Walther MODULAR: expertly engineered fluid handling.

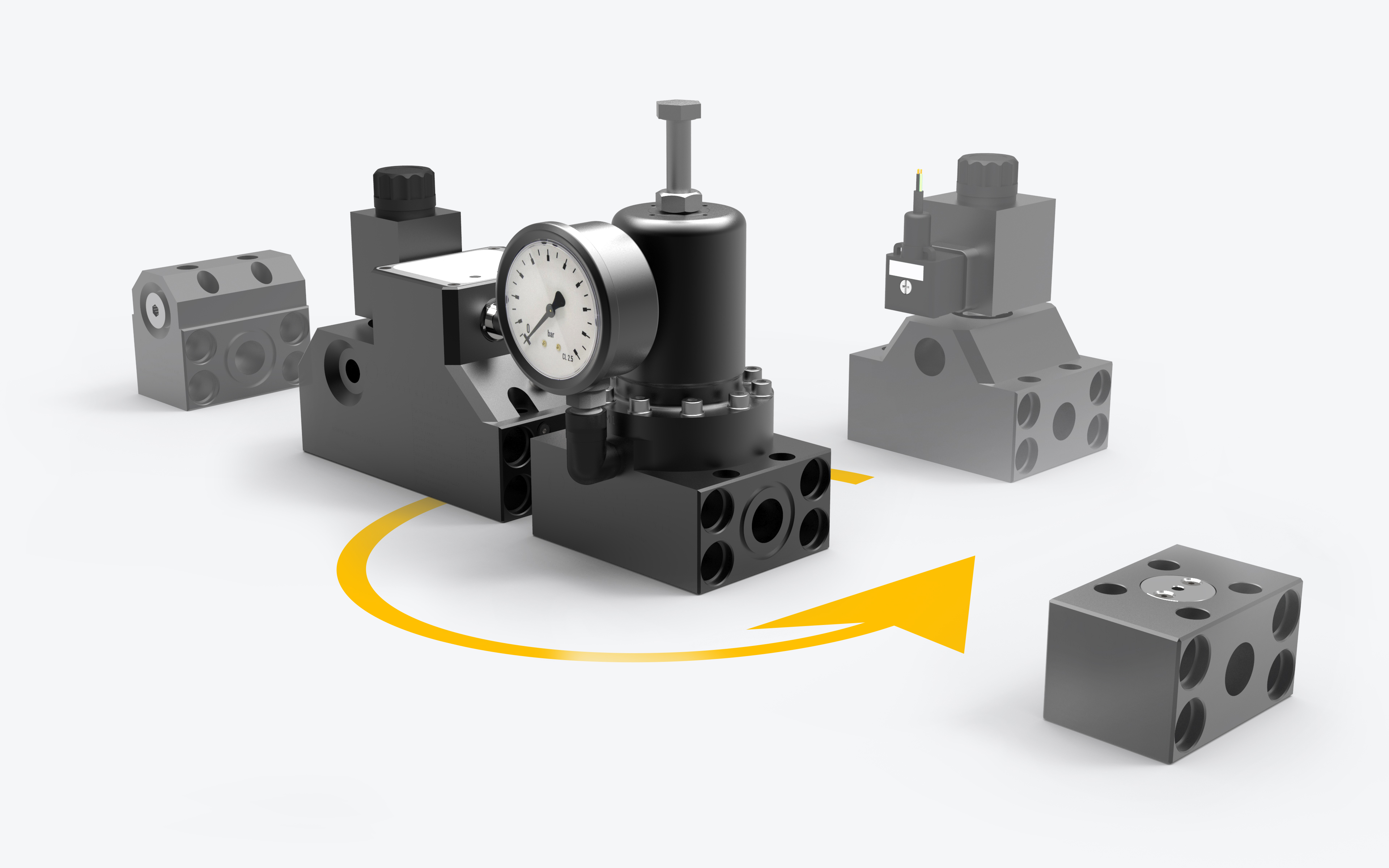

Systems for preparing, handling and supplying viscous media are essential, but are often complex and inflexible, making it difficult to adapt to dynamic production conditions. Integrating different fluid components from different sources is also a challenge. In addition, the design, assembly and maintenance of such systems are usually resource intensive. Walther MODULAR, on the other hand, focuses on flexibility, efficiency and adaptability, enabling the rapid and cost-effective integration of technical functions into new and existing fluid systems, thus fully meeting the requirements of modern industry.

