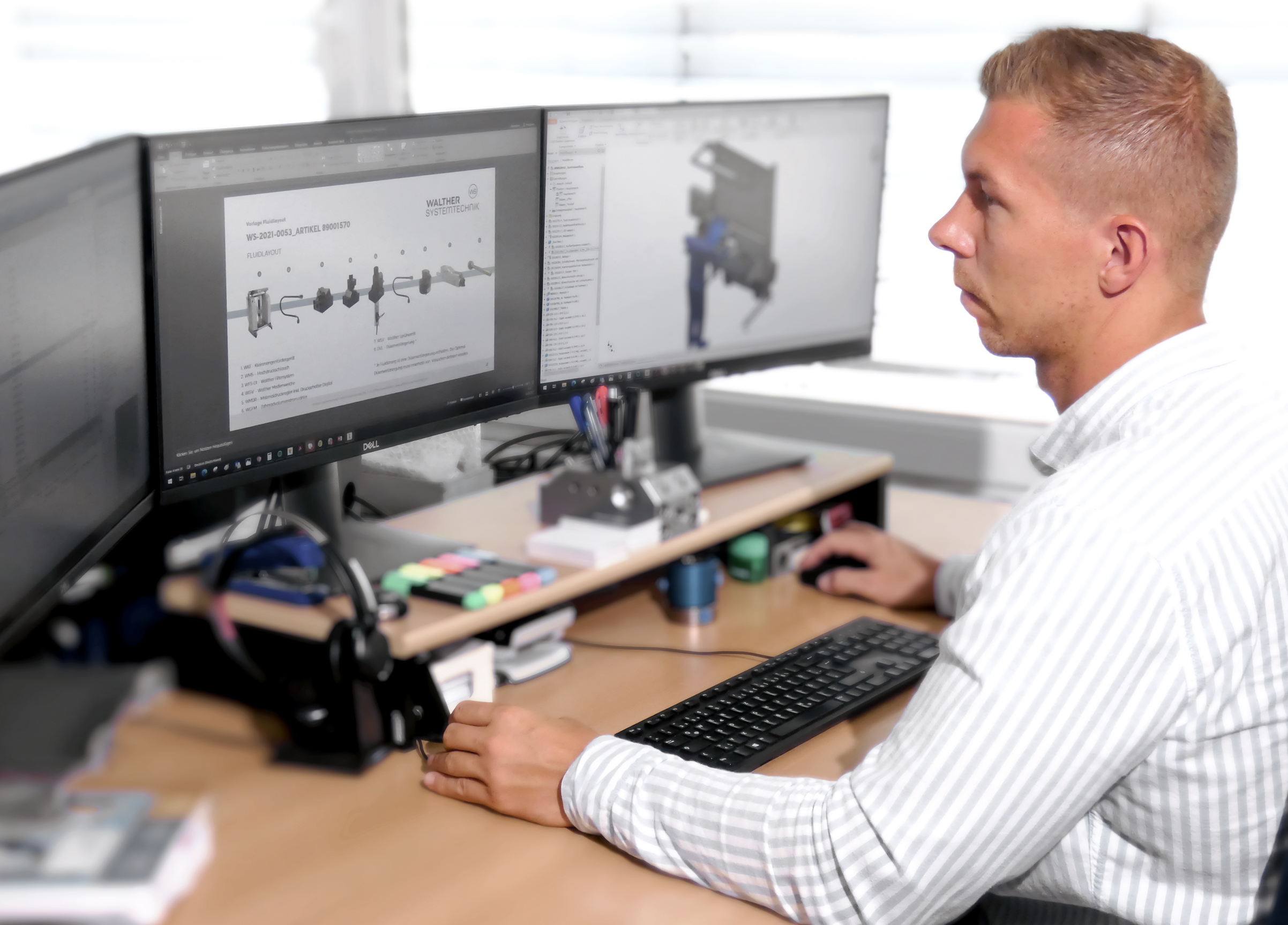

System design by Walther Systemtechnik: The right course from the start.

High-quality individual components are only one step towards for the realization of successful fluid application processes with a high system availability. In addition, it is essential to analyze the overall process and to coordinate the individual components on the basis of the identified environmental conditions and influencing parameters. As your competent partner, we are happy to perform this task for you.

