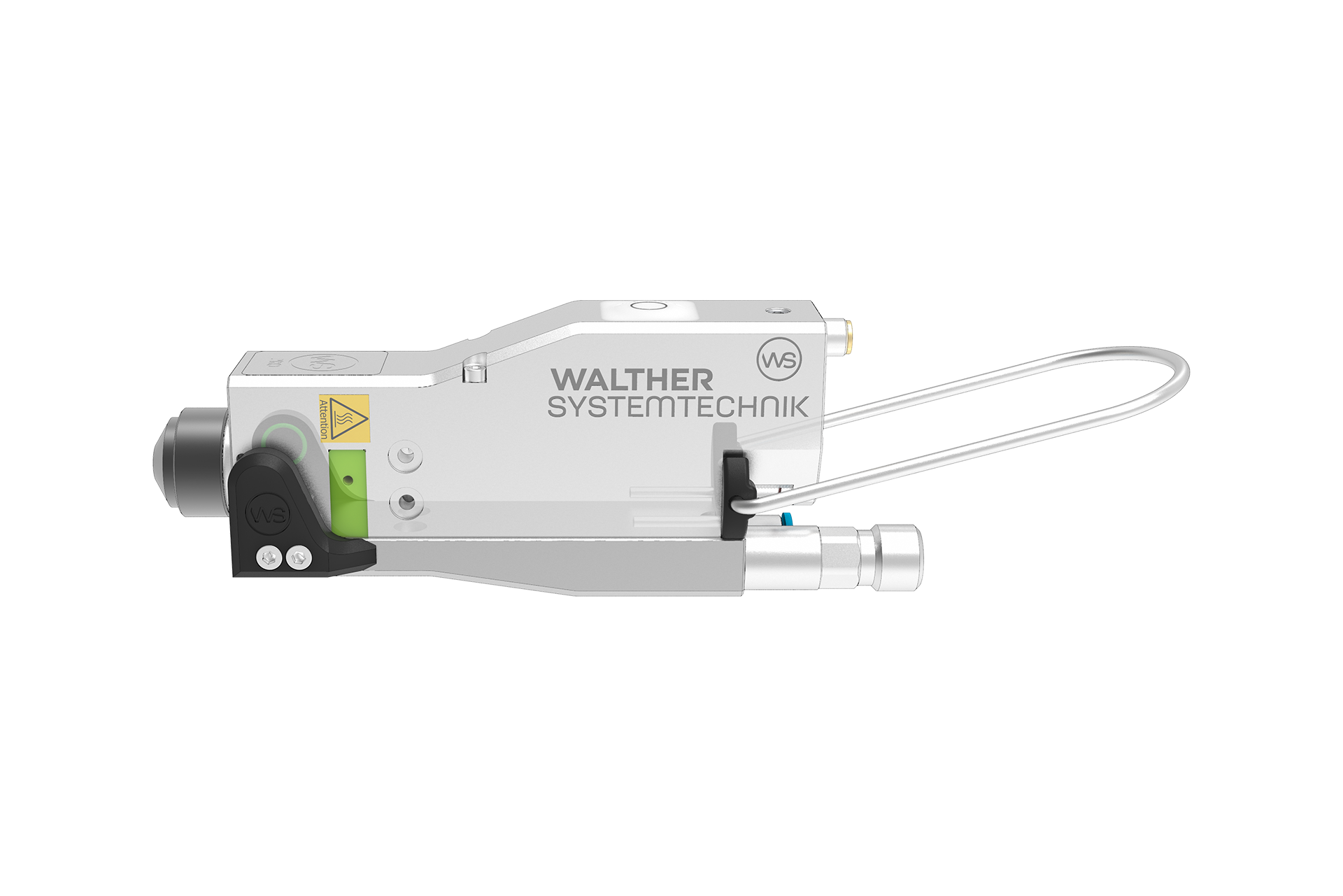

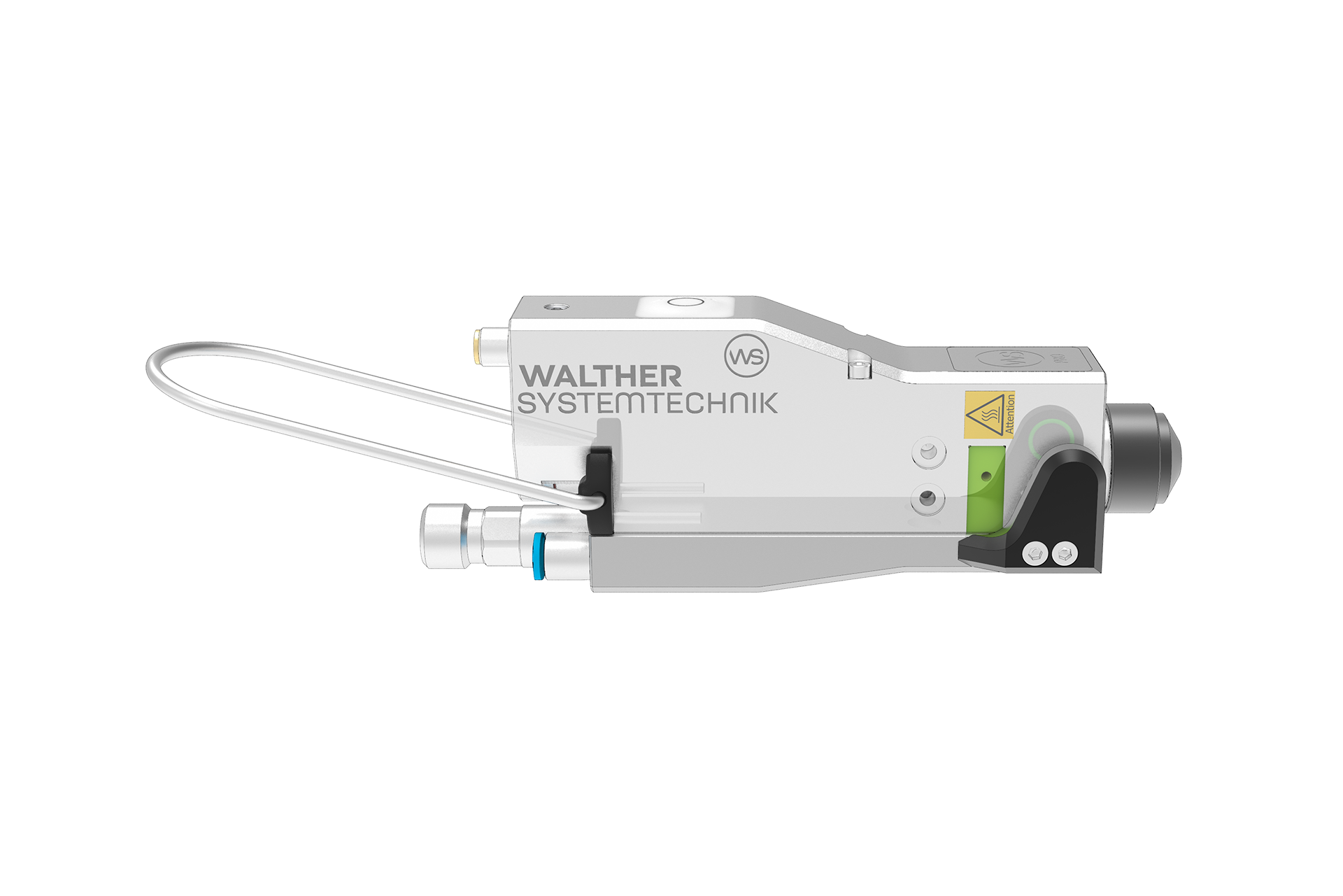

Handheld Spray System WSV

The Handheld Spray System WSV is a ready-to-connect solution for manual spray application of viscous media in industrial production environments. Combining the proven valve technology of the electrically operated Walther spray valve (WSV) with an ergonomically designed hand module, it enables flexible use in assembly, rework or prototyping. Designed for use outside automated production lines, the system provides consistent spray results and can optionally be equipped with process monitoring and documentation via Modbus TCP.