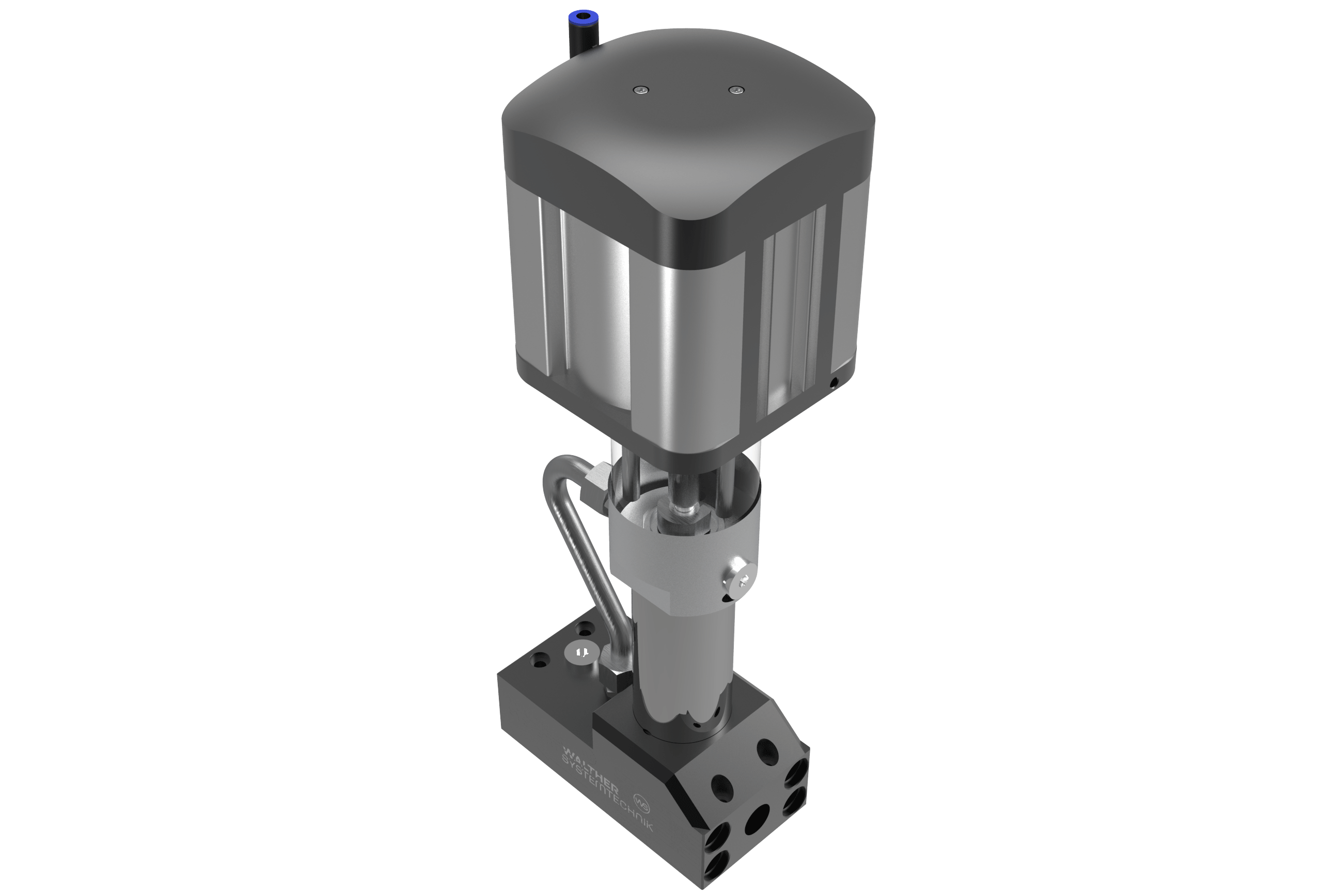

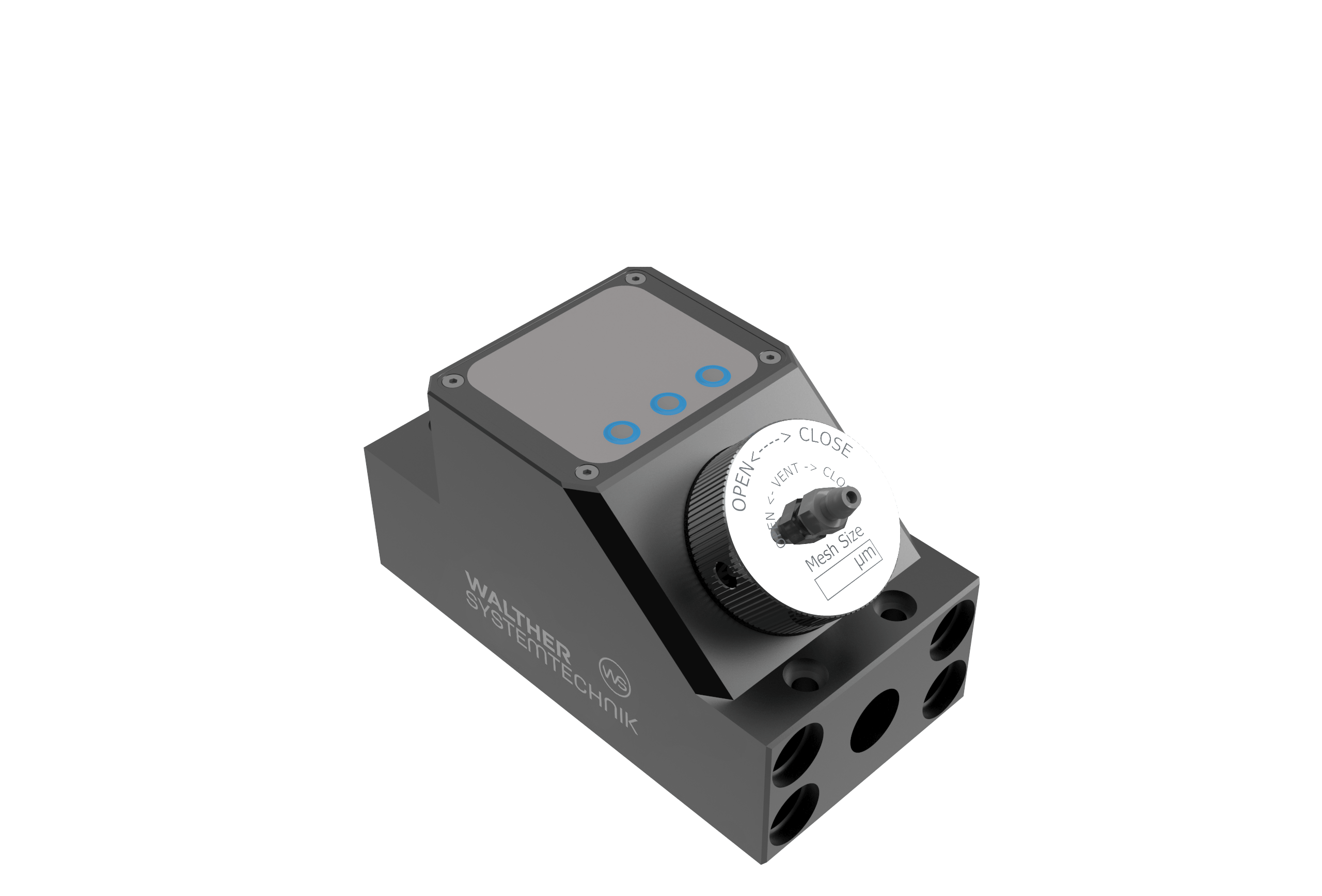

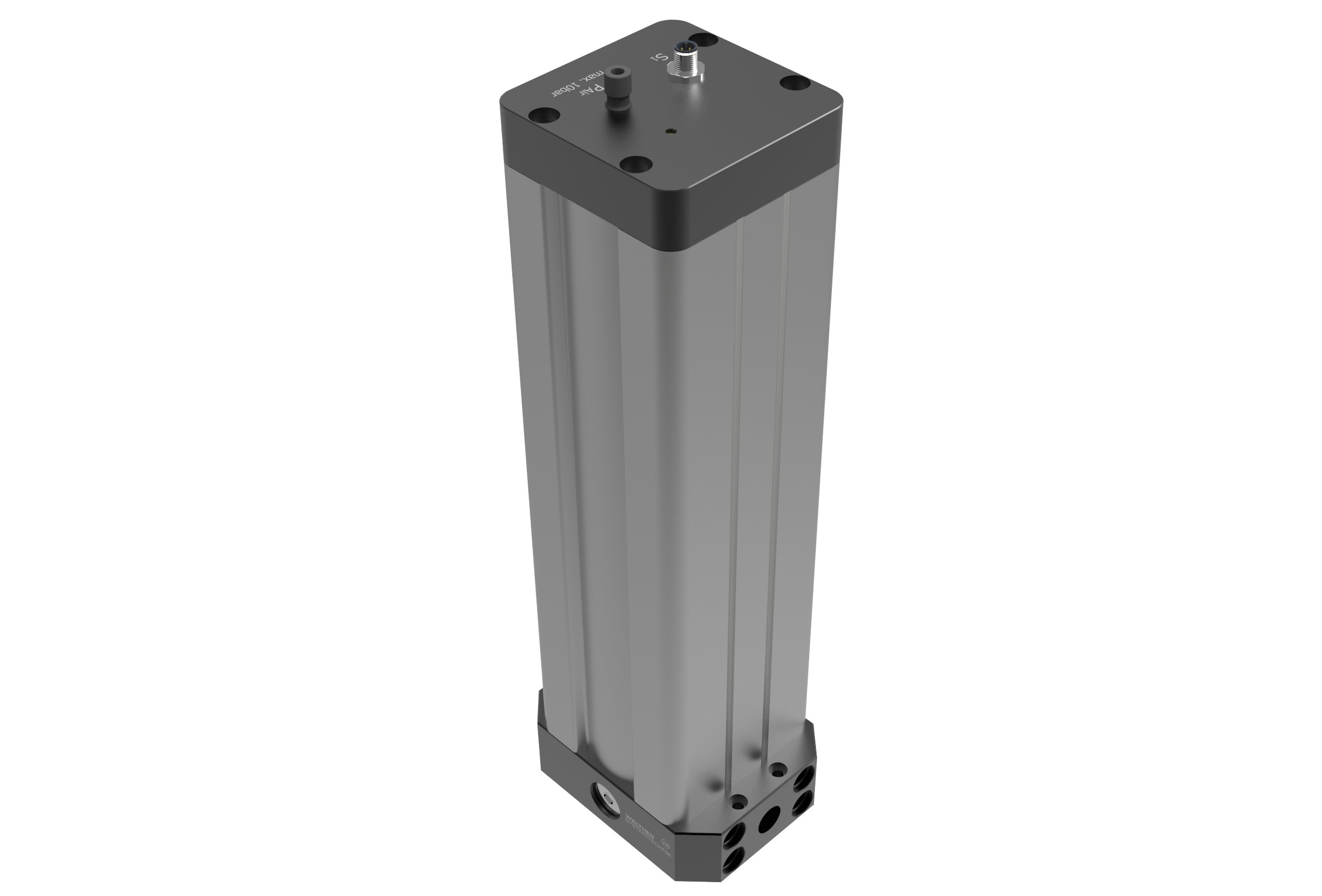

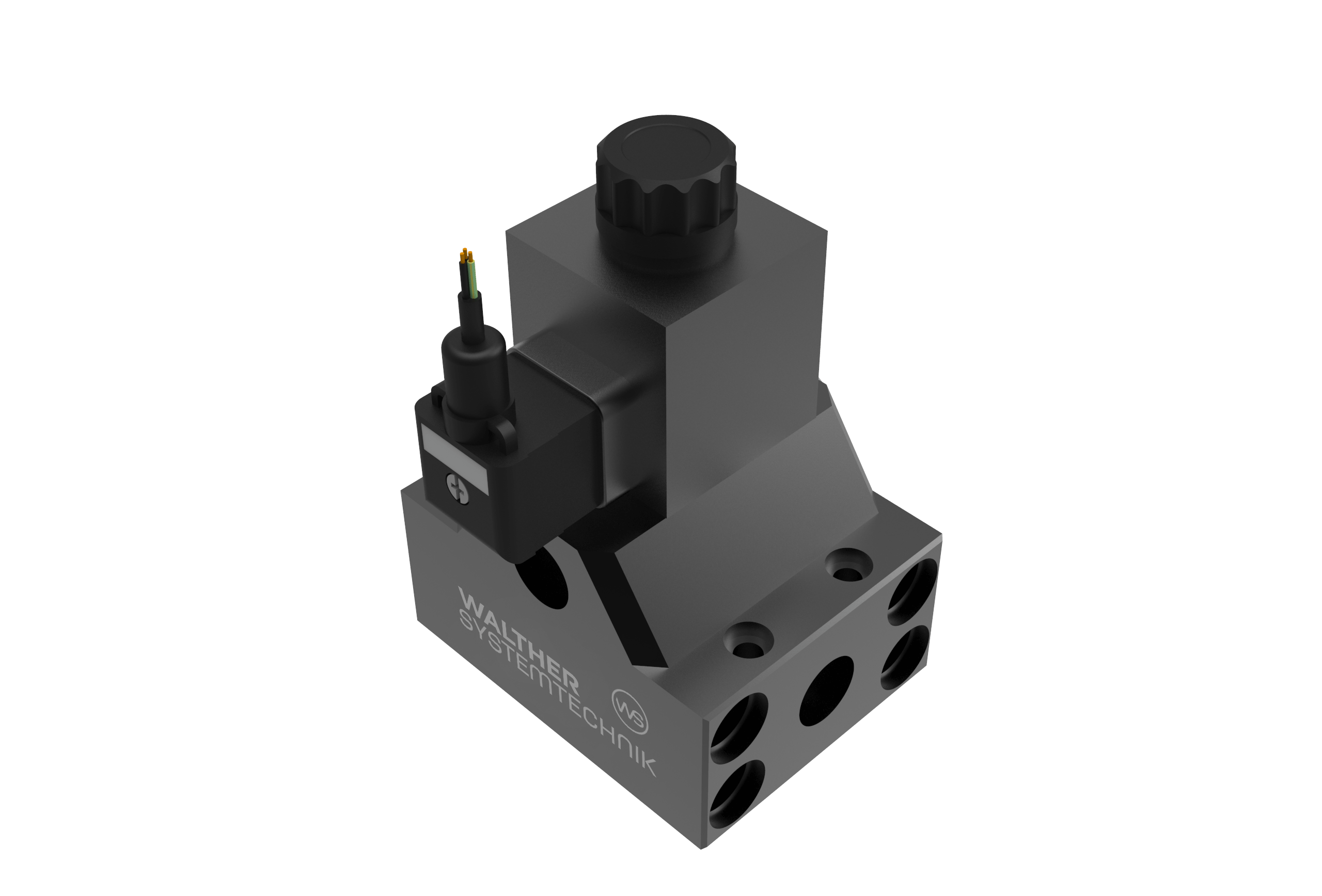