Step by step towards the right concept

Our project planning is based on the installation conditions, integration possibilities and system architecture on site; we carry out preliminary tests with original components and your medium and thus ensure the functionality of the overall concept.

In the next step, we set up your fluid application system in our company. In extensive tests, we check the functionality together with you and optimize the system if necessary.

With the integration into your production environment and by supporting you during commissioning, we are assisting you until your production process is up and running.

Know what matters

Fluid handling is one of the key technologies of many industrial applications. The focus is on economic efficiency, process capability and quality. We master the challenges resulting thereof in close dialogue with our customers from the very beginning.

Your individual fluid system, designed by us, assembled and tested in-house

- Validation of the application equipment for your application task

- Calculation and design of entire systems

- Comprehensive support throughout the entire life cycle of your fluid application system

- All from a single source – including maintenance, service and repair

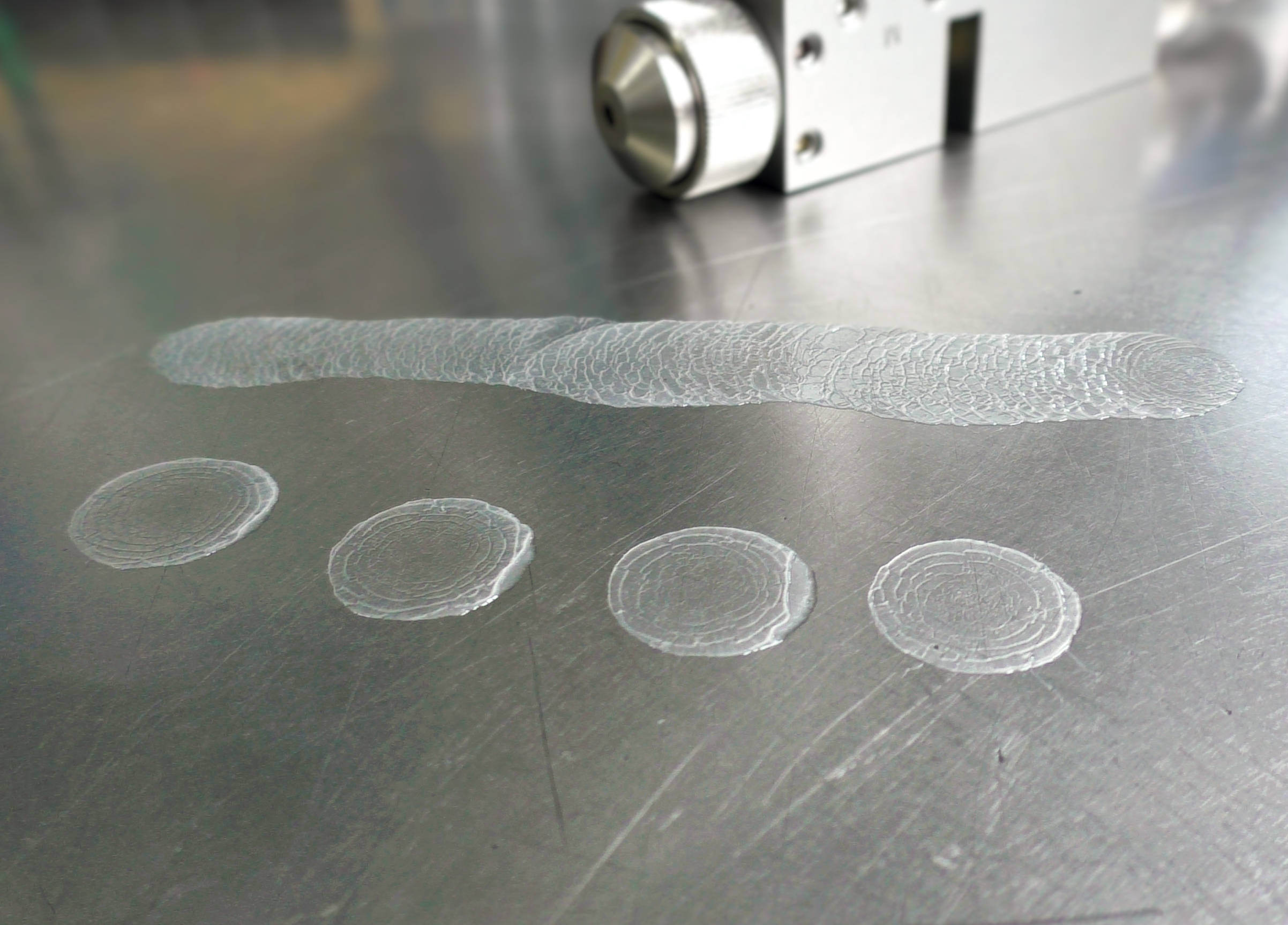

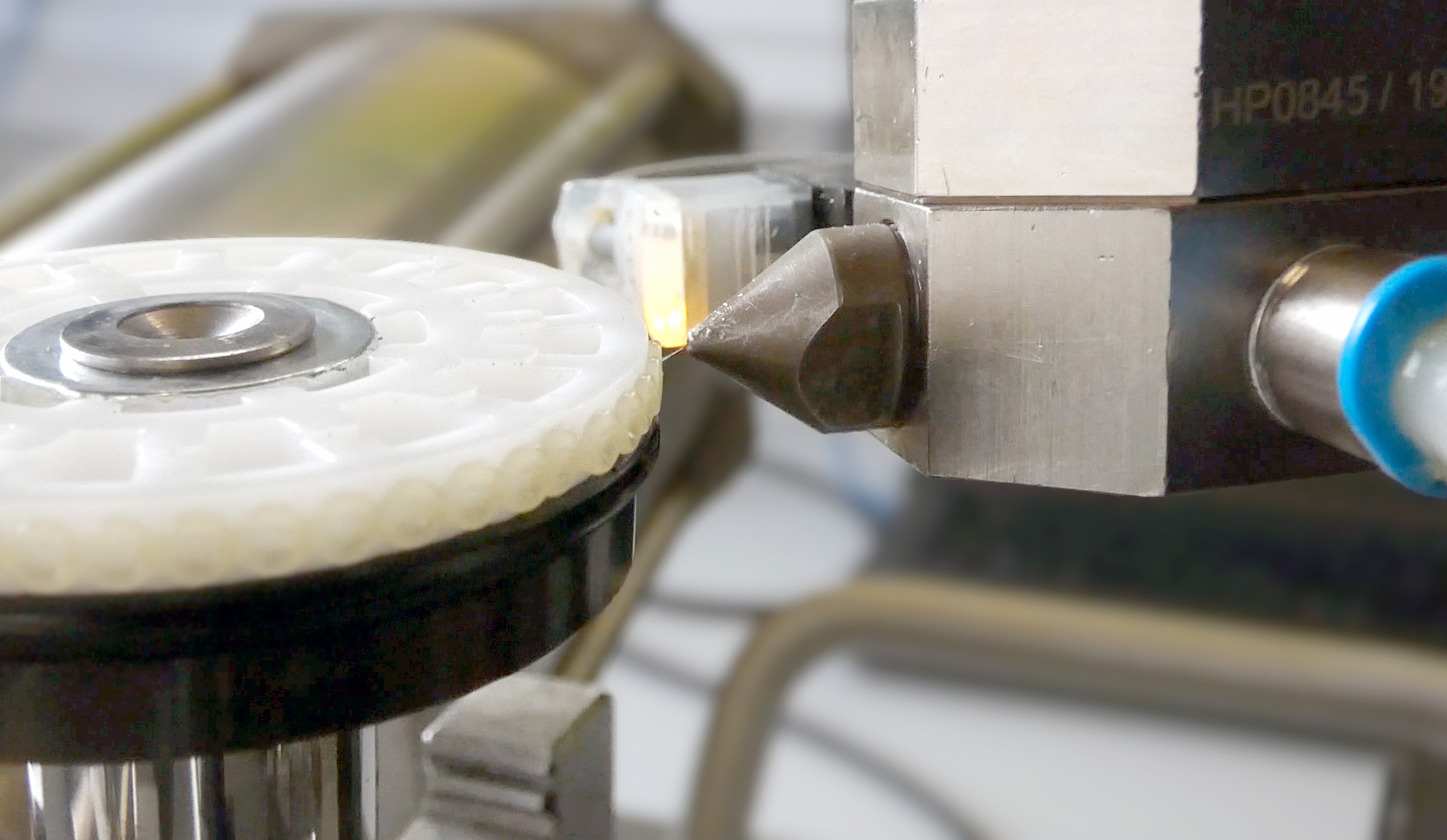

Extensive preliminary testing ...

and the selection of the appropriate equipment ...

are a guarantee for custom-tailored solutions.

