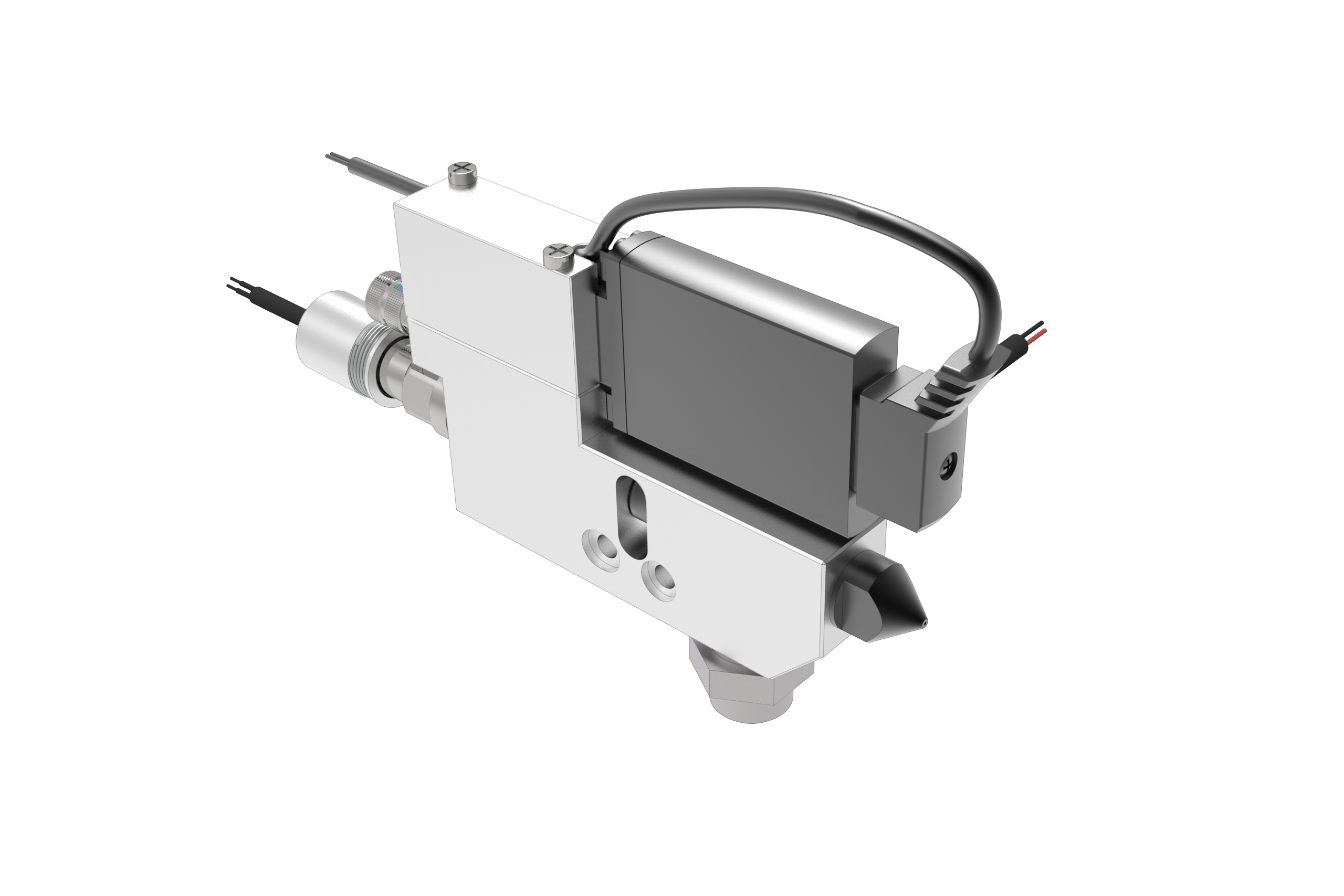

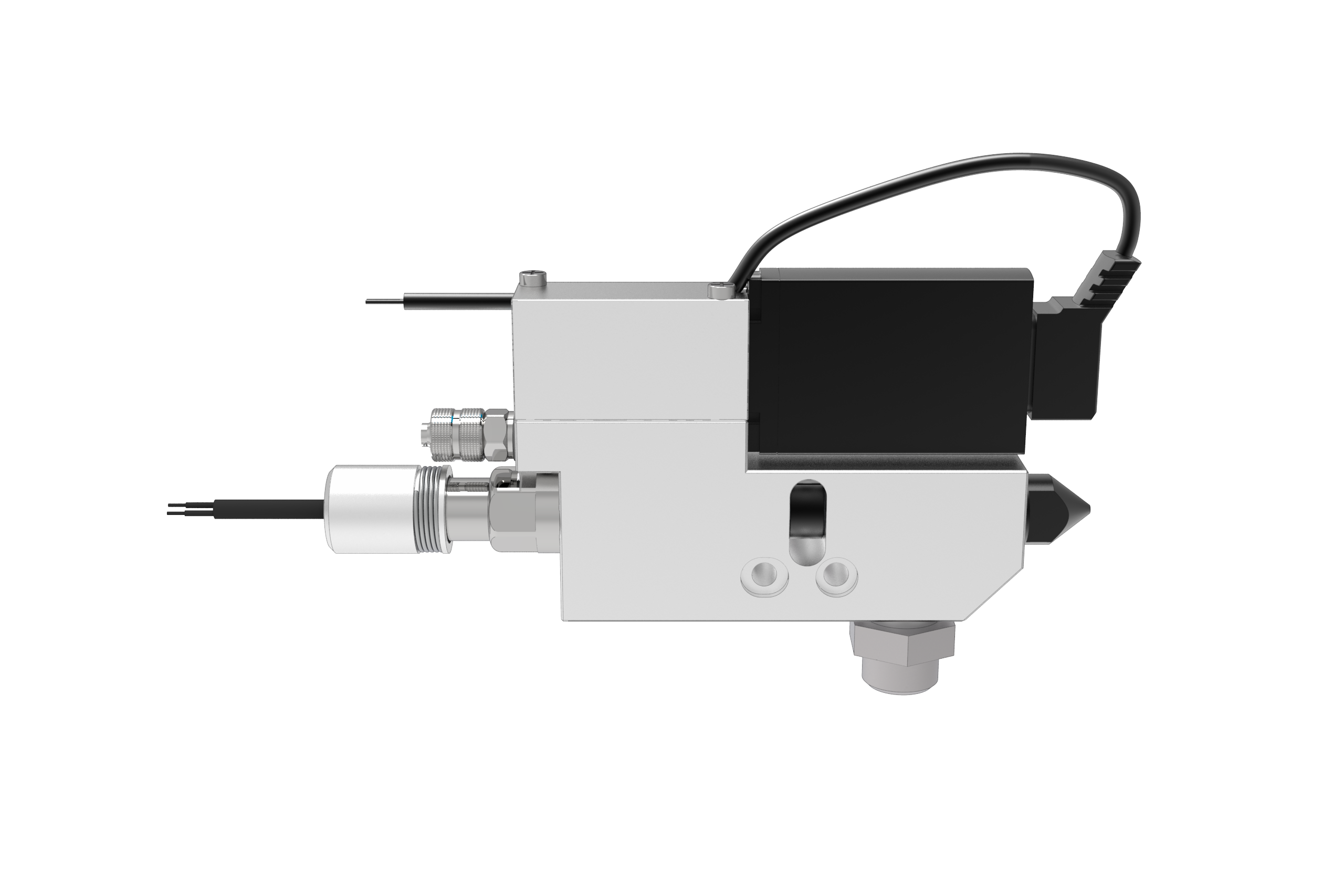

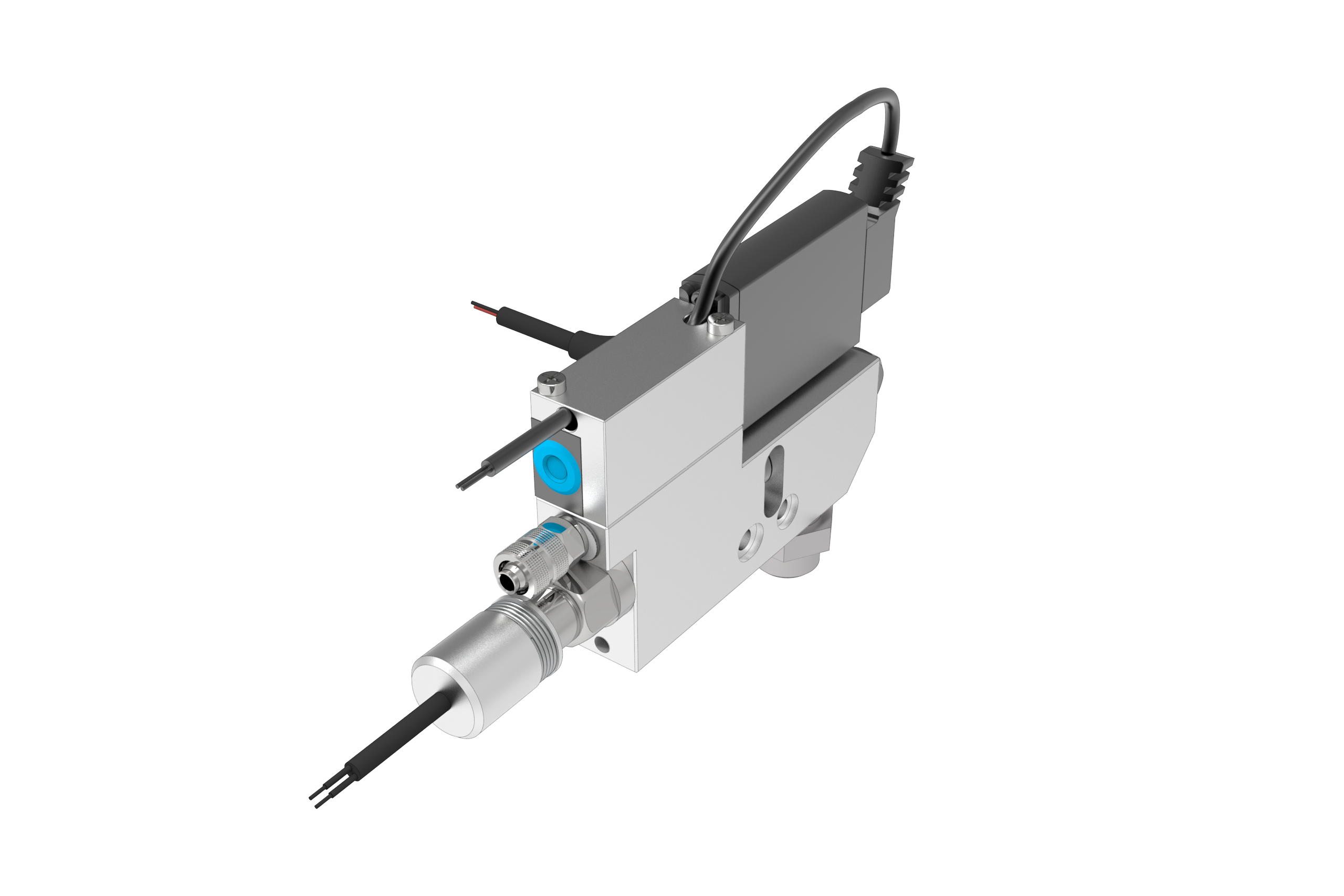

Micro-Point-Puise Valve MPP-03

The MPP-Pulse Valve was designed for a contact-free application of media (pulse/jet). With this device, you can shoot different media as dots onto a component with great process safety and a clean application image, over a distance of up to 150 [mm].

The technology is not only employed by renowned automobile manufacturers and suppliers all over the world for their production and installation processes, but also in food production and medical technology.

Advantage of contact-free application: the application remains repeatable even with large component tolerances. Above that, the medium can be pulsed onto the component without additional traverse movements. With the help of different nozzle types and changes to the standard valve, it is possible to jet in almost any direction. You will be able to precisely wet angled component geometrics and undercuts such as pull-out rails in furniture or rails elements in windows. With the high pulse frequency of up to 200 [Hz], it is also possible to perform bead applications.