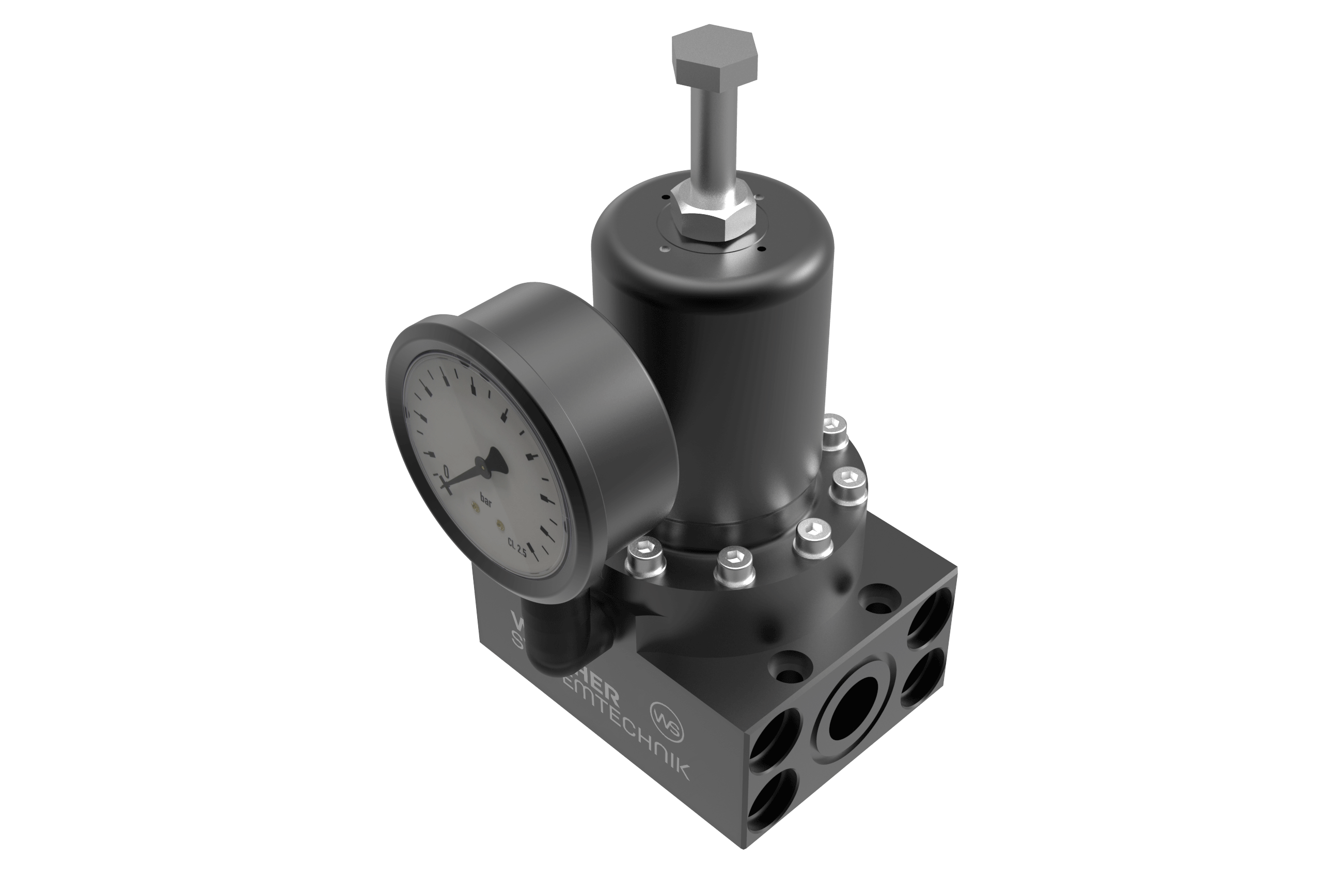

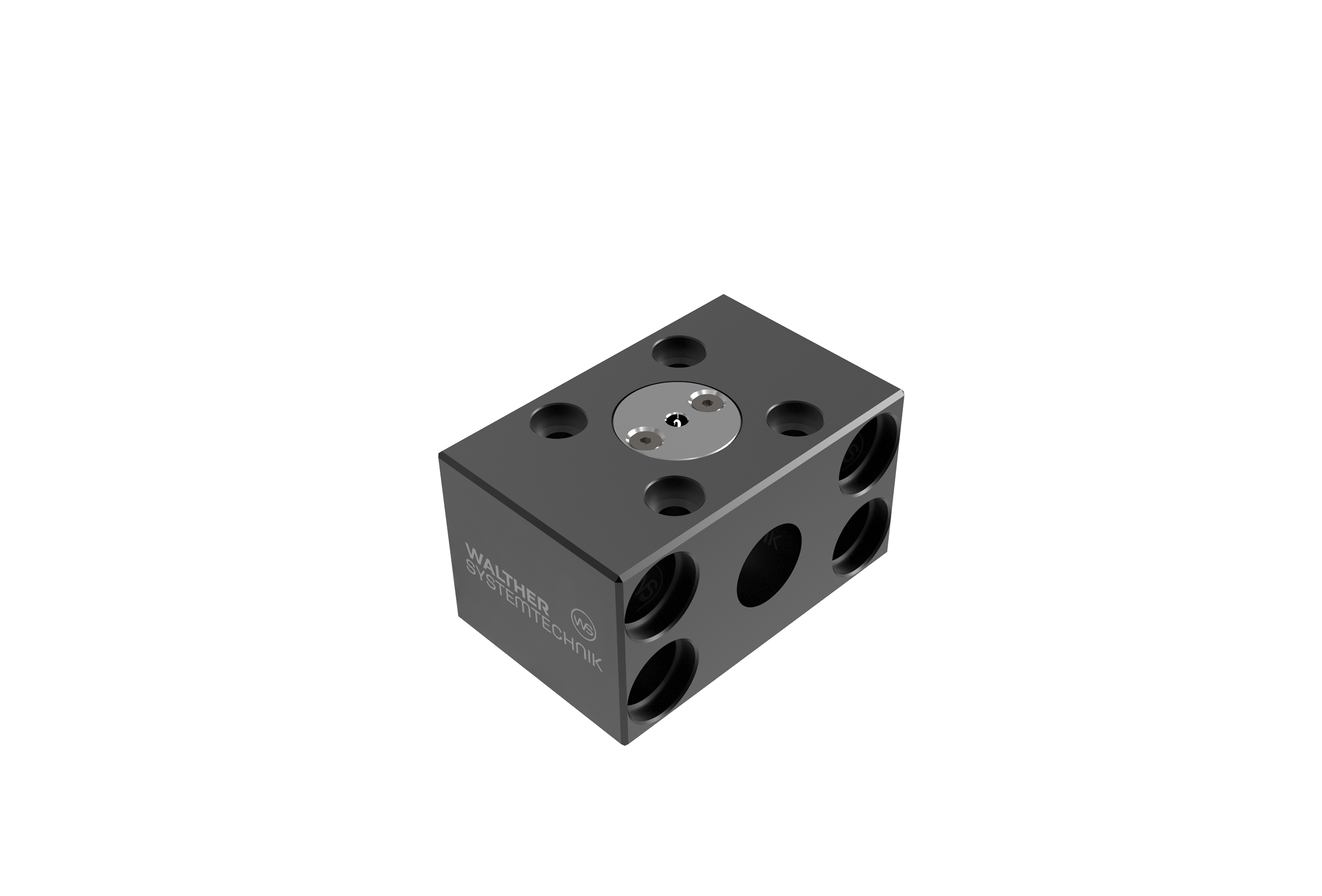

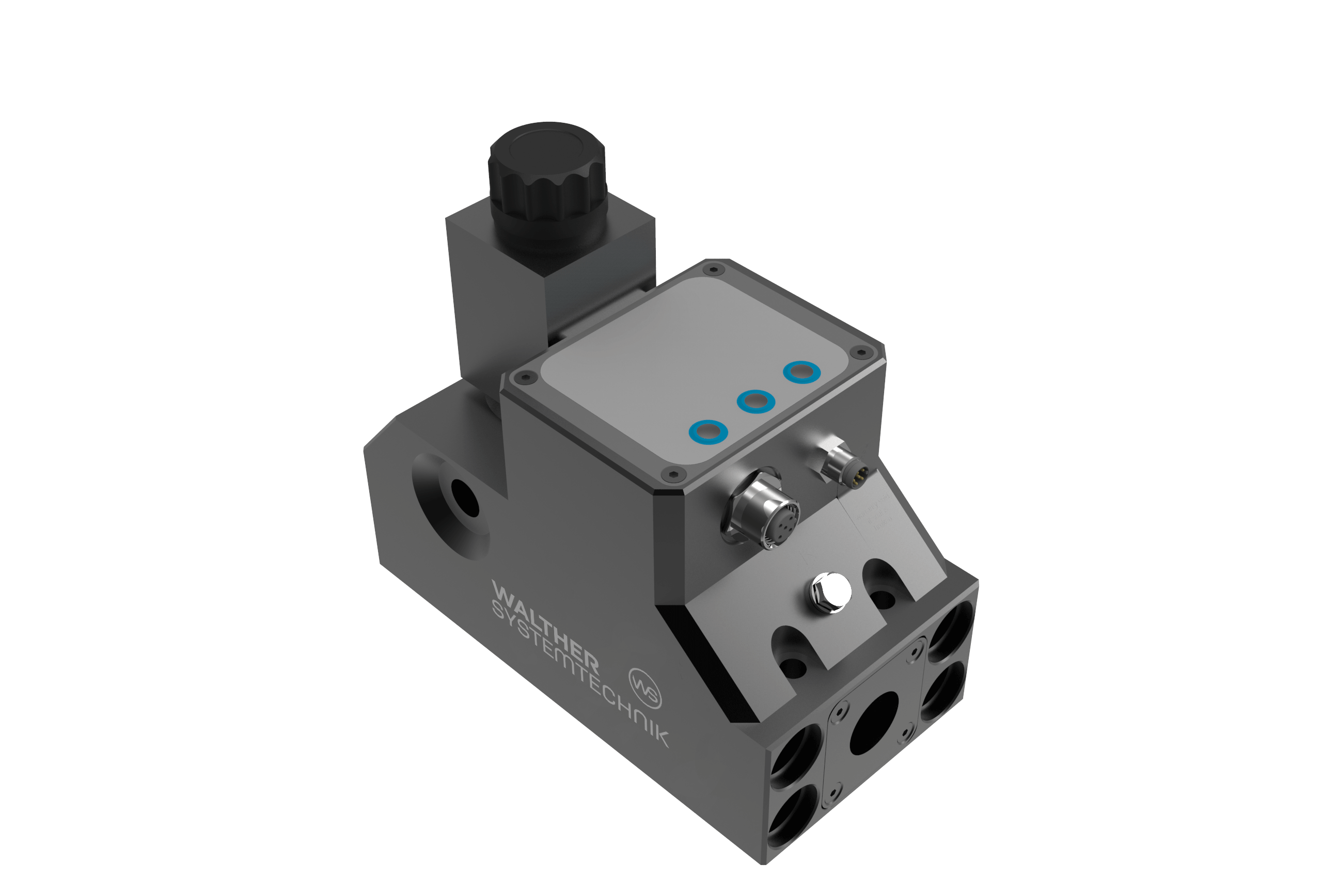

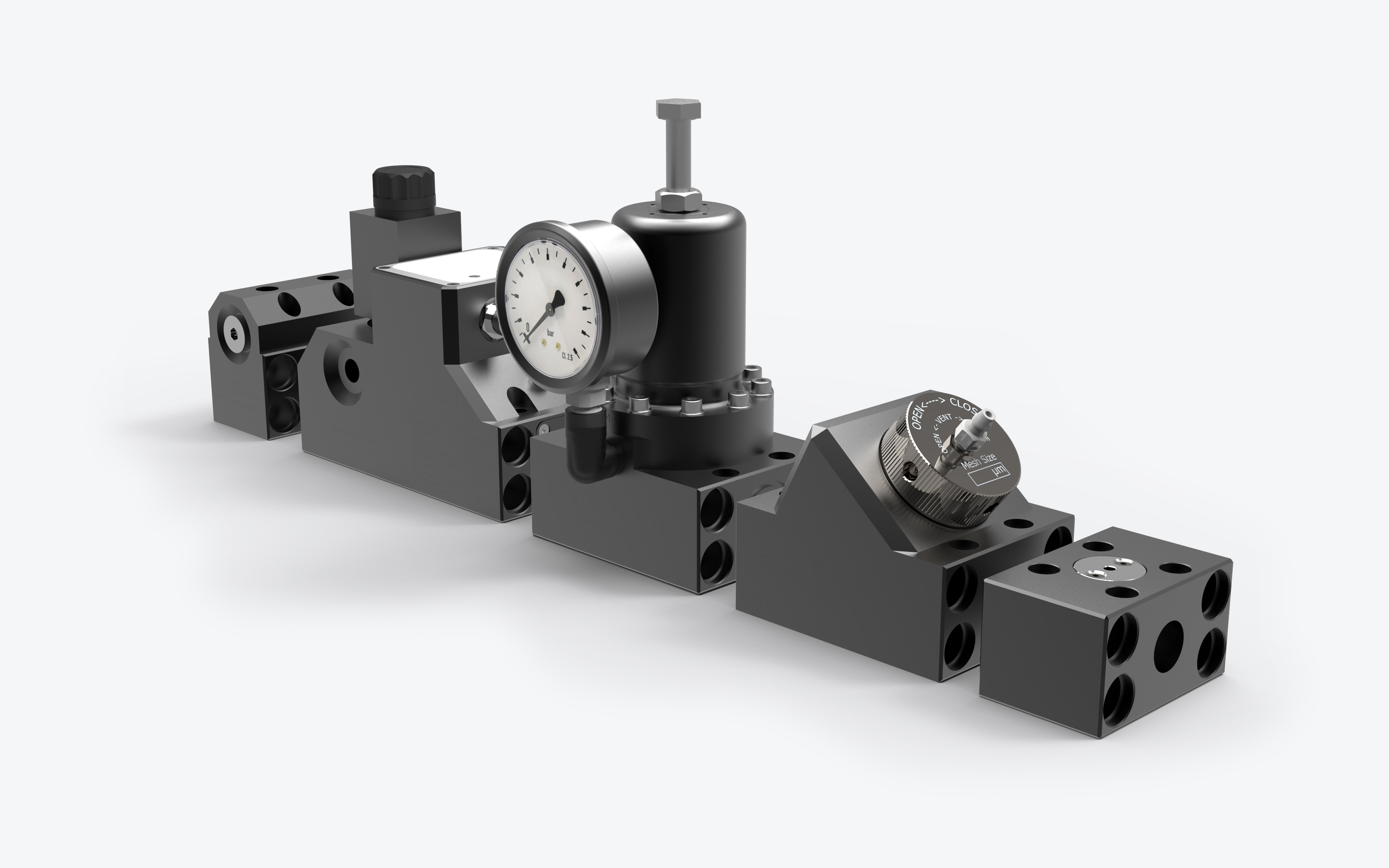