Our achievements in detail: Benefit from a comprehensive service

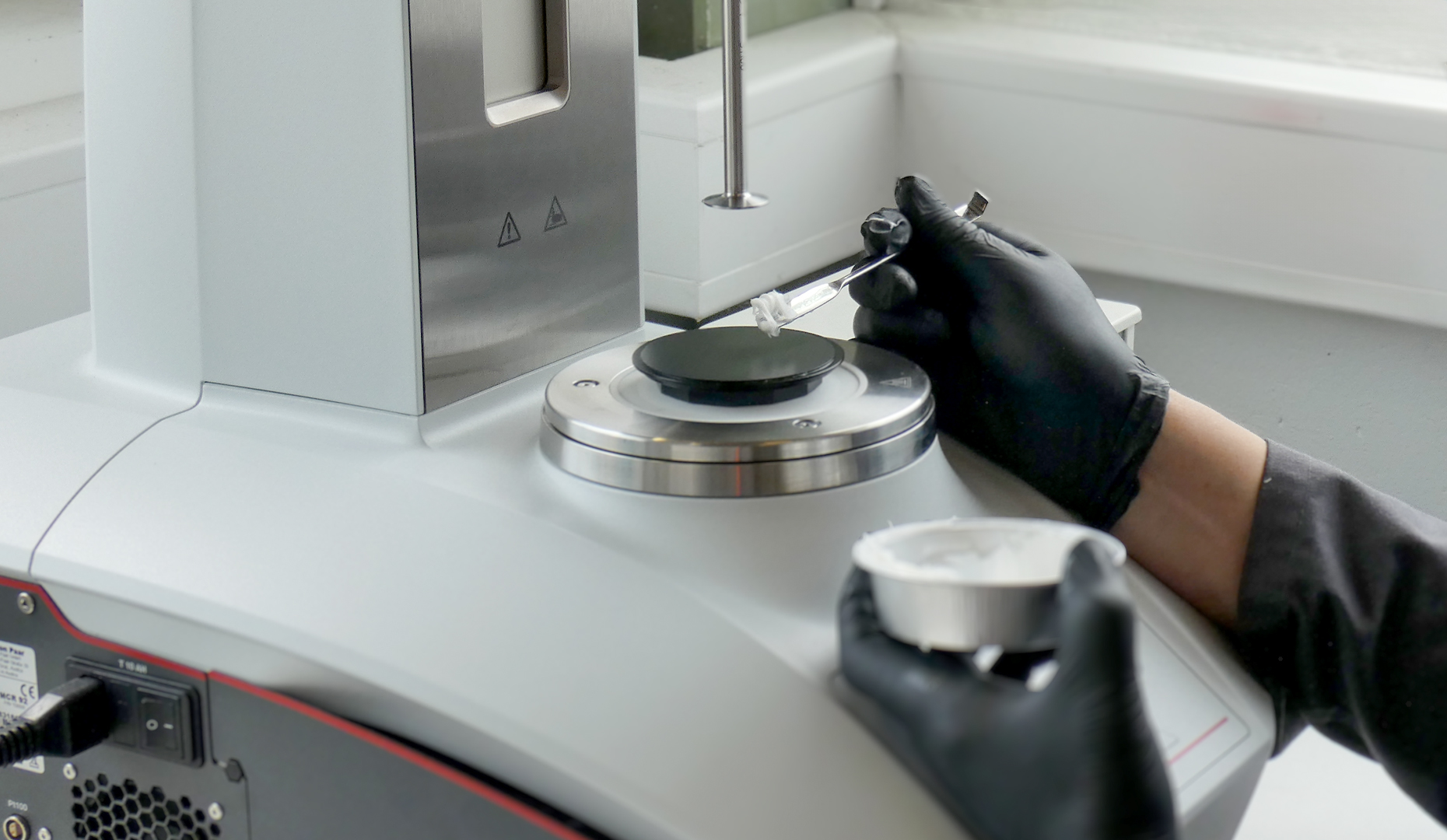

Feasibility check

- Rheological material characterization

- User-specific application tests

- Process capability tests

System design

- System consultation and layout conception

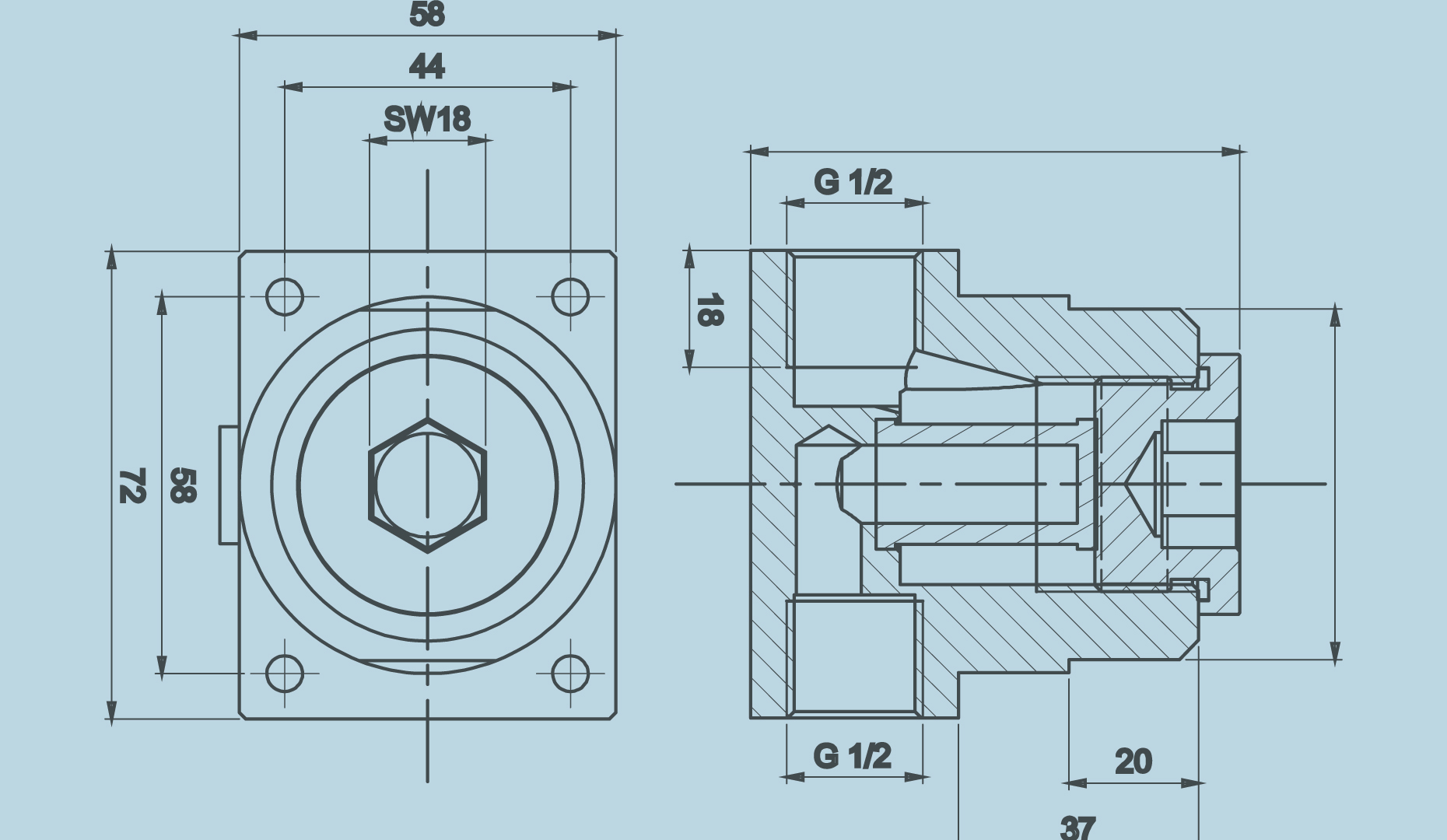

- Function determination and component selection

- Determination of pipe diameters

Assembly

- Installation of individual components

- Fitting and integration of special subassemblies

- Realization of customerspecific interfaces

Start-up and functional tests

- Functional testing on the customer part

- Application-specific capability tests

- Start-up support and employee training