- broad spectrum of use from dynamic smallest quantities to jet-stream dosing

- contact-free medium application

- broad spectrum of use for different media and a wide range of viscosity

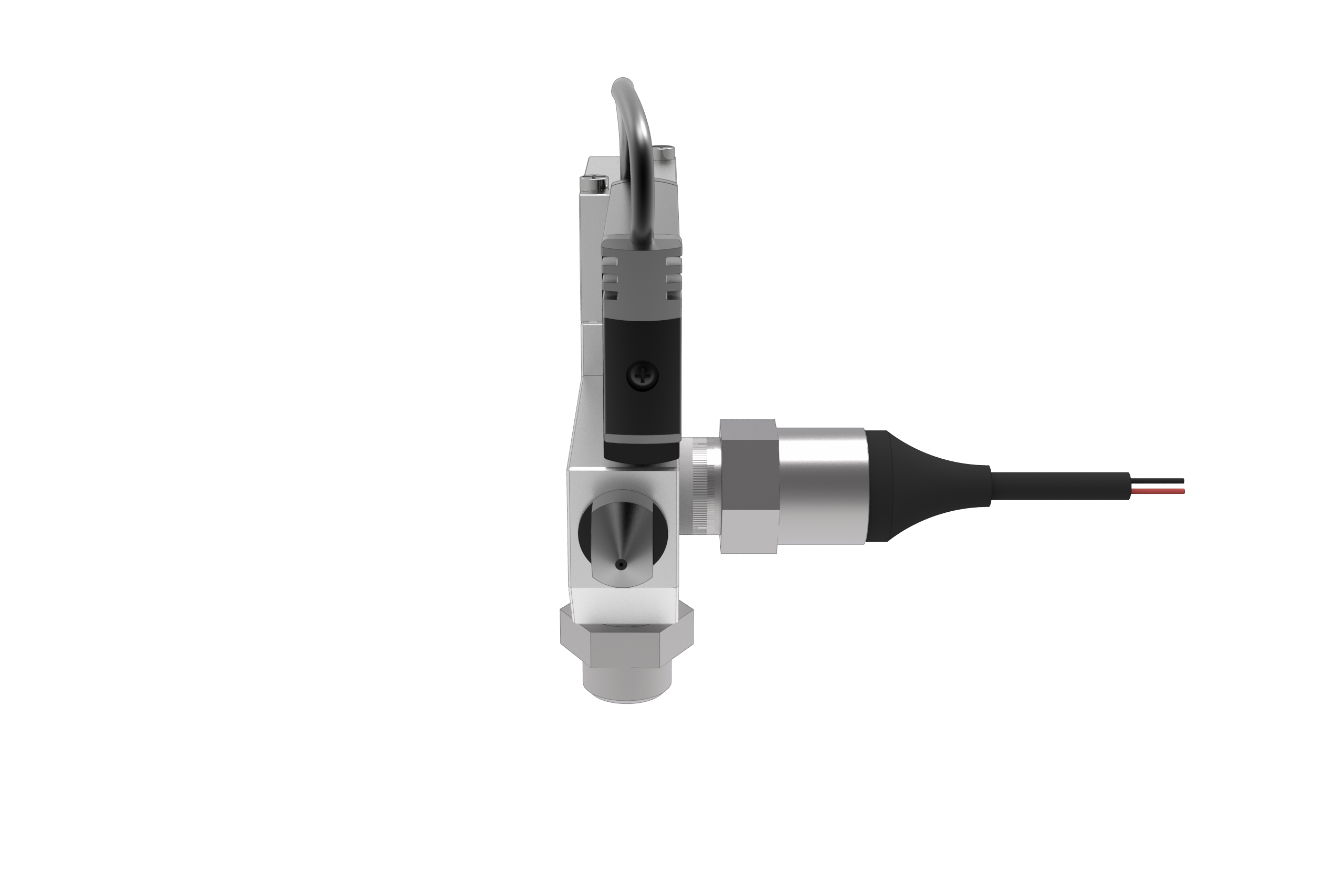