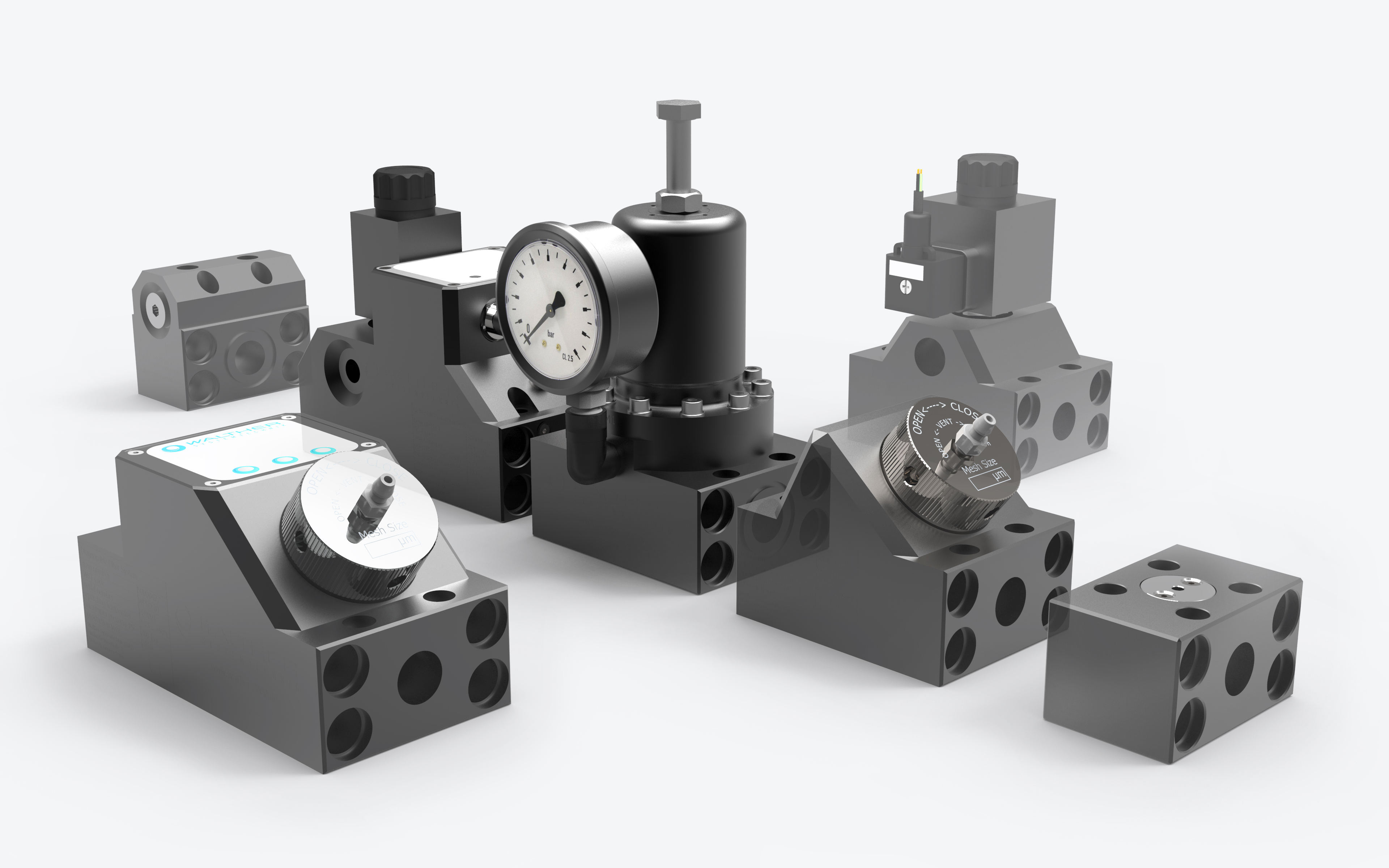

Walther MODULAR is a complete system for the professional handling of viscous media in production environments. It consists of a series of standardised modules that can be configured in different ways and individually adapted to different requirements. Each module in the range has its own primary function. To achieve the desired overall function, the modules are simply plugged together to form assemblies.

Walther MODULAR offers a wide range of freely combinable functions, such as ...

