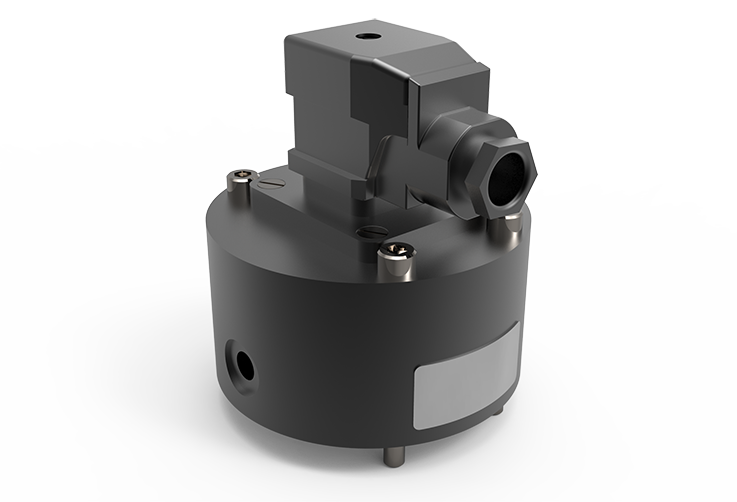

Gear flow meter WGFM

The Walther Gear flow meter WGFM is used for measuring the flow quantity during a dosing process. For this purpose, two gearwheels are driven by the flowing medium inside the Gear flow meter. The movement of the gearwheels is captured by magnetic sensors and converted into signals. With a 128X interpolation of the detected values, the WGFM has a very high resolution.

It also comes with an integrated control unit for a direct evaluation of the raw data (flank signals): Therefore, you will not need any additional installation of external electronic components or other software/programs for the operation of the WGFM. This will guarantee an easy and fast start of operation which can be made either manually or locally via a display.

Digital interfaces (4x DO and fieldbus connection) can be used alternatively for full access via a superordinate control unit. The Walther Gear flow meter has the additional option of directly controlling process valves which will allow you to easily design fluid systems with a controlled application volume. Here, the WGFM will open the downstream process valve, measure the flow quantity and close it when the defined application quantity has been reached.

As a whole, the WGFM serves multiple purposes and stands for increased process control and full flexibility with its four different modes: “meter“, “active control“, “passive control” and “pulsing“ – this applies for decentralized systems as well as for large production lines. The WGFM is available in two sizes which were designed for combining with the Walther Modular Series, or use it as a mobile component in automated systems close to the end effector on moving axes.

- integrated control unit and local operation via display

- no additional installation of external electronic components required

- digital IOs and fieldbus connection for superordinate control units

- easy start of operation

- direct process control of downstream application valves

- operating pressure modular design: max. 315 [bar]

- operating temperature: -10 to +40 [°C]

- measuring range: 0.01 to 10 [L/min]

- measuring precision: up to 0.3% of value for viscosities >20 [mm²/s]

- repeatability: ±0.05% under constant operating conditions

- dimensions (l x w x h): 172 x 79 x 102 [mm]

- digital inlets and outlets: 4 x 24 [VDC]

- Fieldbus: RS485 Modbus RTU

- Walther module length: 2 [TE]