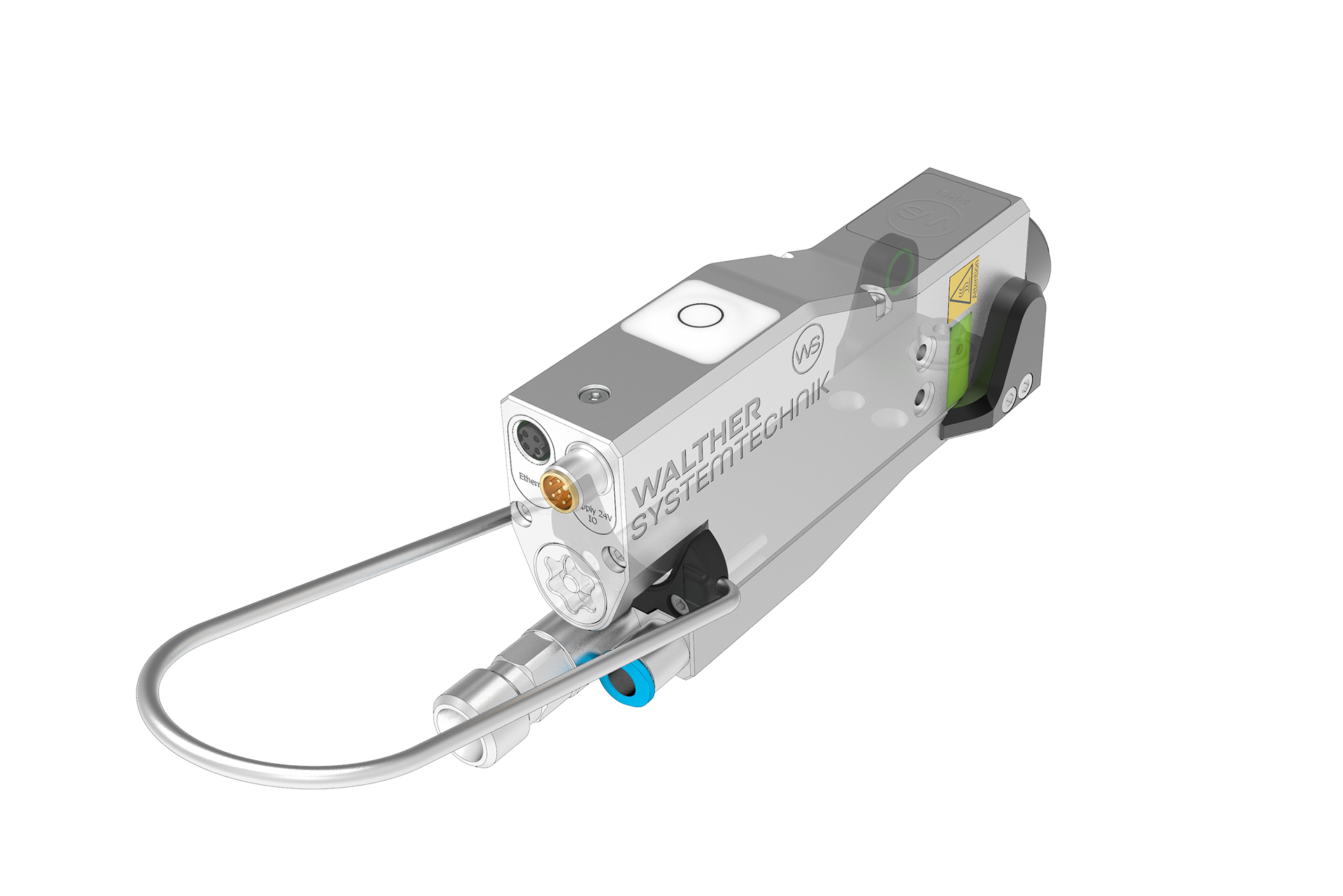

At the heart of the system is the intelligent spray valve WSV, which operates independently of external control units. Parameterisation is carried out via a web-based dashboard accessible through the Ethernet interface. The integrated control unit enables precise adjustment of spray times, opening intervals and spray sequences. Depending on the version, it also allows the regulation of medium temperature and the monitoring of process pressure. The pre- and post-air timings can also be configured individually, enabling precise control of the spray pattern and reliable prevention of dripping, overspray, stringing or buildup. A pushbutton built into the top of the valve serves as a direct trigger for the spray process, eliminating the need for an additional hand or foot switch. However, a corresponding external button can be connected if required.

The hand module is equipped with a sturdy suspension bracket, allowing it to be mounted on a balancer or spring tensioner. This reduces physical strain and supports consistently comfortable operation. The ergonomic grip ensures safe and controlled handling, even during extended use, and minimises the risk of user error due to fatigue or decreasing concentration.

The system is available as a complete set in combination with all standard WSV variants. These range from the basic version with simple control to the professional version featuring integrated medium temperature regulation and process pressure monitoring. All variants can be enhanced with software add-ons such as multi-parameter sets, needle stroke monitoring, and Ethernet bus integration. Thanks to its digital architecture, the system can also be integrated into worker assistance systems, for example for guided assembly tasks or documentation-based production workflows. This makes this hand-guided dispensing solution ideal for manual rework stations, small-series production and manufacturing environments with documentation requirements — wherever precision, flexibility and digital process control are essential.