Flexibility and efficiency in focus

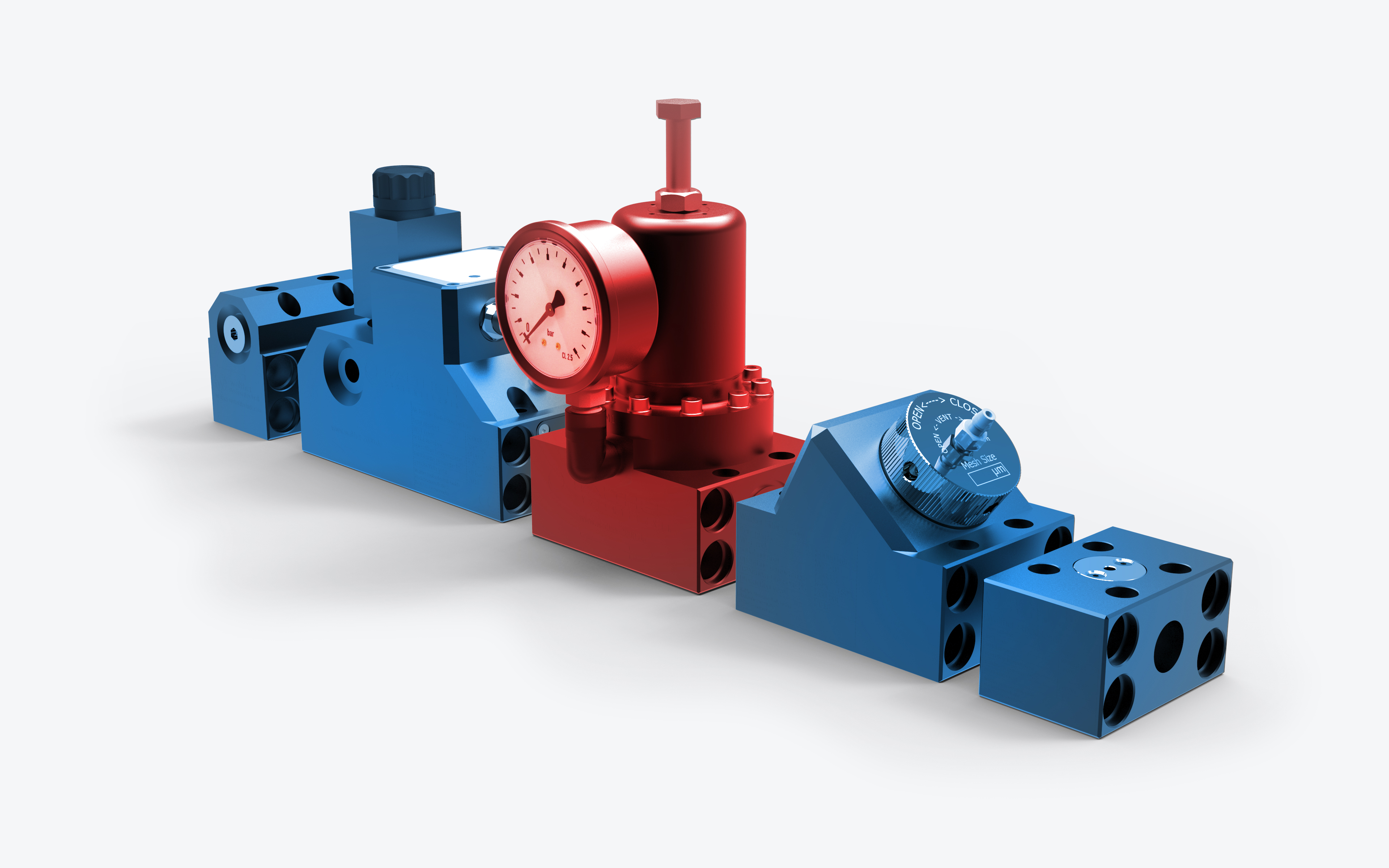

The Walther MODULAR concept offers decisive advantages. All modules can be combined in any way. In addition to standard applications, complex customer-specific solutions can be created within dosing systems and central lubricant supply systems. Even after assembly, the parts remain variable. Modules can be added, changed or grouped together as required to adapt the overall function to new conditions.