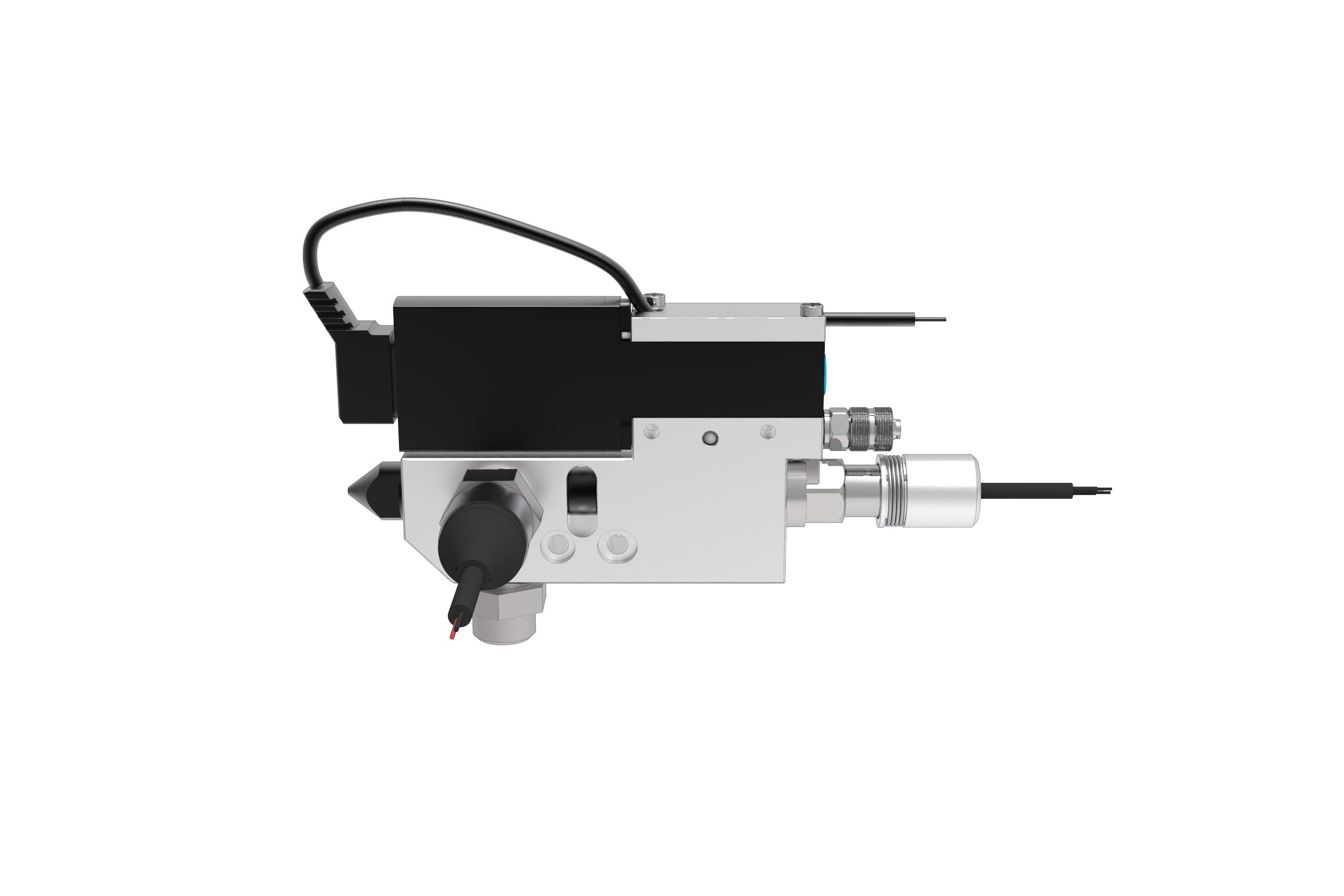

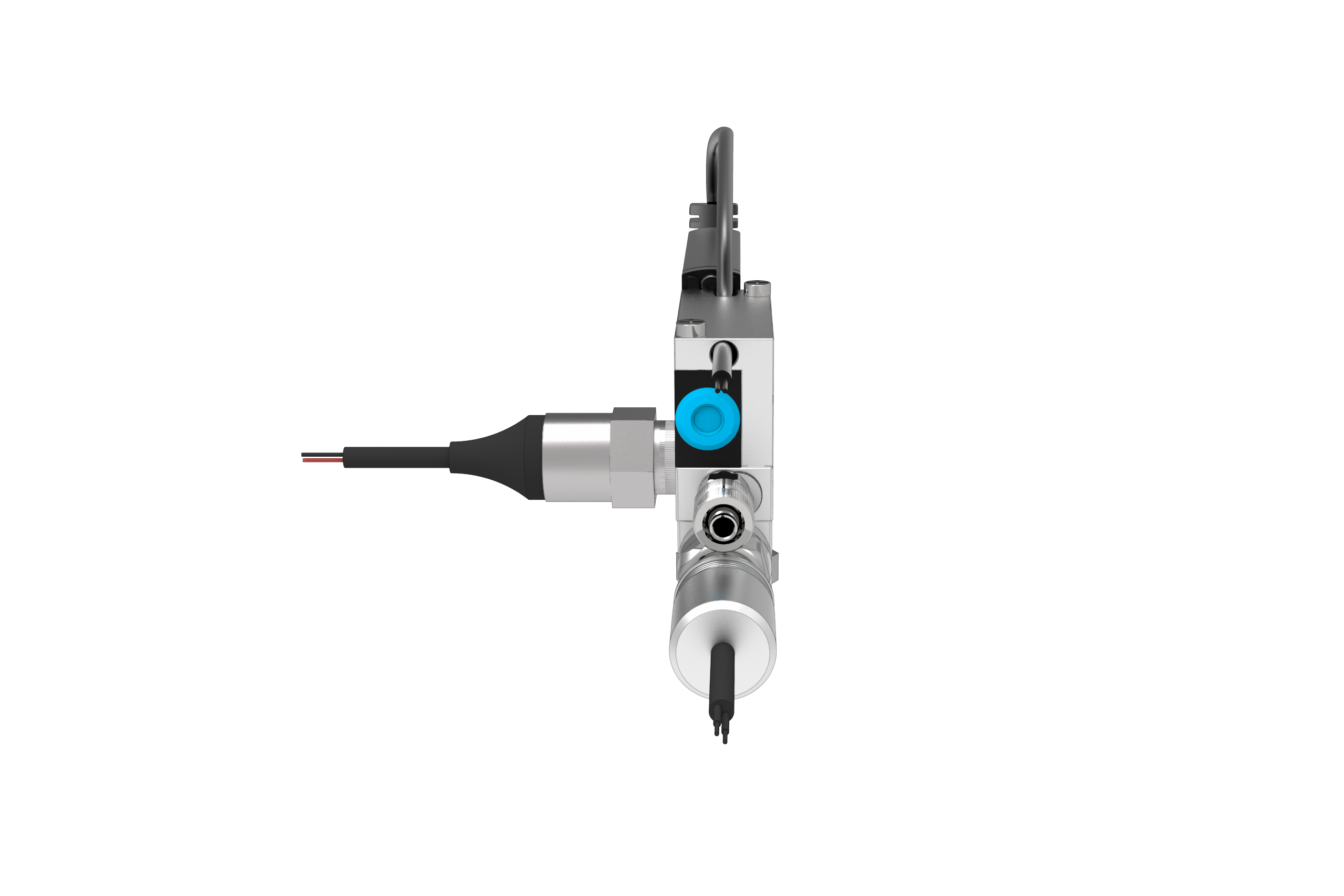

- high flexibility due to replaceable nozzle and dosing needle

- optional light barrier available for monitoring the medium discharge

- optional heating plate available for tempering the valve

- dosing range: 0,0004 to 1,8 [ml]

- max. allowed material pressure: 100 [bar]

- frequency: max. 200 [Hz]

- weight: 440 [g]

- dimensions (l x w x h): 124 x 15 x 58 [mm]

- control air pressure: 6 [bar]