Technical excellence and ease of use

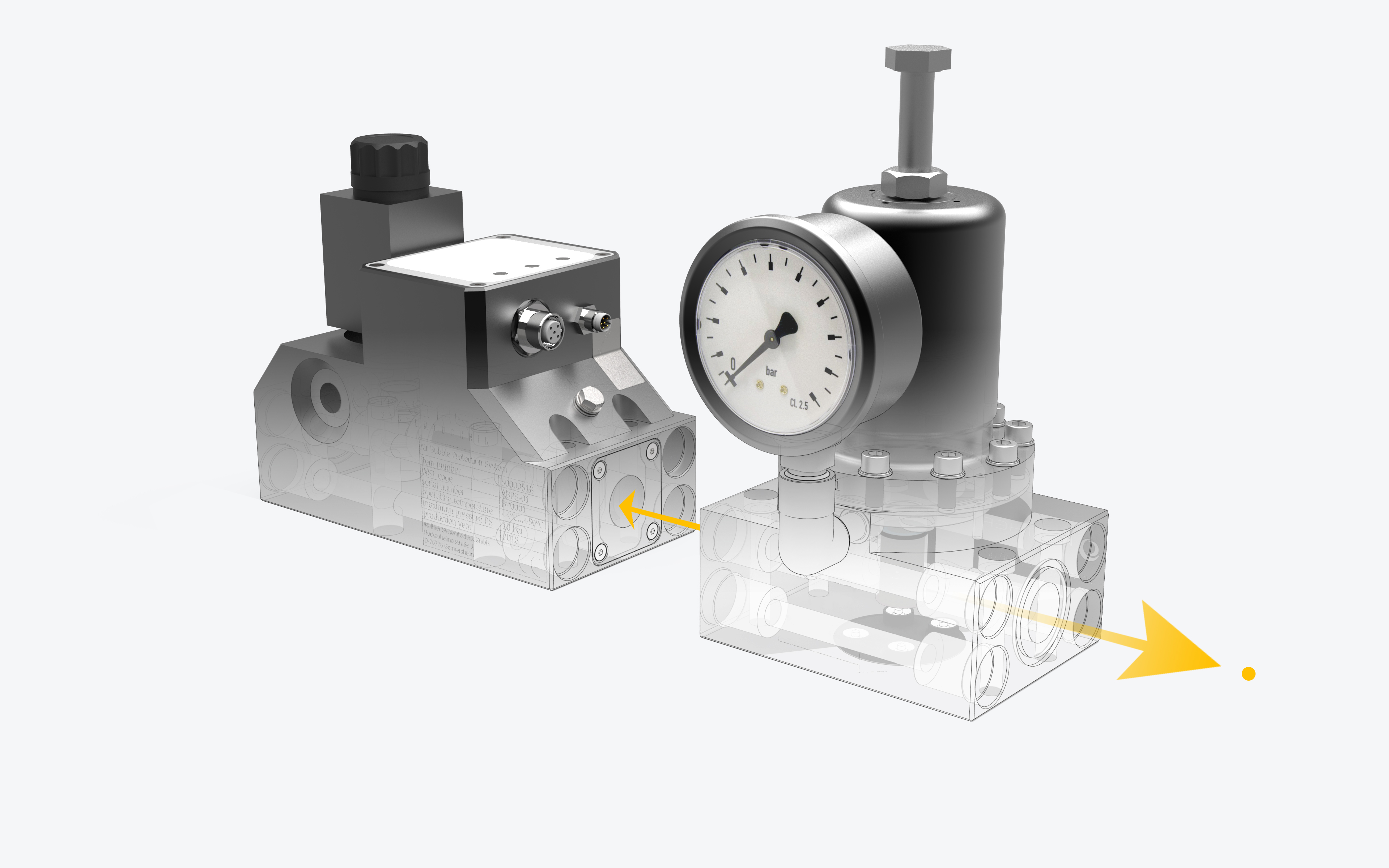

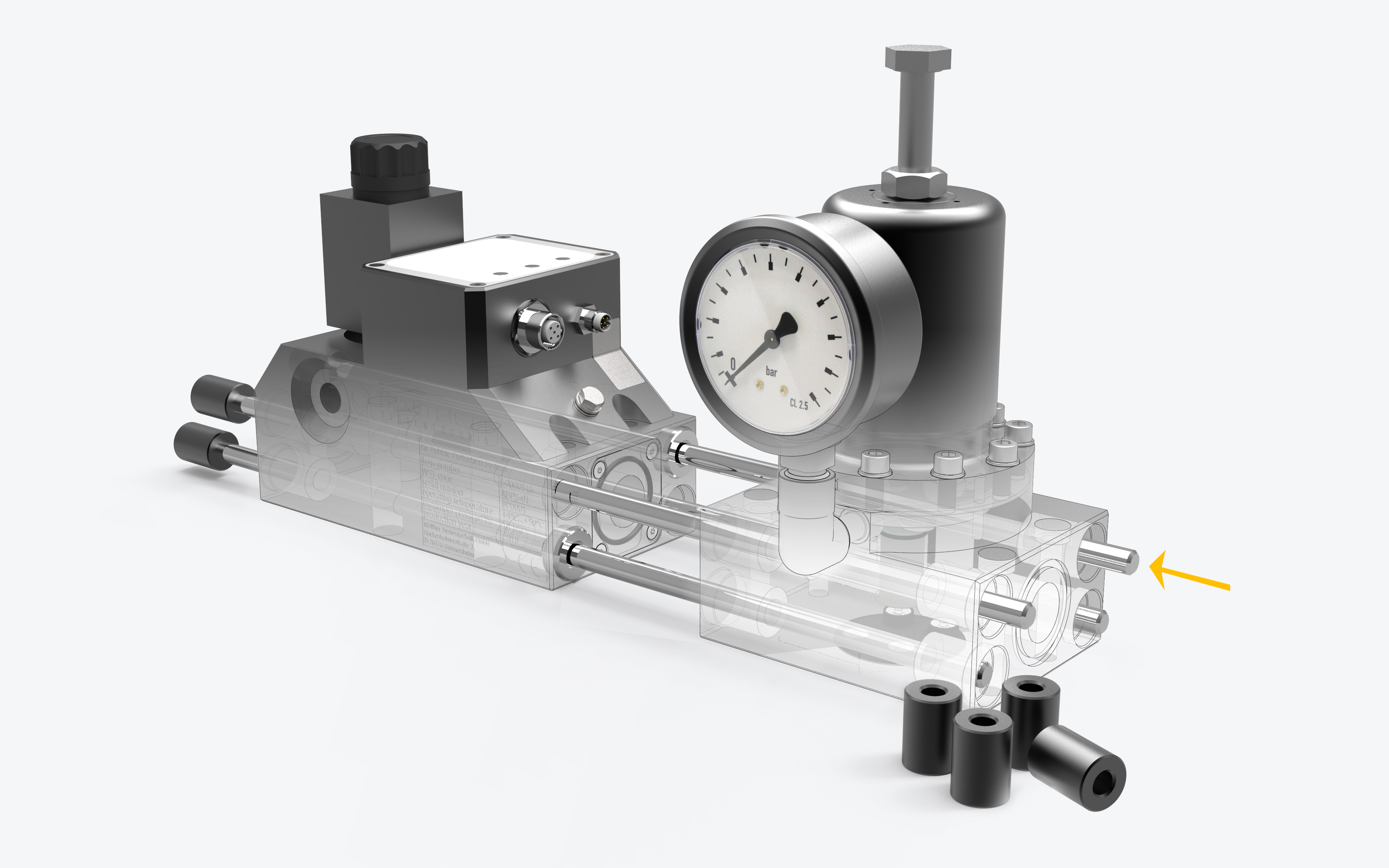

The individual modules are designed to work together and feature a compact design with standardised geometries and interfaces. The innovative locking system with tie rods and only four screws revolutionises the assembly process. This type of connection makes MODULAR-based assemblies less susceptible to leakage. Individual modules can also be installed and removed very easily and in a minimum of time

Safety and reliability

All modules in the Walther MODULAR series operate autonomously. This minimises the dependency between the individual function carriers. Faults in one module are limited to that module. Faulty modules can therefore be easily replaced with spare parts without compromising the performance of the overall system. This independence also minimises the service life of individual modules.

Maximum benefit at minimum cost

The use of modules from the Walther MODULAR series simplifies the functional expansion of complete fluid systems and reduces time and costs. Even complex applications can be implemented in a short time without expert design knowledge, while at the same time reducing engineering risk. The ability to adapt by rearranging or adding modules ensures a high degree of flexibility, while the ease of maintenance minimises downtime.

- Modular system for easy functional expansion of the overall fluid system

- Simple design and low engineering costs

- Flow-optimised thanks to harmonised functional modules

- Harmonised, individually combinable function carriers

- Standardised geometries and interfaces

- Low space requirement due to the compact design

- No additional connectors required between modules

- Low installation effort, low installation costs

- Easy access for maintenance

- Less susceptible to leakage

Your way to customised fluid technology

WALTHER MODULAR is constantly being developed and allows innovations to be integrated into existing systems in a targeted and trouble-free manner. This keeps your production system up to date and ensures high productivity, larger process windows and reliable process stability in the future.

Choose Walther MODULAR and experience how simple and efficient modern fluid technology can be. Or contact us today to find out more about our products and how they can meet your specific requirements.